Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| After the first 10 hours |

|

| After the first 50 hours |

|

| Before each use or daily |

|

| After each use |

|

| Every 50 hours |

|

| Every 150 hours |

|

| Every 400 hours |

|

Lubrication

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

The machine has grease fittings that must be lubricated regularly with No. 2 lithium grease.

Lubricate the following areas:

Servicing the Mower Deck Gearbox Lubricant

The gearbox is designed to operate with SAE 80W-90 gear lube. Although the gearbox is shipped with lubricant from the factory, check the level before operating the cutting unit for the first time.

Checking the Mower Deck Gearbox Lubricant

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 150 hours |

|

-

Park the machine on a level surface.

-

Lower the mower deck to the 2.5 cm (1 inch) height of cut.

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Lift the footrest, exposing the top of the mower deck.

-

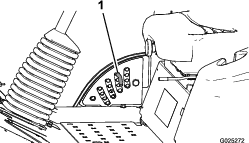

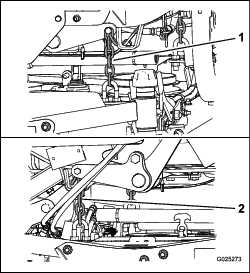

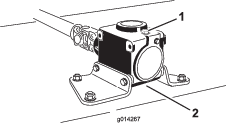

Remove the dipstick/fill plug from the top of the gearbox (Figure 24) and make sure that the lubricant is between the marks on the dipstick.

-

If the lubricant level is low, add enough lubricant until the level is between the marks on the dipstick.

Important: Do not overfill the gearbox and operate the mower deck; otherwise, you may damage the gearbox.

Changing the Mower Deck Gearbox Lubricant

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 400 hours |

|

-

Park the machine and cutting unit on a level surface.

-

Lower the mower deck to the 2.5 cm (1 inch) height of cut.

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Lift the footrest to expose the top of the mower deck.

-

Remove the dipstick/fill plug from the top of the gearbox (Figure 24).

-

Place a drain pan under the drain plug located under the front of the gearbox and remove the plug, draining the lubricant into the pan.

-

Replace the drain plug.

-

Add enough lubricant, approximately 414 ml (14 fl oz), until the level is between the marks on the dipstick.

Important: Do not overfill the gearbox and operate the mower deck; otherwise, you may damage the gearbox.

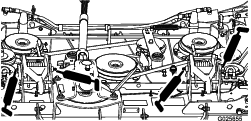

Servicing the Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

The belts, tensioned by the spring loaded idler pulley, are very durable. However, after many hours of use, a belt will show signs of wear. Signs of a worn belt are squealing when belt is rotating, blades slipping when cutting grass, frayed edges, burn marks, and cracks. Replace the belt if any of these conditions occur.

-

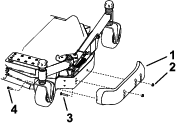

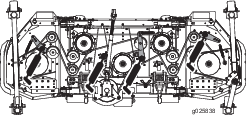

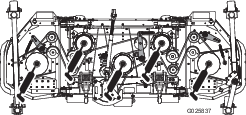

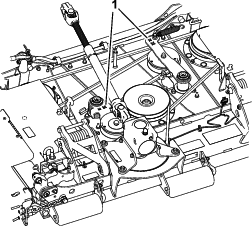

Lower the cutting unit to the shop floor. Remove the belt covers from the top of the cutting unit and set the covers aside.

-

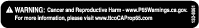

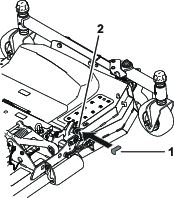

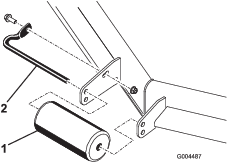

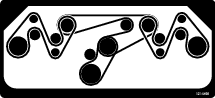

Using a socket wrench in the idler-arm holes, move the idler pulley away from the drive belt to release the belt tension and allow the belt to be slipped off pulley (Figure 25).

-

Remove the old belt from around the pulleys and idler pulley.

-

Route the new belt around the pulleys and idler pulley assembly as shown in Figure 26.

-

Install the belt covers.

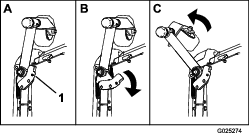

Servicing the Bushings in the Caster Arms

The caster arms have bushings pressed into the top and bottom of the tube and after many hours of operation, the bushings wear. To check the bushings, move the caster fork back and forth and from side to side. If the caster spindle is loose inside the bushings, the bushings are worn; replace them.

