| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 10 hours |

|

Introduction

The debris blower is towed behind a ride-on machine which is intended to be used by professional, hired operators in commercial applications. It is primarily designed to use wind power to quickly clear large areas of unwanted debris on well-maintained lawns in parks, golf courses, sports fields, and on commercial grounds. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Important: To maximize the safety, performance, and proper operation of this machine, carefully read and fully understand the contents of this Operator’s Manual. Failing to follow these operating instructions or to receive proper training may result in injury. For more information on safe operating practices, including safety tips and training materials, go to www.Toro.com.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

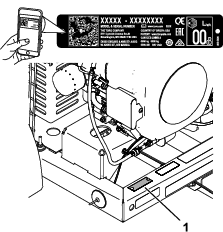

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number (if equipped) to access warranty, parts, and other product information.

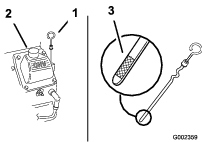

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

The DOT tire information is located on the side of each tire. This information gives load and speed ratings. Replacement tires should have the same or better ratings. Ensure that the tires meet or exceed the weight requirements of your machine.

| Electromagnetic Compatibility |

| Domestic: This device complies with FCC Rules Part 15. Operation is subject to the following two conditions: (1) This device may not cause harmful interference and (2) this device must accept any interference that may be received, including interference that may cause undesirable operation. |

| This equipment generates and uses radio frequency energy and if not installed and used properly, in strict accordance with the manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply within the limits of a FCC Class B computing device in accordance with the specifications in Subpart J of Part 15 of FCC Rules, as stated above. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:Reorient the receiving antenna, relocate the remote control receiver with respect to the radio/TV antenna or plug the controller into a different outlet so that the controller and radio/TV are on different branch circuits.If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions.The user may find the following booklet prepared by the Federal Communications Commission helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available from the U.S. Government Printing Office, Washington, DC 20402. Stock No. 004-000-00345-4. |

| FCC ID: W7OMRF24J40MDME-Base, OA3MRF24J40MA-Hand Held |

| IC: 7693A-24J40MDME-Base, 7693A-24J40MA-Hand Held |

| Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device. |

| Japan Electromagnetic Compatibility Certification | |

| Handheld: |  |

| RF2CAN: |  |

| Mexico Electromagnetic Compatibility Certification | |

| Handheld: |  |

| RF2CAN: |  |

| Korea Electromagnetic Compatibility Certification(Decal provided in separate kit) | |

| Handheld: |  |

| RF2CAN: |  |

| Singapore Electromagnetic Compatibility Certification | |

| Handheld: | TWM240007_IDA_N4021–15 |

| RF2CAN: | TWM-240005_IDA_N4024–15 |

| Morocco Electromagnetic Compatibility Certification | |

| AGREE PAR L’ANRT MAROC | |

| Numero d’agrement: | MR 14092 ANRT 2017 |

| Delivre d’agrement: | 29/05/2017 |

Important: Changing or modifying the machine without the express approval from the party responsible for compliance could void your authority to operate the equipment.Do not change or modify the machine without the express approval from the party responsible for compliance.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

This machine has been designed in accordance with ANSI standard B71.4-2017.

General Safety

This product is capable of throwing objects. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of both this Operator’s Manual and the operator’s manual of the traction unit before using this machine. Ensure that everyone using this product knows how to use this machine and the traction unit and understands the warnings.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and working on the machine.

-

Keep children, bystanders, and pets out of the operating area. Never allow children to operate the machine.

-

Always shut off the engine, remove the key (if equipped), wait for all moving parts to stop, and allow the machine to cool before adjusting, repairing, cleaning, or storing the machine.

Improperly using or maintaining this machine can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety-alert symbol (Figure 2), which means Caution, Warning, or Danger—personal safety instruction. Failure to comply with these instructions may result in personal injury or death.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Connecting the Battery

Parts needed for this procedure:

| Grafo 112X grease (Toro Part No. 505-47) | — |

-

Remove the clips securing the battery cover to the battery box (Figure 3).

Danger

Battery electrolyte contains sulfuric acid, which is fatal if consumed and causes severe burns.

-

Do not drink electrolyte and avoid contact with skin, eyes or clothing. Wear safety glasses to shield your eyes and rubber gloves to protect your hands.

-

Fill the battery where clean water is always available for flushing the skin.

-

-

Attach the positive cable (red cable) to the positive (+) terminal.

-

Attach the negative cable (black cable) to the negative (-) terminal of the battery.

-

Coat the terminals and mounting fasteners with Grafo 112X (skin over) grease (Toro Part No. 505-47) to prevent corrosion.

-

Install the battery cover and secure with the clips.

