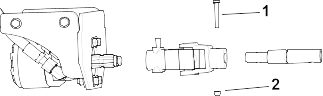

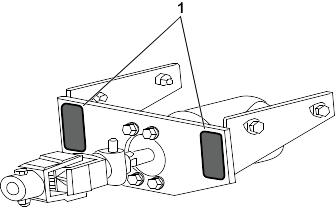

Safety Decal Location

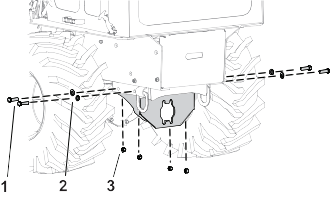

G434640

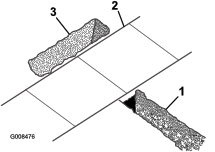

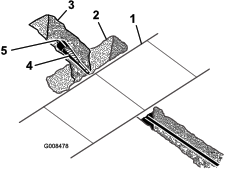

- Decal147-5746

Decal Part: 147-5746

decal147-5746

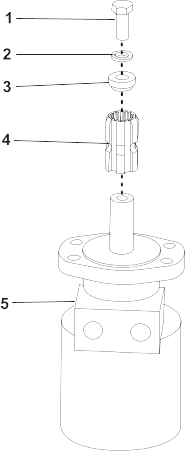

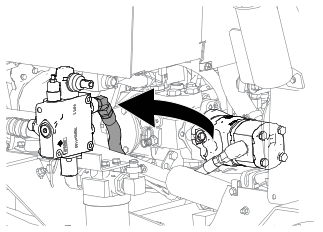

- Rotating shaft hazard; keep away from moving parts.

Decal Part: 147-5747

decal147-5747

Decal Part: 147-5748

decal147-5748

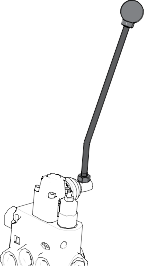

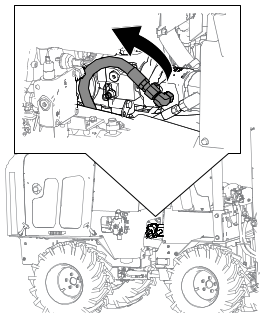

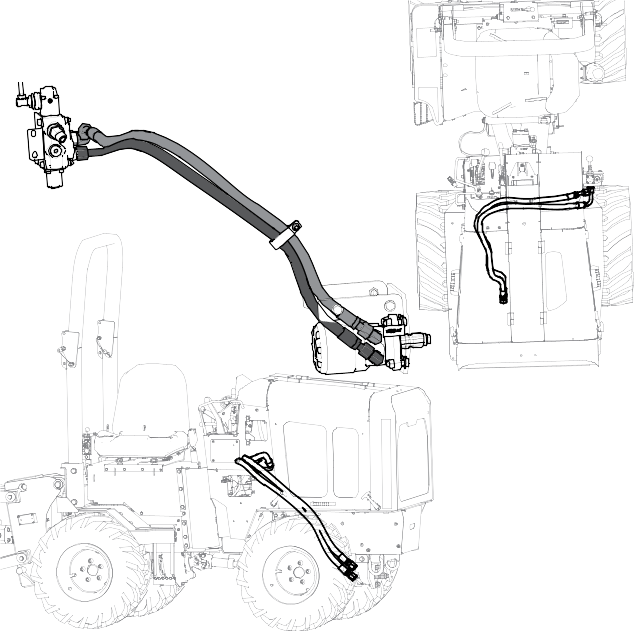

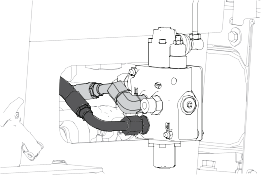

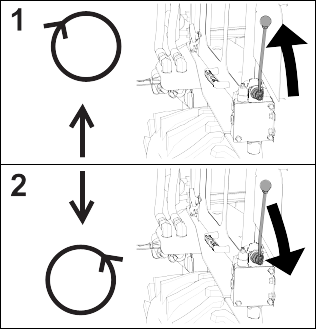

- Push the lever forward to rotate the drill clockwise; Pull the lever rearward to rotate the drill counterclockwise.