|

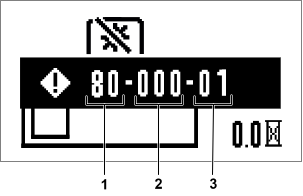

81-XXX-00

82-XXX-00

83-XXX-00

84-XXX-00

85-XXX-00

|

There is a hall signal error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-01

82-XXX-01

83-XXX-01

84-XXX-01

85-XXX-01

|

The hall signal sequence is abnormal.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-02

82-XXX-02

83-XXX-02

84-XXX-02

85-XXX-02

|

The controller started abnormally.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-07

82-XXX-07

83-XXX-07

84-XXX-07

85-XXX-07

|

The motor rotor is locked.

|

Clear any obstructions; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-10

82-XXX-10

83-XXX-10

84-XXX-10

85-XXX-10

|

The motor rotor operates too fast.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-11

82-XXX-11

83-XXX-11

84-XXX-11

85-XXX-11

|

There is an MCU signal error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-12

82-XXX-12

83-XXX-12

84-XXX-12

85-XXX-12

|

The motor current is too high.

|

Restart the machine and reduce the load; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-17

82-XXX-17

83-XXX-17

84-XXX-17

85-XXX-17

|

There is a current overload.

|

Restart the machine and reduce the load; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-19

82-XXX-19

83-XXX-19

84-XXX-19

85-XXX-19

|

There is a current short in the circuit.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-20

82-XXX-20

83-XXX-20

84-XXX-20

85-XXX-20

|

There is a gate driver integrated circuit (IC) component error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-21

82-XXX-21

83-XXX-21

84-XXX-21

85-XXX-21

|

The connector on the motor phase is disconnected.

|

Check for loose connections; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-23

82-XXX-23

83-XXX-23

84-XXX-23

85-XXX-23

|

There is a gate driver IC initialize error.

|

Restart the machine; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-25

82-XXX-25

83-XXX-25

84-XXX-25

85-XXX-25

|

The current ADC signal is abnormal.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-26

82-XXX-26

83-XXX-26

84-XXX-26

85-XXX-26

|

The CAN signal is disconnected.

|

Check for loose connections; if issues persist, contact an Authorized Service Dealer.

|

|

81-XXX-27

82-XXX-27

83-XXX-27

84-XXX-27

85-XXX-27

|

There is an MCU hardware error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-28

82-XXX-28

83-XXX-28

84-XXX-28

85-XXX-28

|

There is a flash data validation error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-29

82-XXX-29

83-XXX-29

84-XXX-29

85-XXX-29

|

There is an MCU non-maskable interrupt error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-30

82-XXX-30

83-XXX-30

84-XXX-30

85-XXX-30

|

There is an MCU error.

|

Contact an Authorized Service Dealer.

|

|

81-XXX-31

82-XXX-31

83-XXX-31

84-XXX-31

85-XXX-31

|

There is a voltage reference error.

|

Contact an Authorized Service Dealer.

|