Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Before each use or daily |

|

| Every 1,000 hours |

|

| Before storage |

|

Caution

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the switch before you perform any maintenance.

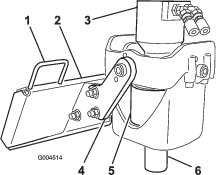

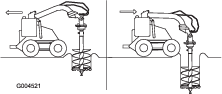

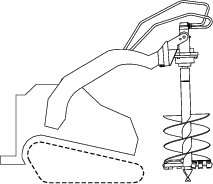

Greasing the Cradle Arm Pivot Points

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Grease Type: General-purpose grease

-

Park the machine on a level surface, engage the parking brake (if applicable), and lower the loader arms.

-

Shut off the engine and remove the key.

-

Clean the grease fittings with a rag.

-

Connect a grease gun to each fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

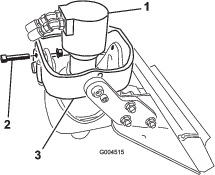

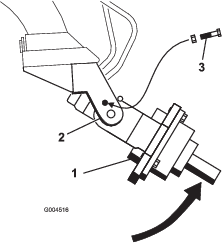

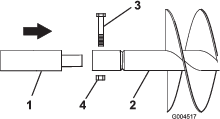

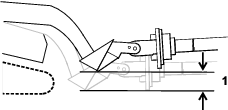

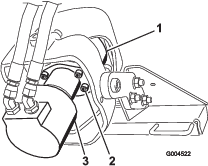

Changing the Planetary Gear Case Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 1,000 hours |

|

Type: Mild, extreme pressure lubricant, rated API-GL-5, number 80 or 90

Capacity: 0.4 L (13.6 fl oz)

-

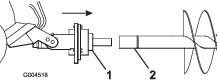

Support the drive head over an oil pan (Figure 13).

-

Remove the 4 bolts securing the motor and remove the motor, allowing all the oil to drain into the pan.

-

When the oil is completely drained, turn the drive head so that the opening is facing the up.

-

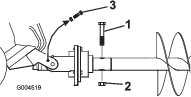

Add oil to the gearcase.

-

Replace the motor and secure it with the four bolts removed previously. Torque the bolts to 142 N∙m (105 ft-lb).

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.