Recommended Maintenance Schedule

|

Before each use or daily

|

Check the digging chain.

|

- |

- |

- |

|

Check the trencher cleaner.

|

- |

- |

- |

|

Check the trencher mounting bolts.

|

- |

- |

- |

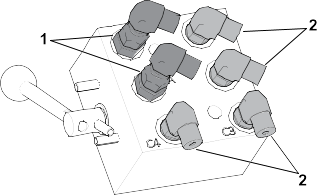

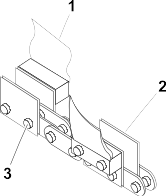

Checking Chain Components

-

If a rock chain bit is in use, check that the bits rotate freely.

-

Clean the chain and check the bits after each use.

-

Replace the bit when the carbide cap or insert is worn.

-

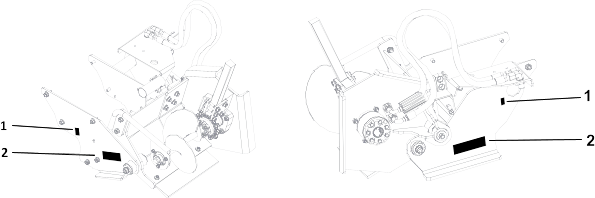

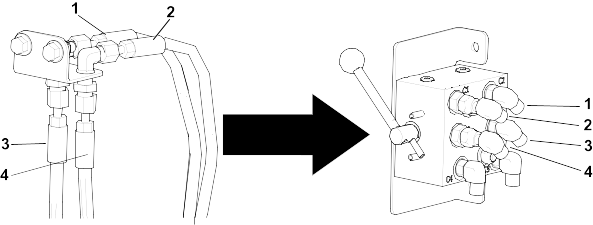

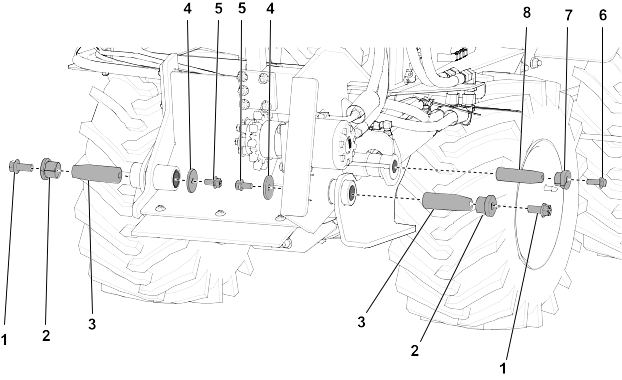

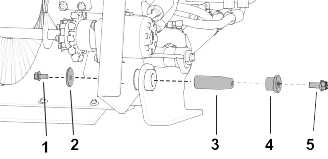

If the sidebars (2) are bent or loose on the chain pins, chain spacers should be used to join the sidebars.

-

Check the pins and bushings for wear by measuring the distance between the chain pins (3) and comparing it with the new chain.

-

Check the teeth (1) for wear.

Note: Replace worn teeth using Toro replacement parts and maintaining the original tooth pattern.