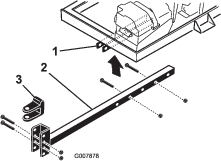

Mounting the Hitch to the Debris Blower

Parts needed for this procedure:

| Debris blower assembly | 1 |

| Hitch | 1 |

| Bolt (3/8 x 3 inches) | 2 |

| Flange nut (3/8 inch) | 2 |

| Hitch clevis | 1 |

| Bolt (5/8 x 4–1/2 inch) | 2 |

| Locknut (5/8 inch) | 2 |

-

Position the debris blower on a flat, level surface.

-

Insert the hitch tube into the frame brackets (Figure 4). Secure the tube to the frame with 2 bolts (3/8 x 3 inches) and flange nuts (3/8 inch) and torque to 40 N⋅m (30 ft-lb).

Note: The hitch tube can be rotated 180 degrees to accommodate different hitch heights.

Connecting the Debris Blower to the Tow Vehicle

Parts needed for this procedure:

| Hitch pin | 1 |

| Clevis | 1 |

-

Back the tow vehicle up to the blower.

-

Adjust the blower hitch clevis to the same level as the tow vehicle hitch as follows:

-

Set the hitch tube on a jack stand to keep it parallel to the ground.

-

Remove the bolts and locknuts securing the hitch clevis (Figure 4) to the hitch tube.

-

Raise or lower the hitch clevis to the position approximately level with the tow vehicle hitch.

-

Secure the clevis to the hitch with the bolts and locknuts previously removed and torque to 203 N⋅m (150 ft-lb). Ensure that the debris blower frame is parallel with the ground.

-

-

Adjust the hitch tube length to assure the blower does not contact the tow vehicle when turning as follows:

-

Remove the bolts and nuts securing the hitch tube to the frame brackets (Figure 4).

-

Secure the tube to the frame with the bolts and flange nuts.

-

-

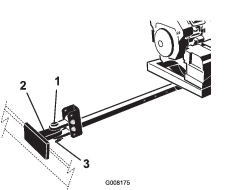

Connect the blower clevis hitch to the tow vehicle hitch with the hitch pin and clevis (Figure 5).

Product Overview

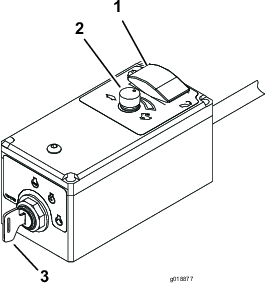

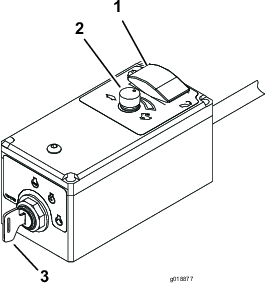

Nozzle-Direction Button

Press the button to rotate the nozzle to the desired direction (Figure 6).

Throttle/Engine Speed

Rotate the knob to FAST (rabbit) or SLOW (turtle) to increase or decrease the speed of the engine (Figure 6).

Remote Ignition Switch

The ignition switch which is used to start and shut off the engine, has three positions: OFF, RUN, and START. Rotate the key clockwise to the START position to engage the starter motor. Release the key when the engine starts. The key moves automatically to the RUN position. To shut engine off, rotate the key counterclockwise to the OFF position (Figure 6).

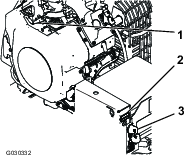

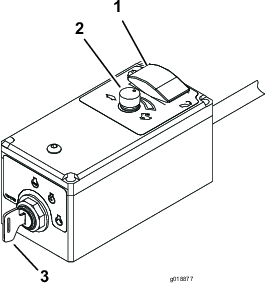

Choke Control

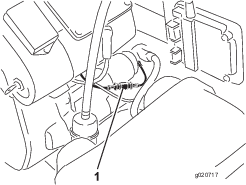

To start a cold engine, move the choke control lever (Figure 7) to the ON position.

Hour Meter

The hour meter (Figure 7) indicates the total hours of machine operation.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

Never allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Always shut off the engine, remove the key, wait for all moving parts to stop, and allow the machine to cool before adjusting, repairing, cleaning, or storing the machine. Know how to stop the machine and shut off the engine quickly.

-

Keep all guards, safety devices, and decals in place. Repair or replace all safety devices and replace all illegible or missing decals. Do not operate the machine unless they are present and functioning properly.

-

Ensure that the traction unit is suitable for use with an implement of this weight by checking with the traction unit supplier or manufacturer.

-

Do not modify this equipment in any manner.

Fuel Safety

-

Use extreme care in handling fuel. It is flammable and its vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved fuel container.

-

Do not remove the fuel cap or fill the fuel tank while the engine is running or hot.

