Important: For 2016 and newer machines, you must install the heavy-duty springs that are supplied with the Cab Kit in order to use the cab on a Workman MD/MDE/MDX/MDXD utility vehicle. For 2015 and older machines, discard the springs included in this kit and order 2 springs (Toro Part No. 117-4847) from your authorized Toro distributor.For Workman MDE machines, the 12 V Plug Adapter Kit (sold separately) must be installed on the machine; refer to the Installation Instructions for the kit. The springs should be installed only by qualified Toro Service Technicians using approved tools. Improper removal, disassembly, or installation of the spring assembly poses a danger to you and bystanders. Please contact your authorized Toro distributor for the appropriate tools and proper installation of this kit.

Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Raise the bed until the bed prop rod is fully engaged; refer to your Operator’s Manual.

-

Shut off the engine and remove the key.

-

Disconnect the battery; refer to the Operator’s Manual for the machine.

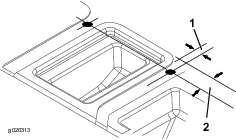

Removing the Strut Assembly (for 2016 and Newer Machines Only)

-

Raise the front of the machine off the ground and support it with jack stands.

-

Remove the front wheel.

-

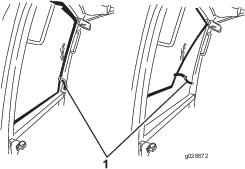

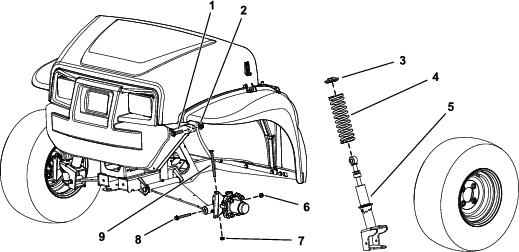

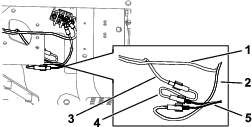

Remove the hex-head bolt (3/8 x 4-3/4 inches) and flange nut (3/8 inch) from the spindle (Figure 1).

-

Remove the hex-head bolt (3/8 x 3-1/2 inches) and flange nut (3/8 inch) from the control arm (Figure 1).

-

Remove the hex-head bolt (1/2 x 2-1/4 inches) and locknut (1/2 inch) securing the strut assembly to the upper frame (Figure 1).

-

Remove the strut assembly (Figure 1).

Note: Repeat this procedure for the other side of the machine.

Installing the Springs (for 2016 and Newer Machines Only)

Parts needed for this procedure:

| Spring | 2 |

Use an approved Toro spring-compression tool to remove and install springs of the strut assembly. Contact your authorized Toro distributor.

-

Place the strut assembly into the compression tool and use the tool to compress the spring.

-

While the spring is compressed, remove the collar.

-

Remove the spring from the strut assembly (Figure 1).

-

Install the new spring over the existing strut assembly (Figure 1).

-

Using the Toro spring-compression tool, compress the spring.

-

While the spring is compressed, install the collar.

-

Carefully release pressure on the spring, allowing it to seat on the collar.

-

Remove the strut assembly from the compression tool.

Note: Repeat this procedure for the other side of the machine.

Installing the Strut Assembly (for 2016 and Newer Machines Only)

-

Install strut assembly to the machine.

-

Secure the upper portion of the strut assembly to the frame using the upper, hex-head bolt (1/2 x 2-1/4 inches) and locknut (1/2 inch) as shown in Figure 1.

-

Torque the hex-head bolt (1/2 x 2-1/4 inches) to 91 to 113 N∙m (67 to 83 ft-lb).

-

Install the hex-head bolt (3/8 x 4-3/4 inches) and flange nut (3/8 inch) to the spindle (Figure 1).

-

Torque the hex-head bolt (3/8 x 4-3/4 inches) to 37 to 45 N∙m (27 to 33 ft-lb).

-

Secure the lower portion of the strut assembly to the control arm using the hex-head bolt (3/8 x 3-1/2 inches) and flange nut (3/8 inch) as shown in Figure 1.

-

Torque the hex-head bolt (3/8 x 3-1/2 inches) to 37 to 45 N∙m (27 to 33 ft-lb).

-

Install the front wheel.

