Maintenance

Warning

Failure to properly maintain the machine could result in premature failure of machine systems, causing possible harm to you or bystanders.

Keep the machine well maintained and in good working order as indicated in these instructions.

Note: Determine the left and right sides of the machine from the normal operating position.

Maintenance Safety

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Disengage the cutting unit(s).

-

Ensure that the traction is in neutral.

-

Engage the parking brake.

-

Shut off the machine and remove the key (if equipped).

-

Wait for all movement to stop.

-

-

Allow machine components to cool before performing maintenance.

-

If possible, do not perform maintenance while the machine is running. Keep away from moving parts.

-

If the machine must be on to perform a maintenance adjustment, keep your hands, feet, clothing, and any parts of the body away from the cutting unit, attachments, and any moving parts. Keep bystanders away.

-

Clean grass and debris from the cutting unit, drive, motor, and battery to help prevent fires.

-

Keep all parts in good working condition. Replace all worn, damaged, or missing parts and decals. Keep all hardware tight to ensure that the machine is in safe working condition.

-

Check the grass catcher components frequently and replace them when necessary.

-

To ensure safe, optimal performance of the machine, use only genuine Toro replacement parts. Replacement parts made by other manufacturers could be dangerous, and such use could void the product warranty.

-

If major repairs are ever needed or if assistance is desired, contact an authorized Toro distributor.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

Pre-Maintenance Procedures

Preparing the Machine for Maintenance

Warning

While you are maintaining or adjusting the machine, someone could start the machine. Accidentally starting the machine could seriously injure you or other bystanders.

Release the traction bail, engage the parking brake, remove the key, and disconnect the battery before you do any maintenance.

Perform the following before servicing, cleaning, or making any adjustments to the machine:

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the machine.

-

Wait for all moving parts to stop before servicing, storing, or making repairs.

-

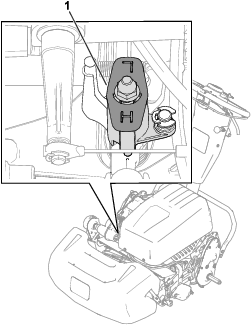

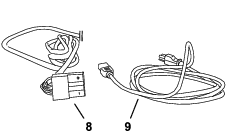

Disconnect the battery by pulling the T-handle connector off of the main-power-supply connector (Figure 25).

Electrical System Maintenance

Electrical System Safety

-

Disconnect the battery before repairing the machine.

-

Charge the battery in an open, well-ventilated area, away from sparks and flames. Unplug the charger before connecting or disconnecting the battery. Wear protective clothing and use insulated tools.

Servicing the Battery Pack

The only user serviceable parts in the battery pack are the labels. If you attempt to open the main compartment of the battery pack or the master controller you will void your warranty. If you are having problems with your battery pack, contact your authorized Toro distributor for help.

Warning

The battery pack contains high voltage which could burn or electrocute you.

-

Do not attempt to open the battery pack.

-

Do not place anything in the connector of the battery pack other than the wire harness connector that came with the product.

-

Use extreme care when handling a battery pack with a cracked case.

-

Only use the charger designed for the battery pack

Disposing of the Battery

The lithium-ion battery must be disposed of or recycled in accordance with local and federal regulations.

Maintaining the Battery Charger

Important: All electrical repairs should be performed by an authorized Toro distributor only.

The operator can perform very little maintenance other than protecting the charger from damage and weather.

Maintaining the Battery-Charger Cords

-

Clean the cords with a slightly damp cloth after each use.

-

Coil the cords when not in use.

-

Periodically examine the cords for damage, and replace them when necessary with Toro-approved parts.

Cleaning the Battery-Charger Case

Clean the case with a slightly damp cloth after each use.

Replacing Fuses

If the machine does not turn on, even after charging, check the machine fuses as follows:

-

Turn off the machine and disconnect the battery pack.

-

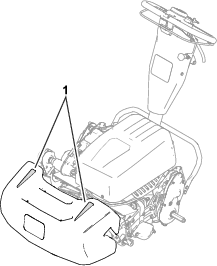

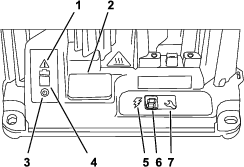

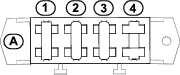

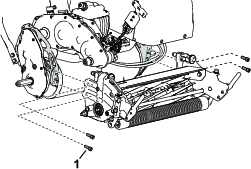

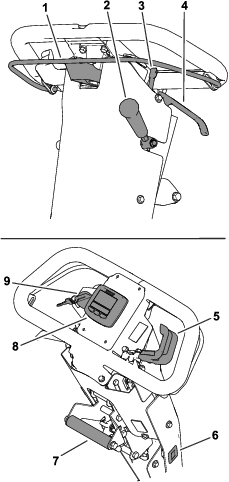

Remove the 4 screws (Figure 26) that secure the battery-pack cover and remove the cover.

