Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

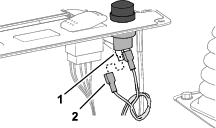

Installing the Rear Light

Parts needed for this procedure:

| Rear light | 1 |

| Bracket | 1 |

| Nut (5/16 inch) | 2 |

| Bolt (5/16-18 x 3/4 inch) | 2 |

| Stamped-steel nut | 2 |

-

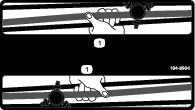

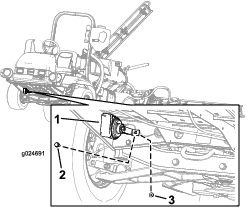

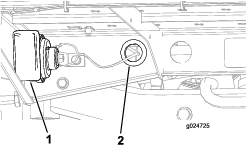

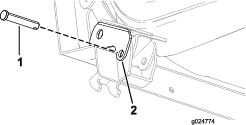

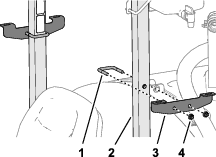

Align the holes of the rear-light bracket with the 2 holes in the boom-frame channel.

-

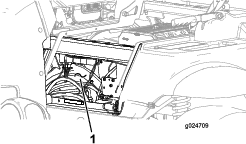

Secure the bracket to the frame with the 2 bolts (5/16 x 3/4 inch) and 2 locknuts (5/16 inch) as shown in Figure 1.

-

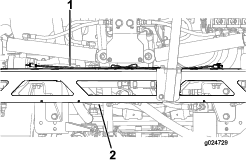

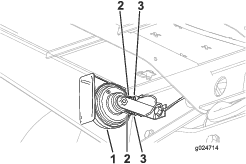

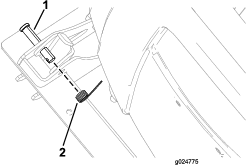

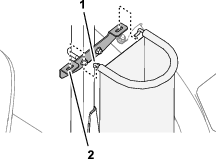

Align the rear-light assembly to the rear-light bracket and secure the assembly with the 2 stamped-steel nuts as shown in Figure 2.

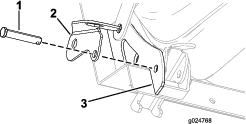

Installing the Horn

Parts needed for this procedure:

| Horn assembly | 1 |

| Hex-head screw (5/16-18 x 3/4 inch) | 1 |

| Flange nut (5/16-18) | 1 |

-

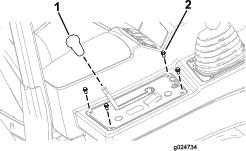

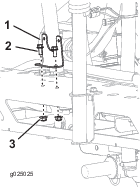

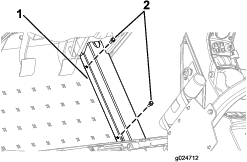

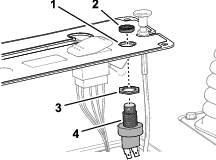

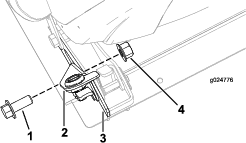

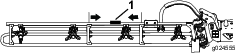

Align the horn assembly with the hole found on the front, right side of the machine (Figure 3).

-

Insert the hex-head screw (5/16-18 x 3/4 inch) through the hole of the horn assembly and the frame of the machine (Figure 3).

-

Install the horn assembly to the machine with the hex-head screw (5/16-18 x 3/4 inch) and the flange nut (5/16-18) as shown in Figure 3.

Routing the Wiring Harness

Parts needed for this procedure:

| Wire harness | 1 |

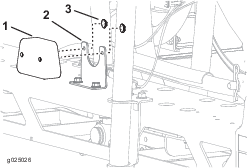

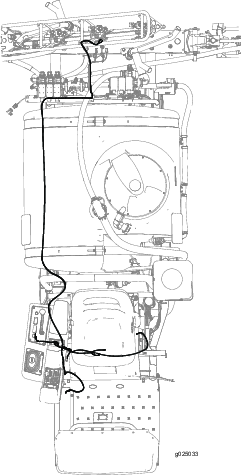

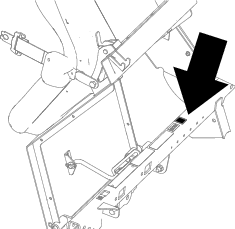

Figure 4 shows an outline of the kit wire-harness routing on the machine.

Routing the Wiring Harness to the Side Console

Routing the Wire Harness to the Horn

-

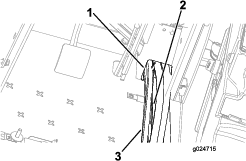

Remove the 2 bolts that secure the hose cover to the machine, and remove the cover (Figure 7 and Figure 8).

