Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Disconnect first the negative cable, then the positive cable from the battery.

Removing the Existing Wheel

-

Chock both front wheels to prevent the machine from moving.

-

Use a jack or hoist to lift the rear of the traction unit by the hoop welded on the caster fork, and remove the tire assembly from the caster fork.

-

Place appropriate jackstands beneath the frame to support the raised machine.

-

Remove the wheel hub assembly from the tire assembly.

Retain the lug nuts.

-

Remove the adapter plates from the caster fork.

Modifying the Caster Fork

If the traction unit has a serial number prior to 269999999, you must modify the caster wheel fork. To modify the caster wheel fork, you must obtain a drill guide (Toro Part No. 112-0256-01) from an authorized Toro distributor. If you do not need to modify the caster wheel fork, proceed to Installing the Motor and Hub Assembly.

-

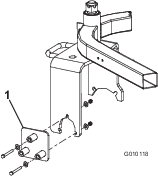

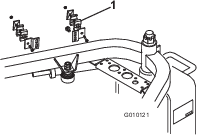

Mount the drill guide to the right side of the caster fork with 2 bolts (5/16 x 3 inches), 4 washers, and 4 nuts (Figure 1).

-

Using the remaining hole in the drill guide, enlarge the hole in the caster fork to 9/16 inch (14 mm) diameter.

Important: Use a new or recently sharpened 9/16 (14 mm) inch drill bit. Proceed slowly when drilling. Do not use excessive force when drilling to prevent jamming the drill.

-

Move the fasteners to the other holes in the drill guide, and repeat the process until all 3 holes are enlarged.

Installing the Motor and Hub Assembly

Parts needed for this procedure:

| Motor and hub assembly | 1 |

| Re-lube flangette | 1 |

| Standard flangette | 1 |

| Bearing | 1 |

| Socket-head screw | 2 |

| Locknut (1/2 inch) | 2 |

| Hardened washer | 3 |

| Spacer | 1 |

| Adapter plate | 1 |

| Hex-head bolt | 3 |

| Decal | 2 |

-

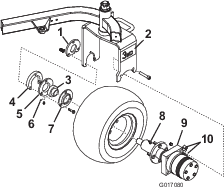

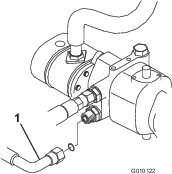

Mount the 2 fittings (45°) to the side of the motor assembly (Figure 2).

Note: Ensure that all O-rings are lubricated and in position before installing the fittings.

-

Remove the grease fitting from the new motor and hub assembly (Figure 2).

-

Mount the tire assembly to the motor and hub assembly with the 4 lug nuts that you previously removed.

Note: Torque the lug nuts to 70 to 90 ft-lb (95 to 122 N∙m).

-

Install the grease fitting to the hub assembly, pointing it away from the hub.

-

Insert the flangettes and bearing onto the end of the motor shaft as shown in Figure 2.

-

Position the motor hub, flangettes with bearing, adapter plate, and tire assembly into the caster fork.

Note: Ensure that the motor is oriented with the hydraulic fittings to the rear of the machine (Figure 2).

-

Loosely secure the motor to the inside of the caster fork with 2 socket-head screws and 2 locknuts (Figure 2).

Note: Tighten the screws to 100 ft-lb (135 N∙m).

-

Loosely assemble the flangettes (with the bearing to the inside of the caster fork) with 3 hex-head bolts (3/8 x 2-1/4 inches), an adapter bearing plate, a spacer mount, 3 hardened washers, and 3 locknuts (3/8 inch).

Important: Ensure that there is no radial load on the motor shaft.

Note: The grease fitting must be in the downward position on the flangette (Figure 2).

-

Torque the flangette screws to 40 ft-lb (55 N∙m).

Important: Failing to carefully follow the above assembly sequence may result in premature motor seal and bearing failure.

-

Apply a thread-locking adhesive (such as Loctite®) to bearing set screws.

Note: Torque the set screws to 80 to 100 in-lb (9 to 11 N∙m).

-

Verify overrunning bearing operation: The tire should roll freely forward, but the wheel motor will engage when the tire is rolled backward.

-

Lower the rear of the traction unit to the ground.

-

Grease all the fittings with No. 2 general purpose lithium-based grease.

-

Apply a 3-wheel-drive decal to each side of the caster fork (Figure 2).

Installing the Hoses

Parts needed for this procedure:

| Self-tapping screws | 4 |

| Tube clamp | 4 |

| Coverplate | 2 |

| Hex-head screw (M8) | 2 |

| Locknut (M8) | 2 |

| Hose assembly (95-0517) | 1 |

| Hose assembly (100-6412) | 1 |

| Hose clamp bracket | 2 |

| Cable tie | 1 |

-

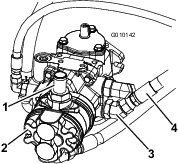

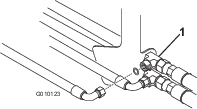

Drain all the hydraulic fluid from the reservoir by removing the upper hose from the pump (Figure 3).

-

Connect the hose after draining the hydraulic fluid.

Note: The hydraulic system capacity is approximately 8.5 US gallons (33 L).

Important: Take care not to contaminate the hydraulic fluid if you are going to reuse it. A very small amount of debris can severely damage the hydraulic system.

-

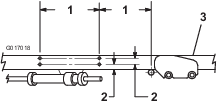

Refer to the dimensions shown in Figure 4 to locate, mark, and drill 4 holes (9/32 inch or 7 mm diameter) into the right-hand frame tube.

-

Secure the hose clamp bracket assemblies (tube clamps, cover plates, clamp brackets, hex-head screws, and locknuts) to the frame with 4 self-tapping screws (Figure 5).

-

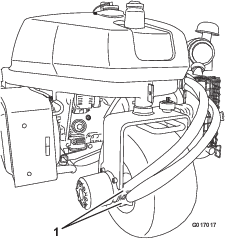

Disconnect the lower hydrostat hose from the hydrostat (Figure 6) and from the upper-bulkhead tee fitting to the front-wheel motors (Figure 7).

Note: Remove and discard the lower hydrostat hose.

-

Connect the 90° fitting end of the new (shortest) hose to the lower port of the hydrostat.

-

Route the hose through the lower position in the hose clamps, behind the caster fork and to the lower port of the rear-wheel motor.

Note: Mount the bottom hose ends horizontally (Figure 8).

-

Secure the hose ends to the fittings.

Note: Use a backing wrench to ensure that the hose does not twist.

-

Secure the hoses together at the rear of the unit with a cable tie.

-

Turn the steering fork fully side-to-side to check for proper hose flex and position.

Note: The hoses should not rub on the tire, rim, tanks, steering fork, or steering hoses.

Note: The hydraulic lines must not be twisted, kinked, have sharp bends, or touch sharp edges, moving parts, or engine exhaust parts.

-

Secure the hoses in the brackets.

Note: The hose clamp brackets are slotted vertically to allow for adjustment.

-

Grease all fittings with No. 2 lithium grease.

Completing the Installation

-

Check the hydraulic-fluid level; refer to your traction unit Operator’s Manual.

-

Connect the positive cable to the battery.

-

Connect the negative cable to the battery.

-

Start the engine.

-

Cycle the traction and lift cylinders to purge the air from the hydraulic system.

-

Check the hydraulic-fluid level.