| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

A walking operator controls this machine, and it is intended to be used by professional, hired operators in commercial applications. The machine is designed primarily for aerating large areas on well-maintained lawns in parks, golf courses, sports fields, and on commercial grounds. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

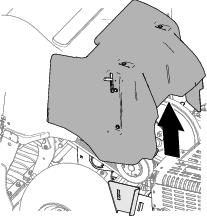

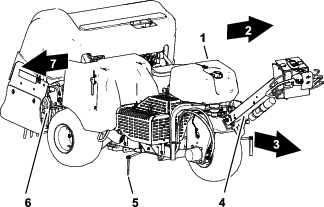

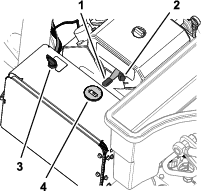

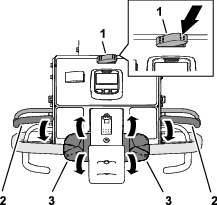

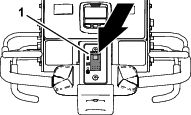

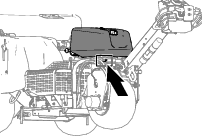

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

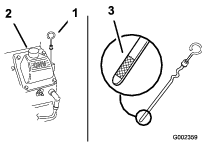

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Because in some areas there are local, state, or federal regulations requiring that a spark arrester be used on the engine of this machine, a spark arrester is available as an option. If you require a spark arrester, contact your Authorized Service Dealer. Genuine Toro spark arresters are approved by the USDA Forestry Service.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

General Safety

This product is capable of causing personal injury. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and working on the machine.

-

Keep the machine away from bystanders while it is moving.

-

Keep clear of the opening around the tines. Keep bystanders and pets away from the machine.

-

Keep children out of the operating area. Never allow children to operate the machine.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop before servicing, fueling, or unclogging the machine.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

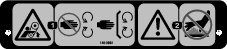

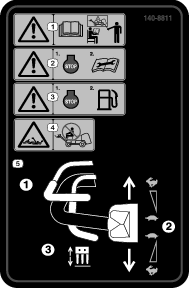

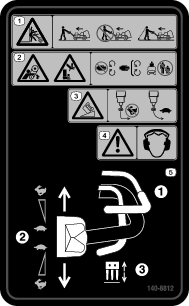

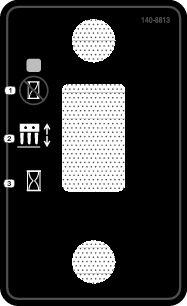

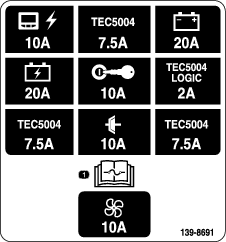

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Note: The front of the machine is located at the operator handle, and is the normal operator position. Left and right are in relation to the direction of travel as you walk with machine following you.

Note: To raise the coring head after uncrating the machine, release the aerate bail and start the engine; refer to Starting the Engine and Raising the Coring Head for more information.

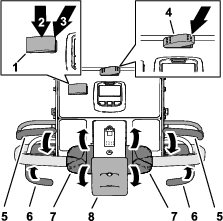

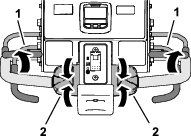

Installing the Rear Wheels

Parts needed for this procedure:

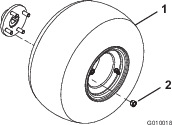

| Wheel assembly | 2 |

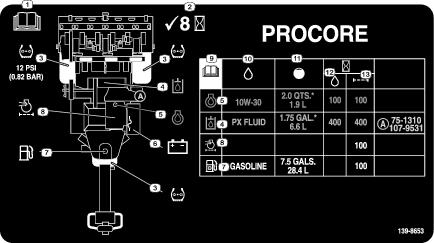

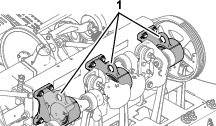

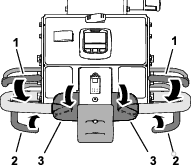

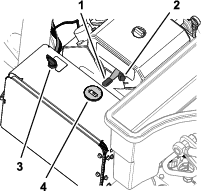

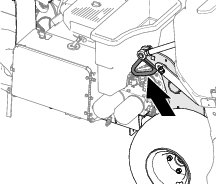

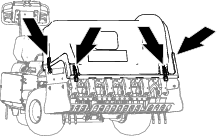

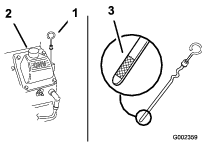

Note: If available, use a hoist to lift the rear of the machine. Use the eyelets in the coring-head bearing housings as hoist attachment points (Figure 3).

-

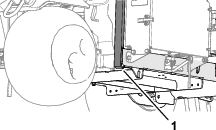

At the rear of the machine, remove the 4 lug nuts that secure the rear of the machine to brackets of the shipping pallet.

-

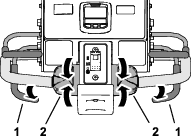

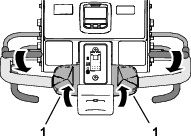

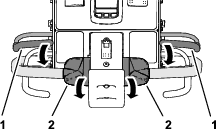

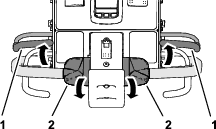

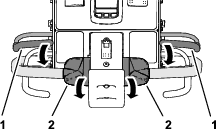

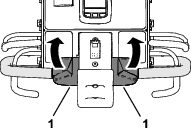

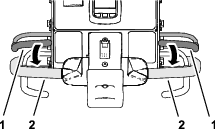

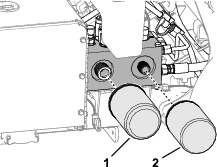

Assemble a wheel assembly onto each rear-wheel hub with the 4 lug nuts (Figure 4).