-

Check the fuses in the fuse block (Figure 27).

-

If any fuse is blown, replace them with a fuse of the appropriate voltage and amperage (Figure 27). Refer to the traction unit Service Manual for specific fuse part numbers.

Important: All fuses on the machine are rated for 80 V. Do not use 12 V automotive fuses.

Drive System Maintenance

Changing the Transmission Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|

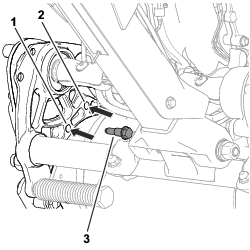

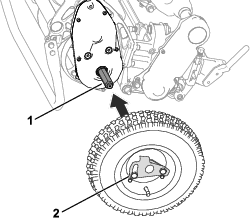

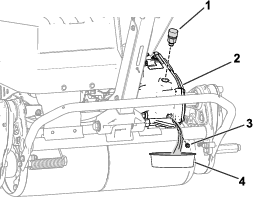

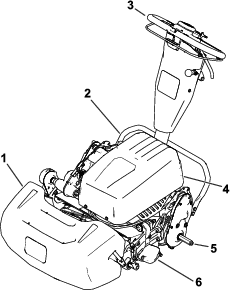

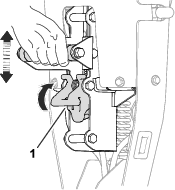

Note: Refer to Figure 28 for this procedure.

-

Remove the breather vent and adapter assembly from the transmission.

-

Have an assistant tip the machine backwards and place a pan under the transmission.

Note: Use the pan to collect the transmission fluid.

-

Remove the drain plug from the transmission and let the fluid drain out.

-

Install the drain plug.

-

Torque the drain plug to 4 to 5 N∙m (32 to 42 in-lb).

-

Add 473 ml (16 fl oz) of Dexron VI synthetic transmission fluid through the adapter vent.

-

Install the breather vent and adapter assembly and tighten it to 12 to 15 N∙m (110 to 130 in-lb).

Controls System Maintenance

Adjusting the Service/Parking Brake

Adjust the service/parking brake if it slips during operation.

-

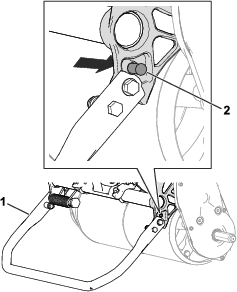

Disengage the parking brake.

-

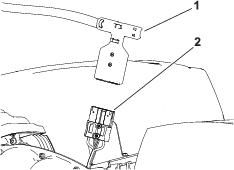

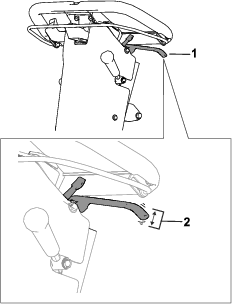

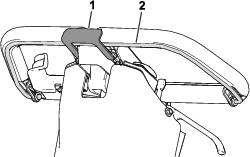

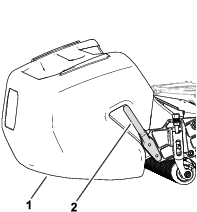

Measure the free play at the end of the parking-brake handle (Figure 29).

The handle free play should be between 12.7 to 25.4 mm (0.50 to 1 inch). If the free play is not within this amount, proceed to step 3 to adjust the brake cable.

-

Perform the following steps to adjust the brake-cable tension:

-

To increase the cable tension, loosen the front-cable jam nut and tighten the rear jam nut (Figure 30). Repeat step 2 and adjust the tension if necessary.

-

To decrease the cable tension, loosen the rear jam nut and tighten the front-cable jam nut (Figure 30). Repeat step 2 and adjust the tension if necessary.

-

Cutting Unit Maintenance

Blade Safety

-

Use care when checking the reel cutting-unit. Wear gloves and use caution when servicing the reel.

-

A worn or damaged blade or bedknife can break, and a piece could be thrown toward you or bystanders, resulting in serious personal injury or death.

-

Inspect the blades and bedknives periodically for excessive wear or damage.

-

Use care when checking the blades. Wear gloves and use caution when servicing them. Only replace or backlap the blades and bedknives; never straighten or weld them.

-

When servicing the blades, be aware that you can still move the blades after you disconnect the power.

Installing the Cutting Unit

-

Move the kickstand to the CUTTING-UNIT-SERVICE position; refer to Kickstand.