Note: Repeat this procedure for the other side of the machine.

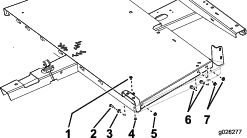

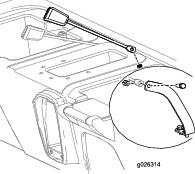

Installing the Compression Spring (for 2015 and Older Machines Only)

Parts needed for this procedure:

| Compression spring | 2 |

Use an approved Toro spring-compression tool to remove and install springs of the strut assembly. Contact your authorized Toro distributor.

Important: For 2015 and older machines, discard the springs included in this kit and order 2 springs (Toro Part No. 117-4847) from your authorized Toro distributor.

-

Raise the front of the machine off the ground and support it with jack stands.

-

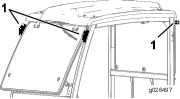

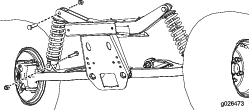

Remove the current shock assemblies as shown in Figure 2.

-

Using a spring compressor, remove the current springs and install the springs from this kit.

-

Install the shock assemblies and turn them 3 clicks up from the longest position.

Note: Refer to the Service Manual for further instructions on replacing the spring and checking the front end toe of the tires.

-

Torque the bolts to 95 to 122 N∙m (70 to 90 ft-lb).

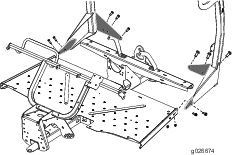

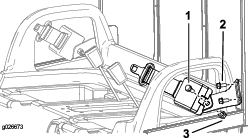

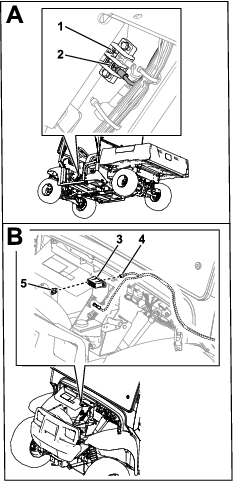

Removing the ROPS Assembly

If your machine does not have a ROPS assembly, proceed to Installing the Floor Mounts.

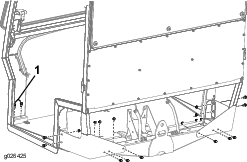

Remove the bolts and nuts that secure the ROPS assembly to the frame of the machine as shown in Figure 3 and remove the ROPS assembly.

Note: Do not remove the seat-belt anchors that are secured on the frame.

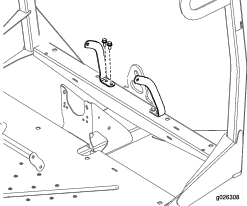

Installing the Floor Mounts

Parts needed for this procedure:

| Floor mount | 2 |

| Nut (3/8 inch) | 6 |

| Bolt (3/8 x 1 inch) | 4 |

| Bolt (5/16 inch) | 2 |

| Nut (5/16 inch) | 2 |

| Bolt (3/8 x 7/8 inch) | 2 |

| Washer | 2 |

-

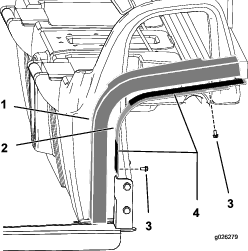

Secure the floor panels to the frame as shown in Figure 4.

-

Torque the 2 bolts (3/8 x 7/8 inch) and 4 bolts (3/8 x 1 inch) to 37 to 45 N∙-m (27 to 33 ft-lb).

-

Torque the 2 bolts (5/16 inch) to 1978 to 2543 N∙cm (175 to 225 in-lb).

Installing the Cab Frame

Parts needed for this procedure:

| Cab frame | 1 |

| Bolts (3/8 x 7/8 inch) | 4 |

| Bolt (3/8 x 3/4 inch) | 10 |

| Nuts (3/8 inch) | 10 |

Installing the Side Panels

Parts needed for this procedure:

| Side-plate panels | 2 |

| Bolts (1/4 inch) | 4 |

| Side-plate foam panel | 2 |

Installing the Seat Belts

Parts needed for this procedure:

| Seat-belt anchor | 2 |

| Bolts (3/8 x 3/4 inch) | 4 |

| Nuts (3/8 inch) | 4 |

| Seat-belt receiver end | 2 |

| Bolt (7/16 inch) | 4 |

| Nut (7/16 inch) | 4 |

| Seat-belt bracket | 2 |

| Seat belt | 2 |

| Bolt (3/8 x 7/8 inch) | 2 |

-

Mount a seat-belt bracket to each ROPS tab with 2 bolts (3/8 inch) as shown in Figure 8.

