Note: Reuse any mounting hardware that you removed and is not replaced with hardware from the kit.

Preparing the Machine

-

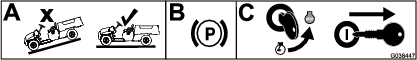

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the machine and remove the key.

Removing the Gas Spring and Lift Bracket

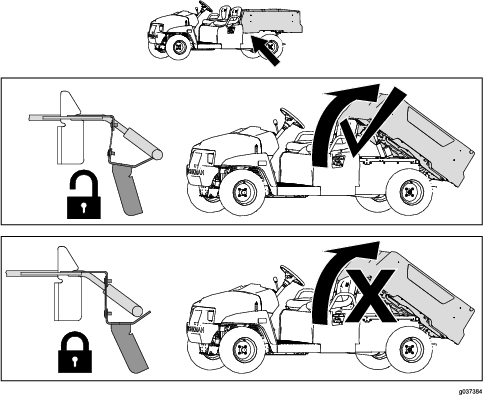

Warning

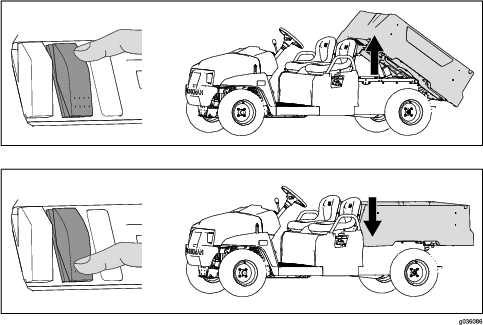

A raised cargo bed could fall and injure persons that are working beneath it.

-

Remove any load material from the bed before raising it.

-

Always properly support the bed in the raised position before working under the bed.

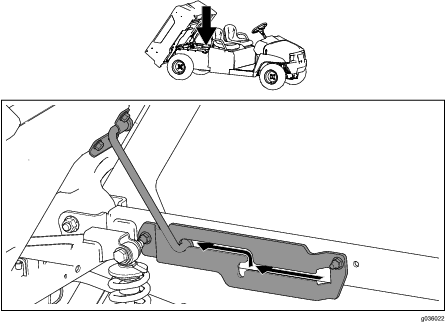

Placing the Bed into the Service Position

Note: If the draw bar is installed on the machine, you must remove it before placing the bed into the service position.

Insert the prop rod into the service position (Figure 4).