-

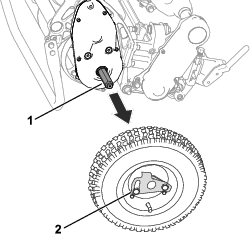

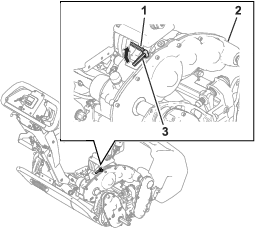

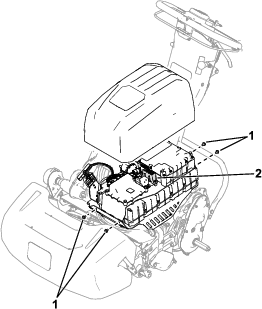

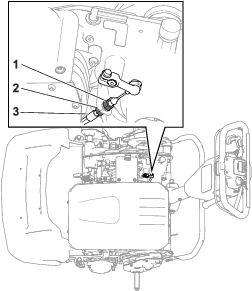

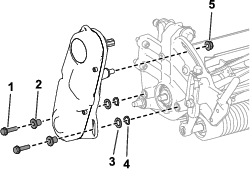

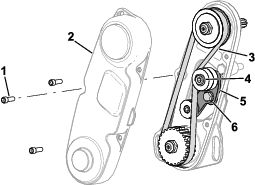

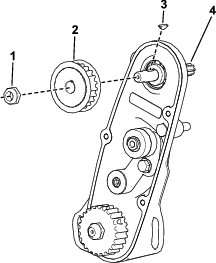

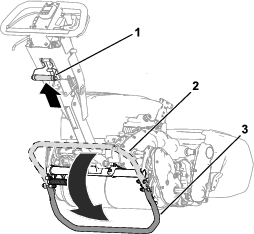

Remove the hardware that secures the reel-drive assembly to the side plate (Figure 31).

-

Remove the reel-drive assembly, flat washers, spring washers, and spacers from the side plate (Figure 31).

-

Align the cutting unit to the frame.

-

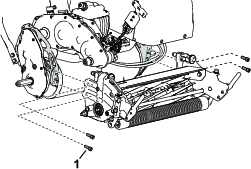

Use 4 socket-head screws to secure the cutting unit to the frame (Figure 32).

-

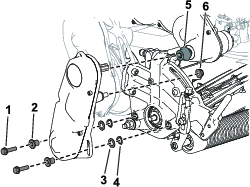

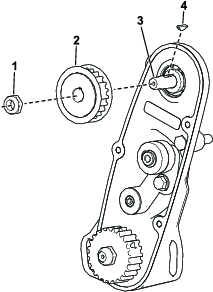

Use the previously removed socket-head screws, washers, and spacers to secure the reel-drive assembly to the cutting-unit side plate (Figure 33).

Ensure that the reel-drive-assembly driveshaft is installed to the transmission-driveshaft coupler (Figure 33).

Removing the Cutting Unit

-

Move the kickstand to the CUTTING-UNIT-SERVICE position; refer to Kickstand.

-

Remove the grass basket (if equipped).

-

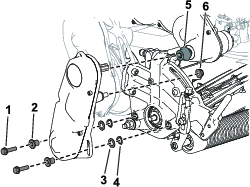

Remove the reel-drive assembly from the cutting unit (Figure 34) and retain the hardware.

-

Remove the socket-head screws that secure the cutting unit to the frame (Figure 35).

-

Remove the cutting unit from the frame.

Backlapping the Cutting Unit

To backlap the cutting unit, perform 1 of the following options:

-

Install the Access Backlap Kit (Model 139-4342) and use a backlapping machine. Contact your authorized Toro distributor to acquire this kit.

-

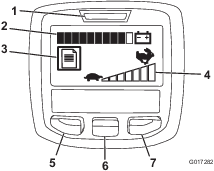

Use the InfoCenter to enter Backlap Mode.

To enter Backlap Mode, select BACKLAP from the SERVICE menu. Follow the InfoCenter prompts to backlap the cutting unit.

Note: Once the bail is released, Backlap Mode is disengaged. You can use the bail-catch fork (shipped in the loose-parts bag) to secure the bail in the engaged position.Remove the bail-catch fork after your backlapping is completed.

Cleaning

Cleaning the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

After each use, wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water, especially near the shift-lever plate, the InfoCenter, the power center, and the machine power connector. Clean the motor to provide proper cooling during operation. Also, keep the battery pack as clean as possible so that it maintains a white color. This reflects sunlight and keeps the battery from overheating in the sun.

Important: Do not use brackish or reclaimed water to clean the machine.

Important: Always store or park the machine out of direct sunlight, as heating from the sun reduces the battery-pack life span.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

)

)