Important: Install the Auxiliary Wire Harness Kit (Toro Part Number 139-1186;

sold separately) before installing this kit.

Preparing the Machine

Note: Determine the left and right sides of the machine from the normal

operating position.

-

Park the traction unit on a level surface.

-

Disengage the auxiliary hydraulics.

-

Lower any equipped attachments; refer to your Operator’s Manual.

-

Engage the traction unit parking brake.

-

Shut off the traction unit engine and remove the key.

-

Wait for the traction unit to cool.

-

Disconnect the traction unit battery; refer to your Operator’s Manual.

Installing the Hydraulic Angle

Parts needed for this procedure:

| Manifold assembly | 1 |

| Bolt (3/8 x 1 inch) | 3 |

| Lock washer | 3 |

| Flat washer | 3 |

| Hose clamp | 1 |

| Bolt (5/16 x 1-1/2 inches) | 1 |

| Long hose | 1 |

| Short hose | 1 |

| Hydraulic cylinder assembly | 1 |

| Pivot pin | 2 |

| Snap ring | 4 |

| Large washer | 4 |

| 14-pin wire harness | 1 |

| Y-adapter | 1 |

Important: You may discard all removed parts unless otherwise noted.

Warning

Seek immediate medical attention if fluid is injected into skin.

Injected fluid must be surgically removed within a few hours by a

doctor.

-

Ensure that all hydraulic-fluid hoses and lines are

in good condition and all hydraulic connections and fittings are tight

before applying pressure to the hydraulic system.

-

Keep your body and hands away from pinhole leaks or

nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks.

-

Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic system.

-

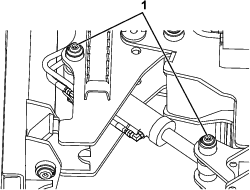

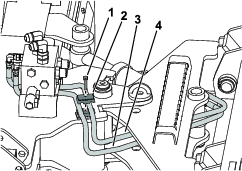

Mark each of the hoses as left or right (from the

operator’s position).

-

Remove the nut and bolt securing the hose clamp to

the hose mount (Figure 1).

-

Disconnect the power rake motor hoses from the attachment

hoses at the angle fitting (Figure 1).

-

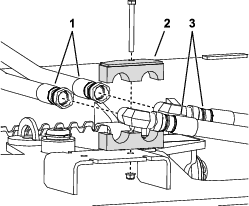

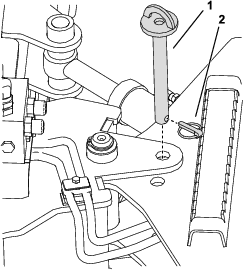

Secure the manifold assembly to the hose mount with

3 bolts (3/8 x 1 inch), lock washers and flat washers (Figure 2).

Note: Secure the manifold with the angled fittings facing toward the

front of the rake.

-

Torque the bolts securing the manifold to 37 to 45

N∙m (27 to 33 ft-lb).

-

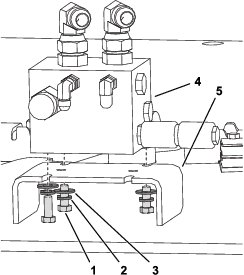

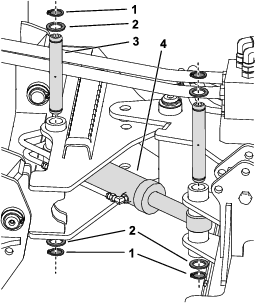

Install the attachment hoses directly to the straight

fittings in the rear of the manifold assembly (Figure 3).

Important: Install the hose connections so that they are secure, but do

not tighten any of these connections until Completing the Installation.

-

Remove the angle fittings from the power rake hoses

and install the hose ends to the angled fittings on top of the manifold

assembly (Figure 3).

Important: Do not twist or cross the hoses. Retain the orientation of the

hoses on the valve as they were in the clamp.

-

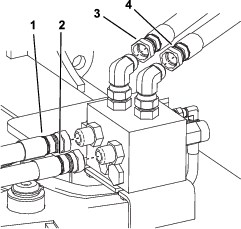

Install the long and short hoses to the manifold,

then route the hoses under the manifold and install the hose clamp

as shown in Figure 4 and Figure 6.

-

Remove the angle pin and the lynch pin that are securing

the power rake from angling (Figure 5).

-

Align the hydraulic cylinder assembly as shown in Figure 6.

Note: You may need to angle the power rake manually to match the cylinder

length.

-

Install a pivot pin at each end of the cylinder with

2 large washers and snap rings at each end of the pivot pins (Figure 6).

-

Use the auxiliary hydraulic controls to adjust the

angle of the power rake.

-

Install the 14-pin wire harness (short wire harness)

to the auxiliary wire harness (sold separately) at the coupler mount

(Figure 7).

-

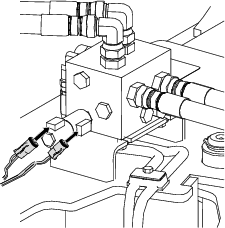

Install the open connector of the Y-adapter (long

wire harness) to the 14-pin wire harness.

-

Route the 2 free connectors on the Y-adapter to the

open connectors left side of the manifold and connect them (Figure 8).

Note: Secure the wire harness using cable ties as needed.

Completing the Installation

-

Tighten the larger hose connections at the top and

rear of the manifold to 115 to 127 N∙m (85 to 94 ft-lb).

Note: When tightening a hose connection to a fitting, always use 2

wrenches; 1 wrench on the hose flats so that the hose does not twist,

and the other wrench on the hose nut to secure the hose to the fitting.

-

Tighten the smaller hose connections at the front

of the manifold to 24 to 27 N∙m (18 to 20 ft-lb).

-

Lubricate the cylinder grease fittings; refer to Lubricating the Hydraulic Angle.

-

Connect the traction unit battery; refer to your traction

unit Operator’s Manual.

-

Turn on the traction unit and test the hydraulic angle

operation.

Important: To operate the cylinder, flow must be running to the attachment.

While flow is running, operate the cylinder using the secondary attachment

function on the joystick.

Note: If the hydraulic angle is not operating correctly, ensure that

the hoses are connected to the correct ports.

-

If any hydraulic fluid was spilled, ensure that the

traction unit hydraulic fluid is at the correct level; refer to your Operator’s Manual.

-

Use the auxiliary hydraulic controls to adjust the

angle of the power rake.