This product complies with all relevant European directives. For details, please see the Declaration of Incorporation (DOI) at the back of this publication.

Note: This kit, when installed to Reelmaster 5010 series Traction Units, is covered by Patent # 7,017,703.

Warning

Bodily injury could occur if the traction unit rolls over.

When operating machine, always use the seat belt and ROPS together.

Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Press the enable/disable switch to the DISENGAGE position.

-

Move the lower mow/raise control to the MOW position.

-

Shut off the engine, and remove the key.

-

Wait for all parts to stop moving.

-

Allow the engine to cool.

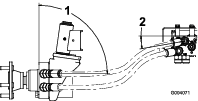

Mounting the Wheel Motor Assemblies

Parts needed for this procedure:

| Right wheel motor | 1 |

| Left wheel motor | 1 |

| Hydraulic fitting, 45° | 4 |

| Bolt (1/2 x 2-1/4 inch) | 8 |

| Lockwasher (1/2 inch) | 8 |

-

Jack up the rear of the machine and support it with jack stands.

-

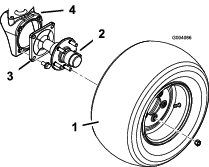

Remove the 5 lug nuts securing each rear tire to the wheel spindle hub (Figure 1). Remove the tires.

-

Remove the 4 flange bolts securing each wheel spindle to each wheel housing (Figure 1). Remove the wheel spindles. The wheel hub does not need to be removed from the spindle.

-

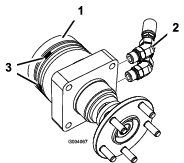

Install two 45° hydraulic fittings into each wheel motor assembly (Figure 2). Position the fittings so they point straight to the rear.

Note: Make sure the O-rings are lubricated and in position on all of the fittings before installation.

-

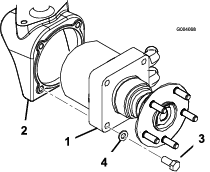

Identify the left and right wheel motors. The wheel motor for the right side of the machine is identified with grooves in the outer surface of the motor housing. For further verification, the left motor can be identified by a small yellow sticker or paint mark on the motor housing.

-

Mount the respective wheel motor assembly to each wheel housing with 4 bolts (1/2 x 2-1/4 inch) and lock washers (1/2 inch) (Figure 3). Torque the bolts to 95 to 108 N⋅m (70 to 80 ft-lb).

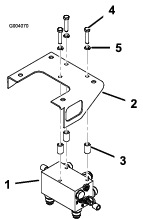

Installing the Manifold

Parts needed for this procedure:

| Manifold | 1 |

| Hydraulic fitting, straight | 7 |

| Diagnostic fitting | 2 |

| Dust cap | 2 |

| Bolt (3/8 x 1-3/4 inches) | 3 |

| Lockwasher (3/8 inch) | 3 |

| Spacer | 3 |

-

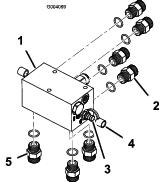

Install 4 straight hydraulic fittings into the rear of the manifold (Figure 4).

-

Install 2 diagnostic fittings into either side of the manifold along with dust caps (Figure 4).

-

Install 3 straight hydraulic fittings into the bottom of the manifold (Figure 4).

-

Mount the manifold assembly to the underside of the manifold bracket with 3 bolts (3/8 x 1-3/4 inches), lock washers (3/8 inch) and spacers. Position the spacers between the manifold bracket and the top of the manifold. The manifold is to be positioned so the fittings point to the rear, and down (Figure 5).

Note: Make sure the O-rings are lubricated and in position on all of the fittings before installation.

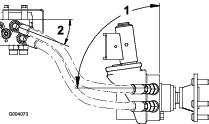

Installing the Wheel Motor Hoses

Parts needed for this procedure:

| Hydraulic hose | 4 |

-

Loosely thread the 45° fitting end of each hydraulic hose onto the straight fittings at the rear of the manifold (Figure 6).

-

Route the 2 left hoses to the left wheel motor. Connect the upper manifold hose to the upper wheel motor fitting and the lower manifold hose to the lower wheel motor fitting (Figure 7). If the hoses are not properly routed they may come in contact with the tires or rear bumper which will cause damage to the hoses.

Important: Do not cross the hydraulic hoses as they are routed from the manifold to the wheel motors.

-

Repeat the procedure for the right wheel motor. Position the hoses as shown in Figure 8 and tighten all the hose fittings.

-

Reinstall the rear tires and torque the lug nuts to 115 to 135 N⋅m (85 to 100 ft-lb).

Important: Check the hose routing to ensure there is proper clearance when the axle is oscillated and when the steering wheel is operated in a full right and left lock turn. The minimum tire to axle clearance should be 1/2 inch (13 mm).

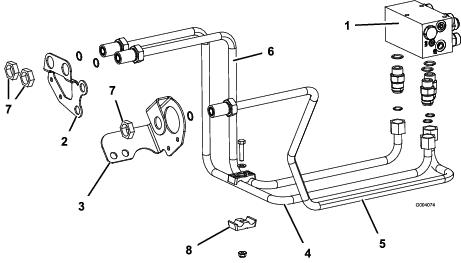

Install the Manifold Tubes

Parts needed for this procedure:

| Hydraulic tube, Part No. 108-7624 | 1 |

| Hydraulic tube, Part No. 108-7625 | 1 |

| Hydraulic tube, Part No. 108-7626 | 1 |

| Bulkhead lock nut | 3 |

| Tube clamp halves | 2 |

| Cap screw (5/16 x 1-1/2 inches) | 1 |

| Flat washer (.344 x .688) | 1 |

| Lock nut (5/16 inch) | 1 |

-

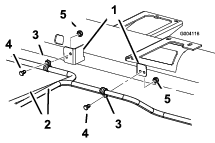

Route the hydraulic tube, Part No. 108-7624, from the left manifold fitting labeled “RF” to the right hole in the right frame bulkhead bracket (Figure 9).