-

Do not add or drain fuel in an enclosed space.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

-

If you spill fuel, do not attempt to start the engine; avoid creating any source of ignition until the fuel vapors have dissipated.

-

Do not fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place containers on the ground, away from your vehicle before filling.

-

Remove the equipment from the truck or trailer and refuel it while it is on the ground. If this is not possible, then refuel from a portable container rather than a fuel-dispenser nozzle.

-

Do not operate the machine without the entire exhaust system in place and in proper working condition.

-

Keep the fuel-dispenser nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock-open device.

-

If you spill fuel on your clothing, change your clothing immediately. Wipe up any fuel that spills.

-

Never overfill the fuel tank. Replace the fuel cap and tighten it securely.

-

Store fuel in an approved container and keep it out of the reach of children. Never buy more than a 30-day supply of fuel.

-

Do not fill the fuel tank completely full. Add fuel to the fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck. This empty space in the tank allows fuel to expand.

-

Avoid prolonged breathing of vapors.

-

Keep your face away from the nozzle and gas tank opening.

-

Avoid contact with skin; wash off spills with soap and water.

-

Adding Fuel

-

Fuel tank capacity: 18.9 L (5 US gallons)

-

Recommended Fuel

-

For best results, use only clean, fresh (less than 30 days old), unleaded fuel with an octane rating of 87 or higher ((R+M)/2 rating method).

-

Ethanol: Fuel with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Fuel with 15% ethanol (E15) by volume is not approved for use. Never use fuel that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved fuel may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use fuel containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless a fuel stabilizer is used.

-

Do not add oil to fuel.

-

Important: Do not use fuel additives other than a fuel stabilizer/conditioner. Do not use fuel stabilizers with an alcohol base, such as ethanol, methanol, or isopropanol.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide the following benefits:

-

Keeps fuel fresh during storage of 90 days or less. For longer storage it is recommended that the fuel tank be drained.

-

Cleans the engine while it runs

-

Eliminates gum-like varnish buildup in the fuel system, which causes hard starting

Important: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of fuel stabilizer/conditioner to the fuel.

Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel. To minimize the chance of varnish deposits in the fuel system, use fuel stabilizer at all times.

Filling the Fuel Tank

-

Shut off the engine.

-

Clean the area around the fuel tank cap and remove the cap (Figure 8).

Note: The fuel tank cap contains a gauge which shows the fuel level.

-

Add fuel to the fuel tank until the level is 6 mm to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck.

Note: This space in the tank allows fuel to expand. Do not fill the fuel tanks completely full.

-

Install fuel tank cap securely.

-

Wipe up any spilled fuel.

Checking the Engine-Oil Level

Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Engine Oil Level.

Checking the Tire Pressure

Checking the Torque of the Wheel Lug Nuts

Check the torque of the wheel lug nuts initially and after the first 10 hours of operation.

Warning

Failure to maintain proper torque could result in failure or loss of wheel and could result in personal injury.

Torque wheel lug nuts to 95 to 122 N⋅m (70 to 90 ft-lb).

Performing Daily Maintenance

Before starting the machine each day, perform the Each Use/Daily procedures listed in Daily Maintenance Checklist.

During Operation

During Operation Safety

General Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not loose clothing or loose jewelry.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Discharged air has considerable force and could cause injury or loss of footing. Stay away from the blower nozzle when the machine is operating.

-

Keep all bystanders away; shut off the machine when bystanders enter the area, do not direct discharge toward them.

-

Do not operate the machine when it is not connected to a towing vehicle.

-

Do not run the engine in or direct the blower nozzle into a confined area without adequate ventilation. Engine exhaust contains carbon monoxide, an odorless gas that is fatal if inhaled.

-

Do not carry passengers on the machine and keep bystanders and pets away from the machine during operation.

-

Operate the machine only in good visibility to avoid holes or hidden hazards.

-

Look behind and down before backing up to be sure of a clear path.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision.

-

Never run an engine in an area where exhaust gasses are enclosed.

-

Never leave a running machine unattended.

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Engage the tow vehicle parking brake.

-

Shut off the engine and remove the key (if equipped).

-

Wait for all movement to stop.

-

-

When transporting the machine on public roads, follow all traffic regulations and use any additional accessories that may be required by law, such as lights, turn signals, slow-moving vehicle (SMV) signs, and others as required.

-

If the machine ever vibrates abnormally, stop the machine immediately, shut off the engine, remove the key, wait for all moving parts to stop, and inspect for damage. Repair all damage to the machine before resuming operation.

-

Reduce speed when operating on rough, uneven terrain, and near curbs, holes, and other sudden changes in terrain.

-

To avoid causing the machine to tip over, be careful when turning and avoid unsafe maneuvers.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution.

