Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

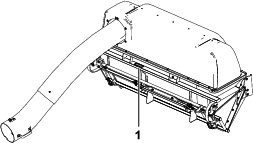

Cleaning the Bagger Screen

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Clean the screen before each use (more often in wet grass).

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

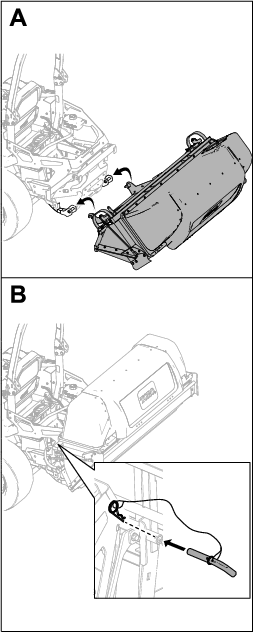

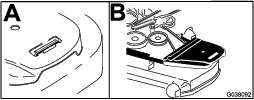

Open the bagger.

-

Clean the debris from the screen.

-

Close the bagger.

Cleaning the Collection System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Wash the inside and outside of the bagger hood, tube, and the underside of the mower. Use a mild automotive detergent to remove dirt.

-

Make sure you remove matted grass from all parts.

-

After washing all parts, let them dry thoroughly.

Note: With all parts installed, start and run the machine for a minute to assist in drying.

Inspecting the Blower Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 25 hours |

|

Check the belts for cracks, frayed edges, burn marks, or any other damage. Replace damaged belts.

Replacing the Blower Belt

-

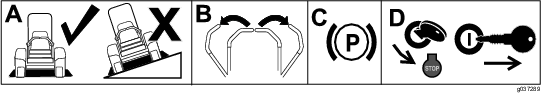

Disengage the PTO, move the motion-control levers to the NEUTRAL-LOCK position, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

