Maintenance

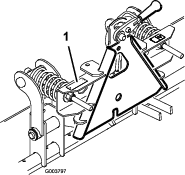

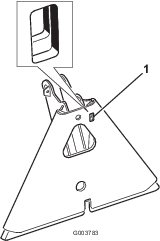

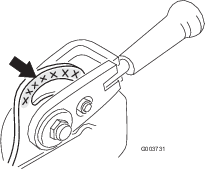

Greasing the Attachment Adapter

If the locking lever on the attachment adapter does not pivot freely and easily, apply a light coat of grease to the area shown in Figure 7.

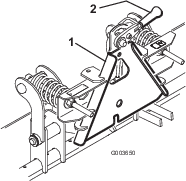

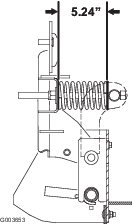

Adjusting the Actuating Rod Springs

The springs and actuating rods are adjusted at the factory. However, if new parts are installed or the springs are removed for any reason, the spring length should be adjusted to 5.24 inches (133 mm) as shown in Figure 8.

Leveling the Finish Grader Blade

To level the blade in relation to the traction unit, place the unit on a level surface (such as a concrete driveway), and slightly vary the rear tire pressure as required.

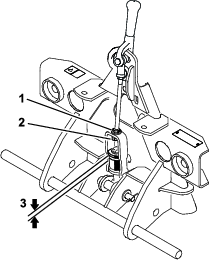

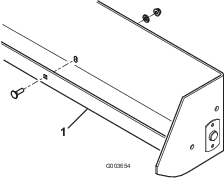

Reversing the Scraper Blade

The scraper blade (Figure 9) can be reversed for a second wear surface after the original edge has worn beyond the lower edge of the finish grader box that it is attached to.

Optional Equipment

| Drag kit | Part No. 140-0274 |

| Weight Kit (Required when using 140-0274) | Part No. 100-6442 |

| Carbide Tine Pack (15 tines included) | Part No. 119-2152 |

| Weeder Tine (15 tines required per machine) | Part No. 110-0260-0P |

| Weeder Blade (5 blades required per machine) | Part No. 132-4427-0P |