Maintenance

Greasing the Hub Assembly

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

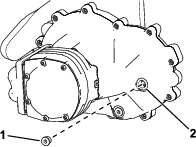

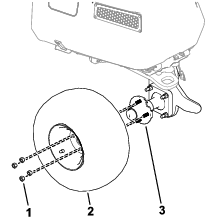

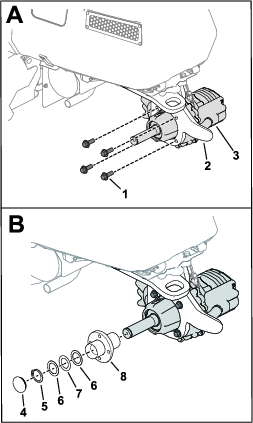

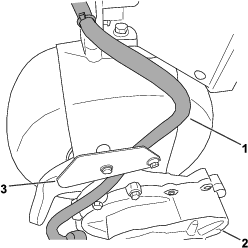

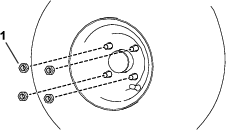

Use No. 2 lithium grease to lubricate the hub assembly. Refer to Figure 10 for the location of the hub-assembly grease fitting.

Changing the Gearbox Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 800 hours |

|

Fluid specification: SAE 80W-90

Gearbox fluid capacity: approximately 1.2 L (40 fl oz)

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Lower the cutting units.

-

Shut off the machine and remove the key.

-

Disconnect the main-power connectors; refer to your machine Operator’s Manual.

Draining the Gearbox Fluid

-

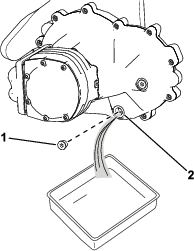

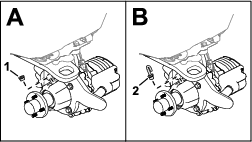

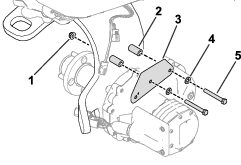

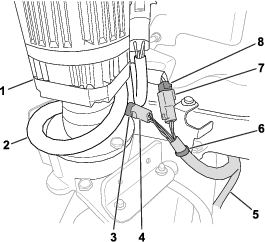

Place a drain pan under the wheel-motor assembly (Figure 11).

-

Remove the plug from the drain port (Figure 11)

Note: The drain port is located on the bottom of the gearbox.

Note: You can loosen the fill-port fitting [shown in Adding Fluid to the Gearbox] to ensure that it can be removed after you drain the fluid.

-

Allow the fluid to drain completely from the gearbox.

-

Clean the plug.

-

Install the drain plug into the drain port (Figure 11).

indicates

that 3-wheel-drive model is activated.

indicates

that 3-wheel-drive model is activated.