Important: To install of this kit, you must purchase and install the separate

ultra sonic boom finishing kit. Order the following finishing kit

for your machine:

|

Multi Pro 1750 Machines—finishing kit Part No. 130-8227

|

|

Multi Pro 5800 Machines—finishing kit

Part No. 130-8229

|

|

Multi Pro WM Machines—finishing kit Part No. 133-2808

|

Note: Determine the left and right sides of the machine from the normal

operating position.

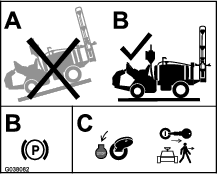

Preparing the Machine

-

Clean the exterior of the machine and sprayer; refer

to the Operator’s Manual for your machine.

-

Move the machine to a level surface, shut off the

engine, set the parking brake, and remove the key.

Caution

If you leave the key in the ignition switch, someone could accidently

start the engine and seriously injure you or other bystanders.

Remove the key from the ignition switch before you install the

kit.

-

Disconnect the negative-battery cable from the battery;

refer to the Operator’s Manual for your

machine.

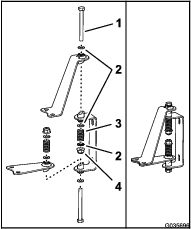

Assembling the Sensor Mounting Hinge

Parts needed for this procedure:

| Hinge | 2 |

| Angled strap (machines without covered booms) | 2 |

| Angled strap (machines with covered booms) | 2 |

| Top or bottom strap | 2 |

| Compression spring | 4 |

| Bushing | 8 |

| Bolt (5/16 x 3-1/4 inches) | 4 |

| Flat washer | 12 |

| Locknut (5/16 inch) | 4 |

Note: Assembly of the sensor mounting hardware depends upon whether

the Covered Boom Kit (Model 41602) is installed.

-

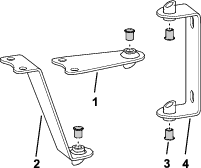

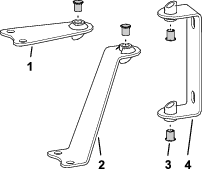

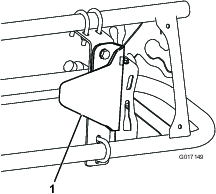

Lay out the hinges and straps as shown in Figure 2 (for an

uncovered boom) or Figure 3 (for a covered boom).

Note: There are 2 sets of 2 angled straps in loose parts. One set

is for an uncovered boom and the other set is for a covered boom.

You will have one set of 2 angled straps (either for the covered boom

or for the uncovered boom) that you will not use on the machine.

Note: The top straps for the uncovered booms also serve as the bottom

straps for the covered booms.

-

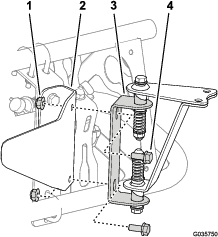

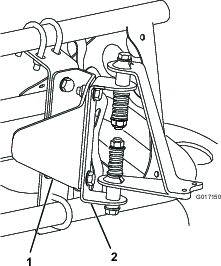

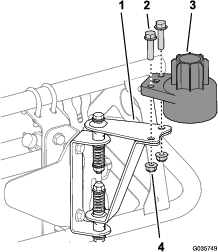

Insert the bushings into the welded

tube openings in the hinges and straps as shown in Figure 2 or Figure 3.

-

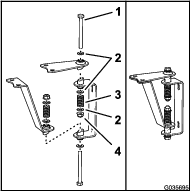

Install a flat washer on each of the 2 bolts (5/16

x 3-1/4 inches).

-

Insert the bolts through the hinged welded tube openings,

hinges, and straps as shown in Figure 4 or Figure 5.

-

Install a flat washer on the exposed

end of each of the bolts (Figure 4 or Figure 5).

-

Install a spring on the end of each bolt (Figure 4 or Figure 5).

-

Install a flat washer and a locknut on the end of

each bolt (Figure 4 or Figure 5), and tighten the locknuts until there is no slack

in the spring.

Note: Check to ensure that the hinges are not so tight that the mounted

sensors do not freely pivot on the hinges.

