Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

| Before storage |

|

| Every 2 years |

|

Caution

If you leave the key in the traction unit ignition switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the ignition before you do any maintenance.

Greasing the Bearings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Before storage |

|

-

Disconnect the attachment from the traction unit; refer to the traction unit Operator’s Manual.

-

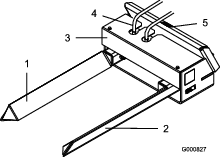

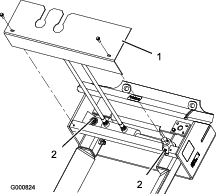

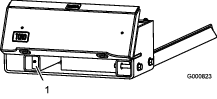

Remove the 2 bolts securing the cover and remove it (Figure 5).

-

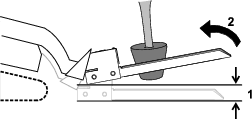

Clean the grease fittings (Figure 5 and Figure 6) with a rag. Make sure that you scrape any paint off the front of the fitting(s).

-

Connect a grease gun to each fitting (Figure 5 and Figure 6).

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

Checking the Hydraulic Hoses

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Before storage |

|

| Every 2 years |

|

-

Check the hydraulic hoses for leaks, loose fittings, kinked lines, loose mounting supports, wear, weather, and chemical deterioration.

-

Make necessary repairs before operating the machine.

Caution

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury, otherwise, gangrene may result.

-

Keep your body and hands away from pin hole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.