| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This rotary-blade, stand-on lawn mower is intended to be used by professional, hired operators. It is designed primarily for cutting grass on well-maintained lawns on residential or commercial properties. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain the product properly and to avoid injury and product damage. The operator is responsible for operating the product properly and safely.

Visit www.Toro.com for more information, including safety tips, training materials, accessory information, help finding a dealer, or to register your product.

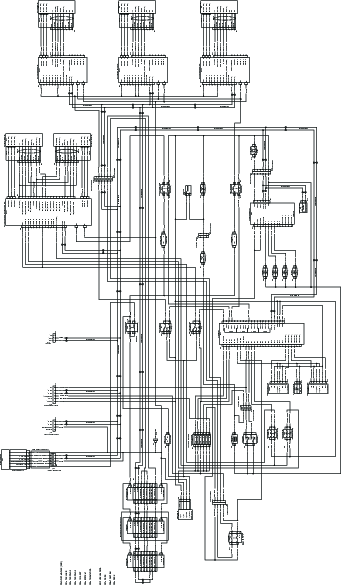

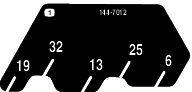

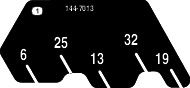

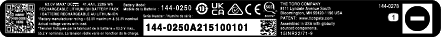

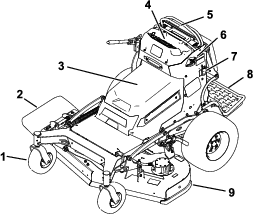

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Safety

General Machine Safety Warnings

WARNING—Read all safety warnings, instructions, illustrations

and specifications provided with this machine.

WARNING—Read all safety warnings, instructions, illustrations

and specifications provided with this machine.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

The term “machine” in all of the warnings listed below refers to your mains-operated (corded) machine or battery-operated (cordless) machine.

-

Work area safety

-

Keep work area clean and well lit.Cluttered or dark areas invite accidents.

-

Do not operate the machine in explosive atmospheres, such as in the presence of flammable liquids, gasses, or dust.The machine creates sparks, which may ignite the dust or fumes.

-

Keep children and bystanders away while operating the machine.Distractions can cause you to lose control.

-

-

Electrical safety

-

Machine plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with an earthed (grounded) machine.Unmodified plugs and matching outlets will reduce risk of electric shock.

-

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators.There is an increased risk of electric shock if your body is earthed or grounded.

-

Do not expose the machine to rain or wet conditions.Water entering a machine will increase the risk of electric shock.

-

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord away from heat, oil, sharp edges, or moving parts.Damaged or entangled cords increase the risk of electric shock.

-

When operating the machine outdoors, use an extension cord suitable for outdoor use.Use of a cord suitable for outdoor use reduces the risk of electric shock.

-

If operating the machine in a damp location is unavoidable, use a residual current device (RCD) protected supply.Use of an RCD reduces the risk of electric shock.

-

-

Personal safety

-

Stay alert, watch what you are doing, and use common sense when operating the machine. Do not use the machine while you are tired or under the influence of drugs, alcohol, or medication.A moment of inattention while operating the machine may result in serious personal injury.

-

Use personal protective equipment. Always wear eye protection.Protective equipment such as a dust mask, non-skid safety shoes, or hearing protection used for appropriate conditions will reduce personal injuries.

-

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack.Energising a machine that has the switch on invites accidents.

-

Remove any adjusting key or wrench before turning the machine on.A wrench or a key left attached to a rotating part of the machine may result in personal injury.

-

Do not overreach. Keep proper footing and balance at all times.This enables better control of the machine in unexpected situations.

-

Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts.Loose clothes, jewelry or long hair can be caught in moving parts.

-

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used.Use of dust collection can reduce dust-related hazards.

-

Do not let familiarity gained from frequent use of the machine allow you to become complacent and ignore machine safety principles.A careless action can cause severe injury within a fraction of a second.

-

-

Machine use and care

-

Do not force the machine. Use the correct machine for your application.The correct machine will do the job better and safer at the rate for which it was designed.

-

Do not use the machine if the switch does not turn it on and off.Any machine that cannot be controlled with the switch is dangerous and must be repaired.

-

Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the machine before making any adjustments, changing accessories, or storing the machine.Such preventive safety measures reduce the risk of starting the machine accidentally.

-

Store an idle machine out of the reach of children and do not allow persons unfamiliar with the machine or these instructions to operate the machine.A machine is dangerous in the hands of untrained users.

-

Maintain the machine and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the operation of the machine. If damaged, have the machine repaired before use.Many accidents are caused by a poorly maintained machine.

-

Keep cutting tools sharp and clean.Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

-

Use the machine, accessories, and tool bits etc., in accordance with these instructions, taking into account the working conditions and the work to be performed.Use of the machine for operations different from those intended could result in a hazardous situation.

-

Keep handles and grasping surfaces dry, clean and free from oil and grease.Slippery handles and grasping surfaces do not allow for safe handling and control of the machine in unexpected situations.

-

-

Battery machine use and care

-

Recharge only with the charger specified by a manufacturer.A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

-

Use the machine only with specifically designated batteries.Use of any other batteries may create a risk of injury and fire.

-

When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another.Shorting the battery terminals together may cause burns or a fire.

-

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.Liquid ejected from the battery may cause irritation or burns.

-

Do not use a battery pack or machine that is damaged or modified.Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk or injury.

-

Do not expose a battery pack or machine to fire or excessive temperature.Exposure to fire temperature above 130°C may cause an explosion.

-

Follow all charging instructions and do not charge the battery pack or machine outside the temperature range specified in the instructions.Changing improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

-

-

Service

-

Have your machine serviced by a qualified repair person using only identical replacement parts.This will ensure that the safety of the machine is maintained.

-

Never service damaged battery packs.Service of battery packs should be performed only by the manufacturer or authorized service providers.

-

Lawn Mower Safety Warnings

-

Do not use the lawnmower in bad weather conditions, especially when there is a risk of lightning.This decreases the risk of being struck by lightning.

-

Thoroughly inspect the area for wildlife where the lawnmower is to be used.Wildlife may be injured by the lawnmower during operation.

-

Thoroughly inspect the area where the lawnmower is to be used and remove all stones, sticks, wires, bones, and other foreign objects.Thrown objects can cause personal injury.

-

Before using the lawnmower, always visually inspect to see that the blade and the blade assembly are not worn or damaged.Worn or damaged parts increase the risk of injury.

-

Keep guards in place. Guards must be in working order and be properly mounted.A guard that is loose, damaged, or is not functioning correctly may result in personal injury.

-

Keep all cooling air inlets clear of debris.Blocked air inlets and debris may result in overheating or risk of fire.

-

While operating the lawnmower, always wear non-slip and protective footwear. Do not operate the lawnmower when barefoot or wearing open sandals.This reduces the chance of injury to the feet from contact with the moving blade.

-

While operating the lawnmower, always wear long trousers.Exposed skin increases the likelihood of injury from thrown objects.

-

Do not operate the lawnmower on excessively steep slopes.This reduces the risk of loss of control, slipping and falling which may result in personal injury.

-

When working on slopes, always be sure of your footing, always work across the face of slopes, never up or down and exercise extreme caution when changing direction.This reduces the risk of loss of control, slipping and falling which may result in personal injury.

-

Use extreme caution when reversing or pulling the lawnmower towards you.Always be aware of your surroundings.

-

Do not touch blades and other hazardous moving parts while they are still in motion.This reduces the risk of injury from moving parts.

-

When clearing jammed material or cleaning the lawnmower, make sure all power switches are off and remove (or activate) the disabling device.Unexpected operation of the lawnmower may result in serious personal injury.

Save all warnings and instructions for future reference.

Additional Safety Messages

Safety-Alert Symbol

The safety-alert symbol (Figure 2) shown in this manual and on the machine identifies important safety messages that you must follow to prevent accidents.

