Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Shift the transmission lever to the P (Park) position.

-

Shut off the engine and remove the key.

-

Raise the machine using a jack and support the machine using jack stands.

When jacking up the front of the machine, always place a wooden block (or similar material) between the jack and the machine frame.

Danger

A machine on a jack may be unstable and slip off the jack, injuring anyone beneath it.

-

Do not start the machine while the machine is on a jack, as the engine vibration or wheel movement could cause the machine to slip off the jack.

-

Always remove the key from the key switch before getting off the machine.

-

Block the tires when the machine is on a jack.

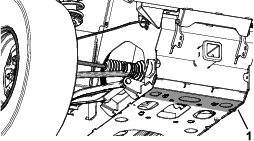

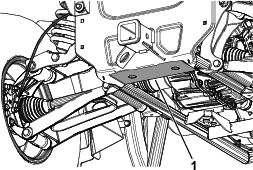

The jacking point at the front of the machine is located at the front frame bottom plate.

The jacking point at the rear of the machine is located at the rear cradle bracket.

-

Removing the Existing Wheels

Remove the 4 existing lug nuts and wheels from the machine.

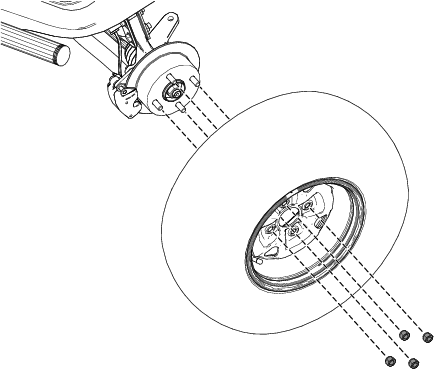

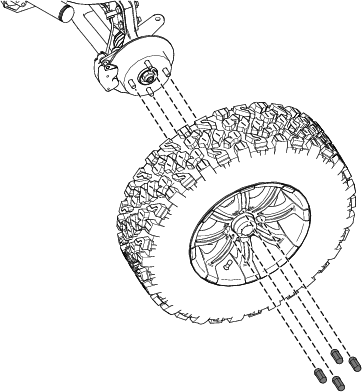

Installing the New Wheels

Parts needed for this procedure:

| Front wheel assembly | 2 |

| Rear wheel assembly | 2 |

| Lug nut | 16 |

-

Install the 2 front wheel assemblies and 2 rear wheel assemblies using the provided 4 lug nuts on each wheel.

-

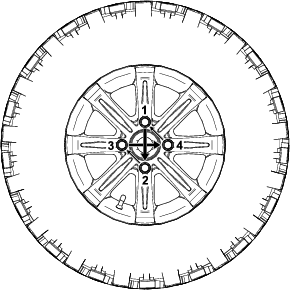

Using a thin wall socket, torque the lug nuts in a crossing pattern to 108 N∙m (80 ft-lb).

-

Adjust the tire pressure on each wheel assembly to the manufacturer’s recommendation.

-

After the first 10 hours of use, inspect and retorque the wheel lug nuts.