-

Review the traction unit specifications to ensure that you do not exceed its slope capabilities.

-

Evaluate the site conditions to determine if the slope is safe for machine operation, including surveying the site. Always use common sense and good judgment when performing this survey.

-

Review the slope instructions, listed below, for operating the machine on slopes. Before you operate the machine, review the site conditions to determine whether you can operate the machine in the conditions on that day and at that site. Changes in the terrain can result in a change in slope operation for the machine.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction. Make turns slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question.

-

Remove or mark obstructions such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstructions. Uneven terrain could overturn the machine.

-

Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction.

-

Use extreme caution when operating the machine near drop-offs, ditches, embankments, water hazards, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in. Establish a safety area between the machine and any hazard.

-

Starting the Engine

Warning

Rotating parts can cause serious personal injury.

-

Keep hands and feet away from the machine when it is running.

-

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury.

-

Never operate the machine with covers, shrouds, or guards removed.

-

Ensure that the blower is attached to the tow vehicle before you start the blower.

-

Move the choke control to the ON position before starting a cold engine.

Note: A warm or hot engine may not require choking. After the engine starts, move the choke control to the OFF position.

-

Rotate the engine ignition key clockwise to the START position to start the engine; release the key whent he engine starts (Figure 10).

Note: If the key was left in the RUN position for an extended time, move the key to the OFF position before proceeding to the starting procedure.

Important: Do not engage starter for more than 10 seconds at a time. If engine fails to start allow 10 second cool-down period between attempts. Failure to follow these instructions can burn out starter motor.

-

After the engine starts, move the choke control to the OFF position. If the engine stalls or hesitates, move the choke back to the RUN position for a few seconds, then set the engine speed to the desired setting. Repeat this as required.

Shutting Off the Engine

-

Decrease the engine speed to 3/4 throttle.

-

Rotate the remote ignition key to the OFF position.

-

If leaving the machine, rotate the engine key to the OFF position and remove it from the switch (Figure 10).

Adjusting the Nozzle Direction

Press the nozzle direction button to rotate the nozzle to the desired direction (Figure 11).

Moving the Machine from the Job Site

Important: Raise the blower nozzle before moving the machine from the job site. If you leave the blower nozzle in the down position during transport, the nozzle may contact the ground, and become damaged.

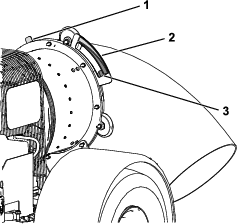

The Nozzle-Position Gauge

The nozzle-position gauge (Figure 12) is located behind the turbine housing, above the fuel tank.

Note: The decal on the nozzle-position gauge indicates the position of the nozzle relative to the ground.

There is a red pointer and a green pointer (Figure 12) attached to the blower nozzle.

Nozzle Alignment

-

When the red pointer is visible in the nozzle position gauge, the blower nozzle is aligned to blow to the right of the machine.

-

When the green pointer is visible in the nozzle position gauge, the blower nozzle is aligned to blow to the left of the machine.

Nozzle Angle

The pointer and gauge indicate the blower nozzle angle as follows:

-

When the pointer is in the same colored region on the decal, that indicates that the chute opening is positioned more parallel to the ground.

-

When a pointer tab is in the different colored region on the decal, that indicates that the chute opening is positioned more toward the ground.

Operating Tips

-

Practice operating the blower. Blow the same direction that the wind blows to prevent material from blowing back into the cleared area.

-

When blowing debris from a job site, run the engine at full throttle.

-

Adjust the blower nozzle position so that the airstream blows under the debris.

-

Use caution when blowing around newly planted sod; the airstream could disrupt the grass.

After Operation

After Operation Safety

General Safety

-

Park the machine on a firm, level surface; shut off the engine, remove the key, wait for all moving parts to stop, and allow the machine to cool before adjusting, repairing, cleaning, or storing the machine.

-

Only disconnect the machine from the traction unit while on a level surface.

-

When disconnecting the machine, always chock the wheels to prevent movement.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

-

Keep all parts of the machine in good working condition and all hardware tightened.

-

Replace all worn, damaged, or missing decals.

Towing Safety

-

Before towing the machine, check with your local county or state safety towing regulations, in addition to meeting Department of Transportation (DOT) safety towing regulations.

-

Always shut off the engine and point the blower nozzle up before transporting.

-

Tow only with a machine that has a hitch designed for towing. Do not attach towed equipment except at the hitch point.

-

Always inspect the hitch and coupling for wear. Do not tow the machine with damaged or missing hitches, couplings, or chains.

-

Check the tire air pressure on the machine. The tires should be inflated to 241 kpa (35 psi) cold. Also, check the tire-tread wear on the machine.

-

Always properly attach the machine safety chains to the towing vehicle.

