| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This machine is a ride-on, rotary-blade lawn mower intended to be used by professional, hired operators in commercial applications. It is primarily designed for cutting grass on well-maintained lawns in parks, sports fields, and on commercial grounds. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

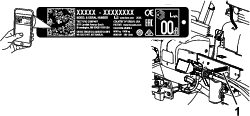

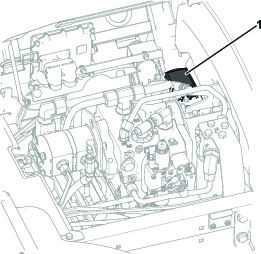

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

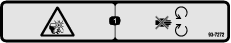

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Warning

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not operate the machine without all guards and other safety protective devices in place and functioning properly on the machine.

-

Keep your hands and feet away from rotating parts. Keep clear of the discharge opening.

-

Keep bystanders and children out of the operating area. Never allow children to operate the machine.

-

Shut off the engine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

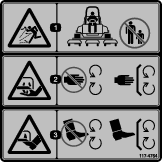

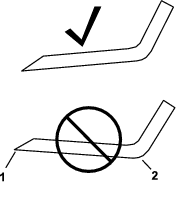

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

CE Machines

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Preparing the Machine

Checking the Tire Pressure

Check the tire pressure before use; refer to Checking the Tire Pressure.

Important: Maintain pressure in all tires to ensure a good quality-of-cut and proper machine performance. Do not underinflate the tires.

Checking the Fluid Levels

-

Check the engine-oil level before starting the engine; refer to Checking the Engine-Oil Level.

-

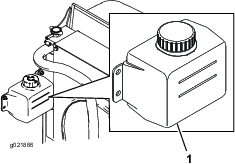

Check the hydraulic-fluid level before starting the engine; refer to Checking the Hydraulic-Fluid Level.

-

Check the cooling system before starting the engine; refer to Checking the Cooling System.

Greasing the Machine

Grease the machine before use; refer to Greasing the Bearings and Bushings. Failure to properly grease the machine results in premature failure of critical parts.

Removing the Shipping Blocks and Pins

-

Remove and discard the shipping blocks from the cutting units.

-

Remove and discard the shipping pins from the cutting-unit suspension arms.

Note: The shipping pins stabilize the cutting units during shipping; remove them before operating the machine.

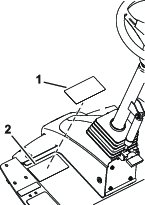

Adjusting the Control Arm Position

You can adjust the control arm position for your comfort.

-

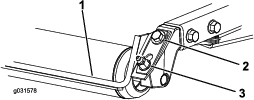

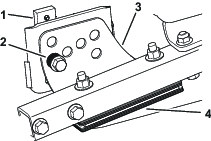

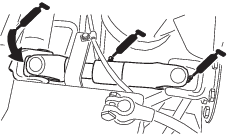

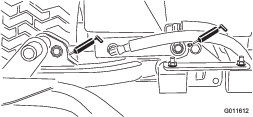

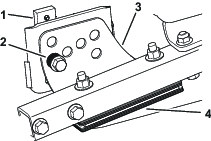

Loosen the 2 bolts securing the control arm to the retaining bracket (Figure 3).

-

Rotate the control arm to the desired position and tighten the 2 bolts.

Adjusting the Machine Software (CE Machines Only)

Contact your authorized Toro distributor to set the machine software to the CE mode.

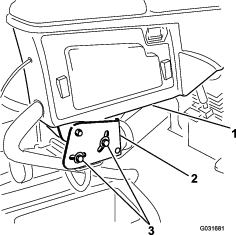

Installing the Hood Latch

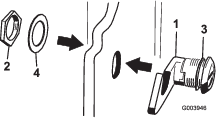

Parts needed for this procedure:

| Hood-latch assembly | 1 |

| Washer | 1 |

-

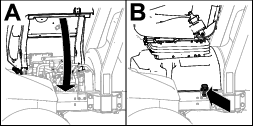

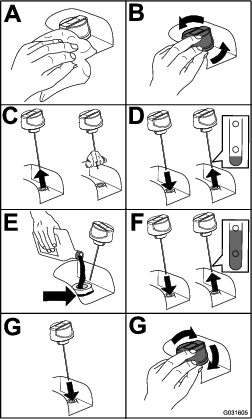

Unlatch and raise the hood.

-

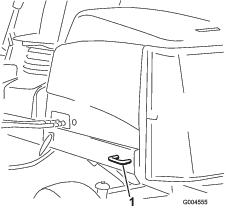

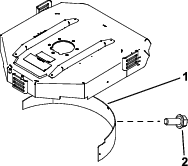

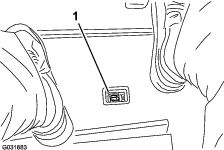

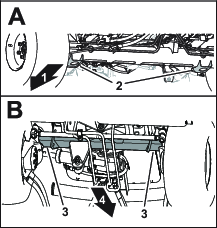

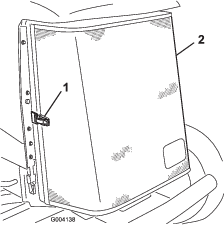

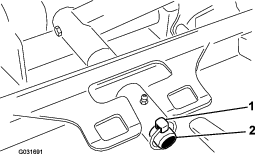

Remove the rubber grommet from the hole in the left side of the hood (Figure 4).

-

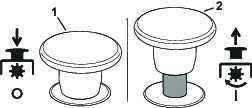

Remove the nut from the hood-latch assembly (Figure 5).

-

On the outside of the hood, insert the hook end of the latch through the hole in the hood and ensure that the rubber-sealing washer remains to the outer side of the hood (Figure 5).

-

On the inside of the hood, insert the metal washer onto the latch, secure the latch with the nut, and ensure that the latch engages the frame catch when it is locked.

Note: Use the enclosed hood-latch key to operate the hood latch.

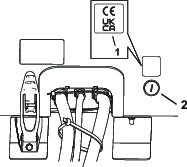

Applying the CE Decals

Parts needed for this procedure:

| CE decal | 1 |

| Production year decal | 1 |

| Warning decal | 1 |

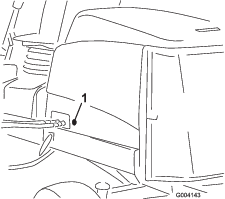

Applying the CE Decal

-

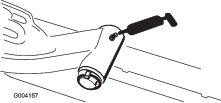

Use rubbing alcohol and a clean rag to clean the area of the hood next to the hood lock, and allow the hood to dry. (Figure 6).

-

Remove the backing from the CE decal.

-

Apply the decal to the hood.

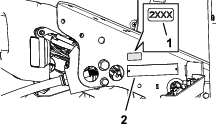

Applying the Year of Production Decal

-

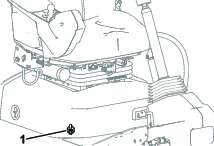

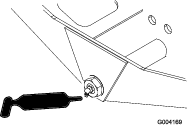

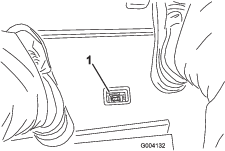

Use rubbing alcohol and a clean rag to clean the floor bracket area next to the serial plate, and allow the bracket to dry (Figure 7).

-

Remove the backing from the year of production decal.

-

Apply the decal to the floor bracket.

Applying the CE Warning Decal

-

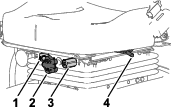

Use rubbing alcohol and a clean rag to clean the surface of warning decal, and allow the decal to dry (Figure 8).

-

Remove the backing from the CE warning decal.

-

Apply the CE warning decal over the existing decal.

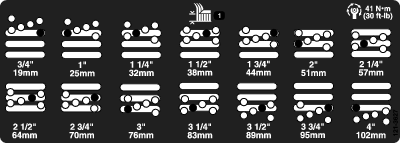

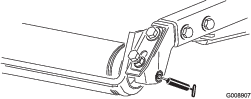

Adjusting the Roller Scraper

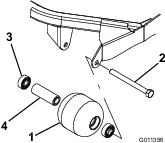

The optional rear roller scraper functions best when there is an even gap of 0.5 to 1 mm (0.02 to 0.04 inch) between the scraper and the roller.