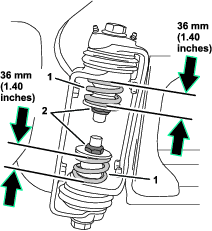

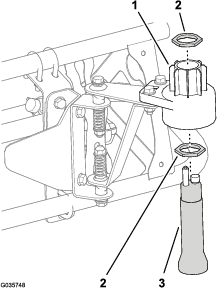

Adjusting the Boom-Hinge Springs

Important: Operating the spray system with the boom-hinge springs under

the incorrect compression could damage the boom assembly. Measure

the springs and use the jam nut to compress the springs to 36 mm (1.40

inches), if necessary.

Use another person or lifting equipment to support the boom

while adjusting the spring height of the boom hinge.

-

Extend the outer booms to the spray position (horizontal).

-

Support the booms while you are adjusting the spring

height.

-

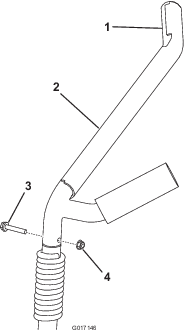

At the pivot bracket and hinge

for the outer boom, adjust the jam nut for the upper spring until

the compressed spring height measures 36 mm (1.40 inches).

-

Adjust the jam nut for the lower

spring until the compressed spring height measures 36 mm (1.40 inches).

-

Repeat steps 3 and 4 for the upper and lower springs

at the other outer boom.

-

At the boom hinge, measure the compression of the

upper and lower springs while the booms are in the extended position

(Figure 6).

-

Compress all springs until they measure 36 mm (1.40

inches).

-

Use the jam nut to compress any spring that measures

greater than 36 mm (1.40 inches).

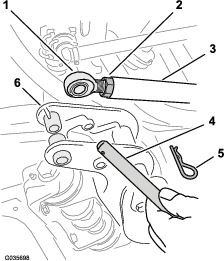

Adjusting the Booms

Note: You will need 2 wooden blocks about 10 cm (4 inches) in height

for this procedure.

The booms are set at the factory to travel downward no farther

than the horizontal position. To enable the ultrasonic boom kit to

maintain a consistent distance between the nozzles and the ground

when the ground slopes downward from the machine, you must adjust

the boom support system to allow the booms to travel below the horizontal

position to maintain a constant nozzle-to-ground distance.

-

Raise the booms and have them rest in the transport

cradle.

-

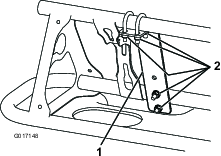

At the pivot brackets of the outer-boom

sections, remove the hairpin and clevis pin that secures the rod end

for the lift cylinder to the pivot bracket (Figure 7).

Note: There should be no more than 16 mm (5/8 inch) of exposed thread

on the eyelet to prevent the engaged threads from stripping and the

rod from pulling away.

-

Carefully lower the outer-boom sections onto wooden

blocks about 10 cm (4 inches) high as shown in Figure 8.

-

Start the machine and fully extend the lift cylinders.

-

Loosen the jam nuts at the rod ends for each lift

cylinder (Figure 7).

-

Adjust the rod end for the lift cylinders end until

the hole in the rod ends align with the holes in the pivot brackets

for the boom sections (Figure 7).

-

At each pivot bracket, secure the rod end to the bracket

with the clevis pin that you removed in step 2.

-

Secure the cotter pins to the pivot brackets with

the hairpin cotters (Figure 7) that you removed in step 2.

-

Tighten the jam nut at each rod until the nuts are

snug (Figure 7).

Replacing the Lift-Cylinder Manifold

Parts needed for this procedure:

| Hydraulic manifold block | 1 |

| Straight-hydraulic fitting | 4 |

Assembling the Cylinder-Lift Manifold

-

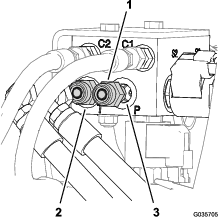

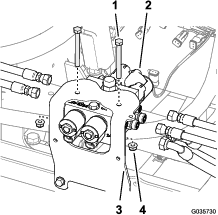

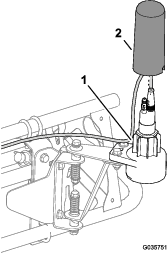

At the back of the sprayer, label the hoses at port-P

and port-T of the lift-cylinder manifold (Figure 9).

-

Remove the hoses from the straight-hydraulic fittings

at port-P and port-T of the lift-cylinder manifold (Figure 9).