The safety-alert symbol appears above information that alerts you to unsafe actions or situations and is followed by the word DANGER, WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This manual uses two other words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury or death.

-

Keep clear of the discharge opening.

-

Allow only responsible and physically capable people to operate the machine.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operator's position. Allow the machine to cool before servicing, adjusting, or cleaning it.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Adjusting the Machine Settings

Use the InfoCenter to adjust the machine settings; refer to InfoCenter Display.

Mounting the Battery Charger on a Wall

You can mount the charger on a wall using the wall-mount key holes cut into the back of the unit. Use screws that have a 6 mm (1/4 inch) diameter shaft and a head diameter of 11 mm (0.45 inch).

Important: Survey your work area and determine a location that best meets the criteria for safe and effective operation of the charger.

Charging the Batteries

Check the battery-system charge; charge them as needed. Refer to Monitoring the Battery-System Charge Level.

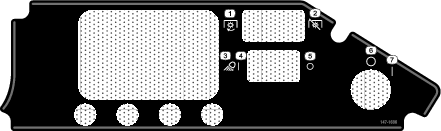

Product Overview

Become familiar with all the controls before you start and operate the machine.

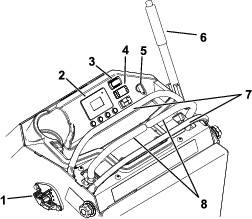

Control Panel

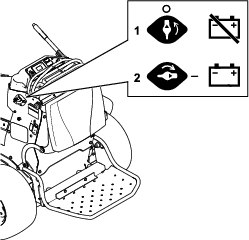

Key Switch

The key switch has 2 positions: ON and OFF.

Use the key switch to turn on or shut off the machine; refer to Starting the Machine and Shutting Off the Machine.

Power-Takeoff Switch (PTO)

Use the power-takeoff switch (PTO) to engage and disengage mower blades or start and stop powered attachments; refer to Operating the Mower-Blade-Control Switch (PTO).

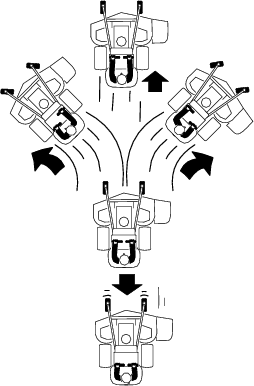

Motion-Control Levers

Use the motion-control levers to drive the machine forward, reverse, and turn either direction.

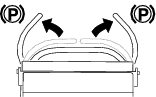

Park Position

Move the motion-control levers outward from the center to the PARK position when exiting the machine to engage the electric brake.

Always move the motion-control levers to the PARK position when you stop the machine or leave it unattended.

Light Switch

Use the light switch to illuminate and shut off the light.

InfoCenter Display

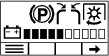

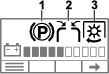

The InfoCenter LCD display shows information about your machine, such as the operating status, various diagnostics, and other information about the machine.

-

Splash screen: shows the battery charge for a few seconds after you move the key to the ON position.

-

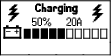

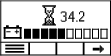

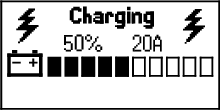

Charging screen: shows the battery charge percentage and amperage.

-

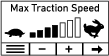

Main information screens: shows current machine information while the key is in the ON position. This screen shows the battery-system charge level and the status of various components. Press the

button to cycle through

the screens. Use the – and + buttons to adjust the maximum traction speed and mower blade speed.

button to cycle through

the screens. Use the – and + buttons to adjust the maximum traction speed and mower blade speed.

| Next |

| Scroll up |

| Scroll down |

| Enter main menu. |

| Change language setting. |

| Increase |

| Decrease |

| Exit menu |

| Save |

| Operating hours |

| Battery charge |

| Motion-control levers are in the unlocked position. |

| Parking brake is engaged. |

| PTO is engaged. |

| Mower blade |

| Traction drive |

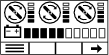

| Fast |

| Slow |

| Energy-saving |

| The traction speed or menu item is locked. |

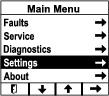

InfoCenter Menus

To access the main menu, press the  button from any of the

main information screens.

button from any of the

main information screens.

Refer to the following tables for a description of the options available from the menus:

Note:  Protected

under Protected Menus—accessible only by entering PIN.

Protected

under Protected Menus—accessible only by entering PIN.

| Menu Item | Description |

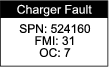

| FAULTS | The FAULTS menu contains a list of the recent machine faults. Refer to the Service Manual or your Authorized Service Dealer for more information on the FAULTS menu. |

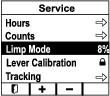

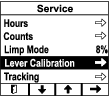

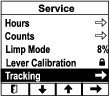

| SERVICE | The Service menu contains information on the machine such as hours of use and counts, power, lever calibration, and tracking. |

| DIAGNOSTICS | The DIAGNOSTICS menu lists various states and data that the machine currently has. You can use this information to troubleshoot certain issues. |

| SETTINGS | The SETTINGS menu allows you to customize and modify configuration variables on the InfoCenter display. |

| ABOUT | The ABOUT menu lists the model number, serial number, and software version (if PIN is entered) of your machine. |

| Menu Item | Description |

| CURRENT | Lists the total number of key-on hours (i.e., hours that the key has been in the ON position). |

| LAST | Indicates the last key-on hour that the fault occurred on. |

| FIRST | Indicates the first key-on hour that the fault occurred on. |

| OCCURRENCES | Indicates the number of fault occurrences. |

| Menu Item | Description |

| HOURS | Lists the total number of hours various components have been

used:

|

| COUNTS | Lists the counts of various components:

|

| LIMP MODE | Displays and adjusts the battery percentage before limp mode starts. Refer to Adjusting the Battery Percentage for Limp Mode. |

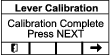

LEVER CALIBRATION | Calibrates the motion-control levers. Refer to Calibrating the Levers. |

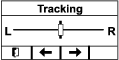

| TRACKING | Adjusts the tracking of the motion-control levers. Refer to Adjusting the Tracking. |

| Menu Item | Description |

| BATTERY STACK | Indicates the status of the batteries. |

| BATTERY PACKS | Indicates the status of individual batteries. |

| CU MOTORS | Indicates the status of each cutting unit motor. |

| TU MOTORS | Indicates the status of each traction unit motor. |

| Menu Item | Description |

| LANGUAGE | Controls the language used on the InfoCenter. |

| BACKLIGHT | Controls the brightness of the LCD display. |

| CONTRAST | Controls the contrast of the LCD display. |

| PROTECTED MENUS | Allows you to access protected menus by inputting a passcode. |

| Menu Item | Description |

| MODEL | Displays the model number of the machine. |

| SN | Displays the serial number of the machine. |

| MAIN CONTROLLER | Displays the software part number and revision of the main controller. |

| DISPLAY CONTROLLER | Displays the software part number and revision of the display controller. |

| TU MOTORS | Displays the software part number and revision of the traction unit motors. |

| CU MOTORS | Displays the software part number and revision of the cutting unit motors. |

| BATTERY PACKS | Displays the software part number and revision of the battery packs. |

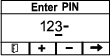

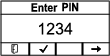

Accessing Protected Menus

Note: The factory default PIN code for your machine is 1234.If you changed the PIN code and forgot the code, contact your Authorized Service Dealer for assistance.

Note: The InfoCenter displays only 2 items at a time; however, the following figures show the full menus for context.

-

In the MAIN MENU, scroll down to SETTINGS and press the

button.

button.

-

In the SETTINGS menu, scroll down to PROTECTED MENUS and press the

button.

button.

-

To enter the PIN code, use the 2 center buttons to input each digit, and press the

button to move on to the next digit. Repeat this

step until the last digit is entered and press the

button to move on to the next digit. Repeat this

step until the last digit is entered and press the  button again.

button again.

-

Press the

button to confirm the PIN code.

button to confirm the PIN code.

Note: If the InfoCenter accepts the PIN code and the protected menu is unlocked, the word “PIN” displays in the upper right corner of the screen.