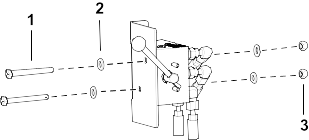

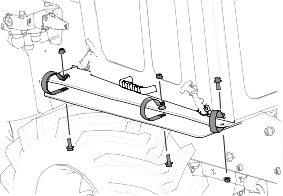

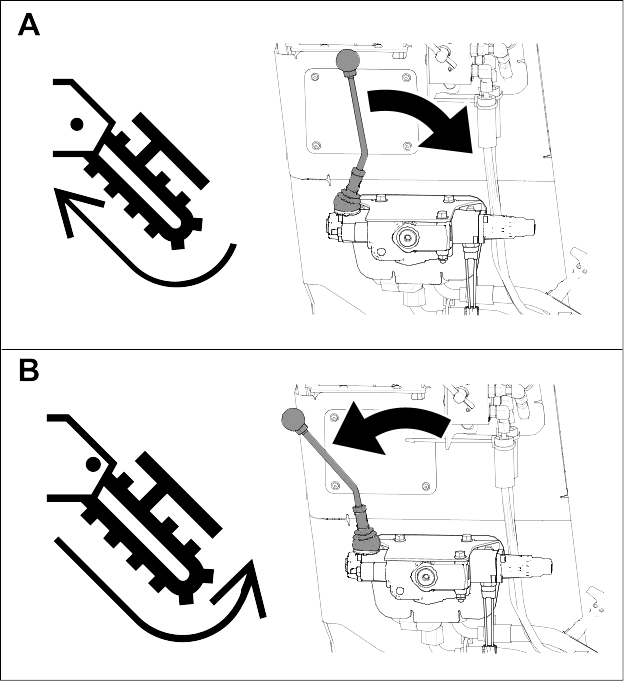

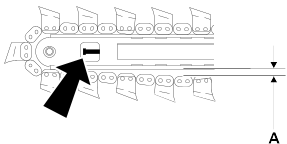

Adjusting the Digging Chain Tension

Check every 10 hours. Adjust as needed.

-

Move the boom into a horizontal position and stop the engine.

-

Set the parking brake.

-

Ensure the distance from the bottom of the boom to the chain (A) measures 38–51 mm (1.5–2 inches).

-

Note: Do not overtighten the chain. Overtightening will cause chain stretch, loss of machine performance, and possible premature

chain failure.

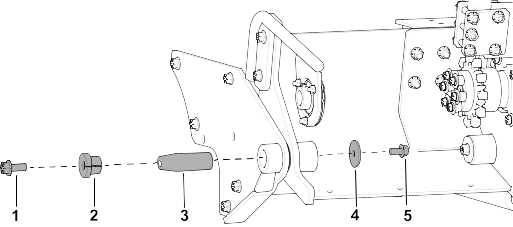

To adjust the tension, loosen the jam nut on the adjustment screw.

-

To tighten the digging chain, turn the adjustment screw clockwise. To loosen it, turn the screw counterclockwise.

-

When the chain is properly tensioned, tighten the jam nut.

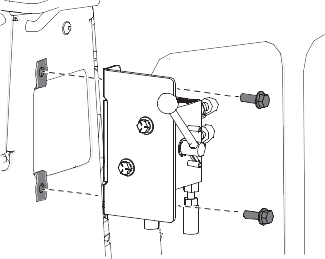

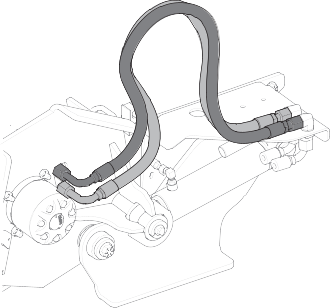

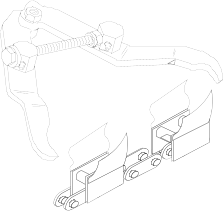

Removing the Chain

Replace the sprockets when a new chain is installed.

-

Fasten and adjust the seat belt.

-

Start the engine.

-

Turn the digging chain until the connector pin is on top of the boom.

-

Lower the boom to the ground.

-

Engage the parking brake.

-

Shut off the machine.

-

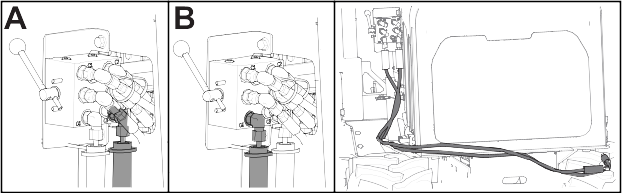

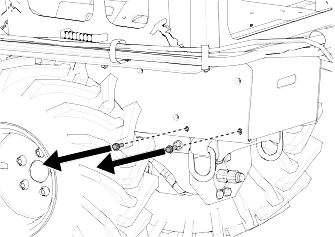

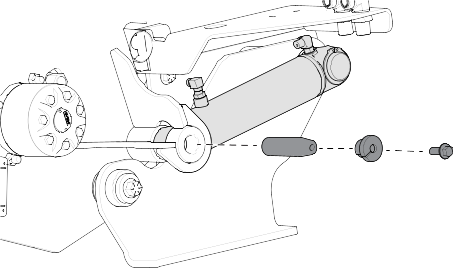

Secure the chain by clamping the links on either side of the connector pin with chain jaws as shown. Squeeze the jaws to reduce

pressure on the pin.