-

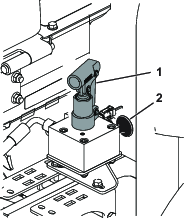

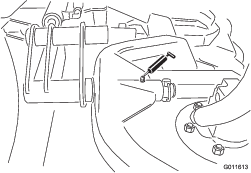

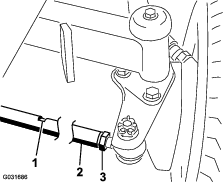

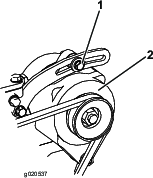

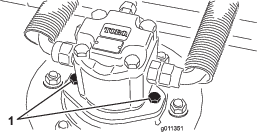

Loosen the grease fitting and the mounting screw (Figure 9).

-

Slide the scraper up or down until you obtain a gap of 0.5 to 1 mm (0.02 to 0.04 inch) between the rod and the roller.

-

Tighten the grease fitting and screw to 41 N∙m (30 ft-lb) in an alternating sequence.

Installing the Mulching Baffle

Contact your authorized Toro distributor for the correct mulching baffle.

-

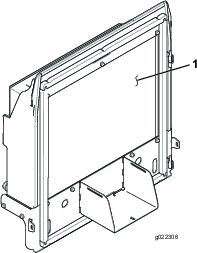

Thoroughly clean debris from the mounting holes on the rear wall and left wall of the chamber.

-

Install the mulching baffle in the rear opening and secure it with 5 flange-head bolts (Figure 10).

-

Verify that the mulching baffle does not interfere with the tip of the blade and does not protrude inside the surface of the rear chamber wall.

Danger

Using the high-lift blade with the mulching baffle could cause the blade to break, resulting in personal injury or death.

Do not use the high-lift blade with the baffle.

Product Overview

Automotive-Style Throttle

Note: This machine does not have a lever or switch to control the engine speed.

When the PTO is engaged to start spinning the cutting units, the machine automatically changes the engine speed to high idle and stays there until the cutting units are disengaged.

When the PTO is not engaged, the machine’s throttle is dependent on the position of the traction pedal, just like the throttle on a car.

Traction Pedal

Power-takeoff (PTO) Switch

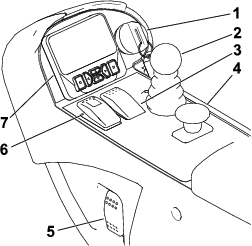

When the PTO switch is engaged, the machine is in MOW mode, which allows you to drive up to 13 km/h (8 mph) when the maximum speed is not limited.

When the PTO switch is not engaged (Figure 11), the machine is in TRANSPORT mode, which allows you to drive up to 16 km/h (10 mph) when the maximum speed is not limited.

Note: Use the protected menus in the InfoCenter to set the maximum speed for each mode.

Parking Brake

To engage the parking brake, (Figure 11) pivot the switch forward on the console. The red light on the switch turns on when it is set. To release the parking brake, pivot the switch backward.

Activating the parking-brake switch causes the traction to automatically decelerate, regardless of traction pedal position, and engage the parking brake as soon as the machine comes to a stop.

Once the engine has been shut off and the machine is not moving, the parking brake engages, regardless of parking-brake switch position.

Tilt-Steering Pedal

To tilt the steering wheel toward you, press the foot pedal down, pull the steering tower toward you to the most comfortable position, and release the pedal (Figure 12). To move the steering wheel away from you, press the foot pedal and release it when the steering wheel reaches the desired operating position.

Lower Mow/Raise Control Lever

This lever (Figure 11) raises and lowers the cutting units.

To lower the cutting units, push the lever forward. When the PTO switch is ENGAGED, the machine is in MOW mode, and the cutting units will start spinning when lowered.

Note: Ensure that you lower the cutting units after the PTO switch has been engaged to start the cutting units. When you lower the cutting units before the PTO switch is engaged, they do not start spinning.

To fully raise the cutting units, pull the lever backward. When the cutting units are raised and the PTO switch is disengaged, the machine is in TRANSPORT mode.

Key Switch

The key switch (Figure 11) has 3 positions: OFF, ON/PREHEAT, and START.

Headlight Switch

Pivot the switch upward to turn on the headlights (Figure 11).

Hydraulic-Filter-Restriction Indicator

The hydraulic-filter-restriction indicator alerts you when the hydraulic filters must be changed; refer to Replacing the Hydraulic Filters.

Power Point

The power point (Figure 15) is a 12 V power supply for electronic devices.

Seat Controls

Seat-Position Lever

Pull the seat-position lever (Figure 16) to move the seat forward and rearward. Release the lever to lock the seat position.

Weight-Adjusting Knob

Rotate the weight-adjusting knob until your weight is displayed in the window of the weight gauge.

Height-Adjusting Knob

Rotate the height-adjusting knob to change the height of the seat.

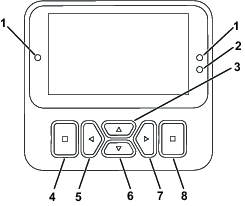

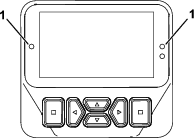

InfoCenter

The InfoCenter LCD display shows information about your machine, such as the operating status, various diagnostics, and other information about the machine (Figure 11).

The screens that display, depend on which buttons you select. The purpose of each button may change depending on what is required at the time.

Note: Specifications and design are subject to change without notice.

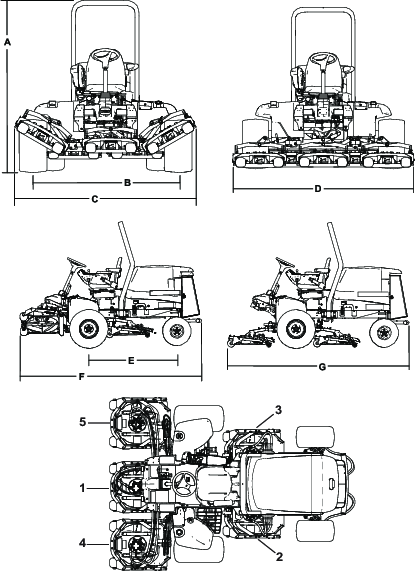

| Description | Figure 17 reference | Dimension or Weight |

| Overall height | A | 217 cm (85.5 inches) |

| Wheel tread (tire center to center) rear | B | 185 cm (72.5 inches) |

| Overall width (transport position) | C | 231 cm (91 inches) |

| Overall width (mowing position) | D | 247 cm (97 inches) |

| Wheel base | E | 152 cm (60 inches) |

| Overall length (transport position) | F | 315 cm (124 inches) |

| Overall length (mowing position) | G | 315 cm (124 inches) |

| Fuel-tank capacity | 53 L (14 US gallons) | |

| Transport speed | 0 to 16 km/h (0 to 10 mph) | |

| Mowing speed | 0 to 13 km/h (0 to 8 mph) | |

| Net weight (with cutting decks and fluids) | 1492 kg (3,289 lb) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

Never allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Shut off the engine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Know how to stop the machine and shut off the engine quickly.

-

Check that operator-presence controls, safety switches, and guards are attached and functioning properly. Do not operate the machine unless they are functioning properly.

-

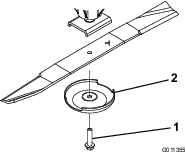

Before mowing, always inspect the machine to ensure that the blades, blade bolts, and cutting assemblies are in good working condition. Replace worn or damaged blades and bolts in sets to preserve balance.

-

Inspect the area where you will use the machine and remove all objects that the machine could throw.

-

This product generates an electromagnetic field. If you wear an implantable electronic medical device, consult your health care professional before using this product.

Fuel Safety

-

Use extreme care in handling fuel. It is flammable and its vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved fuel container.

-

Do not remove the fuel cap or fill the fuel tank while the engine is running or hot.

-

Do not add or drain fuel in an enclosed space.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

-

If you spill fuel, do not attempt to start the engine; avoid creating any source of ignition until the fuel vapors have dissipated.

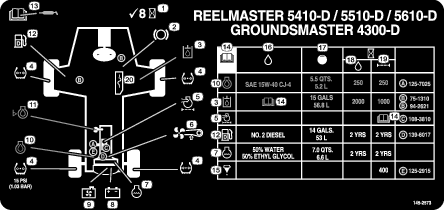

Filling the Fuel Tank

Fuel Tank Capacity

53 L (14 US gallons)

Fuel Specification

Important: Use only ultra-low sulphur diesel fuel. Fuel with higher rates of sulfur degrades the diesel oxidation catalyst (DOC), which causes operational problems and shortens the service life of engine components.Failure to observe the following cautions may damage the engine.

