Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates the location of the model and serial numbers on the product.

This kit is designed to aid in the mixing of chemicals in preparation for turf spray applications on well-maintained lawns in parks, golf courses, sports fields, and on commercial grounds. It is a dedicated attachment for a turf spray application vehicle and is intended to be used by professional, hired operators in commercial applications.

This product complies with all relevant European directives. For details, please see the Declaration of Incorporation (DOI) at the back of this publication.

Read this manual carefully to learn how to operate and maintain your product properly. The information in this manual can help you and others avoid injury and product damage. Although Toro designs and produces safe products, you are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

CALIFORNIA

Proposition 65 Warning

This product contains a chemical or chemicals known to the State of California to cause cancer, birth defects, or reproductive harm.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

This manual identifies potential hazards and has safety messages identified by the safety alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Chemical substances used in the spray system may be hazardous and toxic to you, bystanders, animals, plants, soils, or other property.

Carefully read and follow the chemical warning labels and Material Safety Data Sheets (MSDS) for all chemicals used, and protect yourself according to the chemical manufacturer's recommendations. For example, use appropriate Personal Protective Equipment (PPE), including face and eye protection, gloves, or other equipment to guard against personal contact with the chemical.

Keep in mind that there may be more than 1 chemical used, and information on each chemical should be assessed.

Refuse to operate or work on the sprayer if this information is not available!

Before working on a spray system, make sure that the system has been triple rinsed and neutralized according to the recommendations of the chemical manufacturer(s).

Verify that there is an adequate supply of clean water and soap nearby, and immediately wash off any chemicals that contact you.

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. |

Note: Determine the left and right sides of the machine from the normal operating position.

Parts needed for this procedure:

| Support-frame assembly | 1 |

| Thick square spacer | 2 |

| Thin square spacer | 2 |

| Carriage bolt (3/8 x 1-1/2 inch) | 2 |

| Flanged locknut (3/8 inch) | 1 |

| Cradle arm, right | 1 |

| Cradle arm, left | 1 |

| Pivot pin | 2 |

| Bolt (3/8 x 1-1/4 inches) | 2 |

| Jam nut (3/8 inch) | 2 |

| Handle | 2 |

| Flat washer | 2 |

| Hair pin | 2 |

| Back-plate assembly | 1 |

| Flanged bushing (1/2 inch inside diameter) | 2 |

| Flanged bushing (3/4 inch inside diameter) | 2 |

| Set screw | 2 |

Park the machine on a flat area, set the parking brake, stop the pump, stop the engine, and remove the ignition key.

Remove the fasteners securing the rear tank straps at the top of the tank.

Note: Retain all parts.

Install 2 carriage bolts (3/8 x 1-1/2 inch) to the inboard side of the holes at the left side, rear tank strap.

Install the tank strap fasteners removed previously to secure the straps to the tank.

Note: Make sure that the strap is secure to the tank. Do not overtighten the strap.

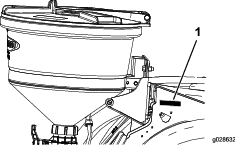

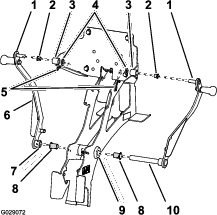

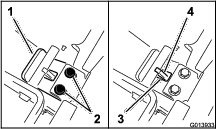

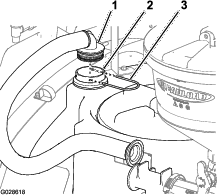

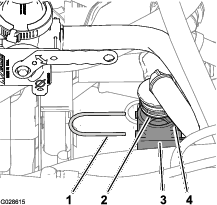

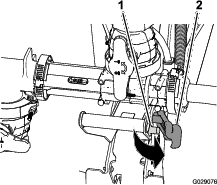

Mount 2 square spacers over the previously installed carriage bolts (Figure 3).

Note: Use the appropriate quantity and thickness of square spacers as needed to ensure that the frame is flush with the tank.

Install the main-support frame over the square spacers and carriage bolts as shown in Figure 3.

Note: Adjust the spaces as needed to ensure that the frame is flush with the tank.