Note: Specifications and design are subject to change without notice.

| Cutting width | 132 cm (52 inches) |

| Width with deflector down | 172 cm (67-3/4 inches) |

| Width with deflector raised | 137 cm (53-3/4 inches) |

| Length with platform down | 192 cm (75-3/4 inches) |

| Length with platform up | 155 cm (61 inches) |

| Height | 126 cm (49-3/4 inches) |

| Weight | 503 kg (1109 lb) |

| Battery Quantity | 8 |

| Rated Voltage | 60 VDC maximum and 55.2 VDC nominal usage |

| Amp Hours | 331.2 Ah |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Before Operation

Before Operation Safety

-

Do not operate the machine unless all safety switches and other devices are in place and working properly.

-

Before leaving the operator's position for any reason, do the following:

-

Park the machine on a level surface.

-

Disengage the drives and the power take-off.

-

Engage the parking brake.

-

Shut off the machine and remove the key.

-

Wait for all moving parts to stop.

-

-

Before mowing, always inspect the machine to ensure that the blades, blade bolts, and cutting assemblies are in good working condition.

-

This product generates an electromagnetic field. If you wear an implantable electronic medical device, consult your health care professional before using this product.

-

Use only accessories and attachments approved by Toro.

-

Do not carry passengers on the machine and keep bystanders and pets away from the machine during operation.

-

This machine produces a sound power level that exceeds 85 dBA at the operator’s ear, which can cause hearing loss through extended periods of exposure. Wear hearing protection when operating this machine.

-

Before operating the machine, ensure that the operator presence controls and either the discharge deflector or the entire grass collection system are in place and working properly. Otherwise, do not operate the machine.

-

When you shut off the machine, the blades should stop. If not, stop using the machine immediately and contact an Authorized Service Dealer.

-

Shut off the machine and attachment(s) if anyone enters the area.

Performing Daily Maintenance

Before starting the machine each day, perform the Each Use/Daily procedures listed in .

Using the Safety-Interlock System

Danger

If safety-interlock switches are disconnected or damaged, the machine could operate unexpectedly, which will result in serious injury or death.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock switches daily, and replace any damaged switches before operating the machine.

Understanding the Safety-Interlock System

The safety-interlock system prevents the PTO from engaging unless you do the following:

-

Move either motion-control lever down to the center, unlocked position.

-

Press the ON position on the PTO switch.

The safety-interlock system also disengages the PTO if you move or release both motion-control levers into the PARK position.

Symbols display on the InfoCenter to notify the user when each interlock component is in the correct position.

Testing the Safety-Interlock System

Test the safety-interlock system before you use the machine each time.

Note: If the safety system does not operate as described, have an Authorized Service Dealer repair the safety-interlock system immediately.

-

Start the machine.

-

With both motion-control levers outward in the PARK position, press the ON position on the PTO switch.

Note: The mower blades should not engage.

-

Move 1 lever down to the center, unlocked position and press the ON position on the PTO switch.

Note: The mower blades should engage.

-

Release the lever to the PARK position.

Note: The blades should stop.

-

Move 1 lever down to the center, unlocked position and press the ON position on the PTO switch.

Note: The mower blades should engage.

-

Press the OFF position on the PTO switch.

Note: The blades should stop.

During Operation

During Operation Safety

General Safety

-

Wet grass or leaves can cause serious injury if you slip and contact the blade. Avoid mowing in wet conditions.

-

Before you start the machine, ensure that all drives are in neutral.

-

Keep away from holes, ruts, bumps, rocks, and other hidden hazards. Use care when approaching blind corners, shrubs, trees, tall grass or other objects that may hide obstacles or obscure vision. Uneven terrain could overturn the machine or cause you to lose your balance or footing.

-

Shut off the machine and disengage the drive to the cutting unit after striking a foreign object or if an abnormal vibration occurs. Inspect the cutting unit for damage and make repairs before starting and operating the machine.

-

Be alert, slow down, and use caution when making turns and crossing roads and sidewalks with the machine. Always yield the right-of-way.

-

Do not use the machine as a towing vehicle.

-

Never raise the mower deck with the blades running.

-

Be aware of the mower discharge path and direct discharge away from others. Avoid discharging material against a wall or obstruction as the material may ricochet back toward the operator. Stop the blades, slow down, and use caution when crossing surfaces other than grass and when transporting the mower.

-

Do not leave a running machine unattended.

-

Be alert and shut off the machine if children enter the area.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution. Before using the machine on a slope, do the following:

-

Review and understand the slope instructions in the manual and on the machine.

-

Evaluate the site conditions of the day to determine if the slope is safe for machine operation. Use common sense and good judgment when performing this evaluation. Changes in the terrain, such as moisture, can quickly affect the operation of the machine on a slope.

-

-

Operate across slopes, never up and down. Avoid operation on excessively steep or wet slopes.

-

Identify hazards at the base of the slope. Do not operate the machine near drop-offs, ditches, embankments, water, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge collapses. Keep a safe distance (twice the width of the machine) between the machine and any hazard. Use a walk-behind machine or a handheld tool to operate in these areas.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction; turn slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering or stability is in question. Be aware that operating the machine on wet grass, across slopes or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering. The machine can slide even if the drive wheels are stopped.

-

Remove or mark obstacles such as ditches, holes, ruts, bumps, rocks or other hidden hazards. Tall grass can hide obstacles. Uneven terrain could overturn the machine.

-

Use extra care while operating with accessories or attachments. These can change the stability of the machine and cause a loss of control. Follow directions for counterweights.

-

If you lose control of the machine, step away from the direction of travel of the machine.

Starting the Machine

-

Stand on the platform.

-

Turn the key switch to the ON position.

Shutting Off the Machine

Caution

Children or bystanders may be injured if they move or attempt to operate the machine while it is unattended.

Always remove the key and engage the parking brake when leaving the machine unattended.

-

Disengage the PTO.

-

Move the motion-control levers outward to the PARK position.

Note: The electric brake will engage automatically.

-

Turn the key switch to the OFF position and remove the key.

Operating the Mower-Blade-Control Switch (PTO)

Use the blade-control switch (PTO) in conjunction with the motion-control levers to engage and disengage the mower blades.

Danger

The rotating blades under the mower deck are dangerous. Blade contact will cause serious injury or death.

Do not put your hands or feet under the mower or mower deck when the blades are engaged.

Danger

An uncovered discharge opening allows objects to be thrown toward you or bystanders. Also, contact with the blade could occur. Thrown objects or blade contact will cause serious injury or death.

Do not operate the mower with the discharge deflector raised, removed, or altered unless a grass collection system or mulch kit is in place and working properly.

Engaging the Mower Blades (PTO)

Disengaging the Mower Blades (PTO)

Disengage the mower blades using 1 of the 2 ways shown.

Note: If you disengage the mower blades by releasing the motion-control levers, you do not need to move the blade-control switch to the OFF position before engaging the blades again.

Side Discharging or Mulching the Grass

This machine has a hinged grass deflector that disperses clippings to the side and down toward the turf.

Danger

Without the grass deflector, discharge cover, or complete grass catcher assembly mounted in place, you and bystanders are exposed to blade contact and thrown debris. Contact with rotating mower blade(s) and thrown debris will cause injury or death.

-

Do not remove the grass deflector from the machine, because the grass deflector routes material down toward the turf. If the grass deflector is ever damaged, replace it immediately.

-

Never try to clear the discharge area or mower blades unless the power takeoff (PTO) is off. Rotate the key to the OFF position and remove the key.

Using the Platform

You can use the machine with the platform in the up or down position. It is your preference on which position to use.

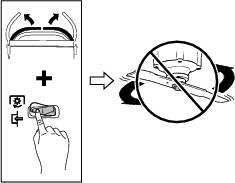

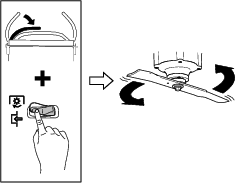

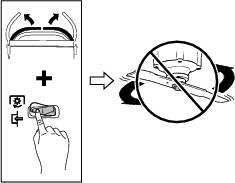

Warning

The operator platform is heavy and may cause injury when you raise or lower it. Carefully lower or raise the operator platform, as suddenly dropping it could injure you.

