-

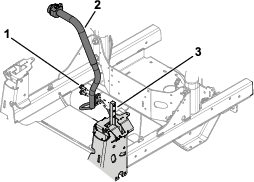

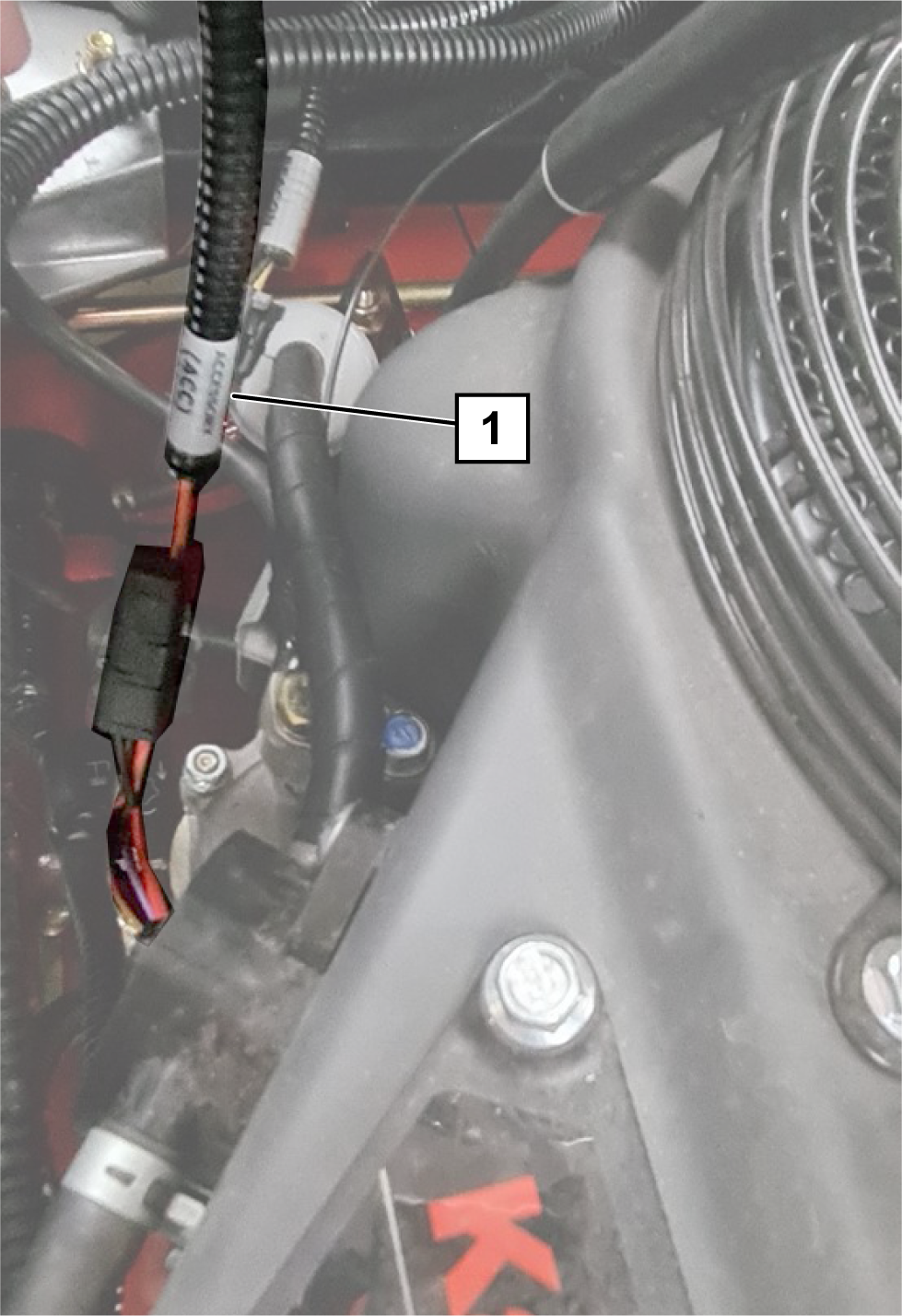

Locate the 2 pin connector on the positive battery

lead of the machine and connect the power adapter wire harness (the

connector marked, ACCESSORY ACC); refer

to Figure 8.

Note: The power adapter wire harness is the smaller harness supplied.

-

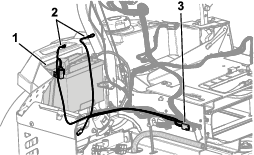

Lay the power adapter wire harness and battery connectors

near (but unable to touch) the battery terminals (Figure 9). Do not

connect the harness to the battery.

Note: Route the small power adapter harness following the positive

battery lead from the battery. Any excess cable length can be gathered

and secured beneath the battery.