-

Torque the lug nuts to 61 to 75 N∙m (45 to 55 ft-lb).

-

Repeat steps 1 though 3 at the other side of the machine.

-

Deflate all tires to 83 kPa (12 psi).

Installing the Handle

Parts needed for this procedure:

| Handle | 1 |

| Locknut (1/2 inch) | 3 |

Assembling the Handle to the Machine

-

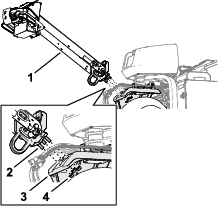

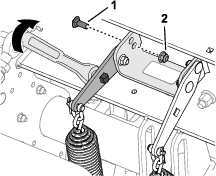

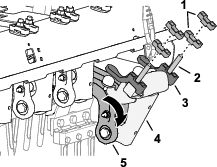

Insert the studs at the end of the handlebar into the holes in the steering arm (Figure 5).

Note: Have another person help hold the handlebar.

-

Thread a flange locknut (1/2 inch) onto each of the 3 studs.

-

Torque the flange locknuts to 91 to 113 N∙m (67 to 83 ft-lb).

-

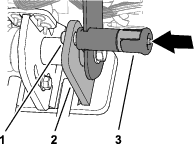

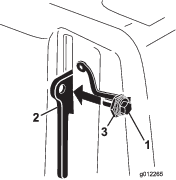

Rotate the handlebar up and secure it with the handlebar-latch pin (Figure 6).

Assembling the Brake Cable

-

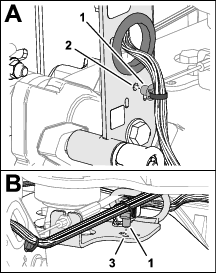

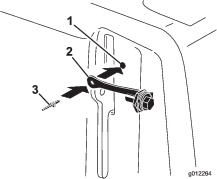

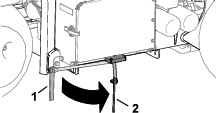

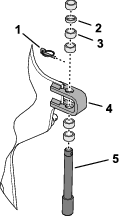

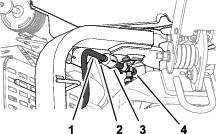

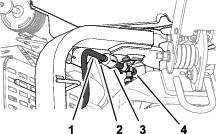

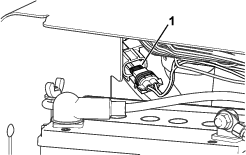

Route the fitting of the brake cable under the bottom of the handle-bar channel (Figure 7).

-

Assemble the brake-cable fitting on to the clevis pin, and secure the fitting to the pin with the washer and hairpin.

Connecting the Wire Harness

-

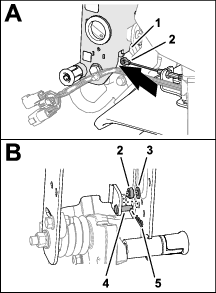

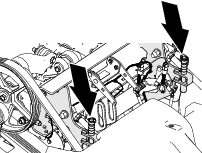

Route the 6-pin connector and the 12-pin connector of the machine wire harness through the grommet in the handle-bar channel (Figure 8).

-

Plug the 12-pin connector of the machine harness into the 12-socket connector of the handlebar wire harness (Figure 9).

-

Plug the 6-pin connector of the machine harness into the 6-socket connector of the handlebar harness.

-

Insert the push-in anchor of the machine harness into the hole in the handle-bar channel (Figure 10).

-

Insert the push-in anchor of the machine harness into the hole in the guide bracket.

-

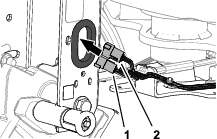

Secure the machine harness to the handle-bar channel with a cable tie through the slots in the channel (Figure 11).

-

Secure the machine harness to the guide bracket with a cable tie through the slots in the bracket.

Installing the Handlebar Cover

-

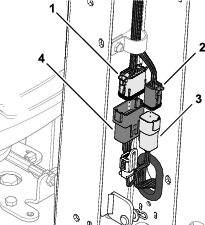

Align the small notch in the handlebar cover with the notch up (Figure 12).

-

Align the holes in the cover with the holes in the handle-bar channel.

-

Secure the cover to the handlebar with the 6 thread-forming screws (1/4 inch).

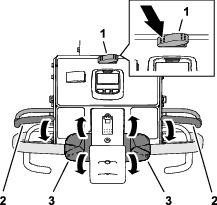

Charging and Connecting the Battery

Parts needed for this procedure:

| Bolt (1/4 x 1 inch) | 2 |

| Flange nut (5/16 inch) | 2 |

Charging the Battery

Danger

Battery electrolyte contains sulfuric acid which is a deadly poison and causes severe burns.

-

Avoid contact with skin, eyes, or clothing. Wear safety glasses to shield your eyes and rubber gloves to protect your hands.

-

Remove, charge, and install the battery where clean water is always available for flushing the skin.

Warning

Charging the battery produces gasses that can explode.

Never smoke near the battery and keep sparks and flames away from it.

Warning

Battery terminals or metal tools could short against metal machine components, causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

When removing or installing the battery, do not allow the battery terminals to touch any metal parts of the machine.

-

Do not allow metal tools to short between the battery terminals and metal parts of the machine.

Warning

Incorrect battery cable routing could damage the machine and cables, causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

Always disconnect the negative (black) battery cable before disconnecting the positive (red) cable.

-

Always connect the positive (red) battery cable before connecting the negative (black) cable.