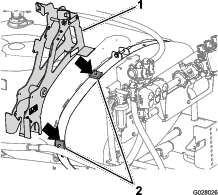

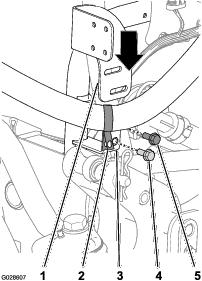

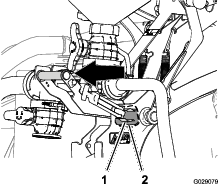

Secure the main-support frame to the tank strap (Figure 4) using 2 flanged locknuts (3/8 inch).

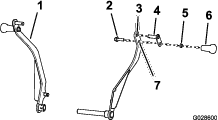

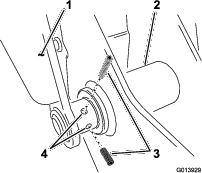

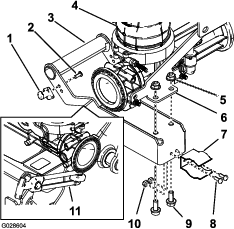

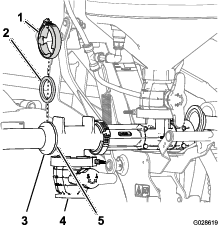

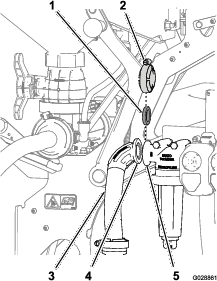

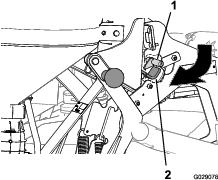

Assemble the pivot pin through the upper hole in the cradle arm (Figure 5).

Apply medium-grade, thread-locking compound to the threads of the bolt (3/8 x 1-1/4 inch).

Assemble the bolt (3/8 x 1-1/4 inch) through the lower hole in the cradle arm and the retainer of the pivot pin (Figure 5) with the jam nut (3/8 inch), and tighten the jam nut to 15 to 17 N-m (11 to 13 ft lb).

Thread the handle onto the bolt (3/8 x 1-1/4 inch) and tighten the handle against the jam nut and tighten the handle by hand (Figure 5).

Repeat steps 1 through 4 to the other cradle arm (Figure 5).

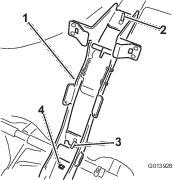

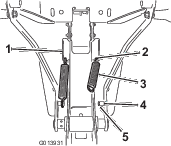

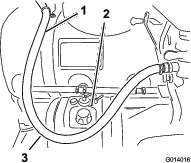

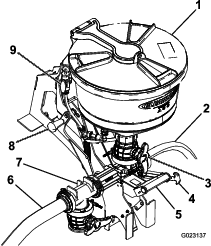

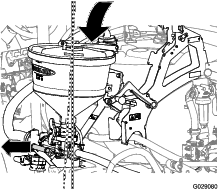

Insert a flanged bushing (3/4 inch inside diameter) into each end of the pivot tube in the main-support frame (Figure 6).

Insert a flanged bushing (1/2 inch inside diameter) into the left and right hubs of the back plate (Figure 6).

Note: Ensure that the flange of the bushings are aligned to the outward side of the hubs.

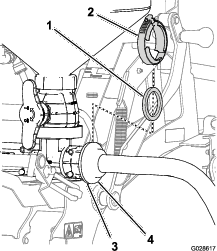

Assemble the lower pivot pin of the right cradle arm through the flanged bushing at the right side of the pivot tube and the pivot (Figure 6).

Note: Align the upper pivot pin of the arm with the right hub of the back plate.

Assemble the upper pivot pin of the right cradle arm through the right hub of the back plate (Figure 6).

Secure the upper pivot pin to the back plate with a washers (1/2 inch) and hair pin (Figure 6).

Assemble the hub of the left cradle arm over the end of the lower pivot pin of the right cradle arm that is protruding to the left of the left flanged bushing in pivot tube (Figure 6).

Note: Align the upper pivot pin of the arm with the left hub of the back plate.

Assemble the upper pivot pin of the left cradle arm through the left hub of the back plate (Figure 6).