-

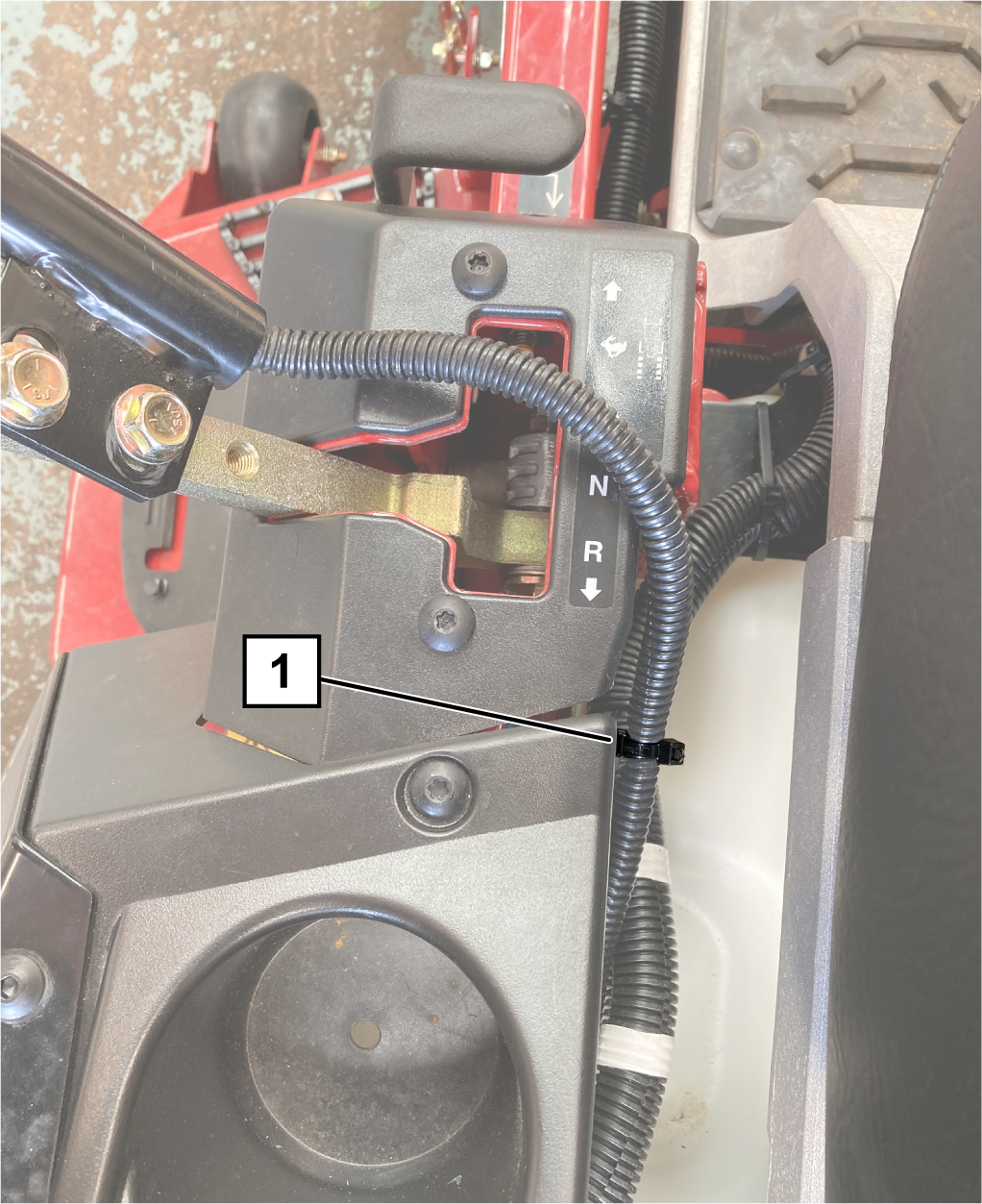

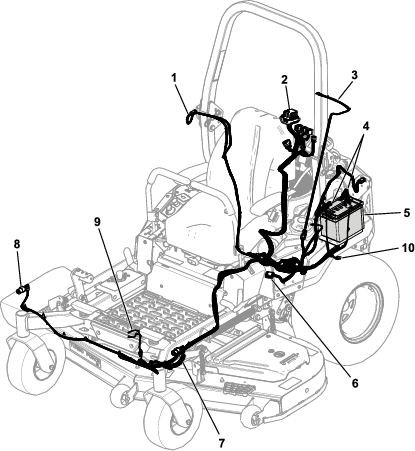

Route the large light kit wire harness by starting

from the control panel.