-

Torque the 4 bolts (3/8 inch) to 37 to 45 N∙m (27 to 33 ft-lb).

-

Mount the retractable end of each seat-belt assembly to each seat-belt anchor bracket with a bolt (7/16 inch) and a nut (7/16 inch) as shown in Figure 8.

Note: If your machine came equipped with a ROPS assembly, the seat-belt anchors are already installed; proceed to Routing the Wire Harness.

-

Torque the 2 bolts (7/16 inch) to 67 to 83 N∙m (49 to 61 ft-lb).

-

Secure the left and right seat-belt anchor to the front frame with 4 bolts (3/8 x 3/4 inch) and 4 nuts (3/8 inch) as shown in Figure 9.

-

Torque the 4 bolts (3/8 x 3/4 inch) to 37 to 45 N∙m (27 to 33 ft-lb).

-

Using the dimensions shown in Figure 10, locate, mark, and drill 2 holes in the top of the seat shroud.

Important: Use caution when drilling these holes; electrical components and control cables are located under the seat shroud.

-

Insert the mounting side of the receiver end of each seat-belt lock assembly into one of the newly drilled holes in the seat base (Figure 11).

-

Mount the receiver end of each seat-belt assembly to each seat-belt anchor with a bolt (7/16 inch) and nut (7/16 inch) as shown in Figure 11.

-

Torque the bolts to 67 to 83 N∙m (49 to 61 ft-lb).

Routing the Wire Harness

Parts needed for this procedure:

| Wire harness | 1 |

| Clip tie | 1 |

| Plug | 1 |

| Fuse (30 A) | 1 |

Note: For Workman MDE machines, the 12 V Plug Adapter Kit (sold separately) must be installed on the machine; refer to the Installation Instructions for the kit.

-

Route the wire harness via 1 of the 2 following options:

-

Route the wire harness under the control panel (Box A of Figure 12). Install the clip tie in the lower hole on the side panel and the plug in the top hole.

-

Drill a hole into the console, install the clip tie in the top hole on the side panel, and install the plug into the lower hole (Box B of Figure 12).

Important: Use caution when drilling this hole; electrical components and control cables are located under the seat shroud.

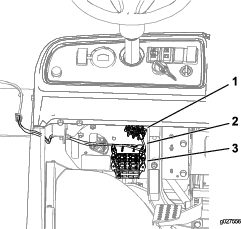

-

-

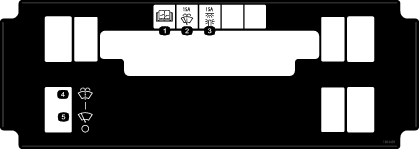

For Workman MDX/MDXD machines: Connect the ring terminal on the harness to the grounding block on the center dash support (A of Figure 14) and insert the fuse-block connector and the fuse (30 A) into an available fuse-block connection (B of Figure 14).

Note: If there is not an available fuse-block connection, you need to add a fuse block to the fuse-block grouping. Contact your Authorized Service Dealer for more information.

-

For Workman MD/MDE machines: Connect the ring terminal on the harness to the grounding block and insert the fuse-block connector and the fuse (30 A) into an available fuse-block connection (Figure 14).

Note: If there is not an available fuse-block connection, you need to add a fuse block to the fuse-block grouping. Contact your authorized Toro distributor for more information.

Workman MDE only:

-

Connect the power-adapter harness to the wire harness (Figure 15).

-

Connect the power-adapter harness and the ground-adapter harness to the wire harness from the 12 V Plug Adapter Kit.

-

-

Connect the battery and lower the bed; refer to the Operator’s Manual.

Product Overview

Control Panel

Windshield Latch

Lift up the latches to open the windshield (Figure 17). Press in the latch to lock the windshield in the open position. Pull out and down on the latch to close and secure the windshield.