-

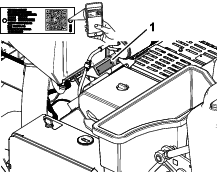

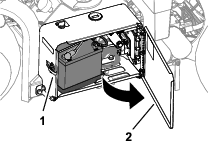

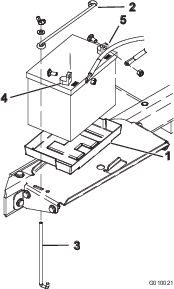

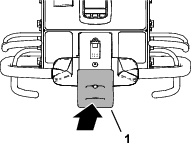

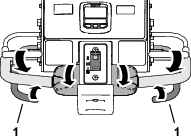

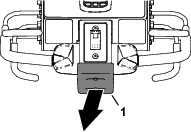

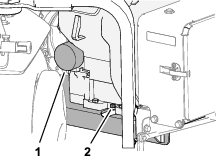

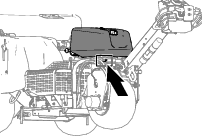

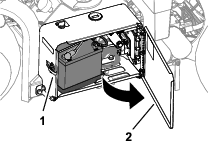

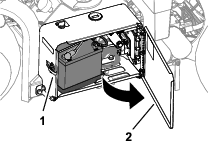

Unlatch and open the battery-compartment door (Figure 13).

-

Remove the battery from the battery compartment.

-

Use a battery charger with a 3 to 4 A charging capacity to charge the battery.

-

When the battery is charged, disconnect the charger from the electrical outlet and battery posts.

Installing the Battery

-

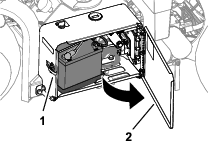

Assemble the battery into the tray in the battery compartment (Figure 14). Position the battery so that the terminals are aligned the outward.

-

Secure the battery to the compartment base with a hold-down rod, 2 J-rods, 2 flat washers, and 2 wing nuts.

-

Secure the positive cable (red) to the positive (+) battery terminal with a carriage bolt and nut.

-

Slide the rubber boot over the positive terminal.

-

Secure the negative cable (black) to the negative (–) terminal of the battery with a carriage bolt and nut.

-

Close and latch the battery compartment door.

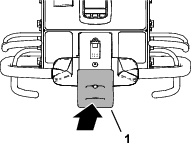

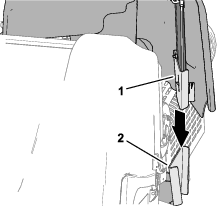

Installing the Rear Hood Latch Lock

Parts needed for this procedure:

| Latch lock | 2 |

| Tap bolt | 2 |

| Internal tooth lock washer | 2 |

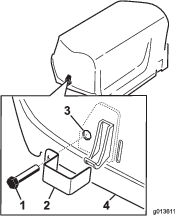

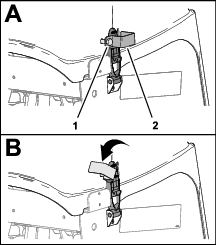

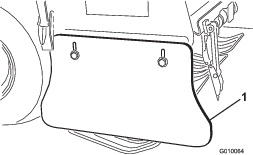

If you are setting up this machine for use in the European Union (CE), install the hood-latch lock onto the rear hood as follows to comply with CE regulations.

-

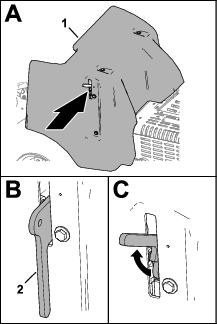

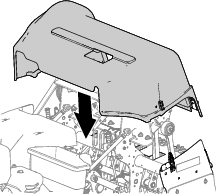

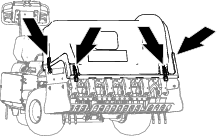

Remove the rear hood.

-

Install a latch lock over the hood latch (Figure 15) with a tap bolt (2 total).

-

Use a pliers and a wrench to thread an internal lock washer onto each bolt (1 to 2 threads) to secure the bolts to the hood.

-

Repeat steps 2 through 3 at the other side of the hood.

-

Install the rear hood.

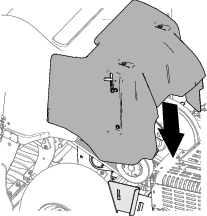

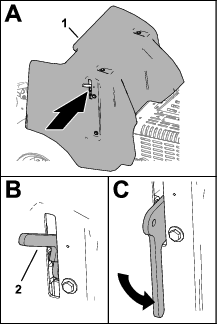

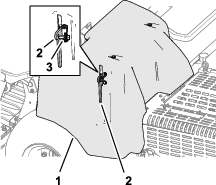

Installing the Belt-Cover Latch Lanyard

Parts needed for this procedure:

| Lanyard | 1 |

| Pop rivet | 1 |

| Bolt (1/4 x 1 inch) | 1 |

| Locknut (1/4 inch) | 1 |

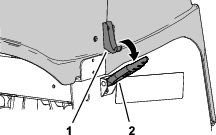

If you are setting up this machine to be compliant with CE, Install the belt cover latch link as follows.

-

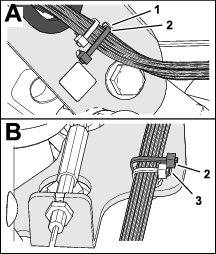

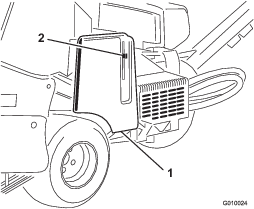

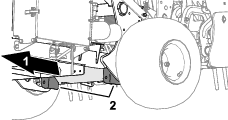

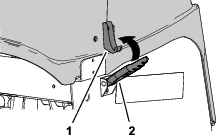

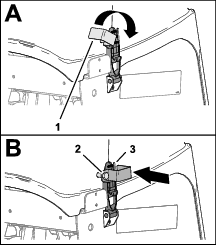

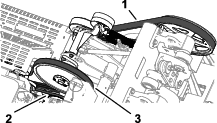

Locate the hole in the belt cover next to the slot for the latch lever (Figure 16 and Figure 17).