-

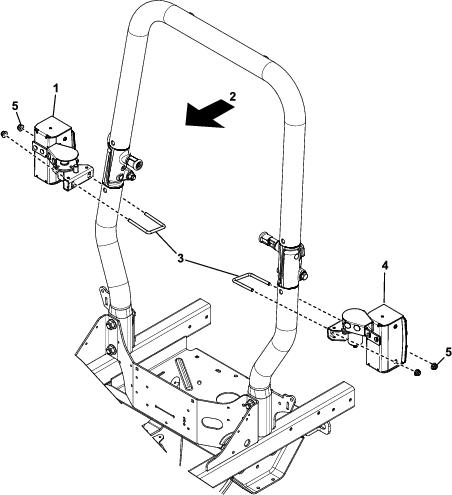

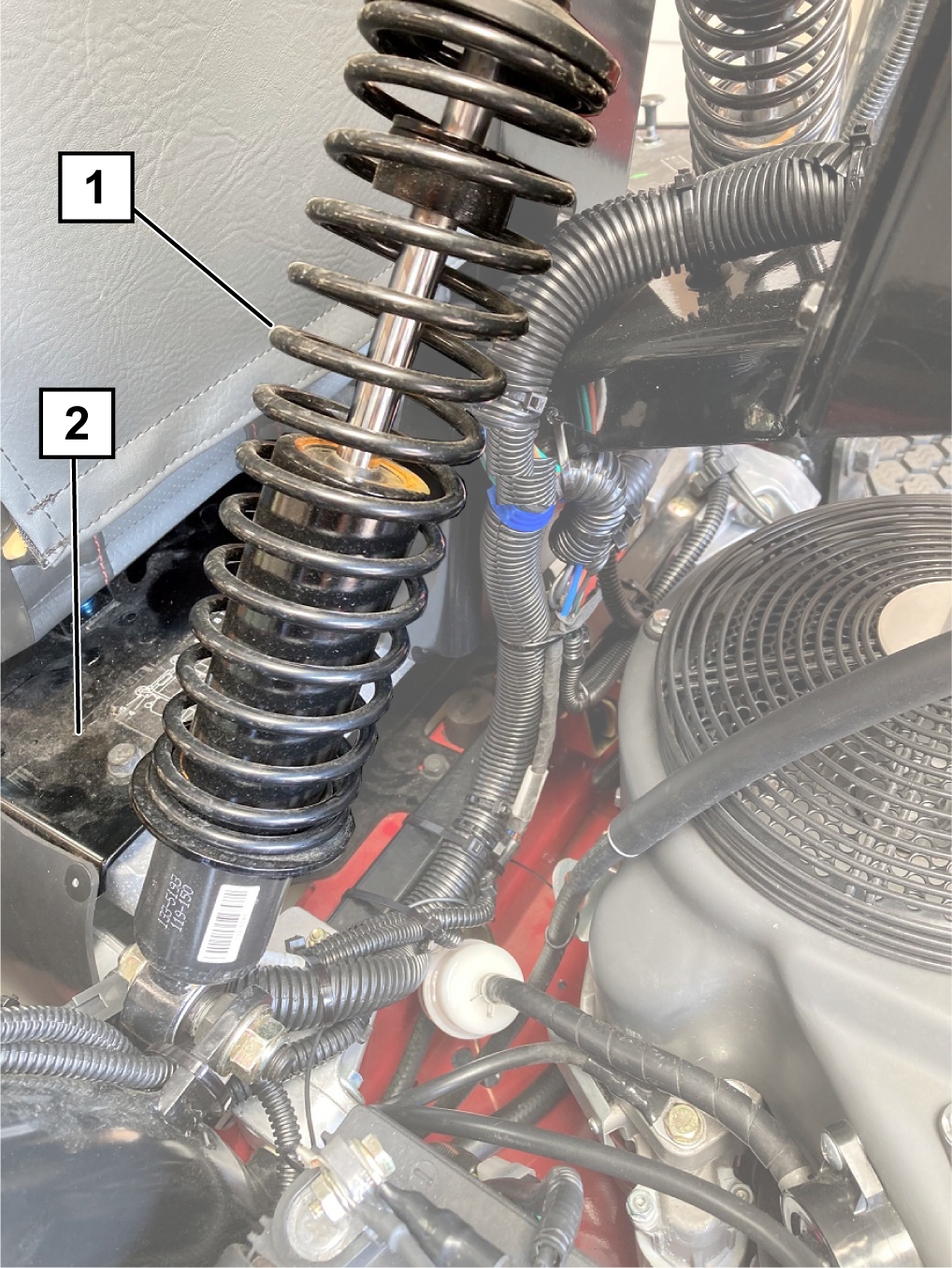

Route the harness down and along the engine side of

the MyRide pivot bar to the left side of the MyRide seat frame (Figure 10).

Note: Allow enough slack in the harness to allow flex when the seat

frame moves up and down. Secure it away from moving parts.