-

Never use kerosene or gasoline instead of diesel fuel.

-

Never mix kerosene or used engine oil with the diesel fuel.

-

Never keep fuel in containers with zinc plating on the inside.

-

Do not use fuel additives.

Petroleum Diesel

Cetane rating: 45 or higher

Sulfur content: Ultra-low sulfur (<15 ppm)

| Diesel fuel specification | Location |

| ASTM D975 | USA |

| No. 1-D S15 | |

| No. 2-D S15 | |

| EN 590 | European Union |

| ISO 8217 DMX | International |

| JIS K2204 Grade No. 2 | Japan |

| KSM-2610 | Korea |

-

Use only clean, fresh diesel fuel or biodiesel fuels.

-

Purchase fuel in quantities that can be used within 180 days to ensure fuel freshness.

Use summer-grade diesel fuel (No. 2-D) at temperatures above -7°C (20°F) and winter-grade fuel (No. 1-D or No. 1-D/2-D blend) below that temperature.

Note: Use of winter-grade fuel at lower temperatures provides lower flash point and cold flow characteristics which eases starting and reduces fuel filter plugging.Using summer-grade fuel above -7°C (20°F) contributes toward longer fuel pump life and increased power compared to winter-grade fuel.

Biodiesel

This machine can also use a biodiesel blended fuel of up to B20 (20% biodiesel, 80% petroleum diesel).

Sulfur content: Ultra-low sulfur (<15 ppm)

Biodiesel fuel specification: ASTM D6751 or EN14214

Blended fuel specification: ASTM D975, EN590, or JIS K2204

Important: The petroleum diesel portion must be ultra-low sulfur.

Observe the following precautions:

-

Biodiesel blends may damage painted surfaces.

-

Use B5 (biodiesel content of 5%) or lesser blends in cold weather.

-

Monitor seals, hoses, gaskets in contact with fuel as they may be degraded over time.

-

Fuel filter plugging may be expected for a time after converting to biodiesel blends.

-

Contact your authorized Toro distributor for more information on biodiesel.

Adding Fuel

Fill the tank to about 6 to 13 mm (1/4 to 1/2 inch) below the top of the tank, not the filler neck, with Number 2-D diesel fuel.

Note: If possible, fill the fuel tank after each use; this will minimize possible buildup of condensation inside the fuel tank.

Checking the Engine-Oil Level

Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Engine-Oil Level.

Checking the Cooling System

Before you start the engine and use the machine, check the cooling system; refer to Checking the Cooling System.

Checking the Hydraulic System

Before you start the engine and use the machine, check the hydraulic system; refer to Checking the Hydraulic-Fluid Level.

Draining the Water Separator

Drain water or other contaminants from the water separator; refer to Draining Water from the Fuel/Water Separator.

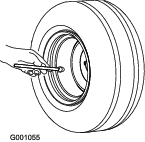

Checking the Tire Pressure

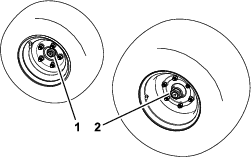

The correct air pressure in the front and rear tires is 83 to 103 kPa (12 to 15 psi).

Important: Maintain pressure in all tires to ensure a good quality of cut and proper machine performance. Do not under-inflate the tires.Check the air pressure in all the tires before operating the machine.

Checking the Torque of the Wheel-Lug Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

| After the first 10 hours |

|

| Every 250 hours |

|

Warning

Failure to maintain the proper torque of the wheel nuts could result in failure or loss of a wheel, and may result in personal injury.

Torque the front and rear-wheel nuts to 94 to 122 N·m (70 to 90 ft-lb) at the recommended service intervals.

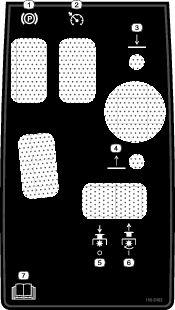

Adjusting the Height of Cut

Important: The cutting units often cut approximately 6 mm (1/4 inch) lower than a reel cutting unit with the same bench setting. It may be necessary to set the cutting-unit bench measurement at 6 mm (1/4 inch) above that of reel cutting units cutting in the same area.

Important: Access to the rear cutting units is greatly improved by removing the cutting unit from the machine. Lower the cutting units and remove the cutting units from the frames by removing these bolts and pins shown in Figure 20.

-

Park the machine on a level surface, engage the parking brake, lower the cutting unit to the ground, shut off the engine, and remove the key.

-

Loosen the bolt securing each height-of-cut bracket to the height-of-cut plate (front and each side) as shown in Figure 21.

-

Beginning with front adjustment, remove the bolt.

-

While supporting the chamber, remove the spacer (Figure 21).

-

Move the chamber to the desired height of cut and install a spacer into the designated height-of-cut hole and slot (Figure 22).

-

Position the tapped plate in-line with the spacer.

-

Install the bolt finger-tight.

-

Repeat steps 4 through 7 for each side adjustment.

-

Torque all 3 bolts to 41 N∙m (30 ft-lb). Always tighten the front bolt first.

Note: Adjustments of more than 3.8 cm (1-1/2 inches) may require temporary assembly to an intermediate height to prevent binding (e.g., changing from 3.1 to 7 cm (1-1/4 to 2-3/4 inches) height of cut).

Checking the Interlock Switches

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Caution

If safety interlock switches are disconnected or damaged, the machine could operate unexpectedly, causing personal injury.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock switches daily and replace any damaged switches before operating the machine.

Important: If your machine fails any of the interlock switch checks, contact your authorized Toro distributor.

Preparing the Machine

-

Drive the machine slowly to an open area.

-

Lower the cutting units, shut off the engine, and engage the parking brake.

Checking the Traction Pedal Start-Interlock

-

Sit in the operator’s seat.

-

Engage the parking brake.

-

Press the PTO switch to the DISENGAGE position.

-

Press the traction pedal.

-

Rotate the key to the START position.

Note: The engine should not start with the traction pedal pressed.

Checking the PTO-Start Interlock

-

Sit in the operator’s seat.

-

Pull up the PTO switch to the ENGAGE position.

-

Rotate the key to the START position.

Note: The engine should not start with the PTO switch in the ENGAGE position.

Checking the PTO-Run Interlock

-

Sit in the operator’s seat.

-

Press the PTO switch to the DISENGAGE position.

-

Start the engine.

-

Pull up the PTO switch to the ENGAGE position.

-

Lower the cutting units to engage the PTO.

-

Rise from the seat.

Note: The PTO should not run when you are out of the operator’s seat.

Note: Do not allow the cutting units to spin for more than a couple seconds during this test to prevent unnecessary wear.

Checking the Parking Brake and Traction Pedal Run-Interlock

-

Sit in the operator’s seat.

-

Engage the parking brake.

-

Press the PTO switch to the DISENGAGE position.

-

Start the engine.

-

Press the traction pedal.

Note: There should be no machine response when you press the traction pedal while the parking brake is engaged. An advisory message should appear on the InfoCenter.

Checking the Automatic Parking Brake Engage

-

Sit in the operator’s seat.

-

Start the engine.

-

Disengage the parking brake.

-

Rise from the seat.

Note: The red light on the parking-brake switch should illuminate when you are out of the operator’s seat, indicating that the parking brake is on.

Checking the Cutting Unit Lower Disable Interlock

-

Sit in the operator’s seat.

-

Start the engine.

-

Ensure that the cutting units are lifted to the transport position.

-

Rise from the seat.

-

Lower the cutting units.

Note: The cutting units should not lower when you are out of the operator’s seat.

Checking the Blade Stopping Time

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

The blades of the cutting unit should come to a complete stop in approximately 5 seconds after you shut down the cutting-unit-engagement switch.

Note: Make sure that the cutting units are lowered onto a clean section of turf or hard surface to avoid thrown dust and debris.

-

Have a second person stand back from the cutting unit at least 6 m (20 feet) and watch the blades on 1 of the cutting unit.

-

While the cutting units are engaged and spinning at full speed, disengage the PTO switch and record the time it takes for the blades to come to a complete stop.

Note: If this time is greater than 7 seconds, the braking valve needs adjustment. Call your authorized Toro distributor for assistance in making this adjustment.

Selecting a Blade

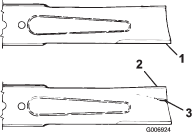

Standard Combination Sail

This blade was designed to provide excellent lift and dispersion in almost any condition. If more or less lift and discharge velocity is required, consider a different blade.