-

Do not tow the machine faster than 88 km/h (55 mph). When off-road towing do not exceed 24 km/h (15 mph).

-

Avoid sudden stops and starts. This can cause skidding or jack knifing. Smooth, gradual starts and stops improve towing.

-

Avoid sharp turns to prevent rolling.

-

Chock the wheels to whenever you park the blower.

Hauling

-

Use care when loading or unloading the machine into a trailer or truck.

-

Use full-width ramps for loading machine into a trailer or truck.

-

Tie the machine down securely using straps, chains, cable, or ropes. Both front and rear straps should be directed down and outward from the machine.

Connecting the Machine to the Towing Vehicle

-

Check the towing-vehicle hitch ball and machine coupler for signs of wear or damage. Replace any parts that are worn or damaged before towing the machine.

-

The machine coupler is 5.1 cm (2 inches). The towing vehicle ball hitch diameter must be 5.1 cm (2 inches). Use of different ball diameter will create an extremely dangerous condition which can result in separation of the coupler and ball or ball failure.

-

After the tow bar has been connected to the machine, secure the machine coupler to the towing-vehicle hitch and ensure that the lock lever is in the locked position.

Caution

The safety chain is intended to prevent complete separation of the machine from the towing vehicle in the event of a tow bar failure.

If the safety chain is removed from the machine, do not tow the machine.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Note: Download a free copy of the electrical or hydraulic schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page.

Important: Refer to your engine owner's manual for additional maintenance procedures.

Maintenance Safety

-

Before cleaning, servicing, or adjusting the machine, do the following:

-

Park the machine on a level surface.

-

Shut off the engine, remove the key, disconnect the spark-plug wire, and wait for all moving parts to stop.

-

Chock the wheels.

-

Remove the machine from the traction unit.

-

Allow machine components to cool before performing maintenance.

-

-

Perform only those maintenance instructions described in this manual. If major repairs are ever needed or you need assistance, contact an authorized Toro distributor.

-

Support the machine with blocks or jack stands when working beneath it.

-

Ensure that all guards are installed securely after maintaining or adjusting the machine.

-

Do not allow untrained personnel to service the machine.

-

Use jack stands to support the machine or components when required.

-

Carefully release pressure from components with stored energy.

-

Do not charge the batteries while servicing the machine.

-

To reduce the potential fire hazard, keep the engine area free of excessive grease, grass, leaves, and accumulation of dirt.

-

If possible, do not perform maintenance while the engine is running. Keep away from moving parts.

-

If you must run the engine to perform a maintenance adjustment, keep your hands, feet, clothing, and all other parts of your body away from the engine and any moving parts. Keep bystanders away from the machine.

-

Clean up oil and fuel spills.

-

Keep all parts in good working condition and all fasteners tightened. Replace all damaged or missing decals.

-

Do not interfere with the intended function of a safety device or reduce the protection provided by a safety device. Check their proper operation regularly.

-

Do not overspeed the engine by changing the governor settings. To ensure safety and accuracy, have an authorized Toro distributor to check the maximum engine speed with a tachometer.

-

If major repairs are ever necessary or assistance is required, contact an authorized Toro distributor.

-

Altering this machine in any manner may affect the operation of the machine, performance, durability, or its use may result in injury or death. Such use could void the product warranty of The Toro Company.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| After the first 10 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 500 hours |

|

Pre-Maintenance Procedures

Caution

Failure to properly maintain the machine could result in premature failure of machine systems causing possible harm to you or bystanders.

Keep the machine well maintained and in good working order as indicated in these instructions.

Warning

If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or bystanders.

Remove the key from the ignition and disconnect the wires from the spark plugs before you do any maintenance. Set the wires aside so that they do not accidentally contact the spark plugs.

Preparing for Maintenance

-

Park the machine on a level surface.

-

Shut off the engine, remove the key, and wait for all moving parts to stop.

-

Chock the wheels.

-

Remove the machine from the traction unit.

-

Allow machine components to cool before performing maintenance.

-

Disconnect the spark-plug wire.

Preparing the Machine for Weld Repairs

Important: Failure to disconnect the battery may permanently damage to the electrical system.

-

Disconnect the negative-battery cable from the battery before welding on the machine.

-

Connect the negative-battery cable to the battery after you finish welding on the machine.

Engine Maintenance

Engine Safety

-

Shut off the engine before checking the oil or adding oil to the crankcase.

-

Do not change the governor speed or overspeed the engine.

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

| Every 100 hours |

|

Checking the Air Filter

-

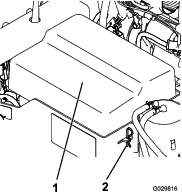

Check the air cleaner body for damage, which could possibly cause an air leak. Ensure the cover is sealing around the air cleaner body (Figure 13).