-

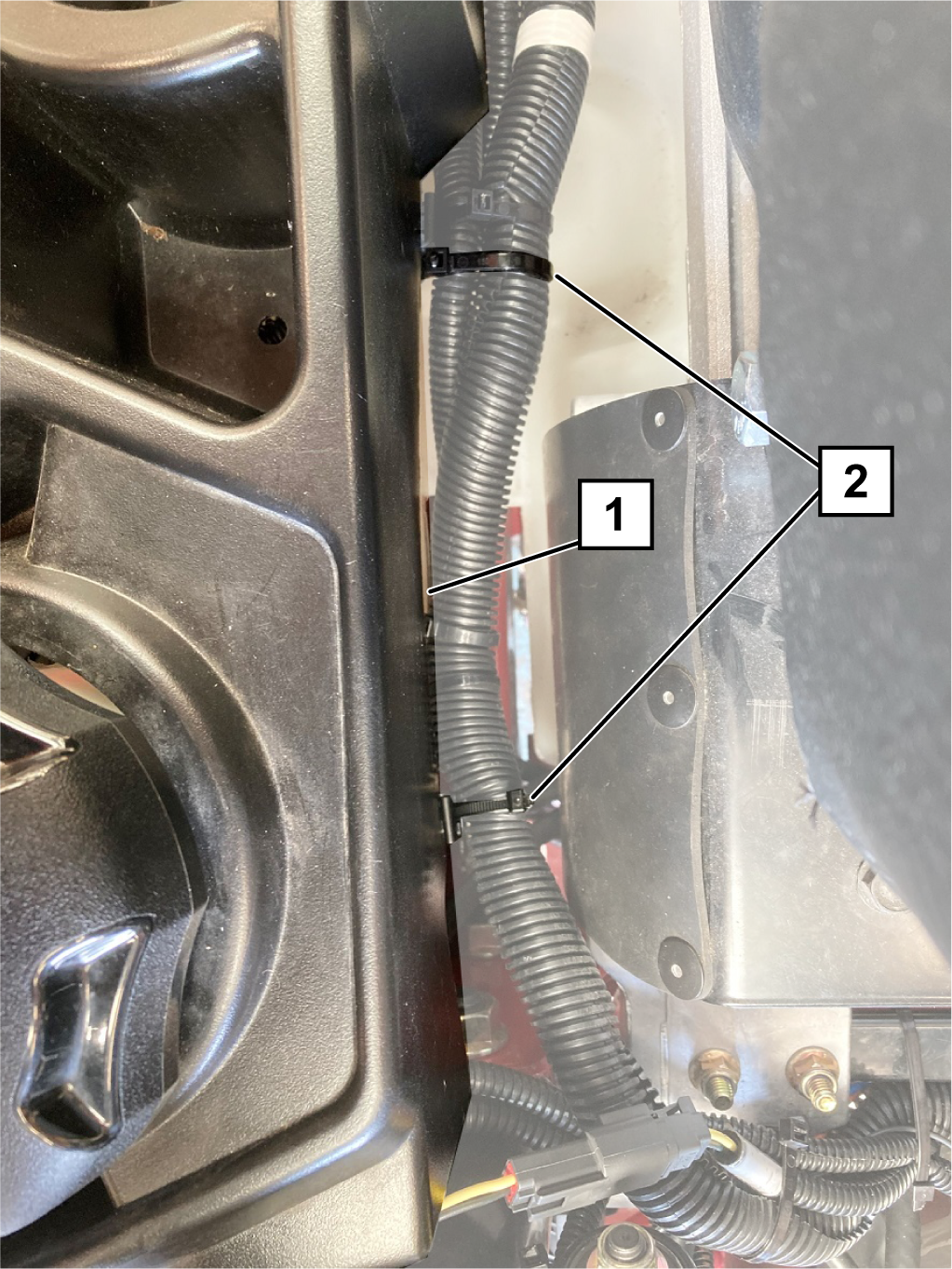

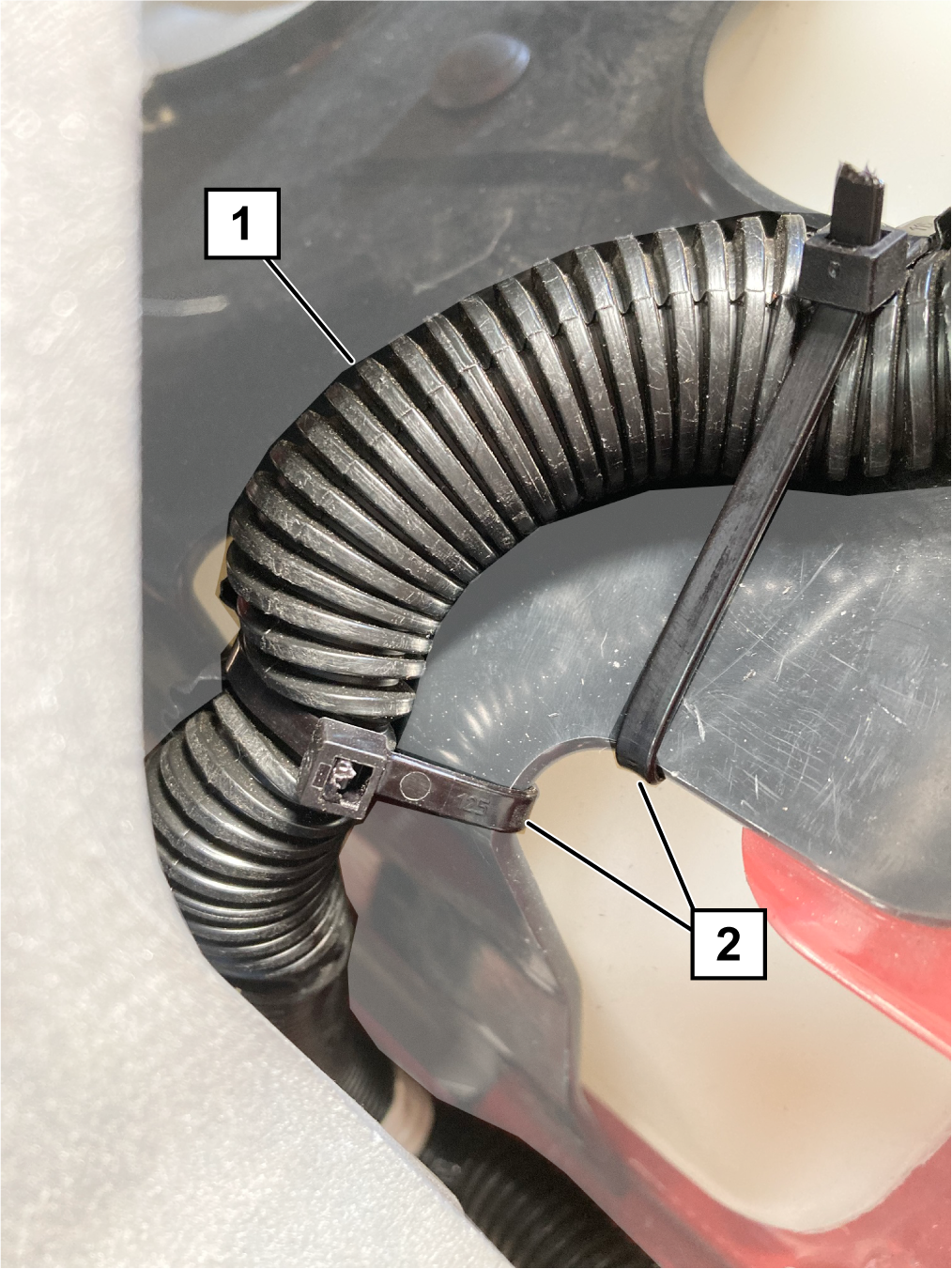

Route the harness along the left side of the MyRide

seat frame and secure the harness with edge clips attached to the

side panels (Figure 11 and Figure 12).