Attributes: Excellent lift and dispersion in most conditions

Angled Sail (Not CE Compliant)

The blade generally performs best in lower heights of cut—1.9 to 6.4 cm (3/4 to 2-1/2 inches).

Attributes:

-

Discharge remains more even at lower heights of cut.

-

Discharge has less tendency to throw left and thus a cleaner look around bunkers and fairways.

-

Lower power requirement at lower heights and dense turf.

High-Lift Parallel Sail (Not CE Compliant)

The blade generally performs better in the higher heights of cut—7 to 10 cm (2 to 4 inches).

Attributes:

-

More lift and higher discharge velocity

-

Sparse or limp turf is picked up significantly at higher heights of cut

-

Wet or sticky clippings are discharged more efficiently reducing congestion in the cutting unit.

-

Requires more horsepower to run

-

Tends to discharge further left and can tend to windrow at lower heights of cut

Warning

Using a high-lift blade with the mulching baffle could cause the blade to break, resulting in personal injury or death.

Do not use the high-lift blade with the mulching baffle.

Atomic Blade

This blade was designed to provide excellent leaf mulching.

Choosing Accessories

Optional Equipment Configurations

| Angle Sail Blade | High-Lift, Parallel-Sail Blade(Do not use with the mulching baffle) (Not CE Compliant) | Mulching Baffle | Roller Scraper | |

| Grass Cutting: 1.9 to 4.4 cm (3/4 to 1-3/4 inches) height of cut | Recommended in most applications | May work well in light or sparse turf | Has been shown to improve dispersion and after-cut performance on northern grasses that are cut at least 3 times per week and less than 1/3 of the grass blade is removed. Do not use with the high-lift, parallel-sail blade | Use it whenever the rollers build up with grass or large, flat grass clumps of grass are seen. The scrapers may increase clumping in certain applications. |

| Grass Cutting: 5 to 6.4 cm (2 to 2-1/2 inches) height of cut | Recommended for thick or lush turf | Recommended for light or sparse turf | ||

| Grass Cutting: 7 to 10 cm (2-3/4 to 4 inches) height of cut | May work well in lush turf | Recommended in most applications | ||

| Leaf Mulching | Recommended for use with the mulching baffle | Not Allowed | Use with combination sail or angle sail blade only | |

| Pros | Even discharge at lower height of cut; cleaner look around bunkers and fairways; lower power requirements | More lift and higher discharge velocity; sparse or limp turf is picked up at high height of cut; wet or sticky clippings are discharged efficiently | May improve dispersion and appearance in certain grass cutting applications; very good for leaf mulching | Reduces roller buildup in certain applications |

| Cons | Does not lift the grass well in high height-of-cut applications; wet or sticky grass has a tendency to build up in the chamber, leading to poor quality of cut and higher power requirements | Requires more power to run in some applications; tends to windrow at lower height of cut in lush grass; do not use with the mulching baffle | Grass will build up in the chamber if you attempt to remove too much grass with the baffle in place |

Overview of the InfoCenter Display

The display shows information about your machine such as the operating status, various diagnostics and other information about the machine. There are multiple screens on the display. You can switch between the screens, at any time, by pressing any of the display buttons and then selecting the appropriate directional arrow.

Note: The purpose of each button may change depending on what is required at the time. Each button is labeled with an icon displaying its current function.

| Hour meter |

| Service is due. |

| The status of the engine speed (rpm) |

| Virtual pedal stop settings |

| The glow plugs are active. |

| The operator must sit in the seat. |

| The parking brake is engaged. |

| Engine coolant temperature (°C or °F) |

| Traction or Traction Pedal |

| Start the engine. |

| The cruise control is engaged. |

| Engine |

| Warm-up mode |

| Reset-standby regeneration request |

| Parked or recovery regeneration request | |

| A parked or recovery regeneration is processing. |

| High exhaust temperature |

| NOx control diagnosis malfunction; drive the machine back to the shop and contact your authorized Toro distributor (software version U and later). |

| The power take-off is disabled. |

| The PTO is on. |

| Battery |

| Fuel level |

| Fuel is low. |

| Warning |

| Active |

| Inactive |

| Previous |

| Next |

| Increase |

| Decrease |

| Previous screen |

| Next screen |

| Increase value |

| Decrease value |

| Menu |

| Scroll up/down |

| Scroll left/right |

| Locked |

Accessible

only by entering PIN

Accessible

only by entering PIN

Using the Menus

To access the InfoCenter menu system, press the menu access button while at the main screen. This brings you to the main menu. Refer to the following tables for a synopsis of the options available from the menus:

| Main Menu—Menu Item | Description |

| Faults | The Faults menu contains a list of the recent machine faults. Refer to the Service Manual or contact your authorized Toro distributor for more information on the Faults menu and the information contained there. |

| Service | The Service menu contains information on the machine such as hours of use, counters, and other similar numbers. |

| Diagnostics | The Diagnostics menu displays the state of each machine switch, sensor, and control output. You can use this to troubleshoot certain issues as it quickly tells you which machine controls are ON and which are OFF. |

| Settings | The Settings menu allows you to customize and modify configuration variables on the display. |

| Machine Settings | The Machine Settings menu allows you to adjust the acceleration, speed, and counterbalance thresholds. |

| About | The About menu lists the model number, serial number, and software version of your machine. |

| Service—Menu Item | Description |

| Hours | Lists the total number of hours that the machine, engine, and PTO have been on, as well as the number of hours the machine has been transported and service due. |

| Counts | Lists numerous counts the machine has experienced. |

Traction Pedal | |

Traction Pump | |

Virtual Speed Sensor | |

| DPF Regeneration | The diesel particulate filter regeneration option and DPF submenus |

| Diagnostics—Menu Item | Description |

| Deck | Indicates the inputs and outputs for raising and lowering the cutting units. |

| Traction | Indicates the inputs and outputs for the traction pedal. |

| Cutting Units | Indicates the inputs, qualifiers, and outputs for raising and lowering the cutting units. |

| PTO | Indicates the inputs, qualifiers, and outputs for enabling the PTO circuit. |

| Engine | Indicates the inputs, qualifiers, and outputs for starting the engine |

CAN Statistics | Indicates the inputs and outputs for the CAN. |

| Settings—Menu Item | Description |

| Enter PIN | Allows a person (superintendent/mechanic) authorized by your company with the PIN code to access protected menus. |

| Backlight | Controls the brightness of the LCD display. |

| Language | Controls the language used on the InfoCenter*. |

| Font Size | Controls the size of the font on the display. |

| Units | Controls the units used on the InfoCenter (English or Metric). |

Protected Menus | Allows a person authorized by your company with the PIN code to access protected menus |

Protect Settings | Allows the ability to change the settings in the protected settings. |

Note: The Machine Settings menu will only show when the PIN is entered.

Machine Settings—Menu Item | Description |

Mow Speed  | Controls the maximum speed while in mow (low range). |

Transport Speed | Controls the maximum speed while in transport (high range). |

Smart Power | Turns Smart Power on and off. |

Counterbalance  | Controls the amount of counterbalance applied by the cutting units. |

Acceleration  | Low, Medium, and High settings control how quickly the traction speed reacts when you move the traction pedal. |

Protected

under Protected Menus—accessible only by entering PIN

Protected

under Protected Menus—accessible only by entering PIN

| About—Menu Item | Description |

| Model | Lists the model number of the machine. |

| SN | Lists the serial number of the machine. |

| Machine Controller Revision | Lists the software revision of the master controller. |

| S/W Revision | Lists the software revision of the primary controller. |

InfoCenter Revision | Lists the software revision of the InfoCenter |

Protected Menus

There are operating configuration settings that are adjustable within the SETTINGS of the InfoCenter. To lock these settings, use the PROTECTED MENU.

Note: At the time of delivery, the initial password code is programmed by your distributor.

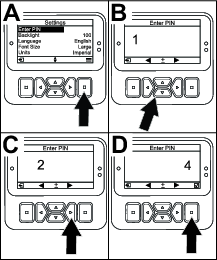

Accessing Protected Menus

Note: The factory default PIN code for you machine is either 0000 or 1234.If you changed the PIN code and forgot the code, contact your authorized Toro distributor for assistance.

-

From the MAIN MENU, scroll down to the SETTINGS menu and press the select button (Figure 24).