Secure the upper pivot pin of the left cradle arm to the back plate with a washer (1/2 inch) and hair pin (Figure 6).

Install 2 set screws to the left arm at the lower hinge point (Figure 7).

Note: Do not tighten the set screw at this time to allow for later adjustment of the cradle system.

Parts needed for this procedure:

| Spring | 2 |

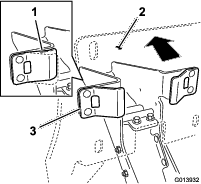

Install the spring in the hole in the lower end of the angled tab on the side of the frame assembly (Figure 8).

Hook the end of a spring into the hole in the angle tab and hook the other end onto the spring post (Figure 8).

Make sure that the spring end is seated properly in the groove in the post (Figure 8).

Repeat steps 1 through 3 for the other side.

Tighten the 2 set screws in the left arm.

Move the cradle assembly into the upper, transport position to adjust the tongue.

Lift up on the handles to raise the assembly while slightly tipping it toward the tank.

Guide the tongue under the crossbar with the welded tab in the upper portion of the frame assembly.

Let the assembly pivot down, toward the tank.

Making sure that the plastic stops are in contact with the spring tabs, apply enough pressure against the back-plate assembly of the cradle to compress the spring tabs midway (Figure 9).

While maintaining the pressure on the back plate, slide the tongue toward you until the lip of the tongue plate contacts the crossbar (Figure 10).

Tighten the fasteners in the tongue to secure its position, then release pressure on the back plate.

Note: Check to see if there is any play in the cradle. It should be held snug to the frame assembly. You can repeat this procedure once you have installed the eductor to adjust the locked position.

Parts needed for this procedure:

| Handle | 1 |

| Socket-head screw (#10-24 x 1/2 inch) | 2 |

| Latch post | 1 |

| Spring clip | 1 |

| Bolt (#10-24 x 1/2 inch) | 2 |

| Locknut (#10-24) | 2 |

| Eductor | 1 |

| Flange-head bolt (5/16 x 3/4 inch) | 2 |

| Flanged-locknut (5/16 inch) | 2 |

| Latch handle | 1 |

| Bolt (3/8 x 1 inch) | 4 |

| Flanged-serrated nut (3/8 inch) | 4 |

| T-fitting and drain valve | 1 |

| Gasket | 1 |

| Flange clamp | 1 |

Note: You can install the latch handle and latch post at either the left or right side of the eductor handle.

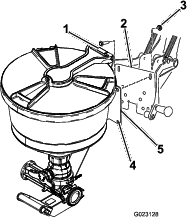

Assemble the latch post to the handle of the eductor (Figure 11) using the 2 socket-head screws (#10-24 x 1/2 inch).

Assemble the spring clip to the latch handle (Figure 11) with the 2 bolts (#10-24 x 1/2 inch) and 2 locknuts (#10-24).

Assemble the handle to the mount plate for the eductor (Figure 11) with 2 flange-head bolts (5/16 x 3/4 inch) and flange locknuts (5/16 inch).

Lower the cradle into the down position.

Align the holes in the eductor mount plate with the slots in the cradle support frame(Figure 12).

Note: The fasteners need to be loose enough so that they can travel in the slot when the eductor is initially raised up into the transport position. This allows you to adjust the travel and alignment of the eductor.

Install 4 bolts (3/8 x 1 inch) and locknuts (3/8 inch) to mount the eductor.

Note: Do not tighten the bolts at this time.

To carefully raise the eductor in the cradle assembly up to the transport position, do the following:

Lift the lower handle to raise the eductor while slightly tipping it toward the tank.

Guide the tongue under the crossbar with the welded tab in the upper portion of the frame assembly.

Then pivot the assembly toward the tank, taking care to line up the spring clip with the large pivot tube in the lower portion of the frame.

Push until the spring clip snaps over the pivot tube as shown in Figure 13.

Check the eductor height on the cradle back plate and adjust as necessary.

Tighten the fasteners securing the eductor to the cradle.

Note: Torque the fasteners to 36-45 N-m (27-33 ft-lb).

Tighten the 2 set screws on the left hand pivot arm, refer to Figure 7 in Assembling the Cradle Arms to the Support Frame.