-

Secure the lanyard assembly to the hole in the belt cover with a pop rivet (Figure 17).

-

Thread the bolt into the latch lever (Figure 18).

Applying the CE Decal and the Production Year Decal

Installing the Tine Holders, Turf Guards, and Tines

A wide selection of tine holders, turf guards, and tines are available for the machine. Refer to Installing Turf Guards, Tine Holders, and Tines.

Product Overview

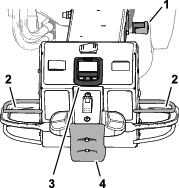

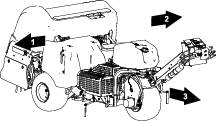

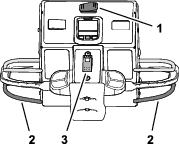

Handlebar Controls

Handle-Bar Latch

Use the handle-bar latch (Figure 21) to secure the handlebar in the upward position and to engage the parking brake.

Important: Secure the handlebar in the up position anytime you leave the operator’s position.

Operator-Presence Bail

The operator-presence bail (Figure 21) helps ensure that you are in the operator’s position while driving the machine or running the coring head.

Note: Releasing the operator-presence bail does not shut off the engine.

The InfoCenter

Use the InfoCenter (Figure 21) to adjust how the coring head controls work.

Bump-Stop Switch

If you contact the bump-stop switch (Figure 21), the machine performs the following actions:

-

The machine stops driving forward.

-

The coring head raises and stops running.

Note: Contacting the bump-stop switch does not shut off the engine. You can drive the machine in the reverse direction, but you must reset the bump switch to drive forward.

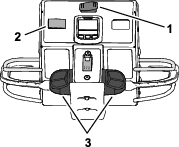

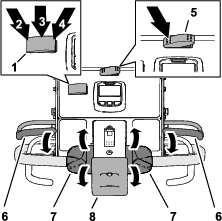

Traction Controls

Transport/Aeration Switch

Use the transport/aeration switch (Figure 22) to control the maximum speed you can drive the machine while aerating or transporting the machine.

-

The AERATION position allows aeration and limits ground speed to 4.0 kph (2.5 mph) or slower.

-

The TRANSPORT position allows you to drive the machine at full ground speed or slower between job sites.

Note: You cannot aerate with the transport/aeration switch in the TRANSPORT position.

Traction Controls

Use the left or right traction control (Figure 22) to drive the machine forward or backward.

Speed-Lock Switch—Transport Mode

Use the speed-lock switch (Figure 22) to maintain the ground speed at which you drive the machine; similar to cruise control in an automobile.

-

The ENGAGE position locks the current ground speed at which the machine is driving.

-

The ON position activates the ground-speed lock.

-

The OFF position shuts off the ground-speed lock.

Speed-Lock Switch—Aerate Mode

Use the speed-lock switch (Figure 22) to maintain the ground speed at the aeration hole spacing rate.

-

The ON position—activates and engages the ground-speed lock to maintain the ground speed at the aeration hole spacing rate when you release the aerate bail at the end of an aeration pass.

-

The OFF position shuts off the ground-speed lock—the machine stops moving forward when you release the aerate bail.

Coring Head Controls

Engine Controls

Throttle Lever

Use the throttle lever (Figure 24) to control the engine speed:

-

Moving throttle lever forward increases engine speed—toward the FAST position.

-

Moving throttle lever backward decreases engine speed—toward the SLOW position.

Note: The engine speed regulates the speed of the coring head.

Choke

Use the choke when starting a cold engine (Figure 24).

Ignition Switch and Key

Use the ignition switch (Figure 24) to start and shut off the engine. The switch has 3 positions:

-

START—rotate key clockwise to the START position to engage the starter motor.

-

RUN—when the engine starts, release the key and it moves automatically to the ON position.

-

OFF—rotate the key counterclockwise to the OFF position to shut off the engine.

Tachometer

Use the tachometer to determine the engine speed (Figure 24).

Fuel-Shutoff Valve

Use the fuel-shutoff valve to control fuel from the fuel tank (Figure 25).

Using the InfoCenter LCD Display

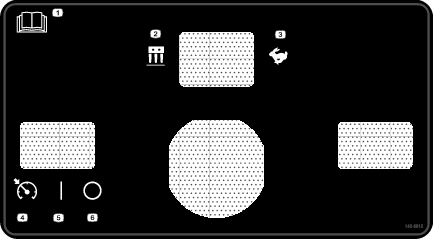

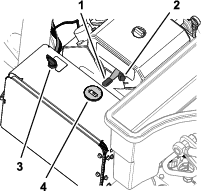

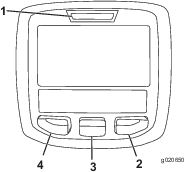

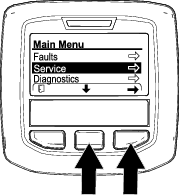

The InfoCenter LCD display shows information about your machine, such as the operating status and various diagnostics (Figure 26). When you first power the electrical system, a splash screen appears briefly, and then the main information screen of the InfoCenter. You can switch between the splash screen and main information screen at any time by pressing any of the InfoCenter buttons and then selecting the appropriate directional arrow.

-

Left Button, Menu Access/Back Button—press this button to access the InfoCenter menus. You can use it to exit any menu that you are currently using.

-

Middle Button—use this button to scroll down menus.

-

Right Button—use this button to open a menu where a right arrow indicates additional content.