-

In the SETTINGSmenu, scroll to the ENTEER PIN and press the select button (Figure 25A).

-

To enter the PIN code, press the up/down navigation buttons until the correct first digit appears, then press the right navigation button to move on to the next digit (Figure 25B and Figure 25C). Repeat this step until the last digit is entered.

-

Press the select button.

Note: If the display accepts the PIN code and the protected menu is unlocked, the word “PIN” displays in the upper right corner of the screen.

-

To lock the protected menu, rotate the key switch to the OFF position and then to the ON position.

Viewing and Changing the Protected Menu Settings

-

In SETTINGS, scroll down to PROTECT SETTINGS.

-

To view and change the settings without entering a PIN code, use the select button to change the PROTECT SETTINGS to

(Off).

(Off). -

To view and change the settings with a PIN code, use the select button to change the PROTECT SETTINGS to

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

Setting the Service Due Timer

The service due timer resets the service due hours after a scheduled maintenance procedure is performed.

-

In SETTINGS , scroll to ENTER PIN and press the select button.

-

Enter PIN; refer to Accessing Protected Menus.

-

In SERVICE , navigate to HOURS and press the select button.

-

Scroll down to SERVICE DUE.

Note: If service is currently due, NOW appears next to SERVICE DUE.

-

Highlight the service interval and press the select button.

Note: The service interval (250 Hrs, 500 Hrs, etc) is located next to SERVICE DUE. Service interval is a protected menu item.

-

When the RESET SERVICE TIMER? screen appears, press the select button for YES or the back button for NO.

-

After you select YES, the interval screen clears and reverts back to the service hours selections.

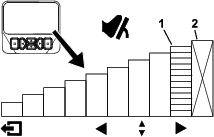

Setting the Maximum Allowed Mow Speed

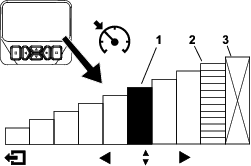

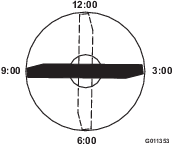

The selected setting is displayed as an X on the traction-speed bar graph along with the cruise control and pedal stop settings. An X in a bar shows you that the maximum speed is limited by the supervisor (Figure 29).

Note: This setting is retained in memory and applied to the traction speed until you change it.

-

In MACHINE SETTINGS, scroll down to MOW SPEED.

-

Use the left and right navigation buttons to increase the maximum mow speed in 0.8 km/h (0.5 mph) increments between 1.6 and 12.9 km/h (1.0 and 8.0 mph).

Setting the Maximum Allowed Transport Speed

The selected setting is displayed as an X on the traction-speed bar graph along with the cruise control and pedal stop settings. An X in a bar shows you that the maximum speed is limited by the supervisor (Figure 29).

Note: This setting is retained in memory and applied to the traction speed until you change it.

-

In MACHINE SETTINGS, scroll down to TRANSPORT SPEED.

-

Use the left and right navigation buttons to increase the maximum transport speed in 0.8 km/h (0.5 mph) increments between 8.0 and 16.0 km/h (5.0 and 10.0 mph).

Turning the Smart Power ON/OFF

-

In SETTINGS, scroll down to SMART POWER.

-

Press the right navigation button to switch between ON and OFF.

Setting the Counterbalance

-

In MACHINE SETTINGS, scroll down to COUNTERBALANCE.

-

Press the right navigation button to select counterbalance and change between the LOW, MEDIUM, and HIGH settings.

Setting the Acceleration Mode

-

In MACHINE SETTINGS, scroll down to ACCELERATION.

-

Press the right navigation button to switch between LOW, MEDIUM, and HIGH.

Accessing the Technician Menu

Note: For operating convenience, you may decide to perform a parked regeneration before the soot load reaches 100%, provided the engine has run more than 50 hours since the last successful reset, parked, or recovery regeneration.

Use the Technician menu to view the current state of engine regeneration control and the current soot level.

-

In SETTINGS, scroll down to DPF RENGERATION and press the select button.

-

In DPF RENGERATION, scroll down to TECHNICIAN and press the select button.

Understanding the Diagnostic Light

-

Flashing red—active fault

-

Solid red—active advisory

-

Solid blue—calibration/dialog messages

-

Solid green—normal operation

Checking the Hydrostatic Braking Distance

This machine will dynamically brake and stop when you return the traction pedal to neutral.

Note: For smooth deceleration, use your foot to slowly control the traction pedal back to neutral. Do not take your foot off the pedal and allow it to snap back to the neutral position unless you intend to stop quickly.

The machine should come to a complete stop in approximately 3.7 m (12 ft) from the maximum transport speed of 10 mph.

-

On flat, dry pavement, mark out the start and end of 3.7 m (12 ft).

-

Drive the machine at the maximum transport speed of 16 km/h (10 mph) and remove your foot at the start of the 3.7 m (12 ft).

-

Check if the machine stops within 0.6 m (2 ft) of the end mark (3.7 m or 12 ft).

-

Contact your Toro distributor if the stopping distance of the machine is not within 0.6 m (2 ft) of this distance.

Overview of Reverse Speeds

Transport Reverse Speed

-

If the maximum transport speed set by the supervisor is above 8.0 km/h (5.0 mph), the maximum reverse speed is 8.0 km/h (5.0 mph).

-

If the maximum transport speed set by the supervisor is at or below 8.0 km/h (5.0 mph), maximum reverse speed is equal to the transport speed set by the supervisor.

Mowing Reverse Speed

-

If the maximum mow speed set by the supervisor is above 6.4 km/h (4.0 mph), the maximum reverse speed is 6.4 km/h (4.0 mph).

-

If the maximum mow speed set by the supervisor is at or below 6.4 km/h (4.0 mph), maximum reverse speed is equal to the transport speed set by the supervisor.

Overview of Displayed Traction Speeds

This machine displays estimated traction speeds in kilometers per hour (km/h) or miles per hour (mph).

-

The instantaneous speed is displayed in the upper left-hand corner of the cruise control and virtual pedal stop screens.

-

The traction speeds are estimated, and calibrated to be most accurate at 8.0 km/h (5.0 mph) while mowing. Displayed speeds are accurate when it is 0.8 km/h (0.5 mph) above or below the display speed while driving on dry, flat pavement.

-

Contact your authorized Toro distributor if the machine's observed speeds deviate more than 2.4 km/h (1.5 mph) from the displayed speeds.

Understanding the Warm-Up Mode

When starting the machine in cold weather, warm-up mode limits the engine speed to low idle for a short period after the engine is started, preventing potential component damage from operating the machine with cold oil.

A snowflake icon  on the InfoCenter screen denotes when warm-up

mode is active. Do not operate the machine until after the warm-up

period.

on the InfoCenter screen denotes when warm-up

mode is active. Do not operate the machine until after the warm-up

period.

During Operation

During Operation Safety

General Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Before you start the engine, ensure that all drives are in neutral, the parking brake is engaged, and you are in the operating position.

-

Do not carry passengers on the machine and keep bystanders and children out of the operating area.

-

Operate the machine only in good visibility to avoid holes or hidden hazards.

-

Avoid mowing on wet grass. Reduced traction could cause the machine to slide.

-

Keep your hands and feet away from rotating parts. Keep clear of the discharge opening.

-

Look behind and down before backing up to be sure of a clear path.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision.

-

Stop the blades whenever you are not mowing.

-

Stop the machine, remove the key, and wait for all moving parts to stop before inspecting the attachment after striking an object or if there is an abnormal vibration in the machine. Make all necessary repairs before resuming operation.

-

Slow down and use caution when making turns and crossing roads and sidewalks with the machine. Always yield the right-of-way.

-

Disengage the drive to the cutting unit, shut off the engine, remove the key, and wait for all movement to stop before adjusting the height of cut (unless you can adjust it from the operating position).

-

Operate the engine only in well-ventilated areas. Exhaust gases contain carbon monoxide, which is lethal if inhaled.

-

Never leave a running machine unattended.

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Disengage the power takeoff and lower the attachments.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

-

Operate the machine only in good visibility. Do not operate the machine when there is the risk of lightning.

-

Do not use the machine as a towing vehicle.

-

Use accessories, attachments, and replacement parts approved by Toro only.

-

Use the cruise control (if equipped) only when you can operate the machine in an open, flat area that is free from obstacles and where the machine can move at a constant speed without interruption.

Rollover Protection System (ROPS) Safety

-

The ROPS is an integral and effective safety device.

