|

|

|

|

|

Warning |  |

|

Danger |  |

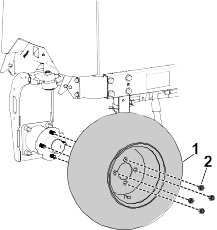

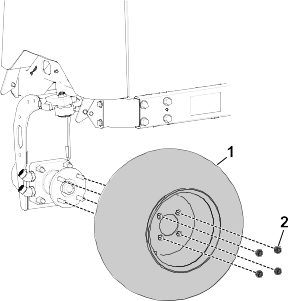

that secure the wheel

that secure the wheel  to the wheel-hub assembly and remove the wheel from the machine.

to the wheel-hub assembly and remove the wheel from the machine.

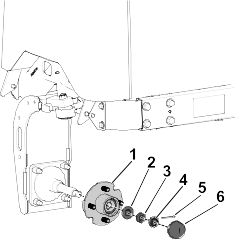

, cotter pin

, cotter pin  , nut retainer

, nut retainer  , jam nut

, jam nut  , tab washer

, tab washer  , and wheel hub

, and wheel hub  .

.

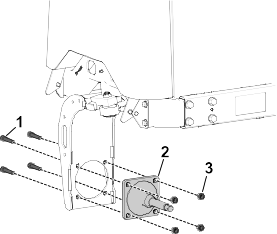

and corresponding mounting bolts

and corresponding mounting bolts  and nuts

and nuts  .

.|

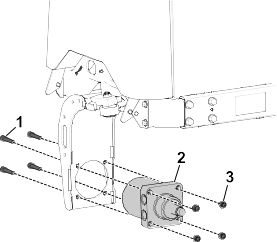

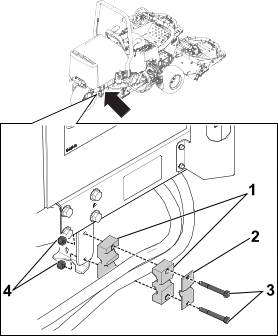

1

|

Hydraulic-motor assembly

|

|

2

|

Hydraulic fitting

|

|

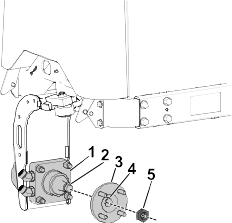

4

|

Bolt (1/2 x 2-3/4 inches)

|

|

4

|

Locknut (1/2 inch)

|

|

1

|

Wheel-hub assembly

|

|

4

|

Lug nut

|

|

1

|

Locknut (1-1/2 inches)

|

to the steering fork with 4 bolts (1/2 x 2-3/4 inches)

to the steering fork with 4 bolts (1/2 x 2-3/4 inches)  and 4 locknuts (1/2 inch)

and 4 locknuts (1/2 inch)  .

.

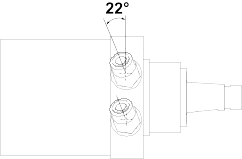

on the hydraulic-motor assembly

on the hydraulic-motor assembly  . Ensure that the groove

. Ensure that the groove  in the hub is aligned with the key

in the hub is aligned with the key  on the motor.

on the motor. until it is lightly seated against the hub.

until it is lightly seated against the hub.

to the wheel hub by lightly seating the 4 lug nuts

to the wheel hub by lightly seating the 4 lug nuts against the wheel.

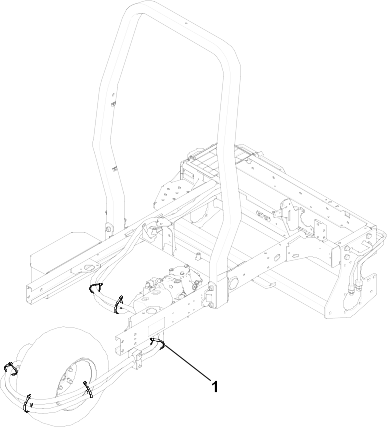

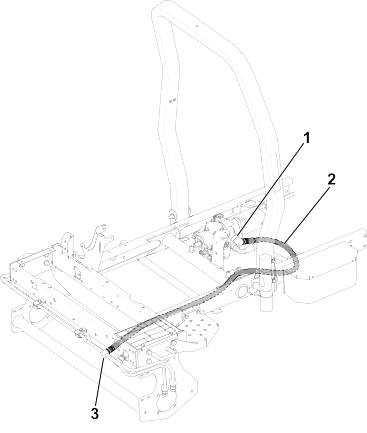

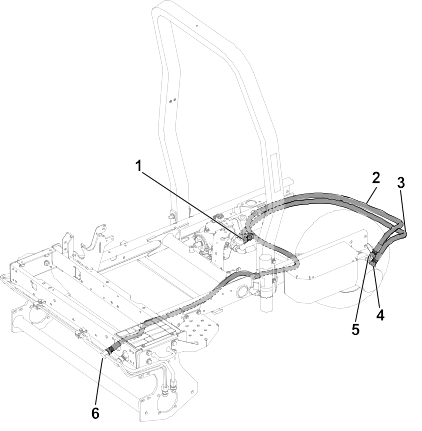

against the wheel. routed between the piston pump

routed between the piston pump and the upper front hydraulic tube

and the upper front hydraulic tube  .

.

|

1

|

Hydraulic hose (70 inches)

|

|

1

|

Hydraulic hose (129 inches)

|

|

2

|

Clamp

|

|

1

|

Clamp case

|

|

2

|

Bolt (5/16 x 2-3/4 inches)

|

|

2

|

Locknut (5/16 inch)

|

|

6

|

Cable tie

|

to the lower hydraulic fitting

to the lower hydraulic fitting  on the hydraulic-motor assembly. Route the other end of the hose to the piston pump

on the hydraulic-motor assembly. Route the other end of the hose to the piston pump  and connect it to the open fitting on the pump.

and connect it to the open fitting on the pump. to the upper fitting

to the upper fitting  on the hydraulic-motor assembly. Route the other end of the hose to the upper front hydraulic tube

on the hydraulic-motor assembly. Route the other end of the hose to the upper front hydraulic tube  and connect it to the open fitting on the tube.

and connect it to the open fitting on the tube.

and clamp case

and clamp case  using 2 bolts (5/16 x 2-3/4 inches)

using 2 bolts (5/16 x 2-3/4 inches)  and 2 locknuts (5/16 inch)

and 2 locknuts (5/16 inch)  . Ensure that the hydraulic hoses are routed between the hose clamps as shown.

. Ensure that the hydraulic hoses are routed between the hose clamps as shown.

. Refer to the following figure for the appropriate cable tie locations.

. Refer to the following figure for the appropriate cable tie locations.