-

Do not put your hands or fingers in the platform-pivot area when lowering or raising the operator platform.

-

Make sure that the platform is supported when you pull the latch pin out.

-

Make sure that the latch secures the platform when folding it up. Push it tight against the cushion for the latch pin to lock into place.

-

Keep bystanders away from the machine when raising or lowering the platform.

Operate the machine with the platform up for the following conditions:

-

Near drop-offs

-

In small areas where the machine is too large

-

In areas with low-hanging branches or obstacles

-

Loading the machine for transport

-

Driving up slopes

Operate the machine with the platform down for the following conditions:

-

Using the machine in most areas

-

Driving across slopes

-

Driving down slopes

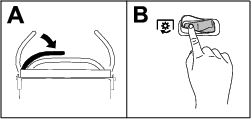

To raise the platform, pull out the knob and lift the platform. Push the platform tight against the cushion for the latch pin to lock it into place.

To lower the platform, push the platform forward against the cushion to release pressure on the latch pin, then pull the knob out and lower the platform.

Driving the Machine

Important: Back the machine over curbs, 1 wheel at a time; driving it forward over curbs could damage the machine.

Caution

Positioning one lever too far in front of the other causes the machine to spin very rapidly. As a result, you may lose control of the machine, causing personal injury to you and damage to the machine.

Slow down the machine before making sharp turns.

-

Move the motion-control levers down to the center, unlocked position.

-

Slowly push the motion-control levers forward or rearward. Move 1 lever farther than the other lever to turn.

Note: The farther you move the motion-control levers, the faster the machine moves in that direction.

-

To stop, pull the motion-control levers back to the NEUTRAL position.

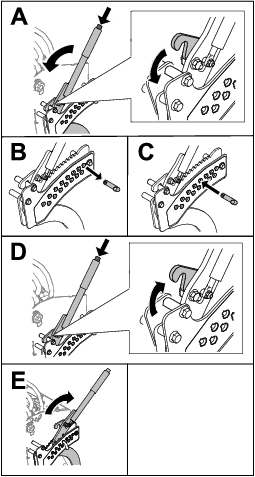

Adjusting the Height-of-Cut

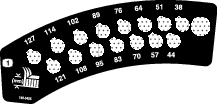

The height-of-cut can be adjusted from 38 to 127 mm (1-1/2 to 5 inches) in 6 mm (1/4 inch) increments.

Adjusting the Slope of the Mower Deck

You can raise the rear of the mower deck in 6.3 mm (1/4 inch) increments, up to 31.8 mm (1-1/2 inch).

-

Disengage the PTO and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Raise the height-of-cut lever and lock it into the transport position.

-

On the left or right side of the machine, raise the lever and remove the pin.

-

Install the pin at the desired position.

-

Repeat the procedure for the other side of the machine.

Using Weights

-

Install weights to improve balance. You can add or remove weights to create optimized performance under different operating conditions and for your preference.

-

Add or remove weights 1 at a time until you achieve the desired handling and balance.

-

Refer to the Operator’s Manual of attachments for recommended weights.

Note: Contact an Authorized Service Dealer to order a weight kit.

Monitoring the Battery-System Charge Level

Refer to the main information screen in the InfoCenter to determine the battery-system charge level.

-

Low battery: When the battery level reaches a low percentage, a low-battery advisory appears on the InfoCenter.

Finish mowing, then transport the machine to a designated battery-charging area and charge the batteries.

-

Limp mode: If the battery level drops below the set limp-mode battery percentage, an advisory appears on the InfoCenter, and the mower blades will disengage and cannot be engaged.

Transport your machine to a designated battery-charging area and charge the batteries.

-

Ultra-limp mode: If the battery level becomes too low during limp mode, an advisory appears on the InfoCenter and traction speed automatically decreases.

Transport your machine to a designated battery-charging area and charge the batteries.

Refer to Charging the Lithium-Ion Batteries.

Adjusting the Battery Percentage for Limp Mode

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

In the MAIN MENU, scroll down to SERVICE and press the

button.

button.

-

In the SERVICE menu, scroll down to LIMP MODE and adjust the percentage using the – and + buttons.

After Operation

After Operation Safety

-

Disengage the PTO whenever you are transporting or not using the machine.

-

Use full-width ramps for loading the machine into a trailer or truck.

-

Tie the machine down securely using straps, chains, cable, or ropes. Both front and rear straps should be directed down and outward from the machine.

-

Replace all worn, damaged, or missing parts and decals. Keep all fasteners tight to ensure that the machine is working properly.

Battery and Charger Safety

General

-

WARNING: Risk of fire and electric shock—The batteries have no user-serviceable parts.

-

Confirm the voltage that is available in your country before using the charger.

-

Do not get the charger wet; keep it protected from rain and snow.

-

A risk of fire, electric shock, or injury may result from using an accessory not recommended or sold by Toro.

-

To reduce risk of a battery explosion, follow these instructions and the instructions for any equipment that you intend to use near the charger.

-

Batteries could emit explosive gasses if they are significantly overcharged.

-

Refer to an Authorized Service Dealer to service or replace a battery.

Training

-

Never allow children or untrained people to operate or service the charger. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Read, understand, and follow all instructions on the charger and in the manual before operating the charger. Be familiar with the proper use of the charger.

Preparation

-

Keep bystanders and children away while charging.

-

Wear appropriate clothing while charging, including eye protection; long pants; and substantial, slip-resistant footwear.

-

Shut off the machine and wait until the machine has completely powered down before charging. Failure to do this may cause arcing.

-

Ensure that the area is well ventilated while charging.

-

The charger is for use on only nominal 120 to 240 VAC operation. For use with 240 V circuits, contact your Authorized Service Dealer for the correct power cord.

Operation

-

Do not charge a frozen battery.

-

Do not abuse the cord. Do not carry the charger by the cord or yank on the power supply cord to disconnect the charger from the receptacle. Keep the cord from heat, oil, and sharp edges.

-

Connect the charger directly to a grounding receptacle. Do not use the charger on an ungrounded outlet, even with a grounding adapter.

-

Do not alter the provided power cord or plug.

-

Remove metal items such as rings, bracelets, necklaces, and watches when working with a lithium-ion battery. A lithium-ion battery can produce enough current to cause a severe burn.

-

Never operate the charger without good visibility or light.

-

Use an extension cord capable of handling 15 A or more. If you are charging outdoors, use an extension cord rated for outdoor use.

-

If the power supply cord is damaged while it is plugged in, disconnect the cord from the wall receptacle and contact an Authorized Service Dealer for a replacement.

-

Unplug the charger from the electrical outlet when not in use, before moving it to another location, or prior to servicing it.

Maintenance and Storage

-

Store the charger indoors in a dry, secure place that is out of the reach of unauthorized users.

-

Do not disassemble the charger. Take the charger to an Authorized Service Dealer when service or repair is required.

-

Unplug the power cord from the outlet before starting any maintenance or cleaning to reduce risk of electric shock.

-

Maintain or replace safety and instruction labels as needed.

-

Do not operate the charger with a damaged cord or plug. Contact an Authorized Service Dealer to obtain a replacement cord.

-

If the charger has received an impact, been dropped, or otherwise damaged, do not use it; take it to an Authorized Service Dealer.

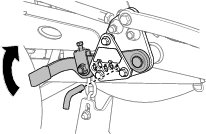

Moving a Non-Functioning Machine

Important: Do not tow the machine without first disengaging the transmission, otherwise you could damage motor components.

Caution

The machine does not have brakes when the transmission is disengaged. It will roll uncontrolled, possibly causing injury.

If you must tow the machine, install the Tow Bar Assembly Kit to prevent the machine from colliding with the towing vehicle. Contact your Authorized Service Dealer to obtain the kit.