-

Remove the straight-hydraulic fittings

from port-P and port-T of the old lift-cylinder manifold (Figure 9).

-

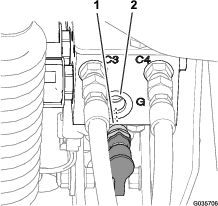

Remove the diagnostic fitting and

cap from port-G of the old lift-cylinder manifold (Figure 10)

-

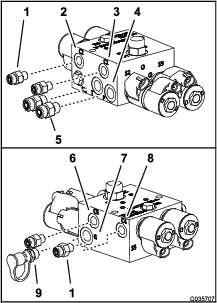

At the new lift-cylinder manifold, assemble the straight-hydraulic

fittings (Figure 11) that you removed in step 3 into port-P and port-T.

-

Assemble the 4 straight-hydraulic fitting from the

ultra sonic boom leveling kit into ports C1, C2, C3, and C4 of the

new lift-cylinder manifold (Figure 11).

-

Assemble the diagnostic fitting and cap that you removed

in step 4 into port-G of the new lift-cylinder manifold (Figure 11).

Replacing the Cylinder-Lift Manifold

-

If installed, remove the hydraulic block cover plate

from the lift-cylinder manifold.

-

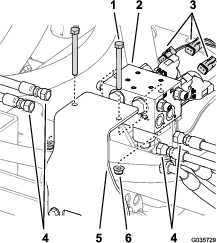

Label all the hoses connected to the lift-cylinder

manifold (ports C1, C2, C3, and C4), and disconnect them from the

cylinder manifold (Figure 12).

-

Disconnect the rear-wire harness connectors from the

solenoids of the lift-cylinder manifold (Figure 12).

-

Remove the lift-cylinder manifold

from the mounting bracket by removing 2 bolts and 2 locknuts (Figure 12).

Note: Save the 2 bolts and 2 locknuts.

-

Replace the mounting bracket for the lift-cylinder

manifold; refer to the installation instructions for the ultra sonic

boom finishing kit.

-

Multi Pro 1750 models—finishing

kit Part No. 130-8227

-

Multi Pro 5800 models—finishing

kit Part No. 130-8229

-

Multi Pro WM models—finishing

kit Part No. 133-2808

-

Install the new lift-cylinder manifold onto the mounting

bracket with the 2 bolts and 2 locknuts that you in step 4.

-

Install all the hoses onto the fittings of the lift-cylinder

manifold as follows:

-

The tank hose (3/8 inch) from the return filter connects

to the “T” port

-

The pressure hose (3/8 inch) connects to the “P”

port.

-

The hoses (1/4 inch) from the extend ports of the

boom-lift cylinders connect to C1 and C3 ports of the lift-cylinder

manifold.

-

The hoses (1/4 inch) from the retract ports of the

boom-lift cylinders connect to C2 and C4 ports of the lift-cylinder

manifold.

Important: Ensure that you install the hoses correctly.

-

Purge the hydraulic system. Refer to the Operator’s Manual.

Note: You will connect the wire harness from the ultra sonic boom

kit to the solenoids of the lift-cylinder manifold in Connecting the Wire Harness at the Boom-Lift Manifold.

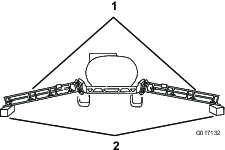

Replacing the Boom-Cradle Arms

Parts needed for this procedure:

The new boom-cradle arms allow the booms to fold up without

contacting each other, preventing any possible damage to the sensors

mounted on the booms.

-

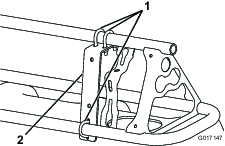

Remove the 2 boom-cradle arms by removing the bolt

and nut (Figure 14).

Note: Save the bolts and nuts to install the new boom-cradle arms.

-

Install each new boom-cradle arm and secure it with

the bolt and nut that you previously removed.