-

Do not remove any of the ROPS components from the machine.

-

Ensure that the seat belt is attached to the machine.

-

Pull the belt strap over your lap and connect the belt to the buckle on the other side of the seat.

-

To disconnect the seat belt, hold the belt, press the buckle button to release the belt, and guide the belt into the auto-retract opening. Ensure that you can release the belt quickly in an emergency.

-

Check carefully for overhead obstructions and do not contact them.

-

Keep the ROPS in safe operating condition by thoroughly inspecting it periodically for damage and keeping all the mounting fasteners tight.

-

Replace damaged ROPS components. Do not repair or alter them.

Additional ROPS Safety for Machines with a Cab or a Fixed Roll Bar

-

A cab installed by Toro is a roll bar.

-

Always wear your seat belt.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution.

-

Evaluate the site conditions to determine if the slope is safe for machine operation, including surveying the site. Always use common sense and good judgment when performing this survey.

-

Review the slope instructions listed below for operating the machine on slopes and to determine whether you can operate the machine in the conditions on that day and at that site. Changes in the terrain can result in a change in slope operation for the machine.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction. Make turns slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question.

-

Remove or mark obstructions such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstructions. Uneven terrain could overturn the machine.

-

Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

-

Use extreme caution when operating the machine near drop-offs, ditches, embankments, water hazards, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in. Establish a safety area between the machine and any hazard.

-

Identify hazards at the base of the slope. If there are hazards, mow the slope with a pedestrian-controlled machine.

-

If possible, keep the cutting unit(s) lowered to the ground while operating on slopes. Raising the cutting unit(s) while operating on slopes can cause the machine to become unstable.

-

Use extreme caution with grass-collection systems or other attachments. These can change the stability of the machine and cause a loss of control.

Understanding the Operating Characteristics of the Machine

-

This machine has an automotive-style throttle that is controlled by the traction pedal.

-

This machine does not have a separate throttle switch or throttle lever.

-

When you remove your foot from the traction pedal, the machine dynamically brakes to a stop.

-

The pedal controls are optimized to provide a reactive yet stable response, allowing you to maintain consistent control over rough terrain, while still allowing for quick, smooth braking.

-

While transporting, the traction pedal will operate similar to a car and change the engine and traction speed dependent on the traction pedal position.

-

When mowing, the engine speed will automatically raise to high idle.

-

If the engine is at low idle, performing a function like lifting the cutting units or pressing the traction pedal raises the engine speed to a minimum working speed, providing enough power to efficiently perform the function.

-

Limit the machine idle time as recommended for diesel particulate filter (DPF) regeneration. Shut of the machine to prevent extended idling time.

-

The maximum speeds set in the PIN protected menu settings are set by the supervisor to limit the machine’s maximum traction speed.

-

The achievable traction pedal use, cruise control, and pedal stop traction speeds are all limited by the maximum speeds set in the PIN protected menu.

Operating the Machine

-

If an obstacle is in the way, lift the cutting units or mow around it.

-

When transporting the machine between work areas, shut off the PTO, and raise the cutting units to the fully upward position. This allows the traction pedal to operate like a car.

-

Always drive slowly in rough areas.

-

Never shut off the machine while driving the machine.

Practice Operating the Machine

-

To get familiar with the features of the machine, practice operating the machine.

-

Lift the cutting units, disengage the parking brake, press the forward traction pedal, and carefully drive to an open area.

-

Practice driving the machine, because it has a hydrostatic transmission and its features can differ from other turf-maintenance machines.

-

Practice moving forward and reverse, and starting and stopping the machine. To stop the machine, remove your foot from the traction pedal and let it return to NEUTRAL.

Note: When going downhill in the machine, you may need to use the reverse pedal to stop.

-

Remove your foot from the traction pedal to stop quickly.

-

Practice driving around obstacles with the cutting units up and down. Be careful when driving between narrow objects so that you do not damage the machine or cutting units.

Overview of the Traction Pedal

The traction pedal controls the forward and reverse speed of the machine and the dynamic braking when you return it to neutral.

-

This machine is equipped with an automotive-style throttle—the engine speed and the machine speed respond to the pedal movement.

-

While transporting, the traction pedal will operate similar to a car and change the engine and traction speed dependent on the traction pedal position.

-

While mowing, the engine automatically raises to high idle to optimize mowing performance, and the traction pedal only controls traction speed.

-

The further you push the pedal forward or reverse, the faster the machine moves.

-

To control the machine to a smooth stop while transporting or mowing, use your foot to return the traction pedal to neutral at your desired rate.

-

To engage maximum braking, remove your foot from the traction pedal, allowing it to return to neutral. The machine dynamically brakes to a stop.

This traction system allows you to customize the acceleration settings for operator comfort and course conditions. Refer to Understanding the Acceleration Mode for changing the settings.

Using the Virtual Pedal Stop (VPS) Feature

The virtual pedal stop (VPS) feature allows you to temporarily set a maximum traction speed that is less than the password-protected supervisor maximum traction speed.

To temporarily set the maximum speed of the machine, press the traction pedal fully forward (Figure 28). You can set a separate speed for the mow range and transport range (Figure 29).

-

To access this feature, press the up or down navigation button from the main screen. (Figure 29).

Note: This feature reverts back to the supervisor maximum speed settings when you turn the key to the OFF position.

-

This feature allows you to customize the speed settings for your comfort level, or to customize the speed settings to fit the application.

-

Whenever you change the maximum traction speed using the supervisor maximum speed settings or Virtual Pedal Stop, the traction pedal is automatically reprogrammed to use the full pedal stroke between neutral and the new maximum speed. This means that you gain more precise control of the traction speed at lower maximum speed settings.

Tips for Using Virtual Pedal Stop (VPS)

-

Set the maximum speed temporarily lower for mowing the cleanup pass on the fairway.

-

Set the maximum speed temporarily lower for improved control operating in or near the maintenance shop.

-

Set the maximum speed temporarily lower for improved control loading the machine onto a trailer.

Operating the Cruise Control

Setting the Cruise Control

The cruise-control switch locks in the cruise control to maintain the desired ground speed. Pressing the rear of the switch turns the cruise control off, the middle position of the switch enables the cruise-control function, and the front of the switch sets the desired ground speed.

After the cruise control switch is enabled and the speed is set (Figure 30), use the InfoCenter to adjust the speed setting of the cruise control (Figure 30 and Figure 31).

To disengage the cruise control, use the following:

-

When in transport range, press the reverse traction pedal, engage the parking brake, or press the cruise control switch to the OFF position.

-

When in mow range, press the reverse traction pedal, engage the parking brake, disengage the PTO, or press the cruise control switch to the OFF position.

Note: Disengaging the cruise control results in the machine dynamically braking to a stop. If you want to disengage cruise control while driving, press the traction pedal for a smooth transition from cruise control to manual speed control.

Adjusting the Cruise Control Speed

Tips for Using the Cruise Control

-

Set a cruising speed for long distances without many obstacles.

-

On rough terrain, use the InfoCenter to control the speed.

-

Use the cruise control for turnarounds as follows:

-

While mowing, set a safe, comfortable speed for turning around at the end of mowing passes.

-

Press the traction pedal to increase the speed for mowing during the mowing pass.

-

Take your foot off the pedal when turning around for the next mowing pass.

-

The machine will slow down to the low cruise control setting, allowing you to make an efficient turnaround at a constant speed.

-

After turning around, use the traction pedal to increase the machine speed for the next mowing pass.

-

Understanding the Acceleration Mode

This feature determines how quickly the machine changes traction speed when the traction pedal is not in the NEUTRAL position.

Note: If you take your foot off the traction pedal, allowing it to return to the NEUTRAL position while the machine is moving, the braking profile is engaged. The braking profile is always the same and cannot be customized by the acceleration mode feature.

Enter the protected menus in the InfoCenter to change the acceleration mode. The acceleration mode has the following 3 positions:

-

Low—least aggressive acceleration and deceleration

-

Medium (default)—medium acceleration and deceleration

-

High—most aggressive acceleration and deceleration

Understanding Counterbalance

The counterbalance system maintains hydraulic back pressure on the cutting-unit lift cylinders. The counterbalance system monitors the real-time traction pressure, dynamically changing the lift-cylinder back pressure to optimize traction capability and after-cut appearance. The counterbalance pressure has been set at the factory to an optimal balance of after-cut appearance and traction capability in most turf conditions. Decreasing the counterbalance setting can produce a more stable cutting unit but can decrease the traction capability. Increasing the counterbalance setting can increase the traction capability, but may reduce the quality of the after-cut appearance; refer to Changing the Counterbalance Settings.