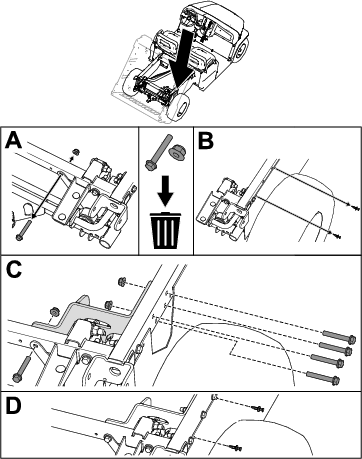

Installing the Lift Bracket

|  |  | ||

| 1x | 5x | 5x |

-

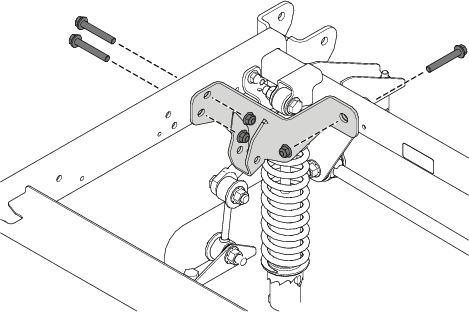

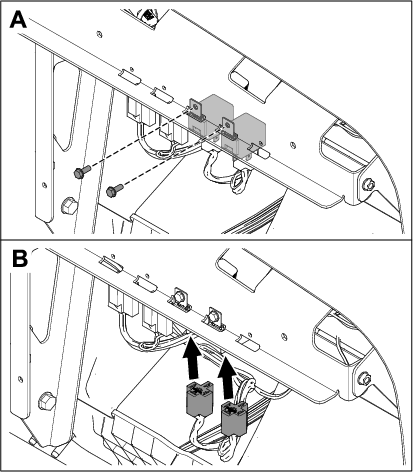

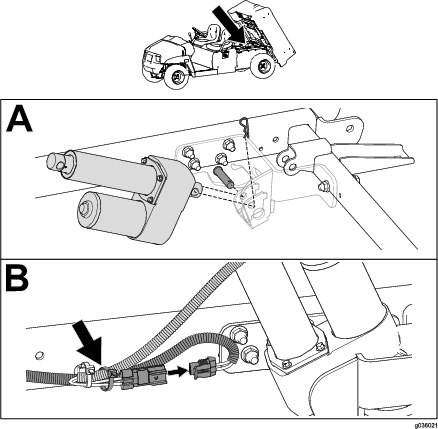

Remove the existing bolt and nut from the rear-frame tube (box A of Figure 5).

Note: Discard the bolt and nut.

-

Remove the 2 existing plastic rivets from the rear-frame tube (box B of Figure 5).

Note: Retain the 2 plastic rivets.

-

Install the lift bracket to the rear-frame tube using the 5 flange-head bolts (3/8 x 2-1/2 inches) and 5 flange nuts (3/8 inch) as shown in box C of Figure 5.

Torque the flange-head bolts (3/8 x 2-1/2 inches) to 37 to 45 N∙m (27 to 33 ft-lb).

-

Install the 2 previously removed plastic rivets into the rear frame tube (box D of Figure 5).

Installing the Lift Latch

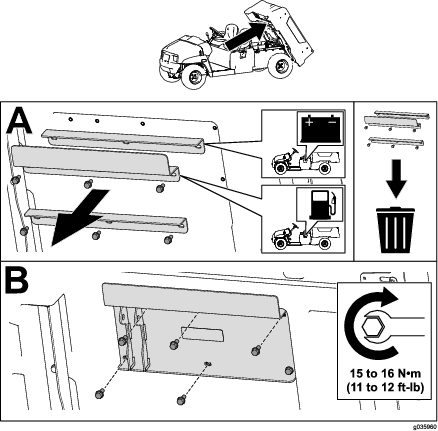

Installing the Lift Plate

|  | ||

| 1x | 6x |

-

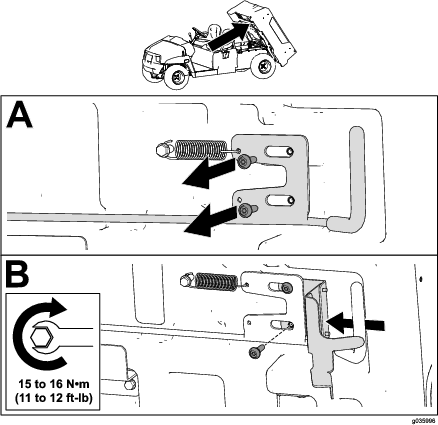

Remove the 6 existing bolts and bed braces from the cargo bed (box A of Figure 7).

Note: Discard the bolts and bed braces.

-

Install the lift plate to the cargo bed using the 6 bolts, and torque the bolts to 15 to 16 N∙m (11 to 12 ft-lb) as shown in box B of Figure 7.

Installing the Fuse

Installing the Relays

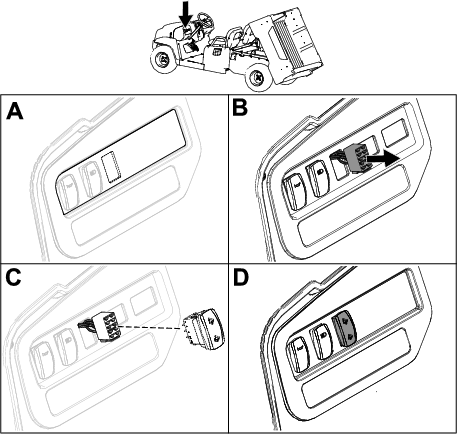

Installing the Switch

| ||||

| 1x |

-

Cut out the opening in the dashboard decal for the switch (box A of Figure 10).

-

Install the switch connector through the opening in the dashboard (box B of Figure 10).

-

Install the switch to the switch connector (box C of Figure 10).

-

Ensure that the switch is oriented properly (box D of Figure 10).