Installing the Sonic-Boom Sensors

Parts needed for this procedure:

| Sonic-boom sensor | 2 |

| Bracket | 2 |

| Programming plug | 2 |

| Sensor cover | 2 |

| Lower sensor housing | 2 |

| Cap tube | 2 |

| Sensor-guard bracket | 2 |

| Sensor cable (4 m) | 2 |

| Large nut | 4 |

| U-bolt | 6 |

| Locknut (1/4 inch) | 8 |

| Bolt (5/16 x 3/4 inch) | 8 |

| Bolt (5/16 x 1-1/4 inches) | 4 |

| Locknut (5/16 inch) | 12 |

| Cable tie | 12 |

Installing the Sensor Mount

-

Install a mounting bracket on the

front side of each boom near the outermost nozzle (Figure 15 and Figure 16) with 3

U-bolts and 6 locknuts (1/4 inch) .

-

Install the sensor guard bracket onto the mounting

bracket with 2 bolts (5/16 x 3/4 inch) and 2 flange nuts (5/16 inch)

as shown in Figure 17.

-

Install the sensor mounting hardware

onto the sensor guard bracket with 2 bolts (5/16 x 3/4 inch) and 2

locknuts (5/16 inch) as shown in Figure 18 (for an uncovered boom) or Figure 19 (for a

covered boom).

-

Repeat steps 1 through 3 for the outer-boom section at

the other side of the machine.

Installing the Sensor

Note: Refer to Before storage for installation of the dust cap.

-

Install the lower sensor housing

onto the sensor mounting hardware (Figure 20) with 2 bolts (5/16 x 1-1/4

inches) and 2 locknuts (5/16 inch).

-

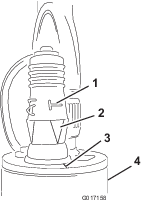

Install the sensor as follows:

-

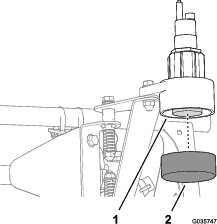

Assemble a large nut onto the sensor (Figure 21).

-

Insert the sensor into the lower sensor housing (Figure 21).

-

Adjust the nut until the sensor is flush with the

bottom of the lower housing.

-

Assemble the other large nut onto the sensor (Figure 21).

-

Torque the nut to 18 to 22 N∙m (13 to 16 ft-lb).

Note: Discard the lock washers that come with the sensors.

-

Install the programming plug on

the sensor (Figure 22).

Important: Ensure that you align the arrow below the sideways “T”

with the notch on the top edge of the sensor (Figure 22).

-

Repeat steps 1 through 3 for the outer-boom section at

the other side of the machine.

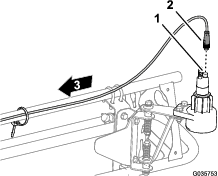

Installing the Wire Harness and Upper Housing

-

Connect the round 4-socket connector

of the sensor-wire harness for the 4-pin connector of the sensor (Figure 23).

-

Route the sensor-wire harness along the front of the

outer-boom section, through the support clamp, and to the 4-socket

connector of the wire harness from the ultra sonic boom finishing

kit—forward of the lift-cylinder manifold (Figure 24).

-

Connect the 4-pin connectors for the left and right

sensor-wire harnesses to the 4-socket connector of the wire harness

for the ultra sonic boom finishing kit (Figure 24) labeled LEFT

SONIC SENSOR and RIGHT SONIC SENSOR.

-

Install the upper housing over the sensor and onto

the lower housing (Figure 25).

Note: Ensure that the sensor wire is routed through the small opening

in the cover before seating the upper housing.

-

Secure the wire coming from the

sensor to the boom with cable ties (Figure 24).

Important: Allow enough slack in the wire around the sensor so that the

sensor can freely pivot on the hinge without pulling on the wire.

-

Repeat steps 1 through 5 for the outer-boom section at

the other side of the machine.

Note: For covered booms only: The sensors should

not detect the boom cover as this may interfere with the signal. If

you experience any difficulties during the calibration process, check

the sensors to ensure that their signals do not detect the boom cover.

Connecting the Wire Harness at the Boom-Lift Manifold

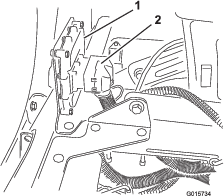

-

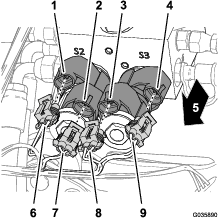

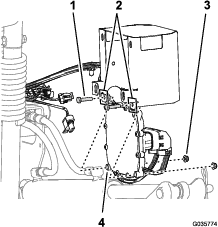

At the front of the lift-cylinder manifold, connect

the 4 electrical connectors of the wire harness for the sonic boom

to the solenoids for controlling boom lift as shown in Figure 26.