-

Disengage the PTO and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

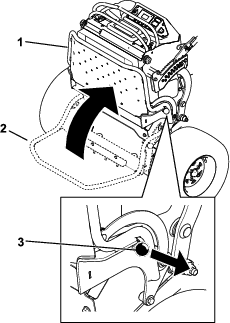

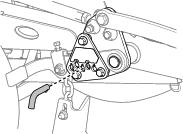

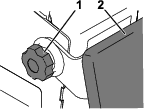

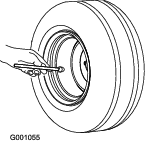

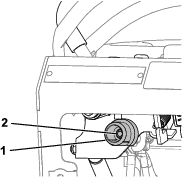

Remove the cap from the motor.

-

Insert a ratchet with a 3/8 inch drive into the square hole in the motor hub. Rotate it counterclockwise until it stops (approximately 4 full rotations) to disengage the transmission. Torque to 41 to 68 N∙m (30 to 50 ft-lb).

Note: The wheel will spin freely.

-

Repeat for the other motor.

-

Move the machine to the desired location.

Important: Do not move the machine faster than 8 km/h (5 mph).

-

Immediately after moving the machine, engage the transmission for operation.

-

Insert a ratchet with a 3/8 inch drive into the square hole in the motor hub.

-

Rotate it clockwise until it stops (approximately 4 full rotations).

-

Torque to 41 to 68 N∙m (30 to 50 ft-lb).

-

Transporting the Machine

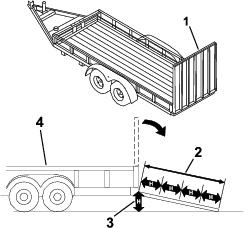

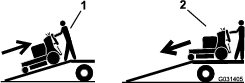

Use a heavy-duty trailer or truck to transport the machine. Use a full-width ramp. Ensure that the trailer or truck has all the necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. Knowing this information could help you or bystanders avoid injury. Refer to your local ordinances for trailer and tie-down requirements.

Warning

Driving on the street or roadway without turn signals, lights, reflective markings, or a slow-moving-vehicle emblem is dangerous and can lead to accidents, causing personal injury.

Do not drive the machine on a public street or roadway.

Warning

Loading a machine onto a trailer or truck increases the possibility of backward tip-over and could cause serious injury or death.

-

Use only full-width ramps; do not use individual ramps for each side of the machine.

-

Ensure that the length of ramp is at least 4 times as long as the height of the trailer or truck bed to the ground.

-

Use extreme caution when operating a machine on a ramp.

-

Back the machine up the ramp and walk it forward down the ramp.

-

Avoid sudden acceleration or deceleration while driving the machine on a ramp as this could cause a loss of control or a tip-over situation.

Selecting a Trailer

Loading the Machine

-

If using a trailer, connect it to the towing vehicle and connect the safety chains.

-

If applicable, connect the trailer brakes and lights.

-

Lower the ramp (Figure 37).

-

Raise the platform.

Important: Always keep the platform up when loading and unloading the machine.

-

Back the machine up the ramp.

-

Shut off the machine and remove the key.

-

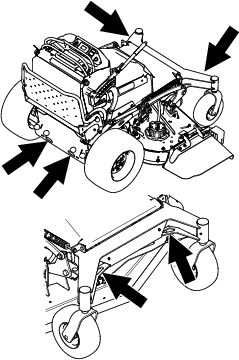

Tie down the machine near the front caster wheels, or front frame holes, and the rear bumper holes with straps, chains, cable, or ropes (Figure 39). Refer to local regulations for tie-down requirements.

Transporting the Lithium-Ion Batteries

The US Department of Transportation and international transportation authorities require that lithium-ion batteries be transported using special packaging and only be transported by carriers certified to haul them. In the US, you are allowed to transport a battery when it is installed on the machine as battery powered equipment, with some regulatory requirements. Contact the US Department of Transportation or the appropriate government body in your country for detailed regulations on transportation of your batteries or the machine with the batteries equipped.

For detailed information on shipping a battery, contact your Authorized Service Dealer.

Using the Lithium-Ion Battery Charger

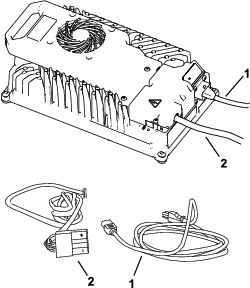

Refer to Figure 40 for an overview of the battery-charger cords.

Connecting to a Power Source

Danger

Contact with water while charging the machine could cause electric shock, causing injury or death.

-

Do not handle the plug or the charger with wet hands or while standing in water.

-

Do not charge the batteries in the rain or in wet conditions.

To reduce the risk of electric shock, this charger has a 3-prong grounded plug (type B). If the plug does not fit into the wall receptacle, other grounded plug types are available; contact an Authorized Service Dealer.

Do not change the charger or the power-supply-cord plug in any way.

Important: Check the power supply cord periodically for holes or cracks in the insulation. Do not use a damaged cord. Do not run the cord through standing water or wet grass.

-

Insert the charger plug on the power-supply cord into the matching input power socket on the charger.

Warning

A damaged charger cord can cause an electrical shock or a fire.

Thoroughly inspect the power supply cord before using the charger. If the cord is damaged, do not operate the charger until you obtain a replacement.

-

Insert the wall plug end of the power supply cord into a grounded electrical outlet.

Charging the Lithium-Ion Batteries

Caution

Attempting to charge the batteries with a charger not provided by Toro can result in excessive heat and other related product malfunctions, which can lead to property damage and/or injury.

Use the Toro-provided chargers to charge the batteries.

Recommended temperature range for charging: 0° to 45°C (32° to 113°F)

Important: Charge the batteries only in temperatures that are within the recommended range.

Note: The charger will not function in temperatures exceeding the minimum or maximum temperatures.

-

Park the machine in the designated location for charging.

-

Shut off the machine and remove the key.

Note: The battery-disconnect must remain in the ON position to charge the batteries.

-

Ensure that the connectors are free of dust and debris.

-

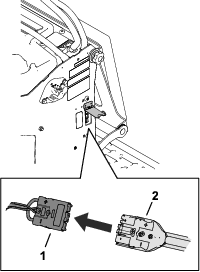

Slide the charger-output connector into the charger connector on the machine.

-

Connect the charger power cord to a power source.

-

Ensure that the InfoCenter screen shows that the batteries are charging.

Note: The InfoCenter shows the battery charge percentage and amperage. Batteries with a lower voltage charge first; once they reach the voltage of the other batteries, all batteries charge simultaneouslyWhen charging is complete, the machine InfoCenter displays 10 solid bars

-

When the machine reaches a sufficient level, disconnect the charger connector from the machine connector.

-

Place the charger connector and cord in a storage position that avoids damage.

-

Start the machine.

-

Verify the charge level using the InfoCenter display.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Warning

Modifying the original machine, parts, and/or accessories may alter the warranty, controllability, and safety of the machine. Making unauthorized modifications to the original machine and/or not using genuine Toro parts could lead to serious injury or death.

-

Do not make unauthorized modifications to the machine, parts, and/or accessories.

-

Use only genuine Toro parts.

Maintenance Safety

-

Before adjusting, cleaning, servicing, or leaving the machine, do the following:

-

Park the machine on a level surface.

-

Disengage the drives and the power take-off.

-

Engage the parking brake.

-

Shut off the machine and remove the key.

-

Wait for all moving parts to stop.

-

Allow machine components to cool.

-

-

Carefully release pressure from components with stored energy.

-

Check the parking brake operation frequently. Service the brake as needed.

-

Never tamper with safety devices. Check their proper operation regularly.

-

Do not rely solely on mechanical or hydraulic jacks to support the machine; support the machine with jack stands whenever you raise the machine.

-

Use care when checking the blades. Wrap the blades or wear gloves, and use caution when servicing the blades. Only replace or sharpen the blades; never straighten or weld them.