Note: The purpose of each button may change depending on what is required at the time. Each button is labeled with an icon displaying its current function.

|

SERVICE DUE |

Indicates when scheduled service should be performed |

|

|

Info icon |

|

|

InfoCenter |

|

|

Hole depth |

|

|

Hole spacing |

|

|

Tine diameter |

|

|

Tines per holder |

|

|

Transport mode |

| Symbols are often combined to form sentences. Some examples are shown below. | |

| Operator should put the traction control in neutral |

| Engine start is denied |

| Engine shutdown |

| PTO denied |

|

|

|

Using the Menus

To access the InfoCenter menu system, press the menu access button while at the main screen. This displays the main menu. Refer to the following tables for a list of the options available from the menus:

|

Menu Item |

Description |

|---|---|

|

Faults |

Contains a list of the recent machine faults. Refer to the Service Manual or your authorized the manufacturer distributor for more information on the Faults menu and the information contained there. |

|

Service |

Contains information on the machine such as hours of use, counters, and other similar numbers. |

|

Diagnostics |

Lists various states that the machine currently has; you can use this to troubleshoot certain issues as it quickly tells you which machine controls are active, and which are shutoff. |

|

Statistics |

Lists counters for machine run data and operations data, such as information, such as engine run time, aeration area/volume/time, aeration travel distance. |

|

Settings |

Allows you to customize and modify configuration variables on the InfoCenter display. |

|

About |

Lists the model number, serial number, and software version of your machine. |

|

Menu Item |

Description |

|---|---|

|

Hours |

Displays the total number of hours that the machine, engine, and PTO have been on, as well as the number of hours the machine has been transported and service due |

|

Counts |

Displays numerous counts the machine experienced |

|

Traction |

Displays if the sensor calibrations are valid, starts the calibration process, and lists the electrical value of the sensor. |

|

Ground Height |

Displays if the sensor calibrations are valid, starts the calibration process, and lists the electrical value of the sensor. |

|

Bail |

Displays if the sensor calibrations are valid, starts the calibration process, and lists the electrical value of the sensor. |

|

Height Sensor |

Displays if the sensor calibrations are valid, starts the calibration process, and the lists electrical value of the sensor. |

|

Menu Item |

Description |

|---|---|

|

Units |

Controls the units used on the InfoCenter (English or metric) |

|

Language |

Controls the language used on the InfoCenter* |

|

LCD Backlight |

Controls the brightness of the LCD display |

|

LCD Contrast |

Controls the contrast of the LCD display |

|

Protected Menus |

Allows an authorized person with the PIN code to access protected menus |

|

Protect Settings |

Allows the ability to change the settings in the protected settings |

|

Max Speed |

Allows the ability to change the maximum forward ground speed—default = 6.4 kph (4 mph) |

|

|

|

|

Menu Item |

Description |

|---|---|

|

Model |

Lists the model number of the machine |

|

SN |

Lists the serial number of the machine |

|

Machine Controller Revision |

Lists the software revision of the master controller |

|

InfoCenter Revision |

Lists the software revision of the InfoCenter |

|

CAN Bus | Lists the machine communication bus status |

|

|

|

|

Menu Item |

Description |

|---|---|

|

Engine Run |

Refer to the Service Manual or your authorized Toro distributor for more information on the Engine Run menu and the information contained there. |

|

PTO |

|

|

Traction |

Protected Menus

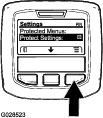

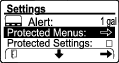

There are 3 protected operating settings within the Settings Menu of the InfoCenter: Max Speed, Area 2—Area, Area 2—Volume. These settings are unlocked by using the Accessing Protected Menus procedure.

Note: At the time of delivery, your distributor may have changed the PIN code.

Accessing Protected Menus

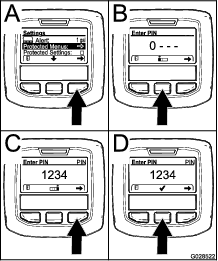

Note: The factory default PIN code for you machine is either 0000 or 1234.If you changed the PIN code and forgot the code, contact your authorized Toro distributor for assistance.

-

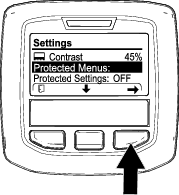

From the MAIN MENU, use the center button to scroll down to the SETTINGS MENU and press the right button (Figure 27).

-

In the SETTINGS MENU, use the center button to scroll down to the PROTECTED MENU and press the right button (Figure 28A).

-

To enter the PIN code, press the center button until the correct first digit appears, then press the right button to move on to the next digit (Figure 28B and Figure 28C). Repeat this step until the last digit is entered and press the right button once more.

-

Press the middle button to enter the PIN code (Figure 28D).

Wait until the red indicator light of the InfoCenter illuminates.

Note: If the InfoCenter accepts the PIN code and the protected menu is unlocked, the word “PIN” displays in the upper right corner of the screen.

Note: Rotate the key switch to the OFF position and then to the ON position locks the protected menu.

You can view and change the settings in the Protected Menu. Once you access the Protected Menu, scroll down to Protect Settings option. Use the right button to change the setting. Setting the Protect Settings to OFF allows you to view and change the settings in the Protected Menu without entering the PIN code. Setting the Protect Settings to ON hides the protected options and requires you to enter the PIN code to change the setting in the Protected Menu. After you set the PIN code, rotate the key switch OFF and back to the ON position to enable and save this feature.

