Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Lower the cutting unit.

-

Shut off the engine and remove the key.

-

Raise the rear of the machine and support it with jack stands. Refer to Operator’s Manual for the correct procedure.

-

Unlatch the hood and rotate it to the service position.

-

Remove the rear wheels.

Installing the Hose Guides to the Cooler-Shroud Brackets

Parts needed for this procedure:

| Right cooler-shroud bracket | 1 |

| Left cooler-shroud bracket | 1 |

| Flange nut (5/16 inch) | 4 |

| Hose guide | 2 |

| Flat washer (5/16 inch) | 4 |

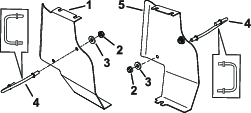

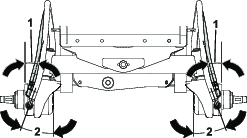

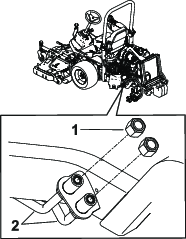

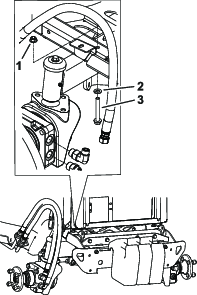

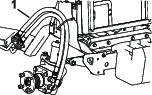

Install the hose guides to the left and right cooler-shroud brackets with 2 flat washers (5/16 inch) and 2 flange nuts (5/16 inch); refer to Figure 1.

Installing the Right Side Hoses

Parts needed for this procedure:

| Straight fitting | 1 |

| 90º elbow fitting | 1 |

| Hose with straight fittings | 1 |

| Hose with 90º elbow | 1 |

| Right cooler-shroud bracket assembly | 1 |

| Cap | 2 |

| Nylon locknut (3/8 inch) | 1 |

| Bolt (3/8 x 3 inches) | 1 |

| Flat washer (3/8 inch) | 1 |

Note: Install 1 side at a time.

-

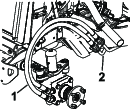

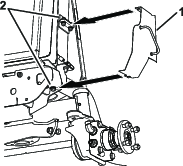

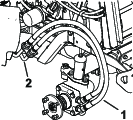

Remove the existing hydraulic hoses from the hydraulic lines in front of the wheel and immediately install the caps to the hydraulic lines (Figure 2 and Figure 3).

-

Remove the existing hose fittings from the wheel motor.

-

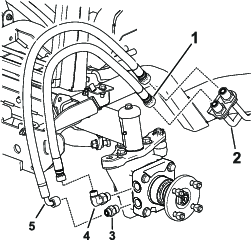

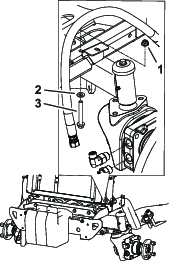

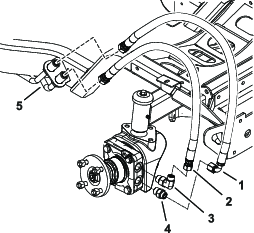

Install the new straight fitting and the 90º elbow fitting to the wheel motor (Figure 4).

-

Adjust the 90º elbow fitting to a 15º angle as shown in Figure 5.

-

Torque the wheel motor fittings to 142 N∙m (105 ft-lb).

-

Install the hose with straight fittings onto the 90º elbow fitting (Figure 4).

-

Install the hose with the 90º elbow to the straight fitting (Figure 4).

-

Adjust the 90º hose elbow to a 20º angle as shown in Figure 5.

-

Torque the hoses onto the fittings with 57 N∙m (42 ft-lb).

Note: Ensure the angles are maintained as shown in Figure 5.

-

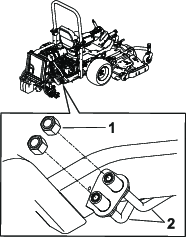

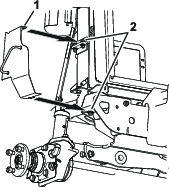

Remove the existing nut and bolt under the radiator that secures the bumper bracket (Figure 6).

-

Replace the existing nut and bolt with a bolt (3/8 x 3 inches), flat washer (3/8 inch), and flange nut (3/8 inch) to the frame. Do not tighten the bolt until the cooler-shroud bracket is installed.