Installing the Lift Cylinder

|  |  |  | ||

| 1x | 2x | 2x | 1x |

Important: Use the cable tie to secure the lift-cylinder wire to the wire harness, away from sharp or moving parts. Ensure that you allow enough slack in the wire harness for its full range of motion.

-

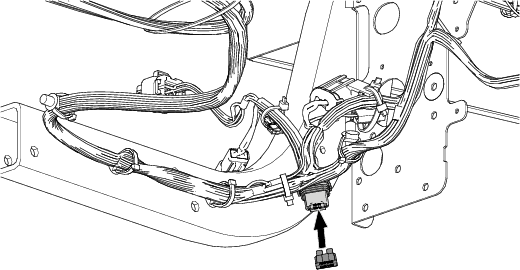

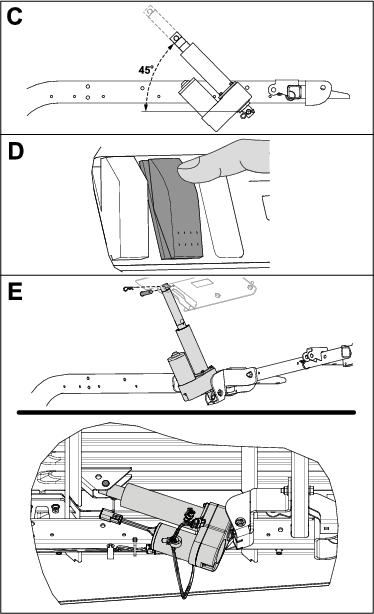

Install the lift cylinder using a clevis pin and hairpin cotter (box A of Figure 11).

-

Connect the wire harness and secure it to the machine rail using the cable tie (box B of Figure 11).

-

Rotate the lift cylinder upward to a 45° angle, then use a block to support the lift cylinder (box C of Figure 12).

-

Press upward on the switch to extend the lift cylinder (box D of Figure 12).

-

Install the extended portion of the lift cylinder to the cargo bed using a clevis pin and hairpin cotter (box E of Figure 12).

Top half—plastic cargo bed; bottom half—steel cargo bed

Important: Use a block to support the lift cylinder so that it extends upward at a 45° angle.

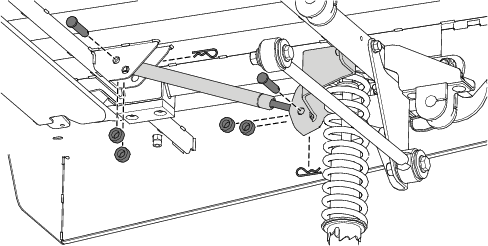

Removing the Prop Rod Assembly

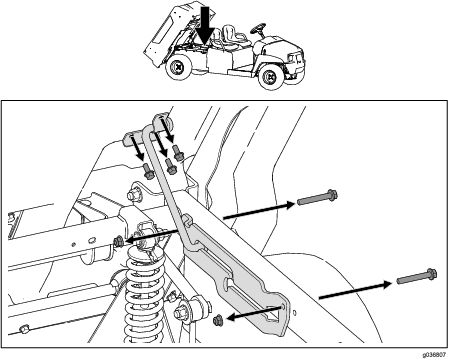

Remove the 2 bolts (3/8 x 2-1/2 inches), 2 flange nuts (3/8 inch), and 3 bolts (5/16 x 3/4 inch) from the prop rod assembly, and remove the prop rod assembly (Figure 13).

Operation

Important: Driving the machine with the cargo bed raised may cause the machine to tip or roll easier. The bed structure may become damaged if you operate the machine with the bed raised.

-

Operate the machine only when the cargo bed is down.

-

After dumping the contents in the cargo bed, lower the bed.

Caution

The bed may be heavy and could crush your hands or other body parts.

Keep your hands and other body parts clear when lowering the bed.

Unlocking and Locking the Bed Latch

Important: Unlock the bed latch when using the electric lift to raise and lower the bed.

Important: Lock the bed latch when using rear attachments.

To unlock the bed latch, pull the bed latch toward you (Figure 14).

To lock the bed latch, push the bed-latch bracket toward the center of the machine until you hear the bed latch lock into position (Figure 14).