-

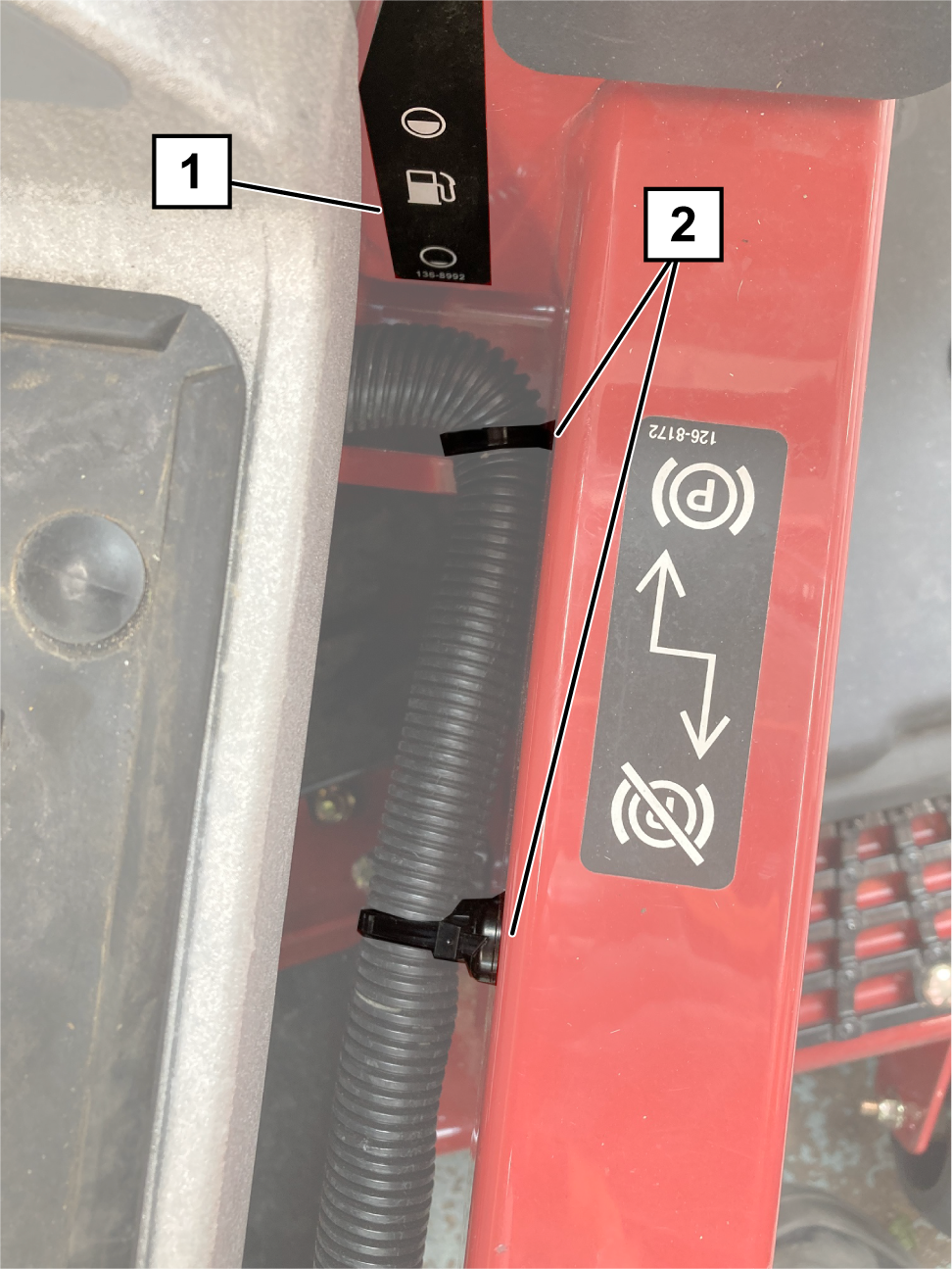

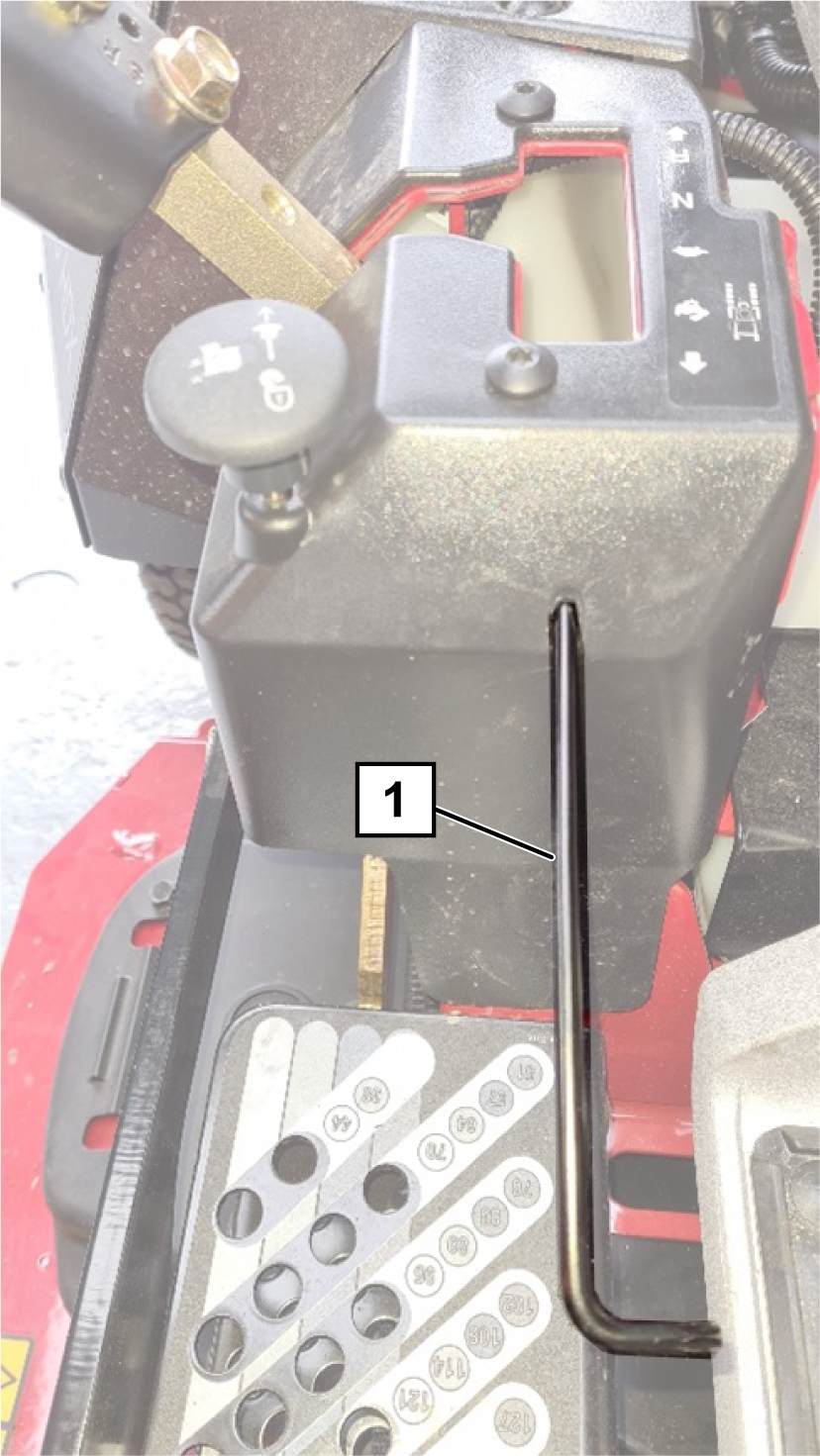

Route the harness under the seat frame toward the

mower deck along the fuel level decal (Figure 13 and Figure 14).

-

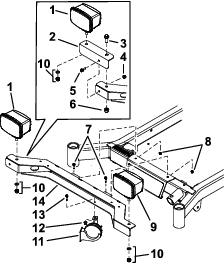

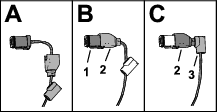

Locate the 2 front light connectors and remove both

parts of the 90° backshell from each connector (Figure 15).

Note: Retain the backshells.

-

Identify and mark the left and right front light connectors.