-

On multi-bladed machines, take care as rotating one blade can cause other blades to rotate.

-

Keep your hands and feet away from hot surfaces.

-

Keep all hardware tightened, especially the blade-attachment hardware.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| After the first 100 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 500 hours |

|

| Before storage |

|

| Yearly |

|

Pre-Maintenance Procedures

Accessing Internal Components

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

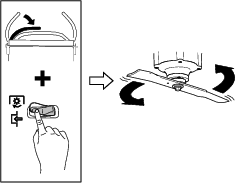

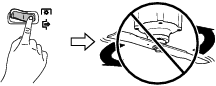

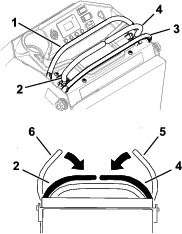

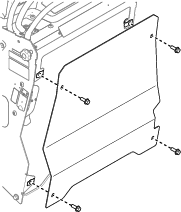

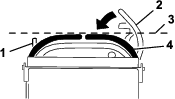

You can release the cushion for rear access to the machine for maintenance or adjustment.

-

Lower the platform.

-

Loosen the twist knobs on each side of the machine.

-

Lower the cushion to the platform.

-

Remove the rear access cover.

-

Perform any maintenance or adjustment on the machine.

-

Install the rear access cover.

-

Raise the cushion, and slide it onto the pins on both sides of the machine.

-

Tighten the twist knobs.

Lubrication

Greasing the Machine

Grease with No. 2 lithium or molybdenum grease.

-

Disengage the blade-control switch (PTO) and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean the grease fittings with a rag.

Note: Make sure to scrape any paint off the front of the fitting(s).

-

Connect a grease gun to the fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

Greasing the Front Caster Pivots

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Grease type: Lithium or molybdenum grease

-

Remove the dust cap and adjust the caster pivots; refer to Adjusting the Caster-Pivot Bearing.

Note: Keep the dust cap off until you have finished greasing the caster pivots.

-

Remove the hex plug.

-

Thread a grease fitting (1/4 inch–28 taper thread) into the hole.

-

Pump grease into the fitting until it oozes out around the top bearing.

-

Remove the grease fitting from the hole.

-

Install the hex plug and dust cap.

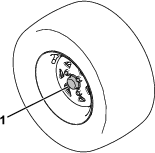

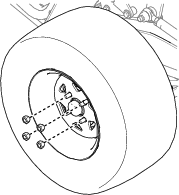

Greasing the Caster-Wheel Hubs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Grease type: Lithium or molybdenum grease

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

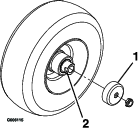

Remove the caster wheel from the caster forks.

-

Remove the seal guards from the wheel hub.

-

Remove 1 spacer nut from the axle assembly in the caster wheel.

Note: Thread-locking adhesive has been applied to lock the spacer nuts to the axle.

-

Remove the axle with the other spacer nut still assembled to it from the wheel assembly.

-

Pry out the seals, inspect bearings for wear or damage, and replace them if necessary.

-

Pack the bearings with a general-purpose grease.

-

Insert 1 bearing and 1 new seal into the wheel.

Note: You must replace the seals.

-

If both spacer nuts in the axle assembly have been removed (or broken loose), apply thread-locking adhesive to 1 spacer nut, threading it onto the axle with the wrench flats facing outward.

Note: Do not thread the spacer nut all of the way onto the end of the axle. Leave approximately 3 mm (1/8 inch) from the outer surface of the spacer nut to the end of the axle inside the nut.

-

Insert the assembled nut and axle into the wheel on the side of the wheel with the new seal and bearing.

-

With the open end of the wheel facing up, fill the area inside the wheel around the axle full of general-purpose grease.

-

Insert the second bearing and the new seal into the wheel.

-

Apply thread-locking adhesive to the second spacer nut, threading it onto the axle with the wrench flats facing outward.

-

Torque the nut to 8 to 9 N∙m (71 to 80 in-lb), loosen it, then torque it to 2 to 3 N∙m (20 to 25 in-lb).

Note: Make sure that the axle does not extend beyond either nut.

-

Install the seal guards over the wheel hub and insert the wheel into the caster fork.

-

Install the caster bolt and tighten the nut fully.

Important: To prevent seal and bearing damage, check the bearing adjustment often by spinning the caster wheel. The wheel should not spin freely (more than 1 or 2 revolutions) or have any side play. If the wheel spins freely, adjust the torque on the spacer nut until there is a slight amount of drag, then apply thread-locking adhesive.

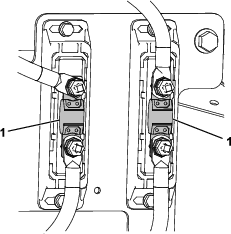

Electrical System Maintenance

Using the Battery-Disconnect Switch

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Unplug the battery charger if it is connected.

-

Turn the battery-disconnect switch to the ON or OFF position.

Servicing the Batteries

Note: The machine is equipped with 8 lithium-ion batteries.

A lithium-ion battery must be disposed of or recycled in accordance with local and federal regulations. If a battery requires service, contact your Authorized Service Dealer for assistance.

Do not open the battery. If you are having problems with a battery, contact your Authorized Service Dealer for assistance.

Maintaining the Lithium-Ion Batteries

Warning

The batteries contain high voltage, which could burn or shock you.

-

Do not attempt to open the batteries.

-

Use extreme care when handling a battery with a cracked case.

-

Use only the charger designed for the batteries.

The lithium-ion batteries hold a sufficient charge to perform intended work during its life span.

To achieve maximum life and use from your batteries, follow these guidelines:

-

Do not open the battery.

-

Store/park the machine in a clean, dry garage or storage area, away from direct sunlight, heat sources, rain, and wet conditions. Do not store it in a location where the temperature exceeds the range specified in Battery Storage Requirements. Temperatures outside of this range will damage your batteries. High temperatures during storage, especially at a high state of charge, reduces the life of the batteries.

-

When storing the machine for more than 10 days, ensure that the machine is in a cool and dry location, out of sunlight, rain, and wet conditions.

-

If you are mowing in hot conditions or in strong, direct sunlight, the battery may overheat. If this happens, a high-temperature alert will appear on the InfoCenter, the cutting units will disengage, and the machine will slow down.

Immediately drive the machine to a cool location out of the sun, turn off the machine, and allow the batteries to cool fully before resuming operation.

-

Maintain the sharpness of the mower blades. A dull blade increases power consumption and reduces the amount of work that the machine performs on each charge.

-

Use lights only when it is necessary.

Maintaining the Battery Charger

Important: All electrical repairs should be performed by an Authorized Toro Dealer only.

The charger requires little maintenance other than protecting it from damage and weather.

-

Clean the battery-charger cords and case with a slightly damp cloth after each use.

Note: Do not clean the dielectric grease from the terminals.

-

Coil the cords when not in use.

-

Periodically examine the cords for damage, and replace them when necessary with Toro-approved parts.

Locating the Fuses

The electrical system is protected by fuses. It requires no maintenance. Refer to the Service Manual for information on testing and servicing the fuses.

Release the cushion from the rear of the machine and remove the rear access cover to access the fuses.

Drive System Maintenance

Checking the Tire Pressure

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Maintain the air pressure in the rear tires at 83 to 97 kPa (12 to 14 psi).

Important: Uneven tire pressure can cause an uneven cut.

Note: The front tires are semi-pneumatic tires and do not require air-pressure maintenance.

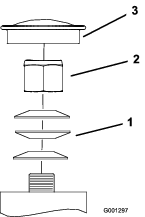

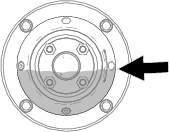

Adjusting the Caster-Pivot Bearing

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 500 hours |

|

-

Disengage the blade-control switch (PTO) and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the dust cap from the caster.

-

Tighten the locknut until the spring washers are flat, and then back off a 1/4 turn to properly set the preload on the bearings.

Important: Make sure that the spring washers are installed correctly as shown.

