Installation

Important: We recommend installing this kit when you perform your next oil change; refer to the Operator’s Manual. Performing the oil change at the end of the day allows the Loctite® 620 to cure overnight.

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for the engine to cool completely.

-

Raise the cargo bed and secure it in the service position using the prop rod; refer to the Operator’s Manual.

Removing the Existing Dipstick Tube

-

Remove the dipstick from the tube.

Retain the dipstick.

-

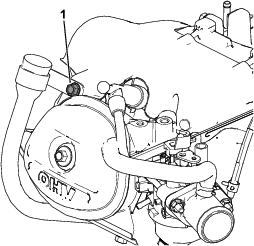

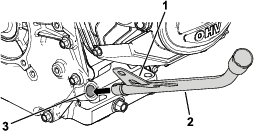

Remove the bolt securing the dipstick tube to the heat shield of the engine (Figure 1).

Retain the bolt.

-

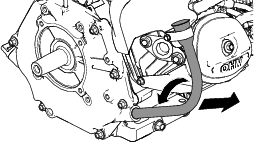

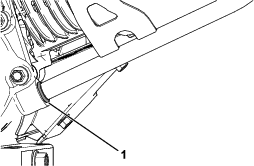

Rotate the dipstick tube to the left and remove it (Figure 2).

-

Install the previously removed bolt to the heat shield and torque the bolt to 10.7 to 11.3 N∙m (95 to 100 in-lb).

Installing the New Dipstick Tube

Parts needed for this procedure:

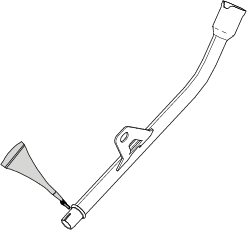

| Dipstick tube | 1 |

| Loctite® 620 (0.5 ml) | 1 |

Important: For best results, allow the Loctite® 620 to cure for 24 hours to develop the proper heat resistance.You can accelerate the curing time to 8 hours if the ambient temperatures are above 22°C (71.6°F).

-

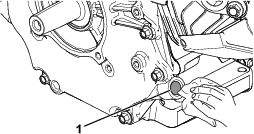

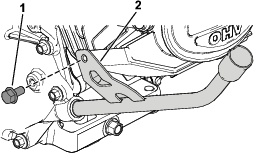

Remove the bolt from the engine-mounting surface (Figure 3).

Retain the bolt.

-

Thoroughly clean the dipstick tube opening where you will install the dipstick tube (Figure 4).

-

Apply the Loctite® 620 uniformly and evenly around the sealing surface of the dipstick tube (Figure 5).

-

Insert the dipstick tube at an angle into the tube opening (Figure 6).

-

Using a rubber mallet, tap the bracket (item 1) on the dipstick tube (Figure 6) to secure the tube into the engine.

Important: Striking anything but the bracket on the tube could damage it.

-

Ensure that the bottom of the dipstick tube is flush with the tube opening (Figure 7).

-

Rotate the dipstick tube so that it is parallel with the engine-mounting surface and secure it using the previously removed bolt (Figure 8).

-

Torque the bolt to 10.7 to 11.3 N∙m (95 to 100 in-lb).

-

Insert the dipstick into the dipstick tube.

-

Ensure that the Loctite® 620 cures properly.

-

Lower the cargo bed.