Note: Replace a damaged air cleaner cover or housing.

-

Release the latches securing the air-filter cover to the air-filter housing (Figure 13).

-

Separate the air-filter cover from the air-filter housing, and clean the inside of the cover (Figure 13).

-

Gently slide the air-filter element out of the filter housing.

Note: To reduce the amount of dust dislodged, avoid knocking the filter against the air-filter housing.

-

Inspect the air-filter element.

-

If the air-filter element is clean, install the filter element, refer to Installing the Air Filter.

-

If the air-filter element is damaged, replace the filter element; refer to Replacing the Air Filter.

-

Replacing the Air Filter

-

Remove the air-filter element; refer to Servicing the Air Cleaner.

-

Inspect the new filter for shipping damage.

Note: Check the sealing end of the filter.

Important: Do not install a damaged filter.

-

Install the new air filter; refer to Installing the Air Filter.

Installing the Air Filter

Important: To prevent engine damage, always operate the engine with the complete air-cleaner assembly installed.

Important: Do not use a damaged element.

Note: Cleaning of the used air-filter element is not recommended due to the possibility of damage to the filter media.

-

Clean the dirt ejection port located on the air-filter cover.

-

Remove the rubber outlet valve from the cover, clean the cavity, and replace the outlet valve.

-

Insert the air-filter element into air-filter housing (Figure 13).

Note: Ensure that the filter is sealed properly by applying pressure to the outer rim of the filter when installing it. Do not press on the flexible center of the filter.

-

Align the air-cleaner cover with the air-cleaner housing (Figure 13).

-

Secure the cover to the housing with the latches (Figure 13).

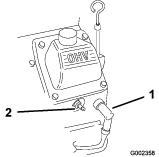

Servicing the Carbon Canister

Replacing the Carbon-Canister Air Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

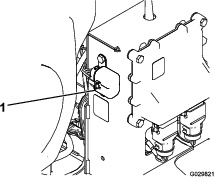

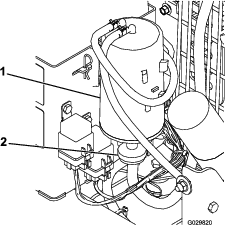

Remove and discard the carbon canister air filter (Figure 14).

-

Install the new air filter.

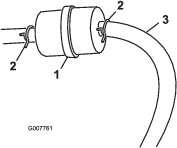

Replacing the Carbon-Canister Purge-Line Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Note: Check the purge-line filter occasionally for dirt. If the filter appears to be dirty, replace it.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

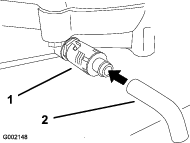

Move the spring-type hose clamps on both sides of the carbon canister purge-line filter away from the filter (Figure 15).

-

Remove and discard the carbon filter (Figure 15).

-

Install a new filter into the hose with the arrow on the filter pointing towards the check valve and secure it with the hose clamps (Figure 15).

Servicing the Engine Oil

Note: Change the oil more frequently when the operating conditions are extremely dusty or sandy.

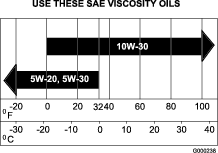

Oil Type: Detergent oil (API service SG, SH, SJ or higher)

Crankcase Capacity (with filter): 2 L (67 oz)

Viscosity: See the table below.

Checking the Engine Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Note: The best time to check the engine oil is when the engine is cool before it has been started for the day. If it has already been run, allow the oil to drain back down to the sump for at least 10 minutes before checking. If the oil level is at or below the ADD mark on the dipstick, add oil to bring the oil level to the FULL mark. Do not overfill. If the oil level is between the FULL and ADD marks, no oil addition is required.

-

Park the machine on a level surface.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean around the oil dipstick (Figure 17) so that dirt cannot fall into the filler hole and damage the engine.

-

Unscrew the oil dipstick and wipe the end clean (Figure 17).

-

Slide the oil dipstick fully into the filler tube, but do not thread it onto the tube (Figure 17).

-

Pull the dipstick out and look at the metal end. If the oil level is low, slowly pour only enough oil into the filler tube to raise the level to the FULL mark.

Important: Do not overfill the crankcase with oil and run the engine. Engine damage can result.

Changing the Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Start the engine and let it run 5 minutes. This warms the oil so that it drains better.

-

Park the machine so that the drain side is slightly lower than the opposite side to ensure that the oil drains completely.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Place a pan below the drain. Rotate the oil drain valve to allow the oil to drain (Figure 18).

Note: Insert a hose may be inserted onto the drain valve to direct the oil flow. The hose is not included with the machine.

-

When the oil has drained completely, close the drain valve.

Note: Dispose of the used oil at a recycling center.