-

Install the dust cap.

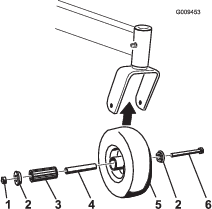

Servicing the Caster Wheels and Bearings

The caster wheels rotate on a roller bearing supported by a spanner bushing. If the bearing is kept well lubricated, wear will be minimal. Failure to keep the bearing well lubricated causes rapid wear. A wobbly caster wheel usually indicates a worn bearing.

-

Disengage the blade-control switch (PTO) and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the locknut and wheel bolt holding the caster wheel to the caster fork.

-

Remove 1 bushing, then pull the spanner bushing and roller bearing out of the wheel hub.

-

Remove the other bushing from the wheel hub and clean any grease and dirt from the wheel hub.

-

Inspect the roller bearing, bushings, spanner bushing and the inside of the wheel hub for wear.

Note: Replace any damaged or worn parts.

-

Place 1 bushing into the wheel hub.

-

Grease the roller bearing and spanner bushing, and slide them into the wheel hub.

-

Place the second bushing into the wheel hub.

-

Install the caster wheel into the caster fork and secure it with the wheel bolt and locknut.

-

Tighten the locknut until the spanner bushing bottoms against the inside of the caster forks.

-

Grease the fitting on the caster wheel.

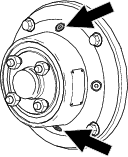

Checking the Wheel-Lug Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

Check and torque the wheel-lug nuts to 75 to 88 N∙m (55 to 65 ft-lb).

Changing the Transmission Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 500 hours |

|

Fluid type: Toro Synthetic Electric Motor Drive Oil

Capacity: 150 mL (5 fl oz)

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the tire.

-

Place a drain pan under the transmission.

-

Remove the top plug and bottom plug. Allow the fluid to drain.

-

Install the bottom plug and torque it to 7 to 8 N∙m (62 to 70 in-lb).

-

Remove a side plug.

-

Add fluid, as specified at the beginning of this procedure, through the top hole until the level reaches the side plug opening.

-

Install the top plug and side plug . Torque them to 7 to 8 N∙m (62 to 70 in-lb).

-

Install the tire and torque the lug nuts to 75 to 88 N∙m (55 to 65 ft-lb).

-

Repeat for the other transmission.

Controls System Maintenance

Calibrating the Levers

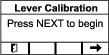

Note: The InfoCenter displays only 2 items at a time; however, the following figures show the full menus for context.

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Enable access to protected menus; refer to Accessing Protected Menus.

-

In the MAIN MENU, scroll down to SERVICE and press the

button .

button .

-

In the SERVICE menu, scroll down to LEVER CALIBRATION and press the

button.

button.

-

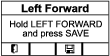

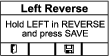

Follow the prompts on the screen. Press the

button after each step;

to exit calibration, press the Exit button.

button after each step;

to exit calibration, press the Exit button.Screen Action

Press the  button.

button.

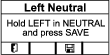

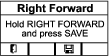

Hold the left motion-control lever in the full FORWARD position and press the  button.

button.

Hold the left motion-control lever in the full REVERSE position and press the  button.

button.

Hold the left motion-control lever in the NEUTRAL position and press the  button.

button.

Hold the right motion-control lever in the full FORWARD position and press the  button.

button.

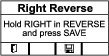

Hold the right motion-control lever in the full REVERSE position and press the  button.

button.

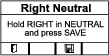

Hold the right motion-control lever in the NEUTRAL position and press the  button.

button.

Press the  button.

button. -

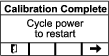

When you complete, exit, or fail calibration, shut off then start the machine to clear the screen.

Adjusting the Tracking

If you push both motion-control levers forward the same distance and the machine pulls to 1 side, adjust the tracking as follows.

Note: The InfoCenter displays only 2 items at a time; however, the following figures show the full menus for context.

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

In the MAIN MENU, scroll down to SERVICE and press the

button.

button.

-

In the SERVICE menu, scroll down to TRACKING and press the

button.

button.

-

Adjust the tracking to the left or right.

Note: Adjusting the tracking to the left causes the machine to steer toward the left; adjusting the tracking to the right causes the machine to steer toward the right.

-

Press the

button.

button.

Adjusting the Motion-Control Levers

If the motion-control levers do not align horizontally, adjust the motion-control levers.

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Turn the battery-disconnect switch to the OFF position.

-

Push the motion-control levers down out of the PARK position.

-

Check the horizontal alignment of both levers by using the front or rear reference bar as a guide.

Note: If a lever is not aligned, proceed to step 6 to adjust the cam for that lever.

-

Release the cushion from the rear of the machine and remove the rear access cover.

-

Loosen the bolt holding the cam.

-

Adjust the cam until it aligns with the front or rear reference bar and tighten the bolt for the cam.

Note: Moving the cam clockwise lowers the handle; moving the cam counterclockwise raises the handle.

Important: Ensure that the flat portion of the cam does not go above a vertical position (right or left); otherwise you may damage the switch.

-

Install the rear access cover and operator cushion.

Mower Deck Maintenance

Servicing the Cutting Blades

To ensure a superior quality of cut, keep the blades sharp. For convenient sharpening and replacement, keep extra blades on hand.

Before Inspecting or Servicing the Blades

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Unplug the battery charger if it is connected.

-

Turn the battery-disconnect switch to the OFF position.

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Inspect the cutting edges.

-

If the edges are not sharp or have nicks, remove and sharpen the blade; refer to Sharpening the Blades.

-

Inspect the blades, especially in the curved area.

-

If you notice any cracks, wear, or a slot forming in this area, immediately install a new blade.

Checking for Bent Blades

Warning

A blade that is bent or damaged could break apart and could critically injure you or bystanders.

-

Always replace a bent or damaged blade with a new blade.

-

Do not file or create sharp notches in the edges or surfaces of the blade.

-

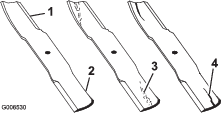

Rotate the blades until the ends face forward and backward.

-

Measure from a level surface to the cutting edge, position A, of the blades.

-

Rotate the opposite ends of the blades forward.

-

Measure from a level surface to the cutting edge of the blades at the same position as in step 2 above.

Note: The difference between the dimensions obtained in steps 2 and 3 must not exceed 3 mm (1/8 inch).

Note: If this dimension exceeds 3 mm (1/8 inch), replace the blade.

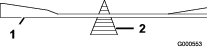

Removing the Blades

Replace the blades if they hit a solid object or if the blade is out of balance or bent.

-

Place a wrench on the flat of the blade retainer or hold the blade end using a rag or thickly padded glove.

-

Remove the blade bolt, washer, and blade from the spindle shaft.

Sharpening the Blades

-

Use a file to sharpen the cutting edge at both ends of the blade.

Note: Maintain the original angle.

Note: The blade retains its balance if the same amount of material is removed from both cutting edges.

-

Check the balance of the blade by putting it on a blade balancer.

Note: If the blade stays in a horizontal position, the blade is balanced and can be used. If the blade is not balanced, file some metal off the end of the sail area only.

-

Repeat this procedure until the blade is balanced.

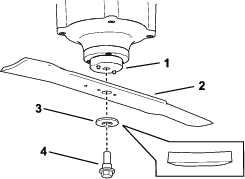

Installing the Blades

Warning

Operating a machine after incorrectly installing the blade assembly and/or not using genuine Toro blade and blade hardware could allow a blade or blade component to be thrown out from under the deck, resulting in serious injury or death.

Always install genuine Toro blades and blade hardware according to the instructions.

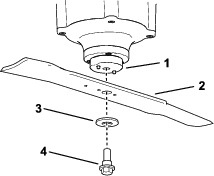

-

Install the blade to the shaft.

Note: Ensure that the washer curves downward, as shown, to ensure proper cutting.

-

Place a wrench on the flat of the spindle shaft and torque the blade bolt to 75 to 81 N∙m (55 to 60 ft-lb).