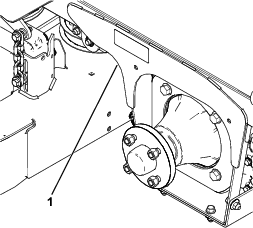

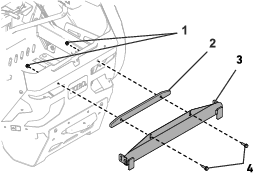

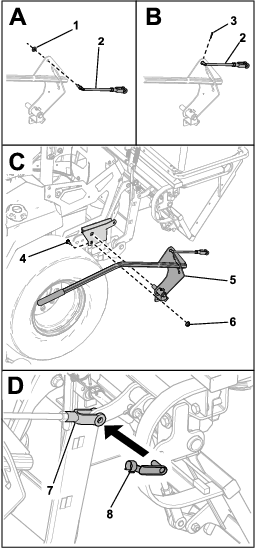

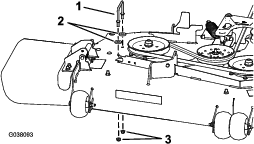

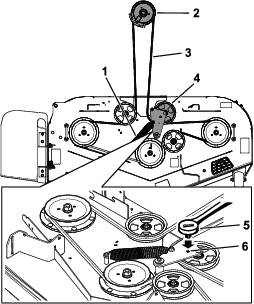

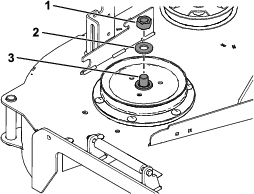

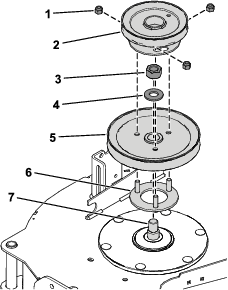

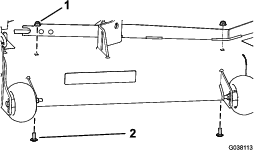

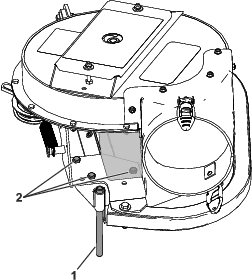

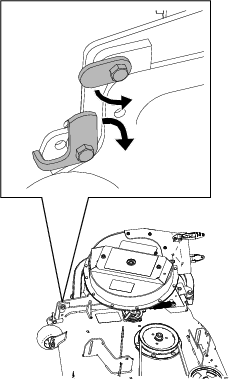

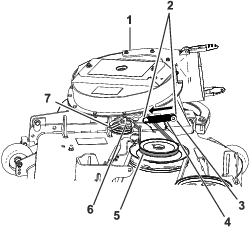

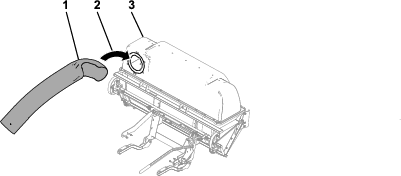

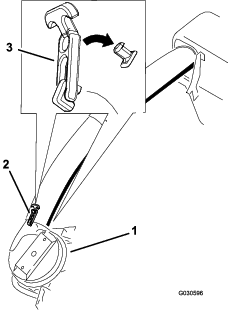

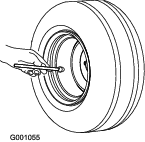

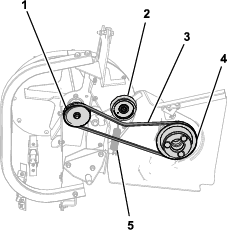

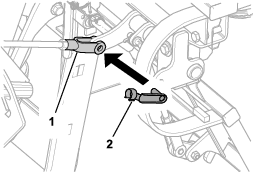

Loosen or remove belt guide (Figure 48).

-

Pull back on the spring-loaded idler pulley to relieve the belt tension (Figure 48).

-

Remove the existing blower belt.

-

Install the new belt around the blower pulley (Figure 48).

-

Tighten or install the belt guide (Figure 48).

-

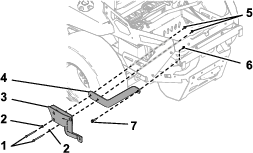

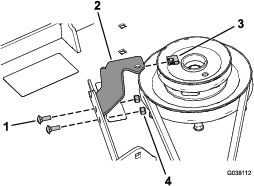

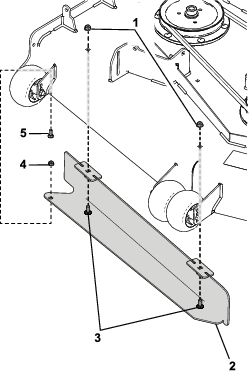

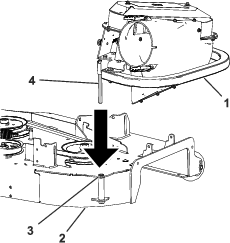

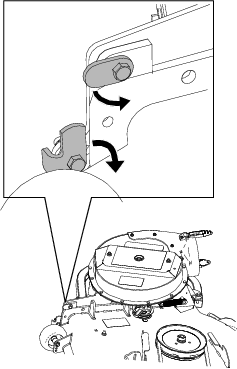

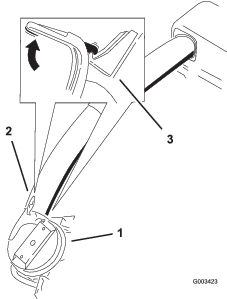

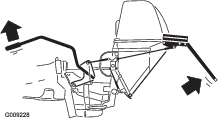

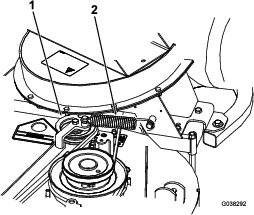

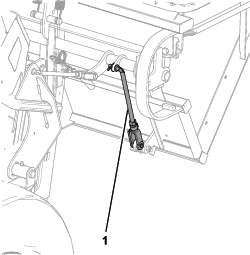

Install the spring as shown in Figure 49.