Note: Specifications and design are subject to change without notice.

| Width | 127 cm (50.1 inches) |

| Wheelbase | 113 cm (44.5 inches) |

| Track width | 97 cm (38.3 inches) |

| Coring width | 122 cm (48 inches) |

| Length | 295 cm (116.3 inches) |

| Head height (raised) | 114 cm (45 inches) |

| Head height (lowered) | 93 cm (36.5 inches) |

| Height, handle | 154.2 cm (60.7 inches) |

| Ground clearance | 12 cm (4.8 inches) |

| Forward speed | 0 to 7.2 kph (0 to 4.5 mph) |

| Reverse speed | 0 to 4 kph (0 to 2.5 mph) |

| Net weight | 745 kg (1,642 lbs) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Refer to the tine configuration table that follows for the tine head, turf guard, and tine information:

| Tine Head Description | Tine Head Spacing | Shank Size | Tine Quantity | Turf Guard Type (quantity) |

|---|---|---|---|---|

| 2x5 Mini-Tine Head | 41 mm (1.60 inch) | 9.5 mm (3/8 inch) | 60 | 5-Tine—short (2) |

| 5-Tine—long (1) | ||||

| 1x6 Mini-Tine Head | 32 mm (1.25 inch) | 9.5 mm (3/8 inch) | 36 | 6-Tine—short (2) |

| 6-Tine—long (1) | ||||

| 3 Tine Head (7/8 inch) | 66 mm (2.60 inch) | 22.2 mm (7/8 inch) | 18 | 3-Tine—short (2) |

| 3-Tine—long (1) | ||||

| 3 Tine Head (3/4 inch) | 66 mm (2.60 inch) | 19.5 mm (3/4 inch) | 18 | 3-Tine—short (2) |

| 3-Tine—long (1) | ||||

| 4 Tine Head (3/4 inch) | 51 mm (2.00 inch) | 19.5 mm (3/4 inch) | 24 | 4-Tine—short (2) |

| 4-Tine—long (1) | ||||

| 5 Needle-Tine Head | 41 mm (1.60 inch) | — | 30 | 5-tine—short (2) |

| 5-Tine—long (1) |

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

Never allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Know how to stop the machine and shut off the engine quickly.

-

Before operating, always inspect the machine to ensure that the tines are in good working condition. Replace worn or damaged tines.

-

Inspect the area where you plan to use the machine and remove all objects that the machine could strike.

-

Locate and mark all electrical or communication lines, irrigation components, and other obstructions in the area to be aerated. Remove the hazards, if possible, or plan how to avoid them.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Check that operator-presence controls, safety switches, and shields are attached and functioning properly. Do not operate the machine unless they are functioning properly.

Fuel Safety

-

Use extreme care in handling fuel. It is flammable and its vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved fuel container.

-

Do not remove the fuel cap or fill the fuel tank while the engine is running or hot.

-

Do not add or drain the fuel in an enclosed space.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

-

If you spill fuel, do not attempt to start the engine; avoid creating any source of ignition until the fuel vapors have dissipated.

Adding Fuel

Fuel Specification

| Type | Unleaded gasoline |

| Minimum octane rating | 87 (US) or 91 (research octane; outside the US) |

| Ethanol | No more than 10% by volume |

| Methanol | None |

| MTBE (methyl tertiary butyl ether) | Less than 15% by volume |

| Oil | Do not add to the fuel |

Use only clean, fresh (no more than 30 days old), fuel from a reputable source.

Important: To reduce starting problems, add fuel stabilizer/conditioner to fresh fuel as directed by the fuel-stabilizer/conditioner manufacturer.

Filling the Fuel Tank

Fuel tank capacity: 26.5 L (7 US gallons)

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

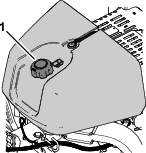

Clean around the fuel-tank cap and remove it (Figure 29).

-

Add fuel to the fuel tank, until the level is 6 mm to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck.

Important: This space in the tank allows fuel to expand. Do not fill the fuel tank completely full.

-

Install the fuel-tank cap securely.

-

Wipe up any spilled fuel.

Performing Daily Maintenance

Before starting the machine each day, perform the each Use/Daily procedure listed in .

Testing the Safety Interlock System

Caution

If safety interlock system is disconnected or damaged, the machine could operate unexpectedly, causing personal injury.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock system daily and replace any damaged safety-interlock parts before operating the machine.

-

The safety interlock system prevents the engine from starting unless the traction control is in the NEUTRAL position.

-

The safety interlock system prevents the engine from starting unless the operator presence bail is fully released.

-

The safety interlock system prevents the engine from starting unless the coring head bail is fully released.

-

The safety interlock system raises the coring head and shuts it off if you drive the machine backward while aerating or contact the bump-stop switch.

Important: If the safety interlock system does not operate as described, have an authorized the manufacturer distributor repair the safety interlock system immediately.

Raising the Coring Head

If the coring head is lowered, perform the following steps. If the coring head is raised, skip to Testing the Starter Interlock.

-

Start the engine and set the engine speed to the SLOW position; refer to Starting the Engine.

-

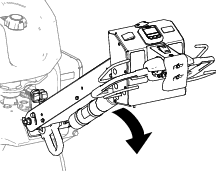

Lower the handlebar (Figure 30).

-

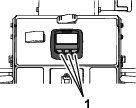

Press any of the buttons on the InfoCenter (Figure 31).

Note: The coring head raises.

-

Shut off the engine; refer to Shutting Off the Engine.

Testing the Starter Interlock

-

If the engine is running, shut it off.

-

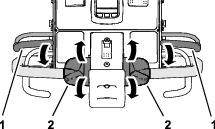

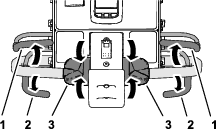

Hold either operator-presence bail to the handlebar and rotate the traction control (Figure 32) forward or rotate it backward, and start the engine.

Important: The engine must not start.

Testing the Operator Presence Interlock

-

Release the operator-presence bail, move the traction control to the NEUTRAL position, and start the engine.

-

Hold either operator-presence bail to the handlebar and rotate the top of the traction control forward (Figure 33).

Note: The machine drives forward.

-

While holding the traction control, release the operator-presence bail (Figure 34).

Important: The machine must stop driving forward.

Testing the Bump-Stop Interlock

-

Hold either operator-presence bail to the handlebar and rotate the top of the traction control forward (Figure 35).

Note: The machine drives forward.

