Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 400 hours |

|

Pre-Maintenance Procedures

Preparing the Machine for Maintenance

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Disconnect the spark-plug wires.

Lubrication

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

| Every 400 hours |

|

Grease Type: No. 2 lithium or molybdenum grease

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean the grease fittings with a rag. Scrape any paint off the front of the fitting(s).

-

Connect a grease gun to the fitting. Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

Note: You will need to remove some of the machine guards to reach all the grease fittings. Replace the guards when finished.

-

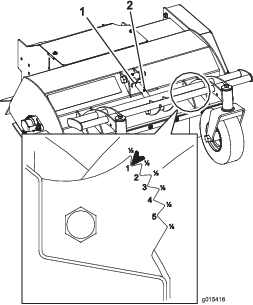

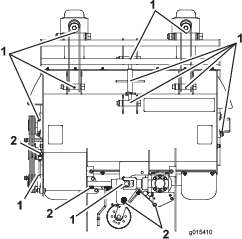

Every 400 operating hours, disassemble the points shown in Figure 5 and apply anti-seize grease.

Drive System Maintenance

Checking the Gearbox Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Fluid type: EP 220 gear lube

-

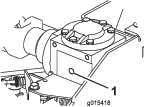

Remove the top guard (Figure 6).

-

Remove the plug from the gearbox fill hole and check the oil level (Figure 7).

The oil should be even with the bottom of the fill hole.

-

If it needs oil, add oil to the fill hole until it starts to run out of the hole.

-

Install the plug in the fill hole.

-

Install the top guard (Figure 6).

Brake Maintenance

Belt Maintenance

Replacing the Rotor Drive Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

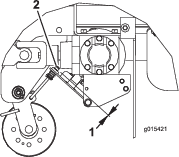

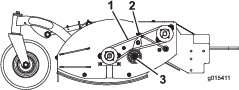

Visually inspect the belt (Figure 9) for dirt, wear, cracks, and/or signs of overheating.

If the belt is excessively worn or shows any signs of damage, replace the belt as follows:

-

Loosen the locknut and adjusting nut to remove the tension from the belt.

-

Remove the idler pulley and worn belt.

-

Install the new belt with the idler pulley.

-

Check the belt tension.

The proper mower belt tension is 2 kg (4.5 lb) of force to deflect the belt 13 mm (1/2 inch) at the midpoint of the longest span (Figure 9).

To adjust the tension, do the following:

-

Loosen the locknut (Figure 9).

-

Turn the adjusting nut to increase or decrease the tension on the belt.

-

Tighten the locknut.

-

Replacing the Gearbox Drive Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

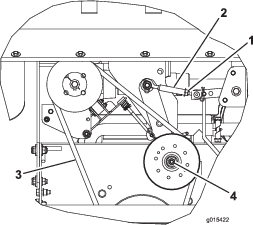

Visually inspect the belt (Figure 10) for dirt, wear, cracks, and signs of overheating. If the belt is excessively worn or shows any signs of damage, replace the belt.

Note: Figure 10 shows the belt viewed from underneath, but the belt can be checked, adjusted, or replaced from either the top or bottom after removing the relevant guard.

To replace the belt, do the following:

-

Remove the idler pulley and belt.

-

Install the new belt with the idler pulley.

-

Engage the blade-control lever (PTO) and check the belt tension.

The proper mower belt tension is 4.5 kg (10 lb) of force to deflect the belt 13 mm (1/2 inch) at the midpoint of the longest span (Figure 10).

Important: The belt must be tight enough to not slip during heavy loads while cutting grass. Over-tensioning the belt reduces the life of the gearbox, belt, and idler pulley.

To adjust the tension, do the following:

-

Loosen the locknut (Figure 10).

-

Rotate the turnbuckle.

Increase the length between the eyebolts to increase the tension to the belt or decrease the length to decrease the tension on the belt.

-

Tighten the locknut.

-

Cutting Unit Maintenance

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

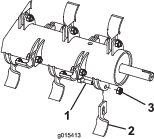

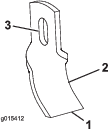

Check the blades for wear or damage, paying particular attention to the cutting edge, curved area, and installation hole (Figure 11). If the blade is excessively worn or damaged, replace the blade. To ensure a superior quality of cut, keep the blades sharp.

Replacing a Blade

Cleaning Under the Guards

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

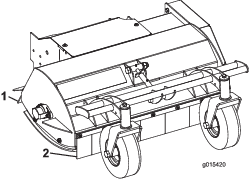

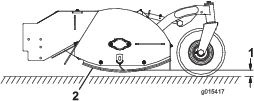

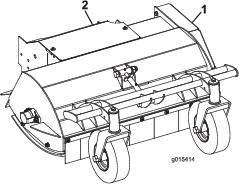

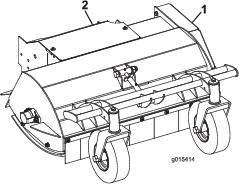

Remove the top and side guards (Figure 13) and remove any debris. Replace the guards when finished.

Checking the Rubber Discharge Guards

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Inspect the front and rear rubber guards for wear or damage (Figure 14). Replace damaged rubber guards to prevent objects being thrown into the operator’s area.