The right connector has blue, yellow, grey, and black wires. The left

connector has brown, yellow, grey, and black wires.

-

Route the two front light connectors to the correct

front light (Figure 20).

-

Route the two front light connectors through the hole

in the centre of the front light bracket, and to each front light.

-

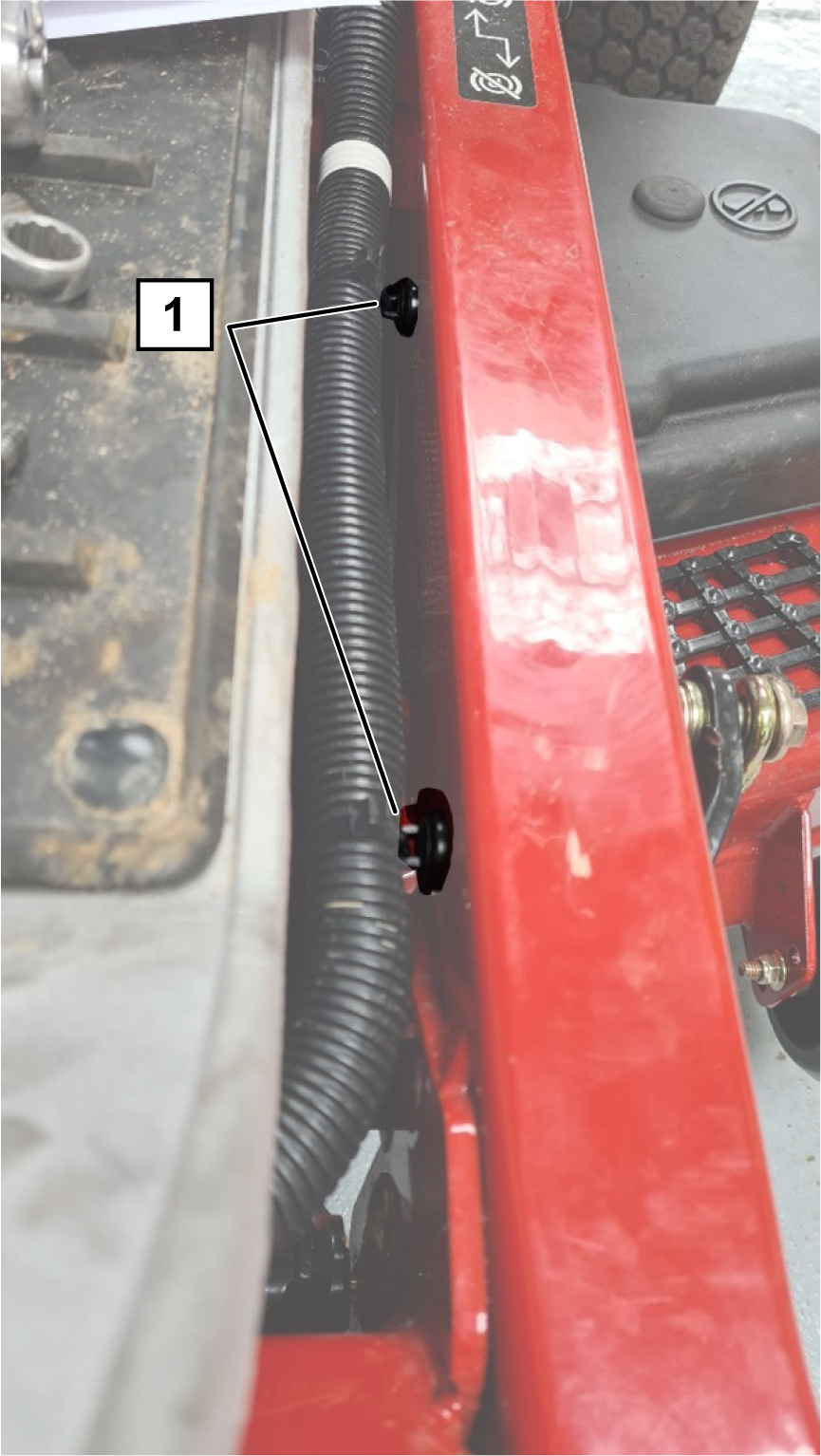

Install 2 anchors to the inside of the left chassis

rail below the operator platform (Figure 16).