Leveling the Mower Deck

Preparing the Machine

Ensure that the mower deck is level any time you install the mower deck or when you see an uneven cut on your lawn.

Level the mower deck side to side before adjusting the front-to-rear slope.

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Unplug the battery charger if it is connected.

-

Turn the battery-disconnect switch to the OFF position.

-

Check the tire pressure of both drive tires; refer to Checking the Tire Pressure.

-

Check the mower deck for bent blades; remove and replace any bent blades; refer to Servicing the Cutting Blades.

-

Lower the mower deck to the 76 mm (3 inch) height-of-cut position.

Checking the Mower Deck Side-to-Side Height

-

Adjust the rear-tire pressure.

-

Set the slope of the mower deck to the lowest setting; refer to Adjusting the Slope of the Mower Deck.

-

Ensure that the blades are not bent; refer to Servicing the Cutting Blades.

-

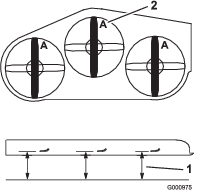

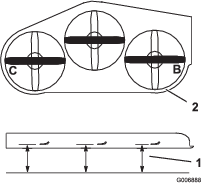

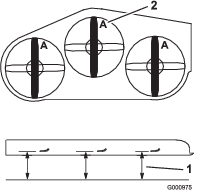

Position the blades side to side.

-

Measure at the B and C locations from a level surface to the cutting edge of blade tips.

-

The difference between measurements B and C should be no more than 6 mm (1/4 inch).

Note: If it is not correct, refer to Leveling the Mower Deck from Side to Side.

Leveling the Mower Deck from Side to Side

-

Loosen the side nut and jam nut in the yokes you want to adjust.

-

Rotate the top bolt of the yokes to adjust the height of the mower deck.

Note: Rotate the bolts clockwise to raise the deck; rotate the bolt counterclockwise to lower it.

-

Tighten the jam nuts and side bolts.

-

Check the side-to-side height; refer to Checking the Mower Deck Side-to-Side Height.

Checking the Mower Deck Front-to-Rear Pitch

-

Adjust the tire pressure in the rear tires to the correct specifications.

-

Set the slope of the mower deck to the lowest setting; refer to Adjusting the Slope of the Mower Deck.

-

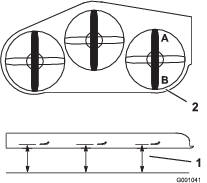

With the machine on level surface, position 1 blade front-to-rear.

-

Measure at A and B locations from a level surface to the cutting edge of the blade tips.

Note: The mower blade should be 6 mm (1/4 inch) lower in front at A than in the rear at B.

-

Rotate the blades and repeat for other blades.

-

If the front-to-rear pitch is not correct, refer to Leveling the Mower Deck from Front to Rear.

Leveling the Mower Deck from Front to Rear

-

Loosen the jam nut and side bolt in the yokes that you want to adjust.

-

Rotate the top bolt of the yokes to adjust the height of the mower deck.

Note: Rotate the bolt clockwise to raise the deck; rotate the bolt counterclockwise to lower it.

-

Tighten the jam nuts and side bolts.

-

Check the front-to-rear pitch; refer to Checking the Mower Deck Front-to-Rear Pitch.

Matching the Height-of-Cut

-

Check the rear tire pressure.

-

Set the height-of-cut to the 76 cm (3 inch) position.

-

With the machine on level surface, position 1 blade front-to-rear.

-

Measure at A, and from a level surface to the cutting edge of the blade tips.

Note: The measurement should be 76 cm (3 inches).

-

If the measurement is not correct, locate the front 2 yokes on the machine.

-

Loosen the side bolt and jam nut of the yokes.

-

Adjust the top bolt of the yokes until the blade tips match 76 cm (3 inches).

-

Tighten the jam nuts and side bolts.

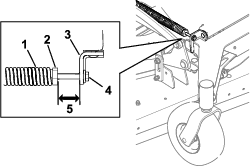

Adjusting the Deck-Lift Spring

Note: Adjusting the compression spring alters how much the deck floats and the amount of effort needed to lift the deck when using the height-of-cut lever.

-

More spring extension reduces the lever lift force required and causes the deck to float more.

-

Less spring extension increases the lever lift force required and causes the deck to float less.

-

Raise the height-of-cut lever and lock it into the transport position.

-

Verify that the distance between the spring nut and the rear side of the welded mount bracket is 41 mm (1-5/8 inch).

-

If needed, adjust the distance by adjusting the bolt on the front of the mount bracket.

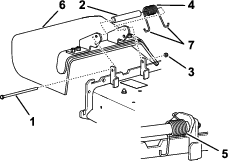

Replacing the Grass Deflector

Danger

An uncovered discharge opening allows objects to be thrown toward you or bystanders. Also, contact with the blade could occur. Thrown objects or blade contact will cause serious injury or death.

Do not operate the mower with the discharge deflector raised, removed, or altered unless a grass collection system or mulch kit is in place and working properly.

-

Remove the locknut, bolt, spring, and spacer holding the deflector to the pivot brackets.

-

Remove the damaged or worn grass deflector.

-

Place the spacer and the spring onto the grass deflector.

-

Place 1 J-hook end of the spring behind the deck edge.

Note: Make sure that 1 J-hook end of spring is installed behind deck edge before installing the bolt as shown in Figure 74.

-

Install the bolt and the nut.

-

Place 1 J-hook end of the spring around the grass deflector.

Important: The grass deflector must be able to rotate. Lift the deflector up to the full open position, and ensure that it rotates into the full-down position.

Cleaning

Cleaning under the Mower Deck

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Remove the grass buildup under the mower daily.

Important: Do not use water to clean the machine. Water can damage the motors and other electric components. Use compressed air to clean debris from the machine.

Warning

Using compressed air improperly to clean the machine could result in serious injury.

-

Wear appropriate personal protective equipment, such as eye protection, hearing protection, and a dust mask.

-

Do not aim compressed air at any part of your body or at anyone else.

-

Refer to the manufacturer’s instructions for the air compressor for operating and safety information.

-

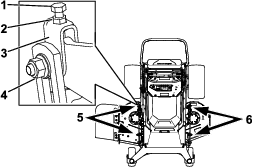

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Turn the battery-disconnect switch to the OFF position.

-

Raise the front of the machine and use jack stands to support the mower.

-

Clean debris from the machine using compressed air.

Disposing of Waste

Engine oil, batteries, hydraulic fluid, and engine coolant are pollutants to the environment. Dispose of these according to your state and local regulations.

Storage

Cleaning and Storage

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before storage |

|

-

Park the machine on a level surface, disengage the PTO, and move the motion-control levers outward to the PARK position.

-

Shut off the machine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove grass clippings, dirt, and grime from the external parts of the entire machine using compressed air.

Important: Do not use water to clean the machine, otherwise you could damage the motors and other electric components.

-

Check the brake; refer to Park Position.

-

Grease the machine; refer to Lubrication.

-

Check the tire pressure; refer to Checking the Tire Pressure.

-

Check and tighten all fasteners. Repair or replace any part that is damaged or missing.

-

Paint all scratched or bare metal surfaces with paint from an Authorized Service Dealer.

-

Store the machine in a clean, dry, garage or storage area. Remove the key from the switch and store it in a memorable place. Cover the machine to protect it and keep it clean.

-

For prolonged storage, follow the battery storage requirements; refer to Battery Storage Requirements.

Battery Storage Requirements

Note: You do not need to remove the batteries from the machine for storage.

Refer to the temperature limits for storage in the following table:

| Storage Temperature | Appropriate Storage Time |

| 45° to 55°C (113° to 131°F) | 1 week |

| 25° to 45°C (77° to 113°F) | 3 weeks |

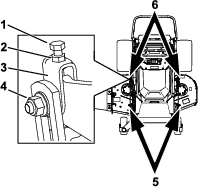

| -20° to 25°C (-4° to 77°F) | 52 weeks |