-

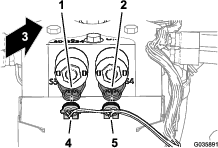

At the back of the lift-cylinder manifold, connect

the 2 electrical connectors of the wire harness for the sonic boom

to the solenoids for controlling sonic enable as shown in Figure 27.

Mounting the Electronic Control

Parts needed for this procedure:

| Electronic controller | 1 |

| Bolt (1/4 x 1-1/8 inch) | 4 |

| Locknut (1/4 inch) | 4 |

Connecting the Wire Harness to the Electronic Controller

Multi Pro 1750 and Multi Pro WM Machines

-

Route the wire harness for the sonic boom to the hydraulic

manifold.

-

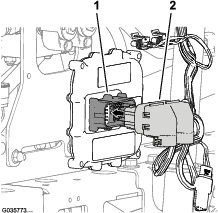

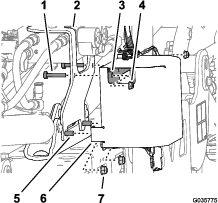

Connect the 50-socket connector of the wire harness

for the sonic boom to the 50-pin connector of the electronic controller,

and secure the connectors with the socket-head screw (Figure 28).

Note: The controller electrical connection is keyed and can be connected

only 1 way.

-

Torque the socket-head screw to 2.7 to 3.2 N-m (24

to 28 in-lb).

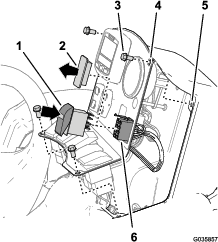

Installing the Controller to the Machine

Multi Pro 1750 and Multi Pro WM Machines

-

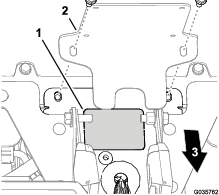

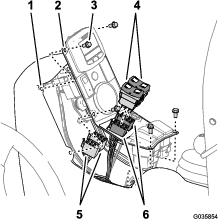

Align the electronic controller to the interior of

the controller cover with the lower outboard mounting holes of the

controller aligned with the holes in the lower rear flange of the

cover (Figure 29)

-

Assemble the controller to the cover with 2 bolts

(1/4 x 1-1/8 inches) and 2 flange locknuts (1/4 inch) as shown in Figure 29.

-

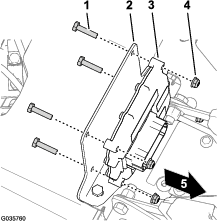

Remove the 2 flange locknuts (5/16

inch) that secure the mounting bracket of the ultra sonic boom finishing

kit from the cylinder mount (Figure 30).

Note: Leave the mounting bracket assembled to the cylinder mount.

-

Assemble the controller cover (Figure 30) onto the flange-head bolt

(5/16 x 1 inch) at the lower forward holes in the cover, and loosely

secure the cover, bracket and mount with the 2 flange locknuts (5/16

inch) that you removed in 3.

-

Assemble the 2 bolts (1/4 x 1-3/8 inches) through

the upper holes in the mounting bracket (ultra sonic boom finishing

kit), rear flange (controller cover), and controller (Figure 30) with the

2 flange locknuts (1/4 inch).

-

Torque the 5/16 flange-head bolt and flange nuts to

1978 to 1243 N∙cm (175 to 225 in-lb).

-

Torque the 1/4 flange-head bolt and flange nuts to

1017 to 2542 N∙cm (90 to 110 in-lb).

Installing the Controller to the Machine

Multi Pro 5800 Machines

-

Rotate the operator and passenger seats forward and

secure the seats with the prop rods.

-

For 2015 and before machines—locate the knockout plug between the inboard operator and

passenger seat-belt halves, and remove the knockout plug from the

console base (Figure 32).

-

Assemble the electronic controller to the mounting

bracket (Figure 32) with the 4 bolts (1/4 x 1-1/8 inch) and 4 locknuts (1/4 inch).

-

Torque the nuts and bolts to 1017 to 1243 N∙cm (90

to 110 in-lb)

Connecting the Wire Harness to the Electronic Controller

Multi Pro 5800 Machines

-

Route the 50-socket connector of the wire harness

for the sonic boom as follows:

-

For 2015 and before machines—the

branch of the wiring harness with the 50-socket connector is routed

through the opening in the console base that you made in step 2; refer to

the installation instructions for the ultra sonic boom finishing kit.