-

Slowly pour approximately 80% of the specified oil into the filler tube (Figure 17).

-

Check the oil level; refer to Checking the Engine Oil Level.

-

Slowly add the additional oil to bring it to the Full mark.

Changing the Oil Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Note: Change the oil filter more frequently when the operating conditions are extremely dusty or sandy.

-

Drain the oil from the engine; refer to Changing the Oil.

-

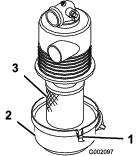

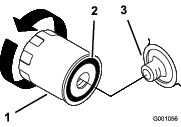

Remove the old filter and wipe the filler adapter gasket surface (Figure 19).

-

Apply a thin coat of new oil to the rubber gasket on the replacement filter (Figure 19).

-

Install the replacement oil filter to the filter adapter, turn the oil filter clockwise until the rubber gasket contacts the filter adapter, then tighten the filter an additional 2/3 to 1 turn (Figure 19).

-

Fill the crankcase with the proper type of new oil; refer to Servicing the Engine Oil.

-

Run the engine for about 3 minutes, shut off the engine, and check for oil leaks around the oil filter.

-

Check the engine oil level and add oil if needed.

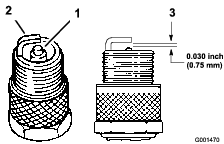

Servicing the Spark Plugs

Ensure that the air gap between the center and side electrodes is correct before installing the spark plugs. Use a spark plug wrench for removing and installing the spark plugs and a gapping tool/feeler gauge to check and adjust the air gap. Install new sparks plugs if necessary.

Type: Champion® RC12YC, Champion® Platinum 3071 or equivalent

Air Gap: 0.76 mm (0.030 inch)

Checking the Spark Plugs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

-

Look at the center of the spark plugs (Figure 20). If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means that the air cleaner is dirty.

Important: Always replace a spark plug when it has a black coating, worn electrodes, an oily film, or cracks.

-

Check the gap between the center and side electrodes (Figure 20). Bend the side electrode (Figure 20) if the gap is not correct.

Removing the Spark Plugs

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Disconnect the wires from the spark plugs (Figure 21).

-

Clean around the spark plugs to prevent dirt from falling into the engine and potentially causing damage.

-

Remove the spark plugs and the metal washers.

Installing the Spark Plugs

-

Install the spark plugs and the metal washer. Ensure that the air gap is set correctly.

-

Tighten the spark plugs to 24.4 to 29.8 N-m (18 to 22 ft-lb).

-

Connect the wires to the spark plugs (Figure 20).

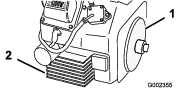

Cleaning the Engine Screen and the Oil Cooler

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Before each use, check and clean the engine screen and oil cooler. Remove any build up of grass, dirt or other debris from the oil cooler and engine screen (Figure 22).

Fuel System Maintenance

Replacing the Fuel Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 500 hours |

|

Never install a dirty filter if it is removed from the fuel line.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Allow the machine to cool down.

-

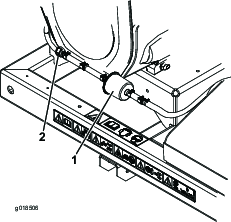

Squeeze the ends of the hose clamps together and slide them away from the filter (Figure 23).

-

Remove the filter from the fuel lines.

-

Install a new filter and move the hose clamps close to the filter (Figure 23).

Servicing the Fuel Tank

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

Drain fuel from the fuel tank when the engine is cold. Do this outdoors in an open area. Wipe up any fuel that spills.

-

Never smoke when draining fuel, and stay away from an open flame or where a spark may ignite the fuel fumes.

-

Park the machine on a level surface to ensure that the fuel tanks drain completely.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Loosen the hose clamp at the fuel filter and slide it up the fuel line away from the fuel filter (Figure 23).

-

Disconnect the fuel line from the fuel filter (Figure 23).

Note: Allow fuel to drain into a fuel container can or drain pan (Figure 23).

Note: This is the best time to install a new fuel filter because the fuel tank is empty.

-

Install the fuel line onto the fuel filter. Slide the hose clamp close to the fuel filter to secure the fuel line (Figure 23).

Electrical System Maintenance

Important: Before welding on the machine, disconnect the controller and the negative cable from the battery to prevent damage to the electrical system.

Electrical System Safety

-

Disconnect the battery before repairing the machine. Disconnect the negative terminal first and the positive last. Connect the positive terminal first and the negative last.

-

Charge the battery in an open, well-ventilated area, away from sparks and flames. Unplug the charger before connecting or disconnecting the battery. Wear protective clothing and use insulated tools.