-

Install the belt onto the spring-loaded idler pulley (Figure 49).

Greasing the Idler Arm and Handle Pivot

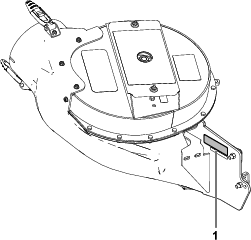

Inspecting the Collection System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 100 hours |

|

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Check the upper tube, lower tube, bagger, and the blower assembly.

Note: Replace these parts if they are cracked or broken.

-

Check the bagger frame.

Note: Replace any parts that are cracked or broken.

-

Tighten all nuts bolts and screws.

Adjusting the Closed Door

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

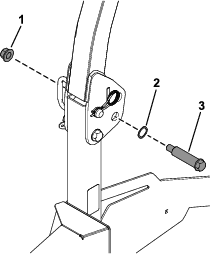

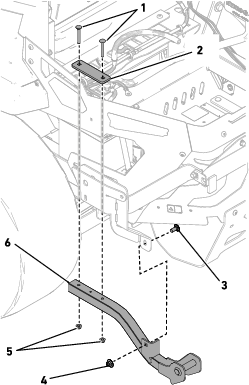

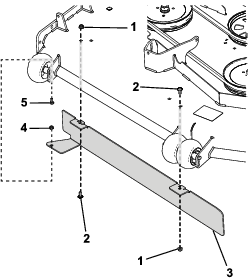

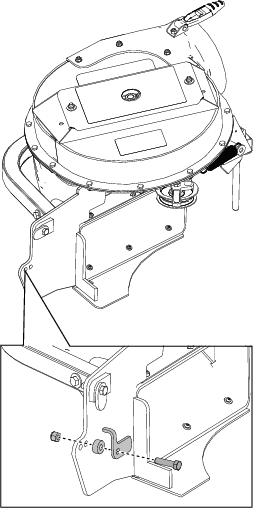

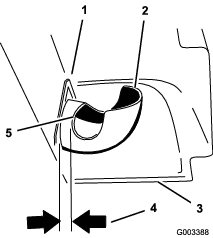

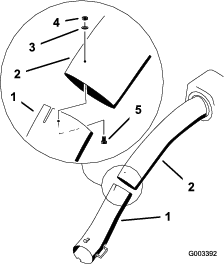

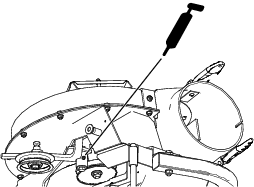

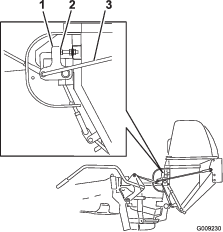

With the door closed, loosen the nuts and adjust the stop bolts so that the contact arm is straight up and down (Figure 52).

-

Adjust the length of the hinge links to so that the door completely closes and reasonable force is on the handle (Figure 52).

Note: Lengthen the links to reduce the force. Shorten the links to increase the force

Note: Make sure that both the left and right sides are adjusted the same distance. With the door closed, the links should be slightly tight to minimize rattling.

-

Tighten the nuts.

Adjusting the Open Door

Note: Perform this procedure after adjusting the door to completely close.

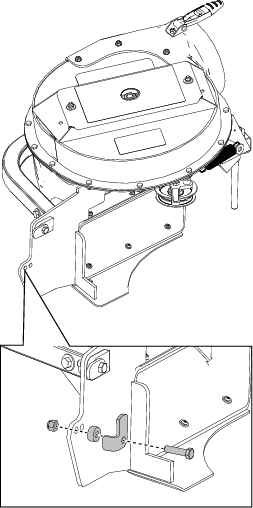

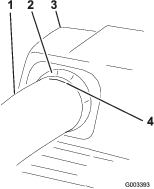

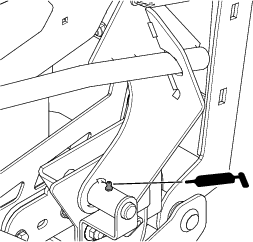

Adjust the handle link to so that the door opens as much as possible (Figure 53 and Figure 54).

