This product complies with all relevant European directives. For details, please see the Declaration of Incorporation (DOI) at the back of this publication.

This spiker is designed for cutting turf on greens and small fairways of golf courses. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

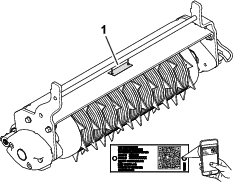

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Safety

General Safety

This product is capable of amputating hands and feet. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and working on the machine.

-

Keep clear of any discharge opening. Keep bystanders and pets away from the machine.

-

Keep children out of the operating area. Never allow children to operate the machine.

-

Park the machine on a level surface, lower the cutting units, disengage the drives, engage the parking brake (if provided), shut off the engine, and remove the key before leaving the operator's position for any reason.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

Spiker Safety

-

The spiker is only a part of a complete machine when installed on a traction unit. Read the traction unit Operator’s Manual carefully for complete instructions on the safe use of the machine.

-

Stop the machine, remove the key, and wait for all moving parts to stop before inspecting the attachment after striking an object or if there is an abnormal vibration in the machine. Make all necessary repairs before resuming operation.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

Use only accessories, attachments, and replacement parts approved by Toro.

Blade Safety

A worn or damaged spiker blade can break, and a piece of it could be thrown toward you or bystanders, resulting in serious personal injury or death.

-

Inspect the spiker periodically for wear or damage.

-

Use care and wear gloves when checking or servicing the spiker.

-

On machines with multiple cutting units, take care as rotating 1 spiker can cause other spikers to rotate.

Installing the Spiker Units

-

Position the spiker unit under the traction-unit suspension arm.

-

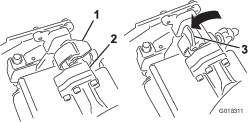

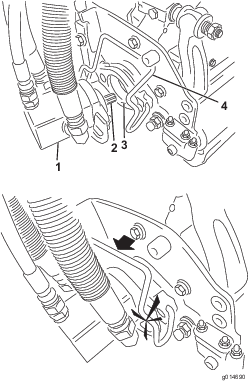

With the latches on the suspension-arm bar opened (Figure 3), push the suspension arm down so that it fits over the bar across the top of the spiker unit (Figure 4).

-

Close the latches to lock the spiker unit in place (Figure 3)

Note: When the latches are properly locked, you can hear and feel a click.

-

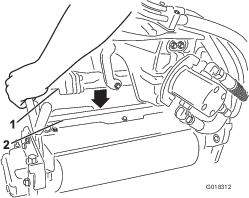

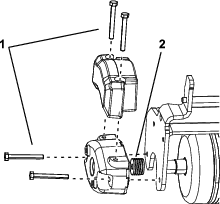

Insert the motor into the left side of the spiker unit (as viewed from the operator’s position), and pull the motor retaining bar on the spiker unit toward the motor until you hear a click from both sides of the motor (Figure 5).

Installing the Electrical Counterweights

Parts needed for this procedure:

| Counterweight (not included) | 3 |

| Bolts (not included) | 6 |

| Washer (not included) | 24 |

Note: If you are installing the spiker on traction unit Model 04540, or on an eTriFlex traction unit Model 04580 or 04590, add an additional counterweight (Part No. 117-6774-03).

-

Remove and discard the existing counterweight bolts from the spiker side plate.

-

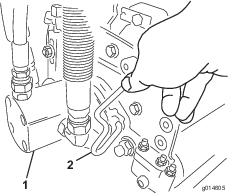

Install 2 bolts (5/16-18 x 2-3/4 inch) as shown in Figure 6.

Note: The bolts (Part No. 322-33) are not included with the spiker.

-

Install 4 washers (1/8 inch) per bolt between the counterweight and the spiker side plate (Figure 6).

Note: The washers (Part No. 63-8410) are not included with the spiker.

-

Install the auxiliary weight (Part No. 117-6774-03) with bolts.

Note: You can use the auxiliary weight and bolts provided with the traction unit, or order additional weights (Part No. 117-6774-03) and bolts (Part No. 322-33).

Operation

Training

Before spiking greens, find a clear area to practice starting, stopping, raising, lowering, and rolling with the spiker. This training helps you gain experience and confidence with the spiker before using it on a green.

Operating Tips

-

Survey the green to determine if there are any obstacles that will be damaged or will damage the spikers, such as sprinkler heads or other protruding objects.

-

Maintain a straight line when spiking. Do not turn the machine when the spikers are fully lowered and contacting the ground.

-

When you reach the edge of the green, raise the spikers before turning or stopping the machine. You must raise the spikers completely before making turns.

Maintenance

Preparing for Maintenance

Before starting on any maintenance procedure, do the following:

-

Park the machine on a level surface.

-

Lower the spiker units fully to the ground so that the suspension hydraulics are fully extended.

-

Engage the parking brake, shut off the engine, and remove the key.

Lubrication

Service interval: Every 15 hours.

Lubricate the 2 grease fittings (Figure 7) on each spiker unit after every 15 hours of operation using a No. 2 lithium grease. For best results, use a hand-operated grease gun.

-

Prepare for maintenance; refer to Preparing for Maintenance

-

Wipe each grease fitting (Figure 7) with a clean rag.

-

Apply grease to the spiker shaft bearings until you feel pressure.

-

Wipe excess grease away.

Removing the Spiker Units

-

Prepare for maintenance; refer to Preparing for Maintenance

-

Push the motor retaining bar out of the slots on the motor toward the spiker unit and remove the motor from the spiker unit.

-

Move the motor to the storage location on the front of the suspension arm.

Important: Do not raise the suspension to the transport position when the reel motors are in the machine-frame holders. Damage to the motors or hoses could result.If you must move the traction unit without the spiker units installed, use cable ties to secure the motors to the suspension arms.

-

Open the latches on the suspension-arm bar of the spiker unit that you are removing.

-

Disconnect the latches from the spiker unit bar.

-

Roll the spiker unit out from under the suspension arm.

-

Repeat steps 2 through 6 for the other spiker units as required.

Servicing the Roller

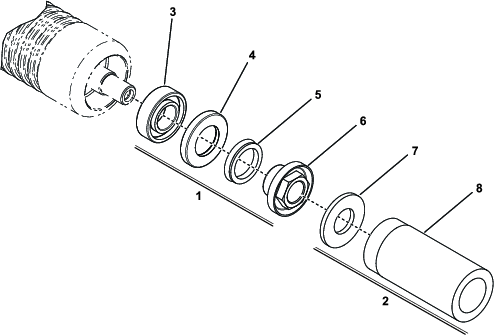

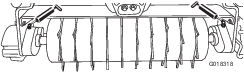

The Greens Roller Rebuild Kit (Part No. 140-5552) and the Greens Roller Rebuild Tool Kit (Part No. 140-5553) (Figure 9) are available for servicing the roller. The Roller Rebuild Kit includes all the bearings, bearing nuts, and seals to rebuild a roller.

The Roller Rebuild Tool Kit includes all the tools and the installation instructions required to rebuild a roller with the roller rebuild kit. Refer to your parts catalog or contact your authorized Toro distributor for assistance.