-

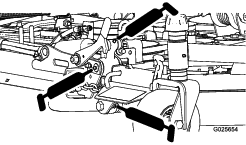

Raise the cutting unit so that the wheels are off the floor. Block the cutting unit so that it cannot accidentally fall.

-

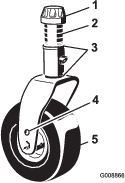

Remove the tensioning cap, spacer(s), and thrust washer from the top of the caster spindle.

-

Pull the caster spindle out of the mounting tube. Allow the thrust washer and spacer(s) to remain on the bottom of the spindle.

-

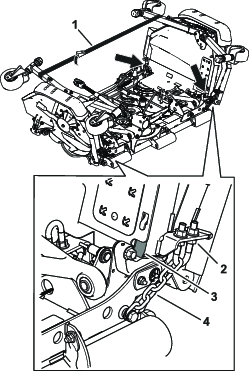

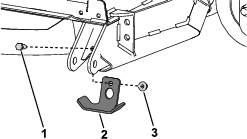

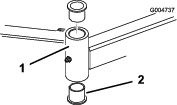

Insert a pin punch into the top or bottom of the mounting tube and drive the bushing out of the tube (Figure 27).

-

Drive the other bushing out of the tube.

-

Clean the inside of the tubes to remove any dirt.

-

Apply grease to the inside and outside of the new bushings.

-

Using a hammer and a flat plate, drive the bushings into the mounting tube.

-

Inspect the caster spindle for wear and replace it if it is damaged.

-

Push the caster spindle through the bushings and the mounting tube.

-

Slide the thrust washer and the spacer(s) onto the spindle.

-

Install the tensioning cap on the caster spindle to retain all parts in place.

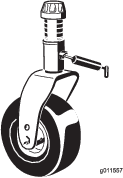

Servicing the Caster Wheels and Bearings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| After the first 10 hours |

|

| Every 50 hours |

|

-

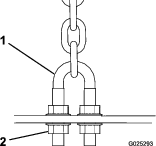

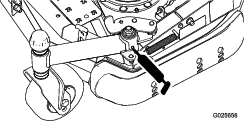

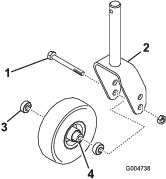

Remove the locknut from the bolt holding the caster wheel assembly between the caster fork (Figure 28).

-

Grasp the caster wheel and slide the bolt out of the fork or pivot arm.

-

Remove the bearing from the wheel hub and allow the bearing spacer to fall out (Figure 28).

-

Remove the bearing from the opposite side of the wheel hub.

-

Check the bearings, spacer, and inside of the wheel hub for wear. Replace any damaged parts.

-

To assemble the caster wheel, push the bearing into the wheel hub.

Note: When installing the bearings, press on the outer race of the bearing.

-

Slide the bearing spacer into the wheel hub. Push the other bearing into the open end of the wheel hub to captivate the bearing spacer inside the wheel hub.

-

Install the caster wheel assembly between the caster fork and secure it in place with the bolt and locknut.

Servicing the Cutting Blades

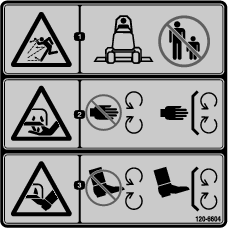

Blade Safety

A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, resulting in serious personal injury or death.

-

Inspect the blade periodically for wear or damage.

-

Use care when checking the blades. Wrap the blades or wear gloves, and use caution when servicing the blades. Only replace or sharpen the blades; never straighten or weld them.

-

On multi-bladed machines, take care as rotating 1 blade can cause other blades to rotate.

Before Inspecting or Servicing the Blades

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

Checking for Bent Blades

-

Disengage the PTO, release the traction pedal and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

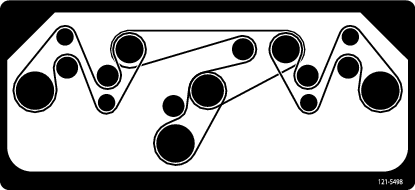

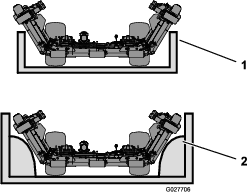

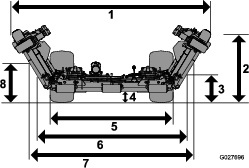

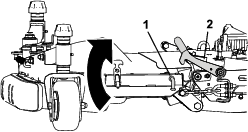

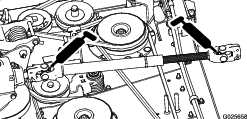

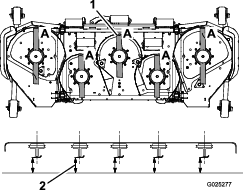

Rotate the blades until the ends face forward and backward (Figure 29).

