Maintenance

Servicing the HVAC Air Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 250 hours |

|

Note: The HVAC air filter is designed to keep the cabin air clean.

-

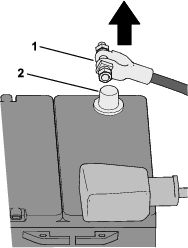

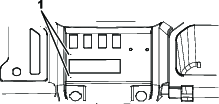

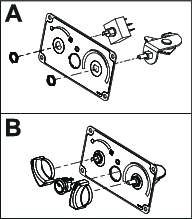

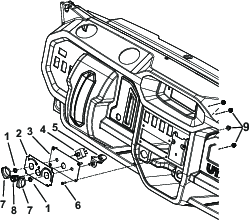

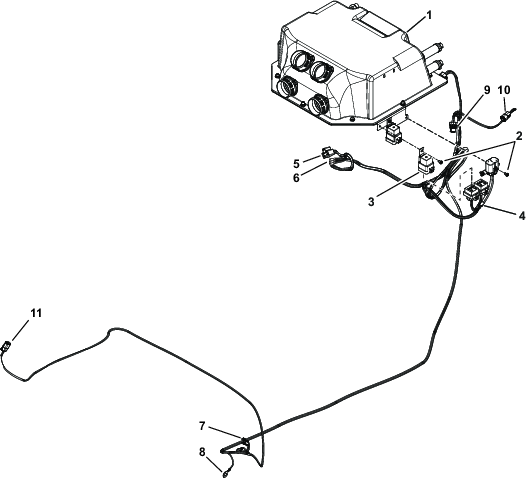

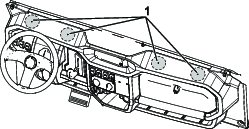

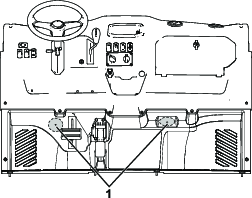

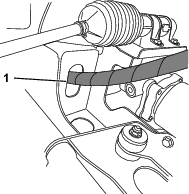

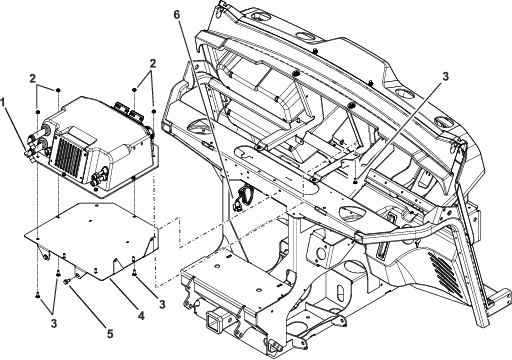

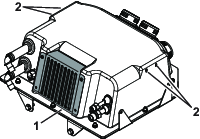

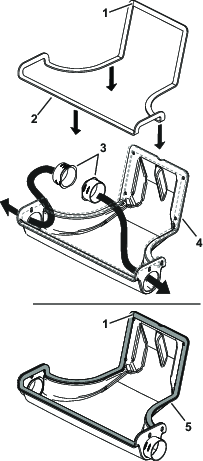

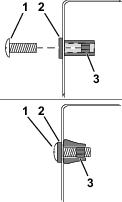

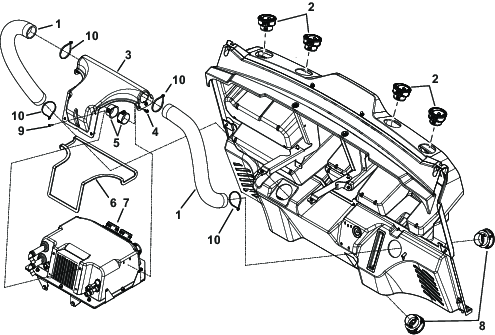

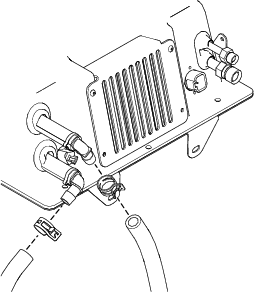

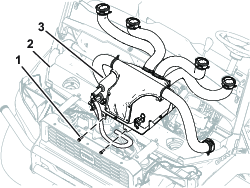

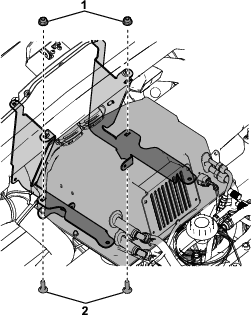

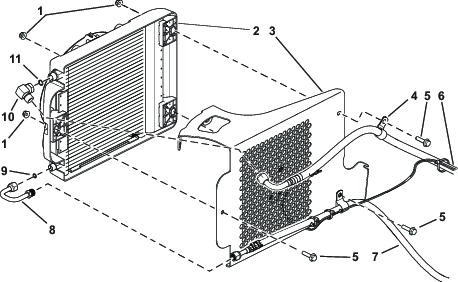

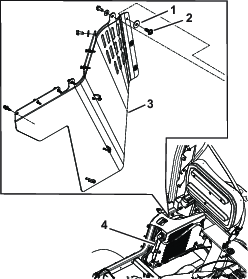

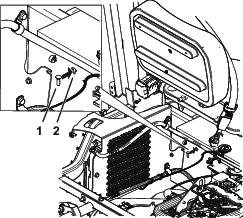

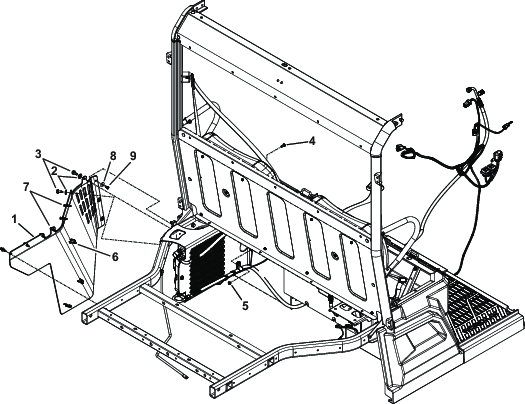

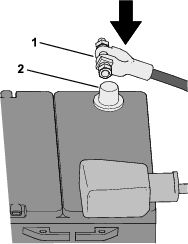

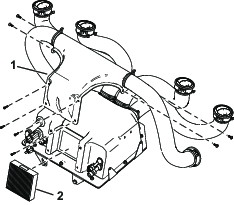

