Maintenance

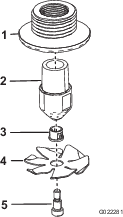

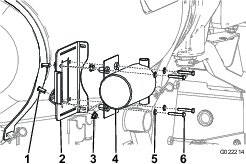

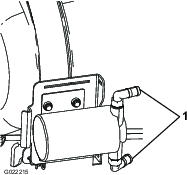

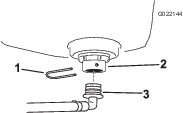

Inspecting the Rinse Pump Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 50 hours |

|

Check the filter for any signs of damage. Replace if any damage is found.

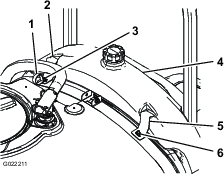

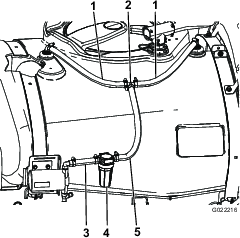

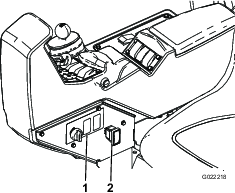

Inspecting the Rinse System for Leaks and Damage

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

After the first 5 hours of operation, inspect all hoses and connections for any leaks or signs of damage. Inspect the hose clamps and retaining forks. Verify that all connections are secure. Replace any damaged parts. Repeat this inspection before each use of the rinse system.

After 100 operating hours, inspect all hoses and O–rings. Replace any damaged parts.

Contact your Authorized Toro Dealer to obtain replacement parts.

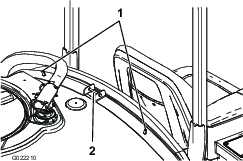

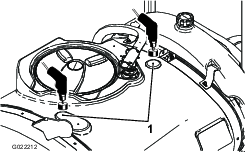

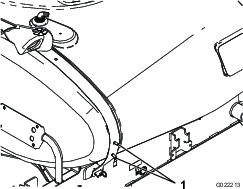

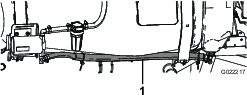

Inspecting the Rinse Tank Straps

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

Once the main tank has been filled with water, check to see if there is any play in the tank straps. If the straps are loose, tighten the fasteners at the top of the straps until they are flush with tank. Do not over tighten.

Important: Over tightening the tank strap fasteners can result in deforming and damaging of the straps.