Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 10 hours |

|

| Yearly |

|

Servicing the Wheel Hub

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Raise the trailer on jack stands.

-

Remove the 4 lug nuts securing the wheel to the wheel hub and remove the wheel.

-

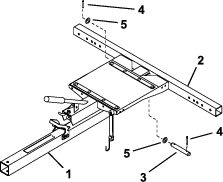

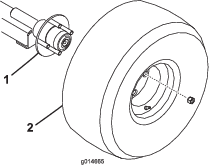

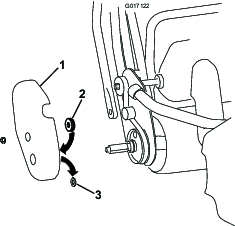

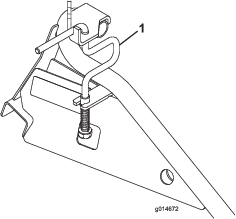

Remove the dust cap from the wheel hub (Figure 16).

-

Remove the cotter pin and retainer locknut (Figure 16).

-

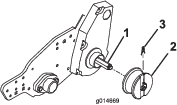

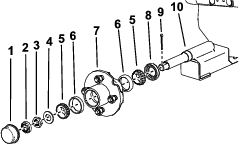

Remove the hub nut, spindle washer and hub assembly from the axle (Figure 16).

-

Inspect all of the hub assembly parts, including the bearings, bearing cups, and oil seal. Replace any damaged parts.

Lubricating the Wheel Hub Assembly

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Wipe away the existing grease from the bearings, bearing cups, and hub assembly with a clean, dry rag.

-

Pack the bearing cups and interior surfaces of the hub assembly with high-temperature grease so that the bearings roller faces are completely coated.

-

Install the bearing cups and bearings to the hub assembly as shown in Figure 16.

-

Clean up any excess grease from the outside of the hub assembly.

Installing the Wheel Hub Assembly

-

Install the oil seal, hub assembly, and spindle washer as shown in Figure 16.

-

Tighten the hub nut while turning the wheel hub assembly to seat the bearings and remove all end play.

-

While turning the wheel hub assembly, torque the hub nut to 8.5 to 20.3 N⋅m (75 to 180 in-lb).

-

Loosen the hub nut until it does not contact the washer and the hub has end play.

-

Tighten the hub nut to 1.7 to 2.3 N⋅m (15 to 20 in-lb) while rotating the hub.

-

Place the retainer locknut over the hub nut so that the cotter pin hole is aligned with a slot on the retainer locknut.

-

Install a new cotter pin through the slot in the retainer locknut and the axle and bend both legs to secure the pin.

-

Secure the hub cap.

Checking the Torque of the Wheel Lug Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 10 hours |

|

Check the torque of the wheel lug nuts at the service interval and each time you install the wheels.

Warning

Failure to maintain proper torque could result in failure or loss of wheel and could result in personal injury.

Torque the wheel lug nuts to 108 N⋅m (80 ft-lb).