Remove the air-intake cover from the HVAC box assembly (Figure 52).

-

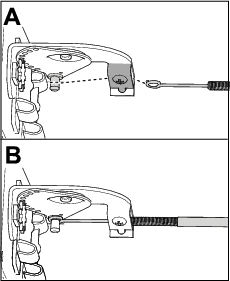

Gently remove the filter from the HVAC box assembly.

Note: Do not attempt to clean the filter.

-

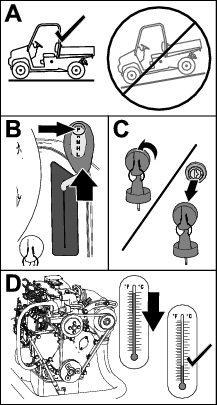

Inspect the new filter for damage by looking into the filter while shining a bright light on the outside of the filter.

Note: Holes in the filter appear as bright spots. Inspect the element for tears, an oily film, or damage to the rubber seal. If the filter is damaged, do not use it.

Note: Use care when handling the filter to avoid damaging or deforming it.

-

Carefully install the filter.

-

Install the air-intake cover onto the HVAC box assembly with the corresponding hardware.

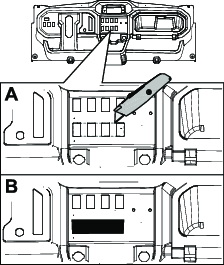

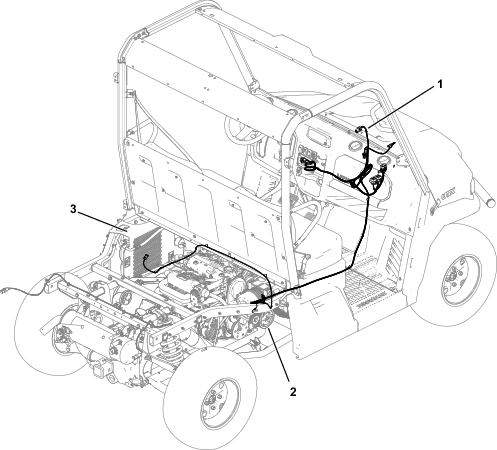

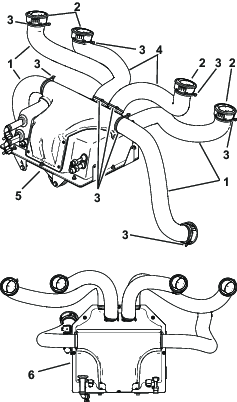

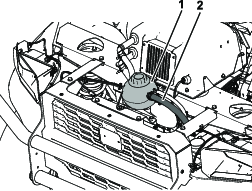

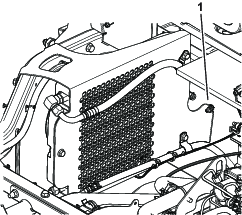

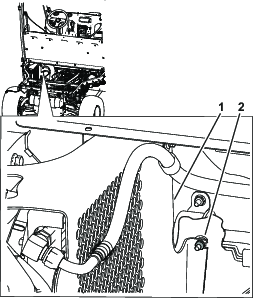

Cleaning the HVAC Box

Important: Do not get the HVAC box or components wet.