-

While holding the operator-presence bail and the traction control, contact the bump-stop switch (Figure 36).

Important: The machine must stop driving forward.

Note: The engine remains running.

-

Reset the bump-stop switch; refer to Resetting the Bump-Stop Switch.

Testing the Coring Head-Reverse Interlock

-

Perform 1 of the following:

-

Move the machine to a turf area where you can aerate without damaging the tines or the area.

-

Remove the tines.

-

-

Hold either operator-presence bail to the handlebar, rotate the top of the traction control forward, and close the aerate bail (Figure 37).

Note: The machine drives forward, coring head runs, and it lowers.

-

While holding the operator-presence bail and aerate bail, rotate the top of the traction control backward (Figure 38).

Important: The coring head must raise and stop running.

Note: The engine remains running.

-

Move the traction control to the NEUTRAL position.

-

If you removed the tines, install them and calibrate the tine ground height; refer to Assembling the Tines to the Coring Head and Calibrating the Tine Ground Height.

Installing Turf Guards, Tine Holders, and Tines

Important: You must calibrate tine ground height each time you change from longer tines to shorter tines or from shorter tines to longer tines.

A wide selection of tine holders, turf guards, and tines are available for the machine. Choose the required components per the accessory chart in Attachments and Accessories.

Preparing the Machine

-

Raise the coring head and lock it in position with the service latch; refer to Supporting the Coring Head with the Service Latch.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

Assembling the Turf Guards

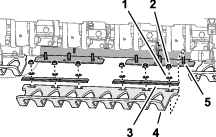

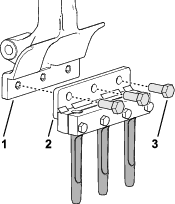

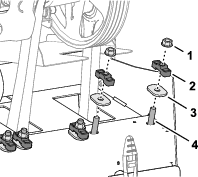

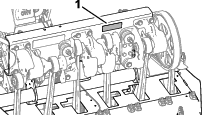

Note: The factory ships turf guard clamps, washers, and flange locknuts secured to the turf guard brackets (Figure 39).

Loosely assemble the turf guards to the turf guard brackets with 4 turf-guard clamps and 12 flange locknuts (3/8 inch) and 12 washers (7/16 x 13/16 inch).

Note: Do not tighten the flange locknuts.

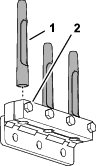

Assembling the Tine Holder

-

Loosely assemble the tine clamp to the tine holder (Figure 40) with 4 bolts (3/8 x 1-1/2 inches). Do not tighten the bolts.

Note: The bolts are parts in the tine holder kits.

-

Assemble the tines into the tine holder and tine clamp (Figure 41).

-

Torque the bolts (3/8 x 1-1/2 inches) securing the tine clamps and tines to 40.6 N∙m (30 ft-lb).

-

Repeat steps 1 through 3 for the other tine clamps, tine holders, and tines.

Assembling the Tines to the Coring Head

-

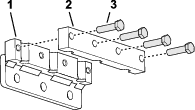

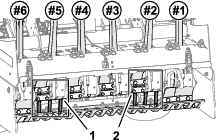

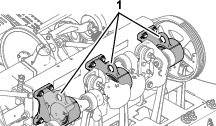

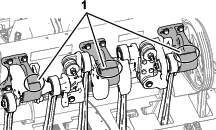

Loosely assemble tine holder and tines to tine arm #2 (Figure 42 and Figure 43) with 3 bolts (1/2 x 1-1/4 inches).

-

Torque the bolts (1/2 x 1-1/4 inches) to 102 N∙m (75 ft-lb).

-

Repeat steps 1 and 2 for tine arm #5.

-

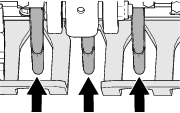

Check the alignment of the turf guard slots to the tines to ensure that they are centered (Figure 44).

Note: Adjust the turf guards as required.

-

Torque the flange locknuts (3/8 inch) that secure the 3 turf-guard clamps and 3 turf guards to the 3 turf guard brackets.

-

Install the remaining tine holder and tines to tine holders #1, #3, #4, and #6 with 12 bolts (1/2 x 1-1/4 inches).

-

Torque the bolts (1/2 x 1-1/4 inches) to 102 N∙m (75 ft-lb).

-

Calibrate the machine for tine to ground height; refer to Running the Teach Ground Height Application.

Hole Depth, Hole Spacing, and Tine Settings

Accessing the Settings Screens

-

Rotate the ignition key to the RUN position.

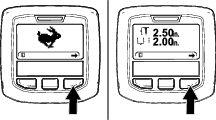

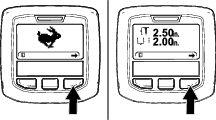

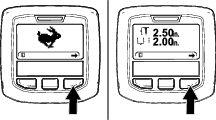

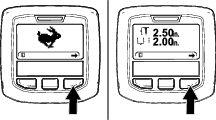

Note: The TRANSPORT mode screen or the AERATE mode screen displays (Figure 45).

-

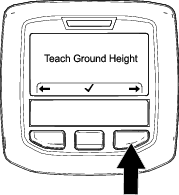

Press the right InfoCenter button twice to display the Calibrating the Tine Ground Height screen (Figure 46).

Note: Press the left InfoCenter button to display the TRANSPORT mode screen.

-

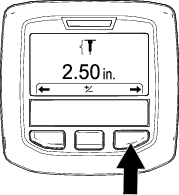

Press the right InfoCenter button to display the Setting the Hole Depth screen (Figure 47).

Note: Press the left InfoCenter button to display the Teach Ground Height screen.

-

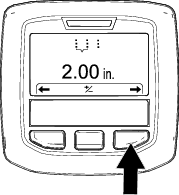

Press the right InfoCenter button to display the Setting the Hole Spacing screen (Figure 48).