Check the overall position of the eductor assembly on the tank strap.

Note: The eductor should be upright, in the transport position. Loosen the lower locknut on the frame assembly securing it to the tank. Do not remove the locknut. Adjust the position as necessary and tighten the locknut. Make sure that the strap is secure to the tank.

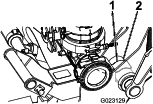

Align the flange of the upper T-fitting to the forward flange of the eductor (Figure 14).

Note: Ensure that the handle for the drain valve is located outward.

Secure the T-fitting the eductor with a gasket and flange clamp (Figure 14).

Parts needed for this procedure:

| Bulkhead fitting | 1 |

| O-ring | 1 |

| Locking ring | 1 |

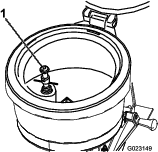

Locate the forward location on the top of the tank as shown in Figure 15.

Note: Locate the drill mark in the center of the molded circle.

Use a 9 cm (3-5/8 inch) hole saw to drill a hole at the drill mark (Figure 15).

Note: You will need to increase the diameter slightly to accommodate the bulkhead.

After drilling the hole, remove any rough edges in the cut, and remove any debris that entered the main tank during the cutting process.

Open the main tank lid and remove the filter screen.

Install the bulkhead fitting and the O-ring up from inside the tank through the previously cut opening (Figure 16).

Secure the bulkhead fitting to the tank with the locking ring.

Parts needed for this procedure:

| Eductor valve | 1 |

| Supply hose—86 cm (33-3/4 inch) | 1 |

| Retainer | 2 |

| Eductor-bypass hose—65 cm (25-3/4 inch) | 1 |

| Inlet hose—22 cm (6-5/8 inch) | 1 |

| Flange clamp | 1 |

| Gasket | 1 |

| Eductor valve bracket | 1 |

| Flanged-head bolt (5/16 x 3/4 inch) | 1 |

| Flanged locknut (1/4 inch) | 4 |

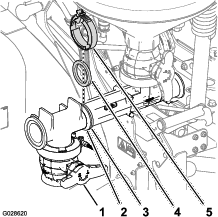

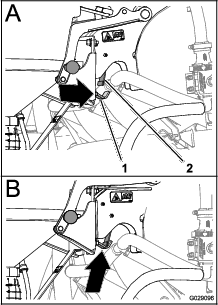

Remove the flange clamp, gasket, elbow, and inlet hose from the pressure-filter head ( A of Figure 17).

Note: Retain the gasket and flange clamp for installation later.

Remove the retainer that secures the straight-barbed fitting of the inlet hose to the lower T-fitting of the sprayer system and remove the inlet hose from the machine (B of Figure 17)

Note: Retain the retainer for installation later; discard the elbow, hose, and straight barbed fitting.

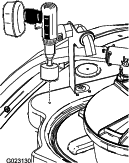

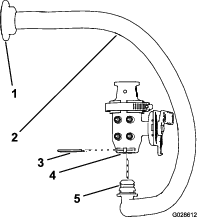

Assemble the 90° elbow of the eductor supply hose into the bottom port of the eductor valve (Figure 18).

Secure the elbow to the valve with the retainer (Figure 18).

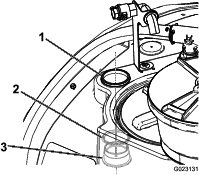

Assemble the straight fitting of the eductor-bypass hose into the side port of the eductor valve (Figure 19).

Secure the straight fitting to the valve with the retainer (Figure 19).

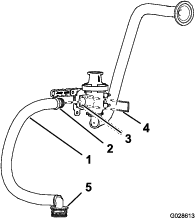

Align a gasket and the straight-flanged fitting of the new inlet hose to the flange of the adapter at the top of eductor valve (Figure 20).

Secure the straight-flanged fitting to the valve with a flange clamp (Figure 20).

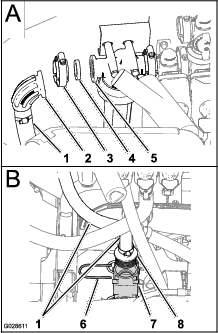

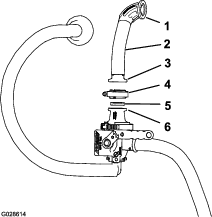

Remove the bolt that secures the R-clamp that supports the hose to the agitation throttle valve from the bracket on the mount tube (Figure 21).

