Maintenance

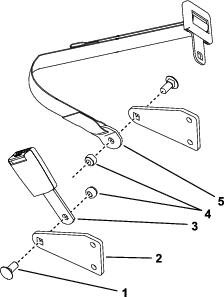

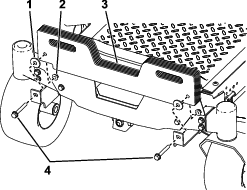

Checking the Seat Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Inspect the seat belt for wear, cuts, and proper operation of the retractor and buckle. Replace the seat belt if it is damaged.

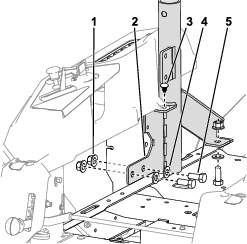

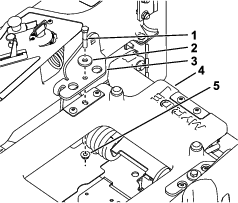

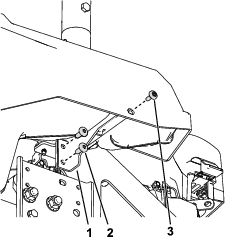

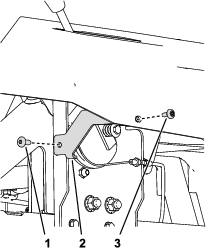

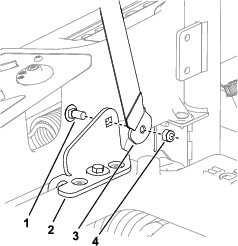

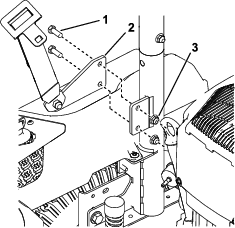

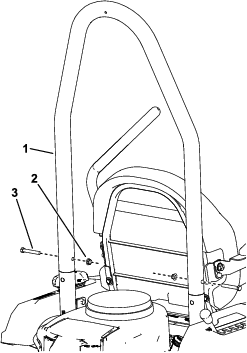

Checking the Rollover Protection System (ROPS)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Visually inspect the ROPS for loose hardware or any other possible problem. Tighten the hardware or correct the problem before operating.