-

Measure from a level surface to the cutting edge, position A, of the blades (Figure 29). Note this dimension.

-

Rotate the opposite ends of the blades forward.

-

Measure from a level surface to the cutting edge of the blades at the same position as in step 3 above. The difference between the dimensions obtained in steps 3 and 4 must not exceed 3 mm (1/8 inch). If this dimension exceeds 3 mm (1/8 inch), the blade is bent and must be replaced; refer to Checking for Bent Blades and Removing and Installing the Blade(s).

Warning

A blade that is bent or damaged could break apart and could seriously injure or kill you or bystanders.

-

Always replace bent or damaged blade with a new blade.

-

Never file or create sharp notches in the edges or surfaces of blade.

-

Removing and Installing the Blade(s)

The blade must be replaced if a solid object is hit, the blade is out-of-balance, worn, or bent. Always use genuine Toro replacement blades to ensure safety and optimum performance. Never use blades made by other manufacturers because they could be dangerous.

-

Raise the cutting unit to the highest position, engage the parking brake, stop the engine, and remove the ignition key. Block the cutting unit to prevent it from accidentally falling.

-

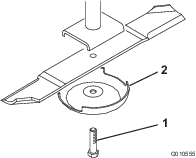

Grasp the end of the blade using a rag or thickly padded glove. Remove the blade bolt, anti-scalp cup, and blade from the spindle shaft (Figure 30).

-

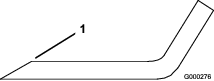

Install the blade-sail facing toward the cutting unit-with the anti-scalp cup and blade bolt. Tighten the blade bolt to 115 to 149 N∙m (85 to 110 ft-lb).

Important: The curved part of the blade must point toward the inside of the cutting unit to ensure proper cutting.

Inspecting and Sharpening the Blade(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 10 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

Danger

A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, resulting in serious personal injury or death.

-

Inspect the blade periodically for wear or damage.

-

Do not try to straighten a blade that is bent.

-

Do not weld a broken or cracked blade.

-

Replace a worn or damaged blade with a new Toro blade to ensure continued safety certification of the product.

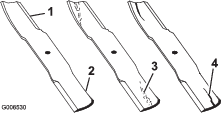

Both cutting edges and the sail, which is the turned up portion opposite the cutting edge, contribute to a good quality-of-cut. The sail is important because it pulls grass up straight, thereby producing an even cut. However, the sail will gradually wear down during operation, and this condition is normal. As the sail wears down, the quality-of-cut will degrade somewhat, although the cutting edges are sharp. The cutting edge of the blade must be sharp so that the grass is cut rather than torn. A dull cutting edge is evident when the tips of the grass appear brown and shredded. Sharpen the cutting edges to correct this condition.

-

Park the machine on a level surface. Raise the cutting unit, engage the parking brake, put the traction pedal in neutral, put the PTO lever in the OFF position, shut off the engine, and remove the key.

-

Examine the cutting ends of the blade carefully, especially where the flat and curved parts of the blade meet (Figure 31). Since sand and abrasive material can wear away the metal that connects the flat and curved parts of the blade, check the blade before using the machine. If you see wear (Figure 31), replace the blade; refer to Removing and Installing the Blade(s).

Warning

If the blade is allowed to wear, a slot will form between the sail and flat part of the blade (Figure 31). Eventually, a piece of the blade may break off and be thrown from under the housing, possibly resulting in serious injury to yourself or bystanders.

-

Inspect the blade periodically for wear or damage.

-

Replace a worn or damaged blade with a new Toro blade to ensure continued safety certification of the product.

-

-

Examine the cutting edges of all blades. Sharpen the cutting edges if they are dull or nicked. Sharpen only the top side of the cutting edge and maintain the original cutting angle to ensure sharpness (Figure 32). The blade will remain balanced if the same amount of metal is removed from both cutting edges.

Note: Remove the blades and sharpen them on a grinder; refer to Removing the Cutting Blades. After sharpening the cutting edges, install the blade with the anti-scalp cup and blade bolt. The blade sails must be on top of the blade. Tighten the blade bolt to 115 to 149 N·m (85 to 110 ft-lb).

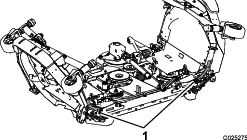

Cleaning Under the Cutting Unit

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

Remove the grass buildup under the cutting unit daily.

-

Disengage the PTO, release the traction pedal to the neutral position, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operator’s position.

-

Raise the cutting unit to the TRANSPORT position.

-

Use a jack to raise the front of the machine and support it with jack stands.

-

Thoroughly clean the underside of the cutting unit with water.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.