The customizable counterbalance setting controls are as follows:

-

Low—the most amount of weight on cutting units and the lowest weight on the drive wheels

-

Medium—medium weight on cutting units and the drive wheels

-

High—the least amount of weight on cutting units and the highest weight on machine drive wheels

Changing the Counterbalance Settings

You can change the amount of required cutting-unit counterbalance (upward lift) to meet your current mowing conditions.

-

Park the machine on a level surface, lower the cutting decks, turn the key in the switch to the OFF position, and engage the parking brake.

-

Turn the key in the switch to the RUN position.

-

In the InfoCenter Settings Menu, scroll down to Counterbalance.

-

Press the right button to select counterbalance and change between the low, medium, and high settings.

Note: After completing the adjustment, move the machine to a test area and operate the machine with the new setting. The new counterbalanced setting may change the effective height of cut.

Understanding Toro Smart Power™

With Smart Power, the operator does not have to listen to the engine speed in heavy load conditions. Smart Power prevents the engine from bogging down in heavy cutting conditions by automatically controlling the machine speed and optimizing cutting performance.

Note: By default, the Smart Power feature is ON.

Starting the Engine

Important: The fuel system automatically bleeds itself before starting the engine if you are starting the engine for the first time, the engine has shut off due to lack of fuel, or you have performed maintenance on the fuel system.

-

Sit on the seat, keep your foot off the traction pedal so that it is in NEUTRAL, engage the parking brake, and ensure that the PTO switch is in the DISENGAGED position.

-

Turn the key in the switch to the RUN position.

-

When the glow indicator dims, turn the key in the switch to the START position. Release the key immediately when the engine starts and allow it to return to the RUN position.

-

Run the engine at low idle speed until it warms up.

Shutting Off the Engine

-

Move all controls to NEUTRAL, engage the parking brake, and allow the engine to reach low idle speed.

Important: Allow the engine to idle for 5 minutes before shutting it off after a full load operation. Failure to do so may engine components.

-

Turn the key in the switch to the OFF position and remove the key.

Cutting Grass with the Machine

-

Start the engine, disengage the brake, disengage the PTO switch, and raise the cutting units.

-

Using the traction pedal like an accelerator pedal on a car, drive the machine to the mowing area.

-

Pull the PTO switch to the ENGAGE position.

-

Start driving the machine and lower the cutting units only when all cutting units are over the mowing area.

-

Begin mowing the area.

-

When you complete a mowing pass, tap the lower control lever rearward to lift the cutting units before leaving the mowing area.

-

Perform a tear-shaped turn to quickly line up for your next pass.

-

Press the lower control lever to automatically lower all cutting units in the mowing area and continue mowing.

Understanding the Diesel-Particulate Filter and Regeneration

The diesel-particulate filter (DPF) removes soot from the engine exhaust.

The DPF regeneration process uses heat from the engine exhaust that is increased by the catalyst to reduce accumulated soot into ash.

To keep the DPF clean, remember the following:

-

Run the engine at full engine speed when possible to promote DPF self-cleaning.

-

Use the correct engine oil.

-

Minimize the amount of time that you idle the engine.

-

Use only ultra low sulfur diesel fuel.

Operate and maintain your machine with the function of the DPF in mind. Engine under load generally produces adequate exhaust temperature for DPF regeneration.

Important: Minimize the amount of time that you idle the engine or operate the engine at low-engine speed to help reduce the accumulation of soot in the DPF.

Caution

The exhaust temperature is hot (approximately 600°C (1,112°F) during DPF regeneration. Hot exhaust gas can harm you or other people.

-

Do not operate the engine in an enclosed area.

-

Ensure that there are no flammable materials around the exhaust system.

-

Ensure that the hot exhaust gas does not contact surfaces that may be damaged by heat.

-

Do not touch a hot exhaust system component.

-

Do not stand near or around the exhaust pipe of the machine.

Understanding the Regeneration Icons

| Icon | Icon Definition |

| • Parked or recovery regeneration icon-regeneration is requested. |

| • Perform the regeneration immediately. | |

| • A regeneration is acknowledged and the request is processing. |

| • A regeneration is in progress and the exhaust temperature is elevated. |

| • NOx control system malfunction; the machine requires service. |

Types of Diesel Particulate Filter Regeneration

| Type of Regeneration | Conditions that cause DPF regeneration | DPF description of operation |

|---|---|---|

| Passive | Occurs during normal operation of the machine at high-engine speed or highengine load | • The InfoCenter does not display an icon indicating passive regeneration. |

| • During passive regeneration, the DPF processes high-heat exhaust gasses, oxidizing harmful emissions, and burning soot to ash. | ||

| Assist | Occurs because of low-engine speed, low-engine load, or after the computer detects the DPF is becoming obstructed with soot | •The InfoCenter does not display an icon indicating assist regeneration. |

| • During assist regeneration, the engine computer adjusts the engine settings to raise the exhaust temperature. | ||

| Reset | Occurs every 100 hours | • When the high exhaust-temperature icon  is displayed in the InfoCenter,

a regeneration is in progress. is displayed in the InfoCenter,

a regeneration is in progress. |

| Also occurs if normal engine operation surpasses the allowed soot accumulation amount within the filter | ||

| • During reset regeneration, the engine computer maintains an elevated engine speed to ensure filter regeneration. |

| Type of Regeneration | Conditions that cause DPF regeneration | DPF description of operation |

|---|---|---|

| Parked | Occurs because the computer determines that the automatic DPF cleaning has not been sufficient. | • When the reset-standby/parked

or recovery regeneration icon  or a regeneration is requested. or a regeneration is requested. |

| Also occurs because you initiate a parked regeneration | ||

| May occur because the inhibit regen has been initiated and has disabled the automatic DPF cleaning from occuring | • Perform the parked regeneration as soon as possible to avoid needing a recovery regeneration. | |

| May result from using the incorrect fuel or engine oil | • A parked regeneration requires 30 to 60 minutes to complete. | |

| • You must have at least a 1/4 tank of fuel in the tank. | ||

| • You must park the machine to perform a parked regeneration. | ||

| Recovery | Occurs because the request for parked recovery has been ignored, allowing the DPF to be critically plugged | • When the reset-standby/parked or recovery

regeneration icon  a recovery regeneration is requested. a recovery regeneration is requested. |

| • A recovery regeneration requires up to 3 hours to complete. | ||

| • You must have at least a 1/2 tank of fuel in the machine. | ||

| • You must park the machine to perform a recovery regeneration. |

Using the DPF Regeneration Menus

Accessing the DPF Regeneration Menus

-

From the MAIN MENU, scroll down to SERVICE and press the select button.

-

In SERVICE, scroll to DPF REGENERATION and press the select button.

-

Select the regeneration function you need.

Time Since Last Regeneration

-

Access the DPF REGENERATION menu, and scroll to LAST REGEN.

-

Select the LAST REGEN entry.

-

Use the LAST REGEN field to determine how many hours you have run the engine since the last reset, parked, or recovery regeneration.

-

Select the back button to return to the DPF REGENERATION screen.

Setting the Inhibit Regen

A reset regeneration produces elevated engine exhaust. If you are operating the machine around trees, brush, tall grass, or other temperature-sensitive plants or materials, you can use the INHIBIT REGEN setting to prevent the engine computer from performing a reset regeneration.

Note: The INHIBIT REGEN option is always used when maintenance is being performed on the machine in an enclosed area.

Note: If you set the InfoCenter to inhibit regeneration, the InfoCenter displays an advisory every 15 minutes while the engine requests a reset regeneration.

Important: When you shut off the engine and start it again, the inhibit regen setting defaults to OFF.

-

Access the DPF REGENERATION menu, and scroll down to INHIBIT REGEN.

-

Select the Inhibit REGEN entry.

-

Change the inhibit regeneration setting from OFF to ON.

Preparing to Perform a Parked or Recovery Regeneration

-

Ensure that the machine has fuel in the tank for the type of regeneration you are performing:

-

Parked Regeneration: Ensure that you have 1/4 tank of fuel before performing the parked regeneration.

-

Recovery Regeneration: Ensure that you have 1/2 tank of fuel before performing the recovery regeneration.

-

-

Move the machine outside to an area away from combustible materials or items that may be damaged by heat.