-

Secure the rear of the hydraulic tube to the manifold fitting and the front to the bulkhead with a bulkhead locknut (Figure 9).

-

Route hydraulic tube, Part No. 108-7626, from the center manifold fitting labeled “REV” to the hole in the left frame bulkhead bracket (Figure 9).

-

Secure the rear of the hydraulic tube to the manifold fitting and the front to the bulkhead bracket with a bulkhead locknut.

-

Route hydraulic tube, Part No. 108-7625, from the right manifold fitting labeled “LF” to the left hole in the right frame bulkhead bracket (Figure 9).

-

Secure the rear of the hydraulic tube to the manifold fitting and the front to the bulkhead with a bulkhead locknut.

-

Secure the 2 right bulkhead lines together with the tube clamp halves, cap screw (5/16 x 1-1/2 inches), flat washer (.344 x .688) and a locknut (5/16 inch) (Figure 9).

Remove the Front Tube and the Hydraulic Hose

-

Raise the front of the unit and support it on jack stands.

-

Remove the lug nuts securing the wheel assemblies and remove the wheels.

-

Remove the cap screws and nuts securing the wheel shields to the front axle flanges (Figure 10).

-

Disconnect the hydraulic tube from the top fitting on the front left wheel motor and the bottom fitting on the front right wheel motor (Figure 10).

-

Remove the R-clamps securing the tube to the frame (Figure 10) and the cable ties securing the brake cables to the hydraulic tubes.

-

Disconnect the left hose from the variable pump and the hydraulic tube (Figure 10). Also, remove the 45° fitting from the bottom of the variable pump (Figure 10).

Note: The right hose can also be removed to improve clearance for the removal and installation of the front tube. This is not necessary but can aid in the installation of this kit.

Install the Front Tubes and the Hydraulic Hose

Parts needed for this procedure:

| Hydraulic tube, Part No. 108-7622 | 1 |

| Hydraulic tube, Part No. 108-7623 | 1 |

| Hydraulic fitting, 90° | 1 |

| Hydraulic hose | 1 |

| Cable tie | 3 |

-

Connect hydraulic tube, Part No. 108-7622, to the right wheel motor fitting and to the right hydraulic tube in the right frame bulkhead (Figure 11).

-

Connect hydraulic tube, Part No. 108-7623, to the left wheel motor fitting and to the left hydraulic tube in the right frame bulkhead (Figure 11).

-

Install a 90° hydraulic fitting into the bottom of the variable pump (Figure 11).

-

Connect the hydraulic hose to the left pump fitting and to the hydraulic tube at left frame bulkhead. If the right hose was removed, connect it at this time.

-

Secure the hydraulic hose to the bottom of the battery tray with a cable tie (Figure 11).

-

Install the wheel shields to the front axle flanges with the cap screws and nuts previously removed (Figure 10).

-

Install the cable ties to secure the brake cables to the hydraulic tubes.

Check the Hydraulic Hoses and Tubes

Check the hydraulic tubes and hoses for leaks, loose fittings, kinked lines, and loose mounting supports. Make necessary repairs before operating.

Note: Keep areas around the hydraulic system clean from grass and debris build up.

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid accidentally injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

-

Keep body and hands away from pin hole leaks or nozzles that eject high pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks.

-

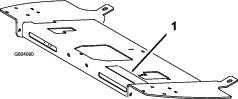

Install the R-clamps removed previously using 2 screws and lock nuts to secure the hydraulic tubes to the machine frame shown in Figure 12.

-

Install the front tires using the fasteners removed previously. Torque the lug nuts to 115 to 135 N⋅m (85 to 100 ft-lb).

-

Remove the machine from the jack stands and lower the unit to the floor.

-

Check the hydraulic oil level. If necessary, add fluid to the bring the level to the full mark on the dipstick. Refer to the Operator's Manual for more information.

-

Operate the machine to test for leaks. Shut down the machine as specified in the Operator's Manual and check for leaks in the hydraulic system.

-

Check the hydraulic oil level one more time. If necessary, add fluid to the bring the level to the full mark on the dipstick. Refer to the Operator's Manual for more information.

Install the Decals

Parts needed for this procedure:

| Decal | 2 |

| Decal 110–8869, danger | 1 |

| Decal 110–8973, CE danger (Europe only) | 1 |

-

Install each decal at locations below as follows:

-

Thoroughly clean the area where you will install the decal.

-

Dampen the area with water or mildly soapy water.

-

Peel the decal from the backing and install it in place.

-

Squeegee across the surface of the decal, starting at the center of the decal and working toward the edges, using overlapping strokes.

-

-

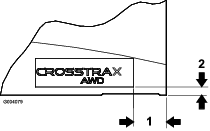

Using the dimensions shown in Figure 13, locate and affix a CROSSTRAX decal to the lower rear corner of each side of the hood.

-

Affix the appropriate danger decal over the existing decal on the operator platform (Figure 14):

-

For domestic units apply decal 110-8869.

-

For CE (European) units apply decal 110-89673.

-