-

For 2015 and after machines—the

branch of the wiring harness with the 50-socket connector is routed

through the large grommet in the console base; refer to the installation

instructions for the ultra sonic boom finishing kit.

-

Connect the 50-socket connector of the wire harness

for the sonic boom to the 50-pin connector of the electronic controller,

and secure the connectors with the socket-head screw (Figure 33).

Note: The electrical connection for the controller is keyed and can

be connected only 1 way.

-

Torque the socket-head screw to 2.7 to 3.2 N-m (24

to 28 in-lb).

Connecting the Wiring Harness and Switches

Parts needed for this procedure:

| Rocker switch (illuminated) | 1 |

| Cable tie | 12 |

Installing the Ultra Sonic-Mode Switch

Multi Pro 1750 Machines

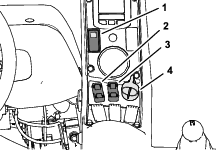

-

If installed, remove the 4 flange-head

bolts (1/4 x 1/2 inch) that secure the panel cover to the top of the

console as shown in Figure 34.

-

Remove the switch plug from the panel cover of the

console (Figure 34).

-

Align the 8-socket connector of the wiring harness

of the ultra sonic boom finishing kit through the opening in panel

cover (Figure 34).

-

Connect the 8-socket connector of the wiring harness

of the ultra sonic boom finishing kit labeled SONIC MODE

MANUAL VS. AUTO to the rocker switch (Figure 34).

-

Insert the rocker switch in the dash panel opening

until the switch snaps securely (Figure 34).

-

Align the holes in the panel cover to the holes in

the top of the console (Figure 34).

-

Secure the panel to the console with the bolts (Figure 34) that you

removed in step 1.

Installing the Ultra Sonic-Mode Switch

Multi Pro 5800 Machines

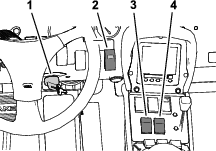

-

Remove the switch plug in the dash panel at the location

shown in Figure 35.

-

Connect the 8-socket connector of the wiring harness

of the ultra sonic boom finishing kit labeled SONIC MODE

MANUAL VS. AUTO to the rocker switch (Figure 35).

-

Insert the rocker switch in the dash panel opening

until the switch snaps securely (Figure 35).

Note: Align the tail of the switch down.

Installing the Ultra Sonic-Mode Switch

Multi Pro WM Machines

-

If installed, remove the 4 flange-head

bolts (1/4 x 1/2 inch) that secure the control panel to the console

as shown in Figure 36.

-

Remove the switch plug from the control panel of the

console (Figure 36).

-

Align the 8-socket connector of the wiring harness

of the ultra sonic boom finishing kit through the opening in control

panel (Figure 36).

-

Connect the 8-socket connector of the wiring harness

of the ultra sonic boom finishing kit labeled SONIC MODE

MANUAL VS. AUTO to the rocker switch (Figure 36).

-

Insert the rocker switch in the control panel opening

until the switch snaps securely (Figure 36).

Note: Align the tail of the switch down.

-

Align the holes in the control panel to the holes

in the top of the console (Figure 36).

-

Secure the panel to the console with the bolts (Figure 36) that you

removed in step 1.

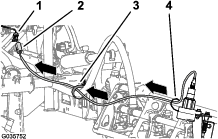

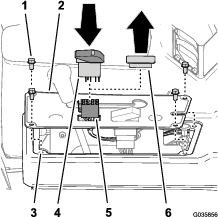

Connecting the Boom-Lift Switches to the Sonic-Boom Harness

Connecting the Switches to the Harness

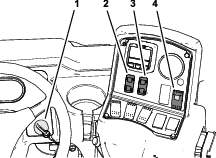

Multi Pro 1750 or Multi Pro WM Machines

-

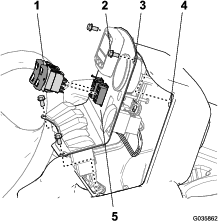

Remove the 4 flange-head bolts

(1/4 x 1/2 inch) that secure the switch panel to the center console,

and lift the panel (Figure 37 or Figure 28).