-

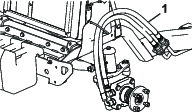

Loosen the bolts on the side of the radiator (Figure 7).

-

Slide the cooler-shroud bracket under the bolt heads on the radiator and bumper bracket (Figure 7).

-

Push the cooler-shroud bracket all the way in and tighten the bolts.

-

Route the hoses through the hose guide (Figure 8).

-

Remove one cap at a time and install the correct hose to the hydraulic line as shown in Figure 4.

Note: Use a backing wrench to prevent the hoses from twisting.

-

Remove the remaining cap and install the hose to the hydraulic line (Figure 4).

-

Torque the hoses to the hydraulic lines with 85 N∙m (63 ft-lb).

Note: Ensure the hoses are aligned above and below each other and not to the side.

-

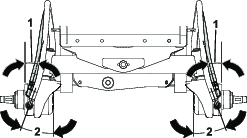

Install the rear wheel and ensure there is a 1.6 to 4.8 mm (1/16 to 3/16 inch ) clearance between the hoses and the tire sidewall.

-

Adjust the hose with the 90º elbow or 90° fitting if the clearance is not correct.

-

Torque the wheel-lug nuts; refer to the Operator’s Manual for the correct procedure.

Installing the Left Side Hoses

Parts needed for this procedure:

| Straight fitting | 1 |

| 90º elbow fitting | 1 |

| Hose with straight fittings | 1 |

| Hose with 90º elbow | 1 |

| Left cooler-shroud bracket assembly | 1 |

| Hose guide | 1 |

| Cap | 2 |

| Nylon locknut (3/8 inch) | 1 |

| Bolt (3/8 x 3 inches) | 1 |

| Flat washer (3/8 inch) | 1 |

-

Remove the existing hydraulic hoses from the hydraulic lines in front of the wheel and immediately install the caps to the hydraulic lines (Figure 9 and Figure 10).

-

Remove the existing hose fittings from the wheel motor.

-

Install the new straight fitting and the 90º elbow fitting to the wheel motor (Figure 11).

-

Adjust the 90º elbow fitting to a 15º angle as shown in Figure 12.

-

Torque the wheel motor fittings to 142 N∙m (105 ft-lb).

-

Install the hose with straight fittings onto the 90º elbow fitting (Figure 11).

-

Install the hose with the 90º elbow to the straight fitting (Figure 11).

-

Adjust the 90º hose elbow to a 20º angle as shown in Figure 12.

-

Torque the hoses onto the fittings with 57 N∙m (42 ft-lb).

Note: Ensure the angles are maintained as shown in Figure 12.

-

Remove the existing nut and bolt under the radiator that secures the bumper bracket (Figure 13).

-

Replace the existing nut and bolt with a bolt (3/8 x 3 inches), flat washer (3/8 inch), and flange nut (3/8 inch) to the frame. Do not tighten the bolt until the cooler-shroud bracket is installed.

-

Loosen the bolts on the side of the radiator (Figure 14).

-

Slide the left cooler-shroud bracket assembly under the bolt heads on the radiator and bumper bracket (Figure 14).

-

Push the cooler-shroud bracket all the way in and tighten the bolts.

-

Route the hoses through the hose guide (Figure 15).

-

Remove one cap at a time and install the correct hose to the hydraulic line as shown in Figure 11.

Note: Use a backing wrench to prevent the hoses from twisting.

-

Remove the remaining cap and install the hose to the hydraulic line (Figure 11).

-

Torque the hoses to the hydraulic lines with 85 N∙m (63 ft-lb).

Note: Ensure the hose are aligned above and below each other and not to the side.

-

Install the rear wheel and ensure there is a 1.6 to 4.8 mm (1/16 to 3/16 inch) clearance between the hoses and the tire sidewall.

-

Adjust the hose with the 90º elbow or 90° fitting if the clearance is not correct.

-

Torque the wheel-lug nuts; refer to the Operator’s Manual for the correct procedure.

-

Lower the hood and latch it.

-

Lower the rear of the machine.

-

Slowly drive the machine forward and reverse to purge the air out of the traction system.

-

Check the fitting connections and hoses for any leaks.

-

Check the hydraulic fluid level; refer to the Operator’s Manual for the correct procedure.