-

Route the wire harness forward and along the hoses to the horn.

-

Route the wire harness through the grommet at the hole in the rear-angle platform to the horn (Figure 9).

-

Connect the wiring-harness leg with the 2 terminals to the 2 terminals on the horn (Figure 10).

-

Install the cover removed in step 1, and secure it with the 2 bolts.

Installing the Horn Switch

Parts needed for this procedure:

| Horn switch, jam nut, and knurled nut | 1 |

| Switch button | 1 |

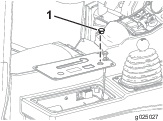

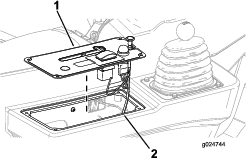

Removing the Control Panel

Assembling the Horn Switch

-

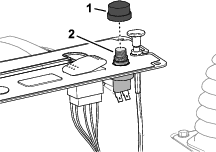

Thread the jam nut onto the body of the horn switch (Figure 16).

-

Insert the horn switch into the hole in the control-panel cover, and secure the switch with the knurled nut.

-

Thread the switch button onto the horn switch (Figure 17).

-

Connect the 2 terminals of the wire harness labeled HORN SWITCH to the terminals of the horn switch (Figure 18).

Assembling the Control Panel

-

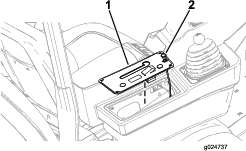

Align the control-panel cover to the side console (Figure 19).

-

Secure the control-panel cover to the side console with the 4 hex-head screws (1/4 x 1/2 inch) that you removed in Removing the Control Panel.

-

Thread the knob onto the differential-lock rod.

Installing the Seat Lock

Parts needed for this procedure:

| Lock-mount bracket | 1 |

| Latch | 1 |

| Grip | 1 |

| Hex-head screw (12 x 20 mm) | 1 |

| Locknut (12 mm) | 1 |

-

Remove the hairpin from the clevis pin (Figure 20).

-

Remove the clevis pin and spring from the latch (Figure 20).

-

Partially insert the clevis pin through the lock bracket (Figure 21).

-

Align the lock bracket and the clevis pin through the hole of the outboard-seat gusset (Figure 21).

-

Align the holes in the latch with the holes in the seat gussets (Figure 22).

-

Partially move the clevis pin inward through the hole in the seat latch (Figure 23).

-

Install the spring onto the clevis pin (Figure 24).

-

Fully insert the clevis pin through the holes in the seat latch and the inboard-seat gusset.

-

Secure the lock bracket to the outboard-seat gusset with the hex-head screw (12 x 20 mm) and the locknut (12 mm) as shown in Figure 25.

Installing the Personal Protective Equipment Storage Bags

Parts needed for this procedure:

| PPE storage bag | 2 |

| Hoop rod | 2 |

| Mount bracket | 2 |

| U-bolt | 2 |

| Flange locknut (3/8 inch) | 4 |

-

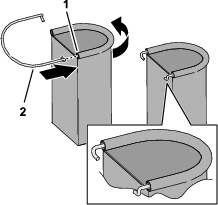

Insert a hoop rod into the sleeve of the PPE storage bag as shown in Figure 26.

-

Repeat step 1 for the other hoop and bag.

-

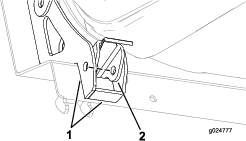

Install the mount bracket to the rollbar tube (Figure 27) with a U-bolt and 2 flange locknuts (3/8 inch).

Note: Ensure that the bracket location does not cover the rollbar decals.

-

Repeat step 3 at the other side of the machine.

-

Insert the hooks of the hoop rod into the slots in the mount bracket (Figure 28).

-

Repeat step 5 at the other side of the machine.

Applying the Decals to the Machine

Parts needed for this procedure:

| Boom lift-point decal | 2 |

| Tank-contents decal | 1 |

| Regulatory decal | 1 |

Applying the Boom Lift-Point Decals

-

Locate the middle of an outer boom, between the brackets, as shown in Figure 29.

-

Clean the surface of the truss tube at the location that you identified in step 1, ensuring the surface is free of dirt, grease, or other foreign material.

-

Remove 1 of the decals from the backing, and adhere the decal to truss tube of the boom.

-

Repeat steps 1 through 3 at the other boom.

Applying the Tank-Contents Decal

Use the erasable surface of the decal to record the tank content.

Affix the tank-contents decal to the rollbar, directly behind the operator’s position.

Applying the Regulatory Decal

-

Clean the surface of the step below the model-serial plate and the emissions decal.

-

Remove the backing from the regulatory decal, and adhere it to the step.

-

Adhere the regulatory decal below the emissions decal.