-

Relieve chain tension.

-

Stand clear of the chain and remove the lock key from the connector pin.

-

Drive the connector pin out of the link.

-

Unclamp the links. Slowly release the cable and lower the chain to the ground.

|

Warning |

|

Raised component. Crushing can cause death or serious injury. Stay away. Use correct equipment and procedures.

-

Lay the chain on the ground with the teeth down.

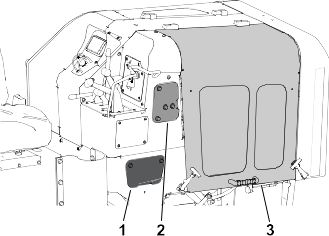

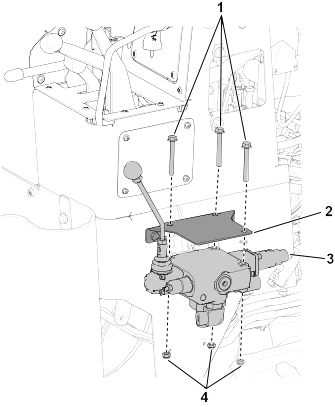

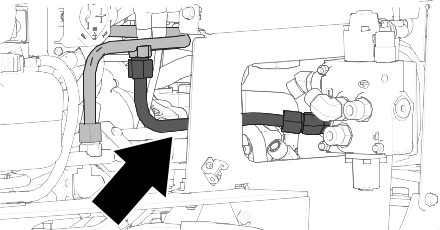

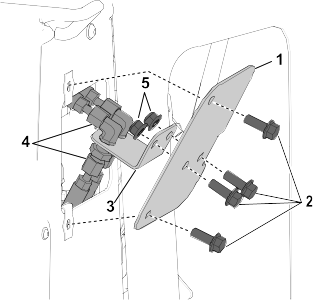

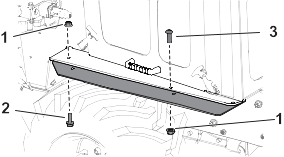

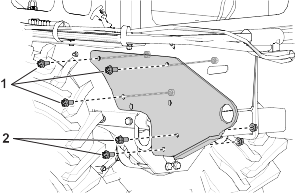

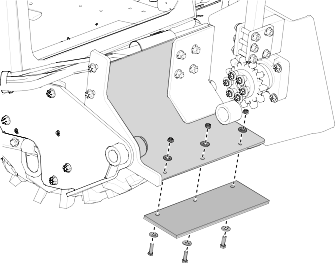

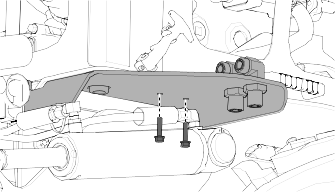

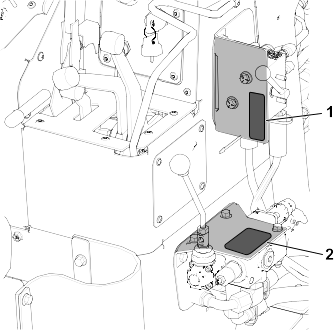

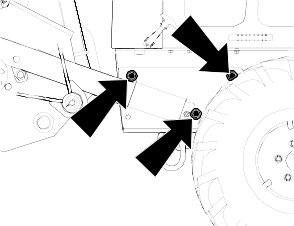

Checking the Trencher Mounting Bolts

-

Check the bolts every 10 hours. Tighten them as needed.