Drive System Maintenance

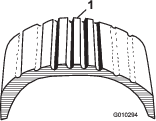

Inspecting the Tires

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Check the tire pressure frequently to ensure proper inflation (97 kPa (14 psi). If the tires are not inflated to the correct pressure, the tires wear prematurely.

Operating accidents can damage a tire or rim, so inspect the tire condition after an accident.

The DOT tire information is located on the side of each tire. This information gives load and speed ratings. Replacement tires should have the same or better ratings.

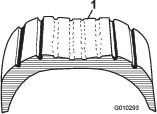

is an example of tire wear caused by under inflation.

is an example of tire wear caused by over inflation.

Belt Maintenance

Adjusting the Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 50 hours |

|

If the belt slips when changing the direction of the nozzle, an adjustment to the belt is required.

-

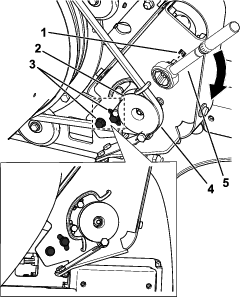

Loosen the bolts securing the pulley mounting bracket to the blower frame (Figure 28).

-

Insert the drive of a torque wrench into the pulley mounting bracket as shown in Figure 28.

-

With the handle of the wrench, pivot the pulley mounting bracket away from the nozzle so the belt is tensioned and the torque wrench reads 22.6 to 26.0 N⋅m (200 to 230 in-lb).

-

While maintaining the correct belt tension, tighten the mounting bolts.

Miscellaneous Maintenance

Checking the Nozzle

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

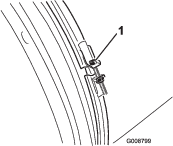

Checking the Nozzle Clamp

Check the nozzle clamp (Figure 29) daily to assure it is tight. If the nozzle is dragged over obstacles or through low areas in the terrain it could be knocked loose from the clamp. Torque the clamp fasteners to 5.1-5.7 N⋅m (45-50 in-lb).

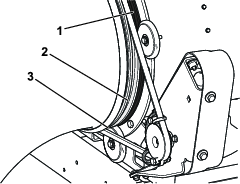

Cleaning the Nozzle Guides

Check and remove any grass, dirt or debris buildup around and in between the nozzle guides (Figure 30). If the nozzle guides for the belts or rollers are not kept free of debris, the nozzle may not rotate freely which could cause the motor to stall.

Cleaning

Washing the Machine

Important: Do not use brackish or reclaimed water to clean the machine.

Important: Do not pressure wash the machine.

-

Wash the machine with mild detergent and water.

-

Avoid excessive use of water, especially near the control console.

Disposing of Waste

Engine oil, engine and remote control batteries are pollutants to the environment. Dispose of these according to your state and local regulations.

Storage

Storage Safety

Shut off the machine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

Storing the Machine

-

Park the machine on a level surface, shut off the engine, remove the key from the ignition, wait for all parts to stop moving, and remove the spark plug wire.

-

Remove grass clippings, dirt, and grime from the external parts of the entire machine, especially the engine. Clean dirt and chaff from the outside of the engine cylinder head fins and blower housing.

Important: You can wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water.

-

Service the air cleaner; refer to Servicing the Air Cleaner.

-

Change the crankcase oil; refer to Changing the Oil.

-

Check the tire pressure; refer to Checking the Tire Pressure.

-

Prepare the machine for storage when non-use occurs over 30 days. Prepare machine for storage as follows:

-

Add a petroleum-based stabilizer/conditioner to fuel in the tank. Follow mixing instructions from stabilizer manufacture. Do not use an alcohol based stabilizer (ethanol or methanol).

Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel, and used at all times.

-

Run the engine to distribute conditioned fuel through the fuel system (5 minutes).

-

Shut off the engine, allow it to cool, and drain the fuel tank; refer to Servicing the Fuel Tank.

-

Start the engine and run it until it stops.

-

Choke the engine. Start and run the engine until it does not start.

-

Dispose of fuel properly. Recycle according to local codes.

Important: Do not store fuel containing stabilizer/conditioner longer than the duration recommended by the fuel-stabilizer manufacturer.

-

-

Remove the spark plug(s) and check its condition; refer to Servicing the Spark Plugs. With the spark plug(s) removed from the engine, pour 2 tablespoons of engine oil into the spark plug hole. Now use the starter to crank the engine and distribute the oil inside the cylinder. Install the spark plug(s). Do not install the wire on the spark plug(s).

-

Check and tighten all fasteners. Repair or replace any part that is damaged or missing.

-

Paint all scratched or bare metal surfaces. Paint is available from your authorized Toro distributor.

-

Store the machine in a clean, dry garage or storage area. Remove the key from the ignition switch and keep it out of reach of children or other unauthorized users. Cover the machine to protect it and keep it clean.