-

Disconnect the 8-socket connectors of the machine-wire

harness from the boom-lift switches (Figure 37 or Figure 38).

Note: If additional clearance is needed, remove the boom-lift switches

from the switch panel.

-

Connect the rocker switches into the 8-socket connectors

of the wiring harness for the ultra sonic boom finishing kit (Figure 37 or Figure 38).

Note: Ensure that the sonic-boom harness connector labeled LEFT ACTUATOR SWITCH is aligned with the left switch

opening in the switch panel.

-

If you removed the switch(es) from the switch panel,

insert the boom-lift switch(es) into the openings in the center-console

panel until the switch(es) snaps securely.

-

Align the holes in the switch panel with the frame

of the console (Figure 37 or Figure 38).

-

Secure the side cover on the center console with the

4 flange-head bolts (1/4 x 1/2 inch) (Figure 37 or Figure 38) that you removed in step 1.

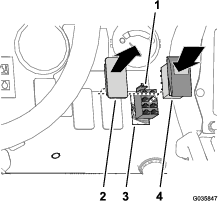

Connecting the Switches to the Harness

Multi Pro 5800 Machines

-

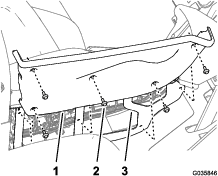

Remove the 5 flange-head bolts

(1/4 x 3/4 inch) that secure the right-side cover to the center console

(Figure 39).

-

Remove the rocker switches for the left and right

boom-lift controls from the center-console panel (Figure 39).

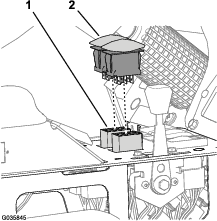

-

Disconnect the 8-socket connectors of the wiring harness

for the machine from the boom-lift switches for the left and right

boom-lift control circuits (Figure 40).

Note: Tuck the connectors for the wire harness for the machine alongside

the harness.

-

Connect the rocker switches into the 8-socket connectors

of the wiring harness for the ultra sonic boom finishing kit (Figure 40).

Note: Ensure that the sonic-boom harness connector labeled LEFT ACTUATOR SWITCH is aligned with the left switch

opening in the center-console panel.

-

Insert the boom-lift switches in the openings in the

center-console panel until the switches snap securely (Figure 40).

-

Align the holes in the right-side cover with the frame

of the center console (Figure 39).

-

Secure the side cover on the center console (Figure 39) with the

5 flange-head bolts (1/4 x 3/4 inch) that you removed in step 1.

Finishing Installation of the Ultra Sonic Boom Leveling Kit

-

Connect the negative-battery cable to the battery;

refer to the Operator’s Manual for your

machine.

-

For Multi Pro 1750 and Multi Pro 5800 machines, rotate

down the seats.

Calibrating the Sonic Booms

Once you initiate the controller processor for calibration,

you will have 20-seconds to calibrate the sensors on the booms. The

distance you set between the sensor on each boom and the ground after

the 20-second calibration period is the boom height setting in automatic

mode until the next time you calibrate the sensor.

Note: For uncovered booms: The default height

setting is 51 cm (20 inches) from the nozzle to the ground. If, after

setting a boom to a height different from that of the factory default

setting, you wish to restore the calibration to the factory-default

setting, calibrate the boom with the boom in the cradle. For covered booms: The default height setting of 51 cm

(20 inches) is for uncovered booms only. You must calibrate the sensors

on covered booms.

-

Ensure that the turf sprayer is parked and away from

any trees, buildings, vehicles, debris, and underground utilities

and plumbing.

-

Lower the booms to the horizontal position.

-

Turn off the ignition key.

-

Press the sonic-boom switch to the ON position (Figure 41, Figure 42, or Figure 43).

-

While pressing and holding both the left boom-lift

control switch to the LOWER position and

the right boom-lift control switch to the RAISE position, turn the ignition key and start the machine.

-

Release the boom switches.

Note: The indicator light on the sonic-boom switch will flash rapidly,

indicating that the sonic boom system is in calibration mode. You

now have 20 seconds to use the Raise and Lower boom switches to set

the desired distance between the booms to the ground. After the 20

seconds, the indicator light flashes slowly.

-

Raise and lower the outer-boom sections using the

boom-lift control switches to adjust the height of each boom until

you achieve the desired distance between the tip of the boom and the

ground.