Introduction

The cement bowl attachment designed for use on Toro compact tool carriers with an Auger Head attachment to mix and pour up to 90.7 kg (200 lb) of dry cement. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

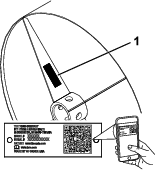

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

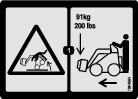

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Warning

CALIFORNIA

Proposition 65 Warning

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Warning

Machining or handling stone, masonry, concrete, metal, and other materials can generate dust, mists, and fumes containing chemicals, such as silica, known to cause serious or fatal injury or illness, such as respiratory disease, silicosis, cancer, birth defects, or other reproductive harm.

-

Control dust, mist, and fumes at the source where possible. Use water for dust suppression when feasible.

-

Use good work practices and follow the recommendations of the manufacturer or suppliers, OSHA, and other occupational and trade associations.

-

Always follow respiratory precautions.

-

When you cannot eliminate the hazards from inhalation, you and any bystanders should wear a respirator approved by OSHA for the material being handled.

General Safety

Always follow all safety instructions to avoid serious injury or death.

-

Do not exceed the rated operating capacity, as the machine may become unstable, which may result in loss of control.

-

Do not transport an attachment with the arms raised or extended (if applicable). Always transport the attachment close to the ground; refer to Transport Position.

-

Have the property or work area marked for buried lines and other objects, and do not dig in marked areas.

-

Read and understand the content of this Operator’s Manual before starting the machine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Never allow children or untrained people to operate the machine.

-

Keep your hands and feet away from the moving components and attachments.

-

Do not operate the machine without the guards and other safety protective devices in place and working on the machine.

-

Keep bystanders and pets away from the machine.

-

Stop the machine, shut off the machine, and remove the key before servicing, fueling, or unclogging the machine.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

Slope Safety

-

Operate the machine up and down slopes with the heavy end of the machine uphill. Weight distribution changes with attachments. An empty load-bearing attachment makes the rear of the machine the heavy end, and a full load-bearing attachment makes the front of the machine the heavy end. Most other attachments make the front of machine the heavy end.

-

Raising or extending (if applicable) the loader arms on a slope affects the stability of the machine. Keep the loader arms in the lowered and retracted position when on slopes.

-

Slopes are a major factor related to loss of control and tip-over accidents, which can result in severe injury or death. Operating the machine on any slope or uneven terrain requires extra caution.

-

Establish your own procedures and rules for operating on slopes. These procedures must include surveying the site to determine which slopes are safe for machine operation. Always use common sense and good judgment when performing this survey.

-

Slow down and use extra care on hillsides. Ground conditions can affect the stability of the machine.

-

Avoid starting or stopping on a slope. If the machine loses traction, proceed slowly, straight down the slope.

-

Avoid turning on slopes. If you must turn, turn slowly and keep the heavy end of the machine uphill.

-

Keep all movements on slopes slow and gradual. Do not make sudden changes in speed or direction.

-

If you feel uneasy operating the machine on a slope, do not do it.

-

Watch for holes, ruts, or bumps, as uneven terrain could overturn the machine. Tall grass can hide obstacles.

-

Use caution when operating on wet surfaces. Reduced traction could cause sliding.

-

Evaluate the area to ensure that the ground is stable enough to support the machine.

-

Use caution when operating the machine near the following:

-

Drop-offs

-

Ditches

-

Embankments

-

Bodies of water

The machine could suddenly roll over if a track goes over the edge or the edge caves in. Maintain a safe distance between the machine and any hazard.

-

-

Do not remove or add attachments on a slope.

-

Do not park the machine on a hillside or slope.

Cement Bowl Safety

-

Wear personal protective equipment (PPE) and appropriate clothing, including the following:

-

Hard hat

-

Respirator or dust mask

-

Face shield

-

Safety glasses

-

Hearing protection

-

Substantial, slip-resistant footwear

-

Long pants

-

Shirt with long sleeves that are tight at the wrists

-

Tight-fitting gloves without drawstrings or loose cuffs

-

-

For a 300 series compact tool carrier, use the counterweight on the traction unit when using the attachment.

Maintenance and Storage Safety

-

Check fasteners at frequent intervals for proper tightness to ensure that the equipment is in safe operating condition.

-

Refer to this Operator’s Manual for important details if you store the attachment for an extended period of time.

-

Maintain or replace safety and instruction labels, as necessary.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Preparing the Machine

-

Park the machine on a level surface and engage the parking brake (if applicable).

-

Raise the loader arms so that the drive head clears the ground.

-

Shut off the engine and remove the key.

Installing the Cement Bowl onto the Auger Drive Head

Parts needed for this procedure:

| Cement bowl | 1 |

| Bolt | 2 |

| Nut | 2 |

-

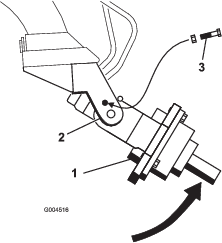

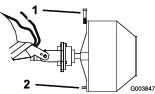

Manually rotate the auger drive head up, until you can slide 2 bolts into the holes on both sides of the cradle arms (Figure 3). Secure each bolt with a nut.

-

Start the engine.

-

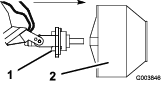

Maneuver the drive shaft into the collar on the back of the bowl (Figure 2).

-

Shut off the engine and remove the key.

-

Secure the bowl to the drive head with the bolt and nut supplied with the auger drive head (Figure 5).

Product Overview

Note: Specifications and design are subject to change without notice.

| Width | 64 cm (25 inches) |

| Length | 46 cm (18 inches) |

| Weight | 34 kg (75 lb) |

| Maximum dry concrete load | 91 kg (200 lb) |

Operation

Mixing and Pouring Concrete

Caution

When full of concrete, the bowl is very heavy and could unbalance the traction unit. The traction unit could tip, seriously injuring you or bystanders.

-

Never use the cement bowl on a 200 or 300 series compact tool carrier without first installing the counterweight, available from your Authorized Service Dealer.

-

Always keep the bowl close to the ground.

-

Lower the loader arms as far as possible while tilting the bowl upward as far as possible.

-

Add up to 91 kg (200 lb) of dry concrete mixture.

-

Move the throttle lever to the FAST position.

-

If your traction unit has a speed selector and flow divider, move the speed-selector lever to the FAST position and move the flow-divider control to the 10 to 11 o’clock position (20 to 30 rpm).

-

Add the appropriate amount of water to the concrete and move the auxiliary hydraulics lever forward to mix.

-

When the cement is sufficiently mixed, move the auxiliary hydraulics lever to NEUTRAL and slowly drive to the work site.

-

Tilt the bowl forward and move the auxiliary hydraulics lever rearward to dump the concrete.

-

When finished using the bowl, wash it before the concrete sets.

Removing the Bowl from the Auger Drive Head

-

Park the machine on a level surface.

-

Lower the bowl in the storage location.

-

Shut off the engine and remove the key.

-

Remove the bolt and nut securing the bowl to the drive head (Figure 5).

-

Start the engine and back the traction unit away from the bowl.

Transport Position

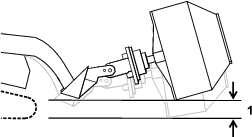

When transporting the attachment, keep it as close to the ground as possible, no more than 15 cm (6 inches) above the ground. Tilt it rearward.

Storage

-

Before long-term storage, wash the attachment with mild detergent and water to remove dirt and grime.

-

Paint all scratched or bare metal surfaces. Paint is available from your Authorized Service Dealer.

-

Store the attachment in a clean, dry garage or storage area. Cover it to protect it and keep it clean.