Align the eductor valve bracket between the R-clamp and hose and the mount-tube bracket (Figure 21).

Align the holes in the eductor valve bracket with the holes in the mount-tube bracket (Figure 21).

At the lower holes in the brackets, assemble the eductor valve bracket with the holes in the mount tube bracket (Figure 21) with a flanged-head bolt (5/16 x 3/4 inch).

At the upper holes in the brackets, assemble the R-clamp and eductor valve bracket to the mount tube bracket with the bolt that you removed in 1 (Figure 21).

Align the studs of the eductor valve to the holes in the eductor valve bracket and secure the valve to the bracket (Figure 22) with the 4 flanged locknuts (1/4 inch).

Parts needed for this procedure:

| Tank hose—141 cm (55-5/8 inch) | 1 |

| Retainer | 1 |

| Flange clamp | 2 |

| Gasket | 2 |

Insert the 90° barbed fitting of the tank hose into the bulkhead fitting (Figure 23) that you installed in step 2 of Installing the Bulkhead Fitting.

Secure the 90° fitting the bulkhead fitting with a retainer (Figure 23).

Align the flanged fitting of the tank hose with the forward flange of the T-drain fitting (Figure 24).

Secure the tank hose to the T-fitting with a gasket and flanged clamp (Figure 24).

Raise and lower the eductor to ensure that the tank hose will not catch on other parts of the sprayer (Figure 24).

Align the flanged fitting of the supply hose to the flange of the eductor (Figure 26).

Secure the supply hose to the eductor with a gasket and flanged clamp (Figure 26).

Insert the 90° barbed fitting of the eductor bypass hose into the lower T-fitting (Figure 27) that you worked with in step 2 of Preparing to Install the Eductor Valve.

Secure the 90° fitting to the lower T-fitting with the retainer (Figure 27) that you removed in 2Preparing to Install the Eductor Valve.

Align the flange of the 90° fitting of the inlet hose with the flange of the pressure filter head (Figure 28).

Secure the inlet hose to the pressure filter head with the gasket and flanged clamp (Figure 28) that you removed in 1 of Preparing to Install the Eductor Valve.

Parts needed for this procedure:

| Suction lance and hose (optional accessory) | 1 |

Note: The suction lance and hose are optional accessories. Contact your Authorized Toro Distributor for more information.

Retain the suction lance and hose for later use. Read and retain the remaining documentation on using the Chemical Pre-Mix Kit.

Close sectionChemicals are hazardous and can cause personal injury.

Read the directions on the chemical labels before handling the chemicals and follow all manufacturer recommendations and precautions.

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

Wear goggles and any other protective equipment recommended by the chemical manufacturer.

Rotate the lid counter clockwise to open it. Close the lid completely before turning it clockwise to lock it. You must close the lid and lock it, before you raised the eductor to the transport position.

Close sectionUse the upper and lower handles to raise and lower the eductor and to lock it into the transport position.

Close sectionUse the main valve to introduce chemicals from the eductor into the hose leading to the main tank.

Close sectionThe bottle rinse is located inside the eductor tank. Once the eductor switch is on, the bottle rinse has pressure and is supplied by the contents of the main tank. To use the bottle rinse, invert the chemical container over the spout and use the rim of the container to depress the rinse. Press down to actuate the spout and rinse the interior of the chemical container.

The flush valve can rinse the inside of the eductor tank. Once the eductor switch is on, the flush valve will have pressure and is supplied by the contents of the main tank. To open the valve, turn the handle 90° counterclockwise. This will in introduce water to the tank. Turn the handle 90° clockwise to close the valve.

Close sectionGrasp the eductor handle and pull the latch handle off the latch post (Figure 31 and Figure 32).

Grasp the eductor handle at the top of the cradle in addition to the eductor handle and pull the eductor handle out until the spring clip releases from the pivot tube (Figure 31 and Figure 33).

Pull the eductor handle outward and down until the hook of the latch at the inboard side of the back plate is clear of the latch rod of the main support-frame assembly (Figure 34).

