Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Before storage |

|

Greasing the Backhoe

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 25 hours |

|

| Before storage |

|

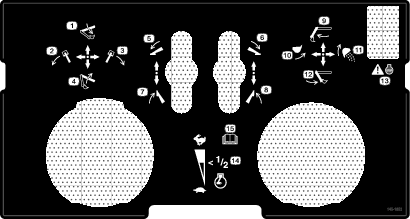

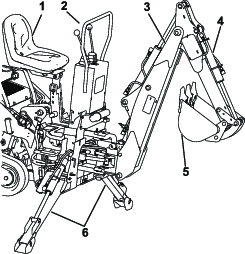

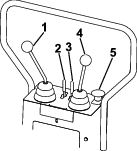

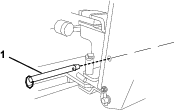

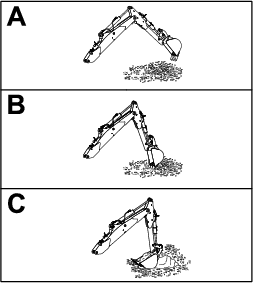

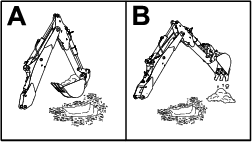

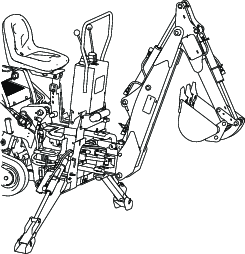

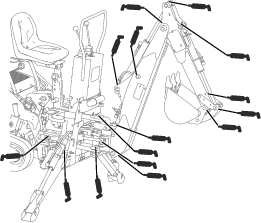

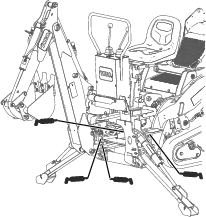

Grease the 19 fittings, as shown in Figure 14 and Figure 15, every 8 operating hours. Grease all fittings immediately after every washing.

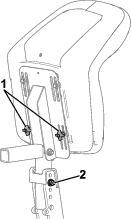

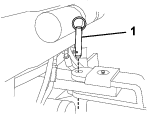

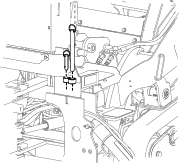

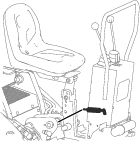

Also, grease the fitting in the swing cylinder pivot pin, located under the seat column (Figure 16).

Grease Type: General-purpose grease

-

Park the machine on a level surface, disengage the auxiliary hydraulics lever, lower the attachment, and engage the parking brake (if equipped).

-

Shut off the engine and remove the key.

-

Clean the grease fittings with a rag.

-

Connect a grease gun to each fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

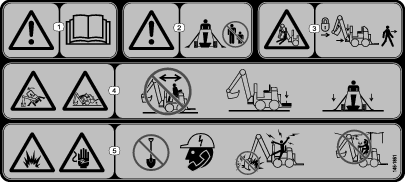

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.