-

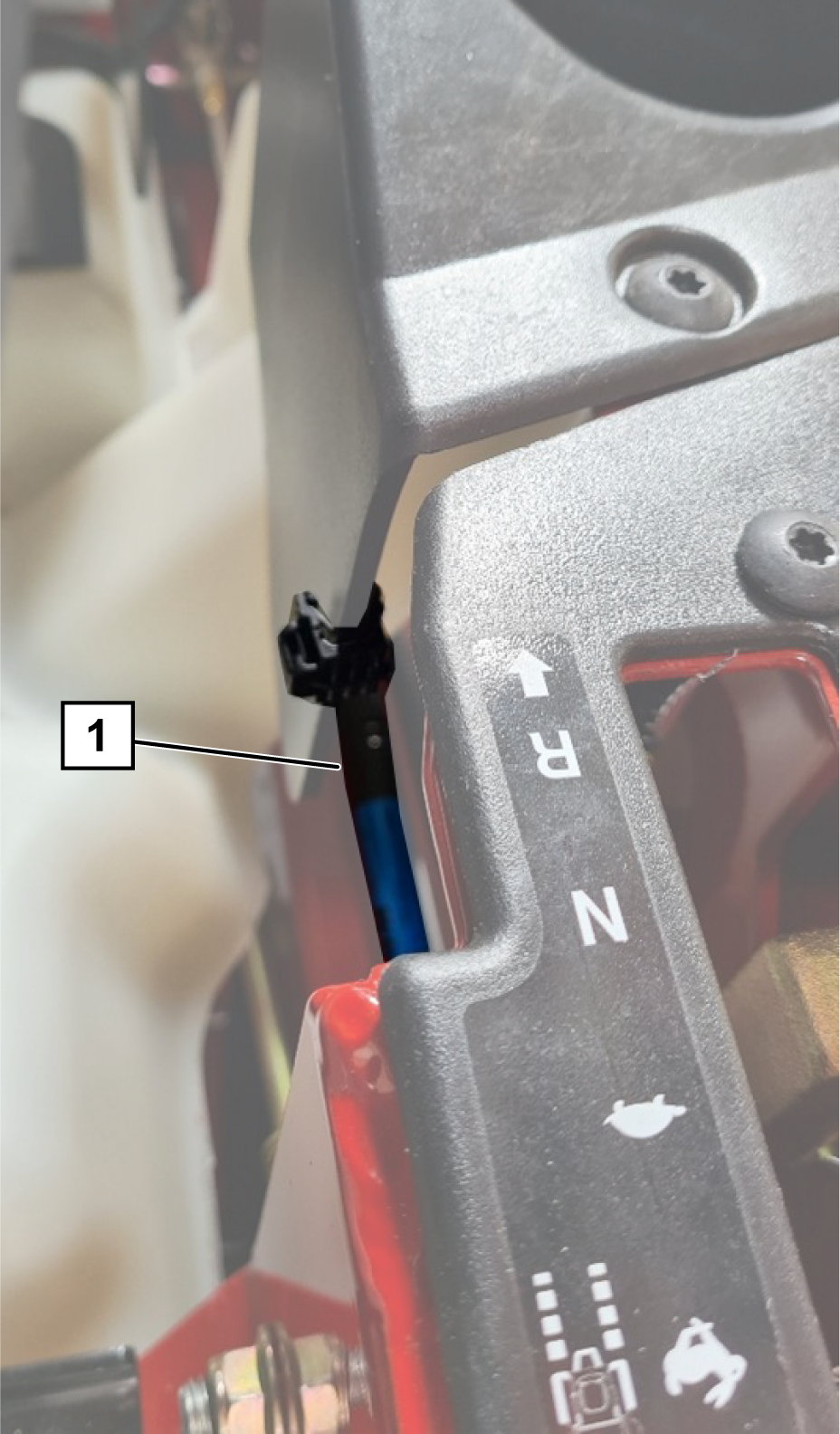

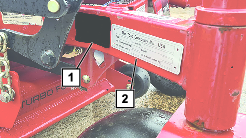

Install the harness clip edge, to the left plastic

side of the operator platform (Figure 17).

-

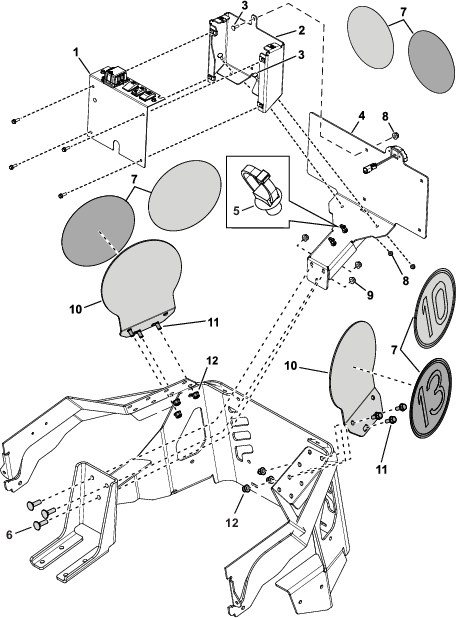

Layout the wiring harness connections to their approximate

positions at the rear of the machine (Figure 20).