Fully lower the eductor while holding the eductor handle outward slightly (Figure 35).

Note: You will need to tip the bottom of the eductor outward so that you can align the hook of the latch under the spring plate at the bottom of the main-support frame.

When the latch of the back plate is under the spring plate (A of Figure 36), rotate the eductor handle inward so that the hook portion of the latch is aligned behind the spring plate (B of Figure 36).

Grasp a handle at the top of the cradle in addition to the eductor handle and pull the eductor handle outward until the hook portion of the latch is aligned outward of the spring plate (Figure 33 and Figure 36).

Raise the eductor while holding the eductor handle outward slightly (Figure 35).

Note: Tip the top of the eductor inward as needed so that you can align the latch at the inboard side of the back plate under the latch rod of the main-support-frame assembly.

Push in the handles at the top of the cradle until the hook portion of the latch is aligned behind the latch rod of the main-support frame (Figure 34).

Push in the eductor handle so that the hook raises to the latch rod and the spring clip fully seats around the pivot tube (Figure 33).

Pull the latch handle onto the latch post (Figure 32).

Important: Under some conditions, heat from the engine, radiator, and muffler can potentially damage the grass when operating the sprayer in a stationary mode. Stationary modes include tank agitation, hand spraying, or using a walking boom.

Take the following precautions:

Avoid stationary spraying when conditions are very hot and/or dry, as turf can be more stressed during these periods.

Avoid parking the machine on the turf while stationary spraying. Park the machine on a cart path whenever possible.

Minimize the amount of time that the machine is left running over any particular area of turf. Both time and temperature affect how much the grass may be damaged.

Set the engine speed as low as possible to achieve the desired pressure and flow. This will minimize the heat generated and the air velocity from the cooling fan.

Allow heat to escape upward from the engine compartment by raising the engine guard/seat assemblies during stationary operation rather than being forced out under the vehicle. Refer to your Operator’s Manual for more information on raising the seat assemblies.

Note: Use a heat-shield blanket underneath the vehicle during stationary operation for additional heat protection. Contact your Authorized Toro Distributor to obtain a Toro heat-shield blanket kit for turf sprayers.

Close sectionThe following procedure assumes the following operational states exist for the standard tank agitation: The sprayer is started and running, the pump is engaged and set to the desired pressure, and the throttle is in the mid-range position.

Note: Close the eductor hopper valve and hopper rinse ball valve(s) before starting the eductor.

Lower the eductor.

Open the lid to check for foreign objects which may hinder performance or contaminate the system.

Close and lock the lid by turning the cover clockwise.

Turn the eductor valve to open the eductor circuit.

Open the hopper valve (red handle) located on the bottom of the hopper.

Unlock and open the lid slowly by turning the cover counterclockwise.

Pour the required amount of chemical into the hopper.

Note: Avoid splashing liquids or powdered chemicals outside of the hopper.

If applicable, rinse the empty chemical containers. Place the container opening over the container rinse valve and press down.

Note: This will activate the rinse valve and rinse the container.

Close and lock the lid by turning the cover clockwise. Open the rinse ball valve and turn it on for 20 seconds to rinse the hopper.

Note: Close the ball valve and return the locking band to the locked position.

Open the lid and inspect for chemical residue.

Repeat step 3 as necessary.

Close the hopper valve.

Note: Lance suction depends upon eductor pressure and flow. For best results, use pressure up to 10 bar (150 psi) maximum.

Insert the suction lance body into the eductor until the O-ring seals on the hopper drain.

Use the free end of the lance to pierce the bag or container to vacuum powdered or liquid chemical.

Place the lance end into a clean container of water to rinse the lance assembly.

Remove the lance body from eductor and drain any remaining fluid into the hopper.

Close the hopper valve (red handle).

Close all the valves.

Note: Close the hopper valve first.

Remove all chemical residue.

Close and lock the hopper lid by turning the cover clockwise.

Return the agitation valve to the fully open position.

Close the eductor valve.

Return the eductor to the transport position, and lock it with the transport strap.

| Problem | Possible Cause | Corrective Action |

|---|---|---|

| The eduction rate is low. |

|

|

| There is no rinsing or flushing action. |

|

|

| There are leaks at the fittings. |

|

|