-

Park the machine on a level surface, move all controls to NEUTRAL, disengage the PTO, and lower the cutting units.

-

Engage the parking brake and allow the engine to reach low idle speed.

Performing a Parked or Recovery Regeneration

When a parked regeneration is requested by the engine computer, follow the messages on the InfoCenter.

Important: The computer of the machine cancels DPF regeneration if you increase the engine speed from low idle or release the parking brake.

-

Access the DPF REGENERATION menu, and scroll down to PARKED REGEN or RECOVERY REGEN.

-

Select the PARKED REGEN entry or the RECOVERY REGEN entry.

Note: Initiating a recovery regeneration requires you to enter the correct PIN code.

-

At the REGEN PARAMETERS screen, verify that you have 1/4 tank of fuel if you are performing the parked regeneration or 1/2 tank of fuel if you are performing the recovery regeneration. Verify that the parking brake is engaged and the engine speed is set to low idle. Press the select button to continue.

-

At the INITIATE DPF REGEN screen, select the next button to continue.

-

The InfoCenter displays theINITIATE DPF REGEN message.

Note: If needed, press the cancel icon to cancel the regeneration process.

-

The InfoCenter displays the time to complete message.

-

The InfoCenter displays the home screen and the regeneration acknowledge icon appears

.

.Note: While the DPF regeneration runs, the InfoCenter displays the high exhaust-temperature icon

.

. -

When the engine computer completes a parked or recovery regeneration, the InfoCenter displays an advisory. Press any button to exit to the home screen.

Note: If the regeneration fails to complete, follow the advisory and press any button to exit to the home screen.

Canceling a Parked or Recovery Regeneration

Use the PARKED REGEN CANCEL or RECOVERY REGEN CANCEL setting to cancel a running parked or recovery regeneration process.

-

Access the DPF REGENERATION menu, scroll to PARKED REGEN or RECOVERY REGEN.

-

Press the select button to cancel a Parked Regen or Recovery Regen.

Operating Tips

Changing Mowing Patterns

Change mowing patterns often to minimize a poor after-cut appearance from repeatedly mowing in the same direction. This is the most effective way to prevent washboarding.

Resolving After-Cut Appearance

Refer to the After-cut Appearance Troubleshooting Guide available at www.Toro.com.

Using Proper Mowing Techniques

-

To achieve the professional straight-line cut and striping that is desirable for some applications, find a tree or other object in the distance and drive straight toward it.

-

Bolt-in mulching baffles are available for the cutting units. The mulching baffles perform well when you maintain turf on a regular schedule to avoid removing more than 25 mm (1 inch) of growth per cutting. When you cut too much growth with the mulching baffles installed, the after-cut appearance may deteriorate and the observed power to cut the turf increases. The mulching baffles also perform well for shredding leaves in the fall.

Selecting the Proper Height-of-Cut Setting to Suit Conditions

Remove no more than approximately 25 mm (1 inch), or 1/3 of the grass blade when cutting. In exceptionally lush and dense grass, you may need to raise your height-of-cut setting.

Mowing with Sharp Blades

A sharp blade cuts cleanly and without tearing or shredding the grass blades like a dull blade. Tearing and shredding causes the grass to turn brown at the edges, which impairs growth and increases susceptibility to diseases. Ensure that the blade is in good condition and that there is a full sail; refer to Inspecting and Sharpening the Blade.

Checking the Condition of the Cutting Unit

Ensure that the cutting chambers are in good condition. Straighten any bends in the chamber components to ensure correct blade tip/chamber clearance. Ensure all rollers and pivoting joints do not have play in them to prevent turf damage or poor after cut appearance.

Maintaining the Machine after Mowing

After mowing, thoroughly wash the machine with a garden hose with no nozzle to avoid contamination and damage to the seals and bearings caused by excessive water pressure. Ensure that the radiator and oil cooler are kept free of dirt or grass clippings. After cleaning, inspect the machine for possible hydraulic-fluid leaks, damage, or wear to the hydraulic and mechanical components, and check the cutting-unit blades for sharpness.

After Operation

General Safety

-

Shut off the engine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

To help prevent fires, ensure that the cutting units, drives, mufflers, cooling screens, and engine compartment are free from grass and debris buildup. Clean up oil or fuel spills.

-

If the cutting units are in the transport position, use the positive mechanical lock (if available) before you leave the machine unattended.

-

Allow the engine to cool before storing the machine in any enclosure.

-

Remove the key and shut off the fuel (if equipped) before storing or hauling the machine.

-

Never store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

-

Maintain and clean the seat belt(s) as necessary

Identifying the Tie-Down Points

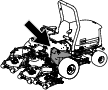

Hauling the Machine

-

Remove the key and shut off the fuel (if equipped) before storing or transporting the machine.

-

Use care when loading or unloading the machine into a trailer or a truck.

-

Use full-width ramps for loading the machine into a trailer or a truck.

-

Tie the machine down securely.

Pushing or Towing the Machine

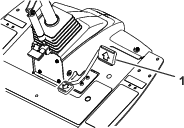

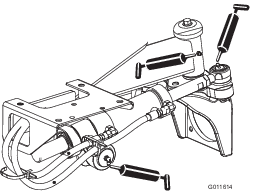

In an emergency, you can move the machine forward by actuating the bypass valve in the variable-displacement hydraulic pump and pushing or towing the machine.

Important: Do not push or tow the machine faster than 3 to 4.8 km/h (2 to 3 mph). If you push or tow at a faster speed, internal transmission damage may occur.The bypass valves must be open and the brake released whenever you push or tow the machine.

-

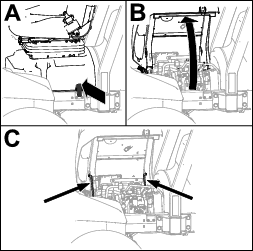

Unlatch the seat base and tilt the seat open.

-

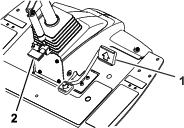

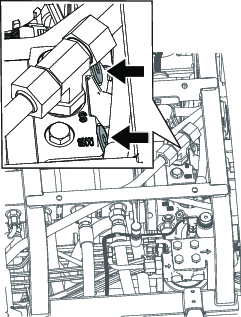

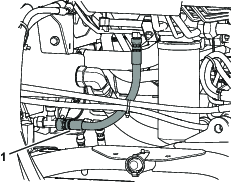

Locate the bypass valve under the seat and on the top of the hydrostat (Figure 37).

-

Loosen the valves with 3 turns to allow the oil to bypass internally.

Note: Because the fluid is bypassed, the machine can be moved slowly without damaging the transmission.

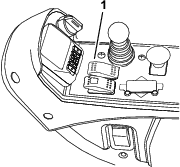

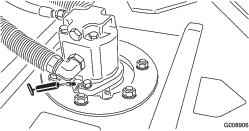

-

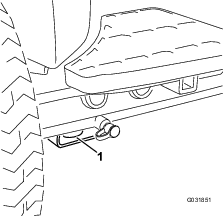

Locate the brake release manifold near the front right tire and behind the hydraulic tank (Figure 38).

-

Insert the long end of a ratchet or similar object, hold the black knob in on the manifold, and pump the manifold 3 times. As soon as there is substantial resistance when pumping the brake is released.

Important: Do not pump the manifold after it does not pump easily. Damage could occur if the manifold is pumped too much.

Note: Once the pressure is built up in the manifold, the brake will be released for approximately 60 minutes. If needed after 60 minutes, release the brake again by pumping the manifold.

-

Push or tow the machine.

-

Set the brake by pulling the black knob out or starting the engine.

Note: The brake automatically resets when you start the engine and you do not need to pull the black knob out.

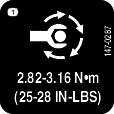

-

Close the bypass valves. Torque the valves to 11 N∙m (5 to 8 ft-lb).

Important: Ensure that the bypass valves are closed before you start operating the machine. Running the engine with an open bypass valve causes the transmission to overheat.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Maintenance Safety

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Disengage the power takeoff and lower the attachments.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

-

Wear appropriate clothing, including eye-protection; long pants and substantial, slip-resistant footwear. Keep hands, feet, clothing, jewelry, and long hair away from moving parts.

-

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the switch before you perform any maintenance.

-

Allow machine components to cool before performing maintenance.

-

If the cutting units are in the transport position, use the positive mechanical lock (if equipped) before you leave the machine unattended.

-