Note: Lengthen the handle link to open the door farther. Shorten the handle link to open the door less

Note: How far the door opens is controlled by the contact arm hitting the stop. The stop is not adjustable and prevents the door from being opened too far.

Adjusting the Latches

Note: Adjust the open door and closed door positions before adjusting the latches.

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Close the door.

-

Ensure that the latches completely engage and contacts the latch rod welded to the door (Figure 55).

Note: The latches need to be tight against the latch rod. They need to be loose enough to move or wiggle.

Inspecting the Mower Blades

-

Inspect the mower blades regularly and whenever a blade strikes a foreign object.

-

If blades are badly worn or damaged, install new blades. Refer to your mower Operator's Manual for complete blade maintenance.

Installing the Mower Blades

In most mowing conditions, the standard high-lift blades will provide the best bagging performance.

The Toro Atomic blade is recommended for bagging leaves in dry conditions. In dry dusty conditions, the medium-lift or low-lift blades reduces dust and dirt blowout while providing effective bagging air flow.

Contact an Authorized Service Dealer for the proper blades for different mowing conditions.

Refer to the mower Operator's Manual for more information on installing blades.

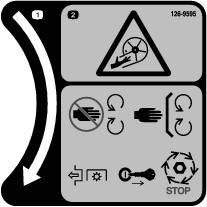

Replacing the Grass Deflector

Warning

An uncovered discharge opening could allow the machine to throw objects toward you or bystanders, resulting in serious injury. Also, contact with the blade could occur.

Never operate the machine unless you install a mulch plate, discharge deflector, or grass collection system.

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

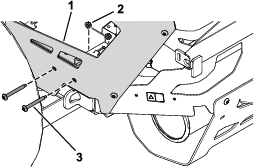

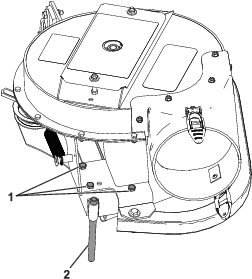

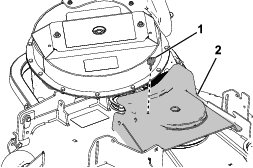

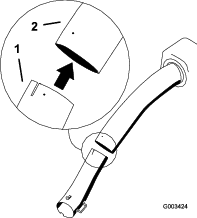

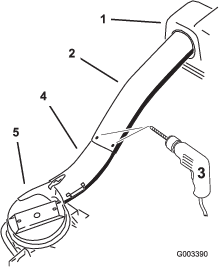

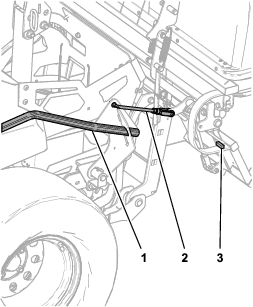

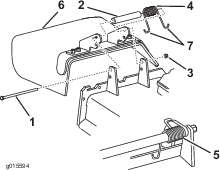

Remove the locknut, bolt, spring, and spacer holding the deflector to the pivot brackets (Figure 56).

-

Remove the damaged or worn grass deflector (Figure 56).

-

Place the spacer and the spring onto grass deflector.

-

Place 1 J-hook end of the spring behind the deck edge.

Note: Make sure that 1 J-hook end of the spring is installed behind the deck edge before installing the bolt as shown in Figure 56.

-

Install the bolt and the nut.

-

Place 1 J-hook end of the spring around the grass deflector (Figure 56).

Important: The grass deflector must be able to rotate. Lift the deflector up to the full open position and ensure that it rotates into the full down position.