Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Before storage |

|

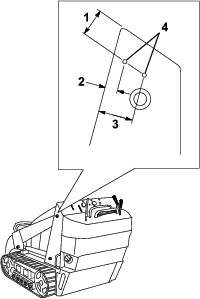

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Before storage |

|

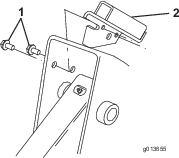

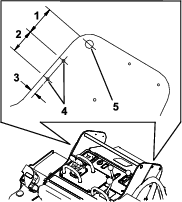

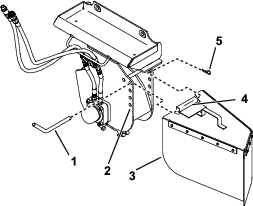

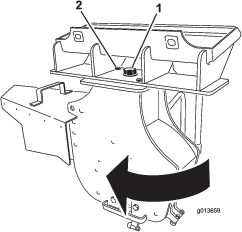

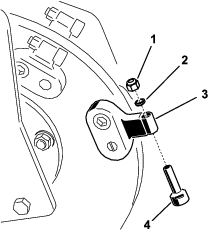

Grease the fitting in Figure 16.

Grease Type: General-purpose grease

-

Park the machine on a level surface, lower the loader arms, and engage the parking brake (if applicable).

-

Shut off the engine and remove the key.

-

Clean the grease fitting with a rag.

-

Connect a grease gun to the fitting.

-

Pump grease into the fitting until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

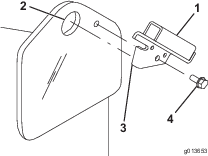

Replacing the Teeth

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

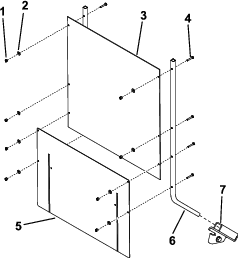

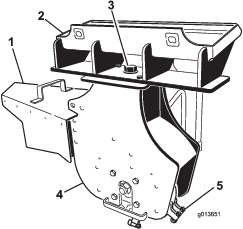

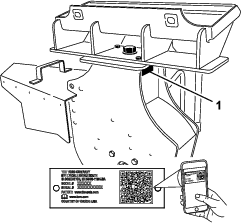

Due to the high amount of wear placed on the teeth, you will need to rotate and replace them periodically.

Each tooth is indexed with 3 positions so that you can rotate it twice, exposing a new sharp edge before replacing the tooth.

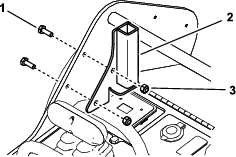

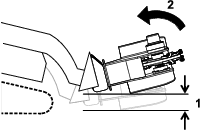

To rotate a tooth, loosen the nut securing the tooth (Figure 18). Push the tooth forward and rotate it one third of a turn, bringing an unused edge to the outside. Torque the nut securing the tooth to 37 to 45 N∙m (27 to 33 ft-lb).

To replace a tooth, remove the nut securing the tooth to remove it, then install a new tooth and nut in the same position (Figure 18). Torque the nut securing the tooth to 37 to 45 N∙m (27 to 33 ft-lb).

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.