-

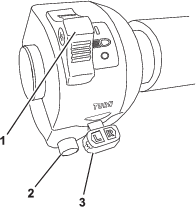

Connect the control lever connector to the light kit

wire harness (Figure 20).

-

Connect the 3 pin accessory connector to the accessory

(ACC) connector of the power adaptor harness installed earlier (Figure 9).

-

Connect the beacon wire harness to the beacon connector

of the light kit wire harness.

-

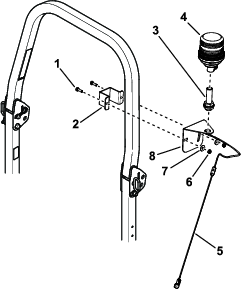

Route the left-rear light connector up the front of

the roll bar frame next to the beacon wire harness. Push connector

through the rear light mount and connect to a rear light with 2 screws

(#10 x 1-1/4 inches); refer to Figure 18.

-

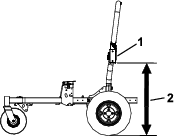

Adjust the light until it is 95 cm (37-1/2 inches)

from the ground.

-

Repeat steps 11 and 12 for the right-rear light.

-

Use cable ties to secure the wires for the rear lights

and beacon harness to the roll bar.

-

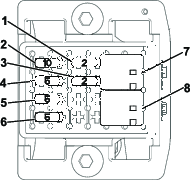

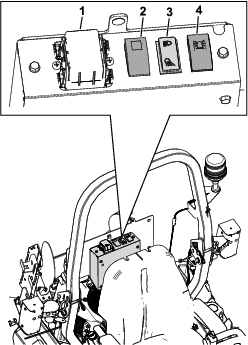

Remove the fuse box cover and install the fuse box

to the control panel with 2 button head screws (M6 x 12 mm); refer

to Figure 4.

-

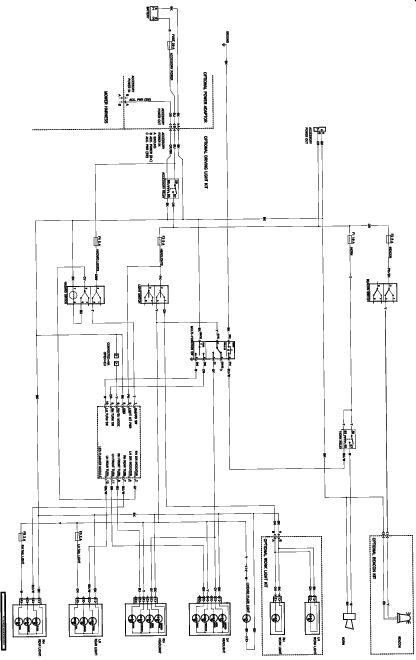

Connect the light kit wire harness to each switch,

to the flasher unit, and to the licence plate light.

-

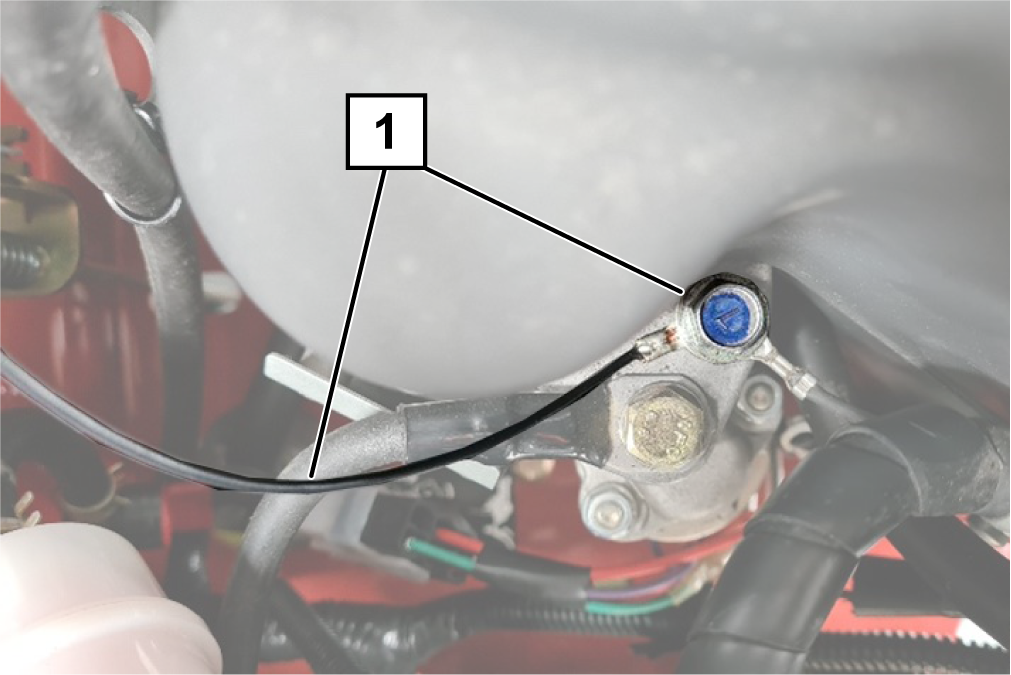

Connect the single black wire from the light kit wire

harness to the ground on top of the engine (Figure 19).

Note: Use the inner connection.

-

Connect the horn (Figure 3).

-

Connect the positive battery cable and positive ring

terminal from the power adaptor harness.

-

Connect the negative battery cable and negative ring

terminal from the power adaptor harness.

-

Secure all the wires and harnesses away from moving

parts and hot parts with cable ties.