Note: Press the left InfoCenter button to display the Setting the Hole Depth screen.

-

Press the right InfoCenter button to display the Setting the Tine Diameter screen (Figure 48).

Note: Press the left InfoCenter button to display the Setting the Hole Spacing screen.

-

Press the right InfoCenter button to display the Setting the Tine Quantity screen (Figure 50).

Note: Press the left InfoCenter button to display the Setting the Tine Diameter screen.

Setting the Hole Depth

-

Ensure that the coring head is raised; refer to Raising the Coring Head.

-

Rotate the ignition key to the RUN position.

-

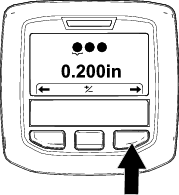

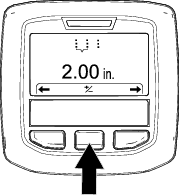

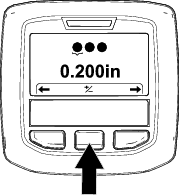

Press the right InfoCenter button until the Setting the Hole Depth screen displays (Figure 51 and Figure 52).

-

Press the center button to select the Set Depth option.

Note: The Set Depth screen displays.

-

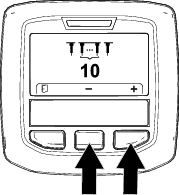

Adjust the tine depth (Figure 53) as follows:

-

Press the InfoCenter center button to decrease hole depth.

-

Press the right button to increase hole depth.

-

-

Press the left InfoCenter button to save your setting and exit the set depth screen.

-

Rotate the ignition key to the OFF position.

Setting the Hole Spacing

Note: When you select a target hole spacing rate, the machine controls the ground speed to maintain the hole spacing distance.

-

Ensure that the coring head is raised; refer to Raising the Coring Head.

-

Rotate the ignition key to the RUN position.

-

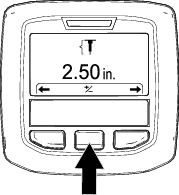

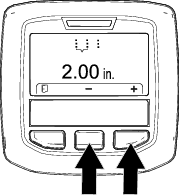

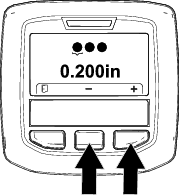

Press the right InfoCenter button until the Setting the Hole Spacing screen displays (Figure 54 and Figure 55).

-

Press the center button to select the Set Spacing option.

Note: The Set Spacing screen displays.

-

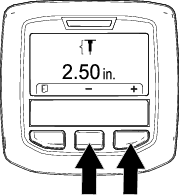

Adjust the hole spacing (Figure 56) as follows:

-

Press the InfoCenter center button to decrease hole spacing.

-

Press the right button to increase hole spacing.

-

-

Press the left InfoCenter button to save your setting and exit the Set Hole Spacing screen.

-

Rotate the ignition key to the OFF position.

Setting Tine Diameter

-

Ensure that the coring head is raised; refer to Raising the Coring Head.

-

Rotate the ignition key to the RUN position.

-

Press the right InfoCenter button until the Setting the Tine Diameter screen displays (Figure 58).

-

Press the center button to select the Set Diameter option.

Note: The Set Diameter screen displays.

-

Adjust the tine diameter (Figure 59) as follows:

-

Press the InfoCenter center button to decrease tine diameter.

-

Press the right button to increase tine diameter.

-

-

Press the left InfoCenter button to save your setting and exit the Set Hole Spacing screen.

-

Rotate the ignition key to the OFF position.

Setting the Tines Quantity

-

Ensure that the coring head is raised; refer to Raising the Coring Head.

-

Rotate the ignition key to the RUN position.

-

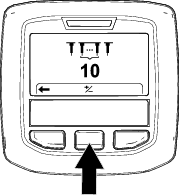

Press the right InfoCenter button until the Setting the Tine Quantity screen displays (Figure 61).

-

Press the center button to select the Set Quantity option.

Note: The Set Quantity screen displays.

-

Adjust the tine quantity (Figure 62) as follows:

Important: The tine quantity is the number of tines of 1 holder.

-

Press the InfoCenter center button to decrease tine quantity.

-

Press the right button to increase tine quantity.

-

-

Press the left InfoCenter button to save your setting and exit the Set Hole Spacing screen.

-

Rotate the ignition key to the OFF position.

Calibrating the Tine Ground Height

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Calibrate the tine ground height each time you change tines or replace worn tines.

Preparing the Machine

-

Ensure that the coring head is raised.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

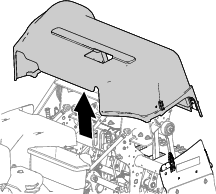

Remove the coring-head cover; refer to Removing the Coring-Head Cover.

-

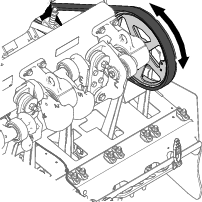

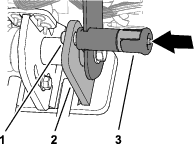

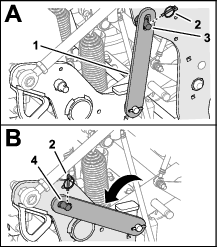

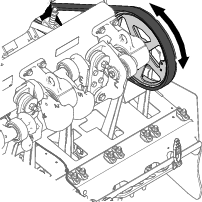

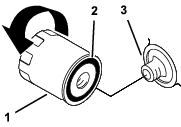

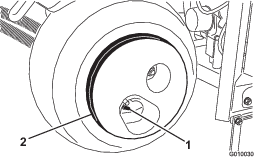

Rotate coring-head pulley (Figure 63) until the outermost tines are aligned closest to the ground (Figure 64).

Important: Keep your fingers away of the area where the belt merges and departs the pulley so that you do not pinch your fingers.

-

Install the coring-head cover; refer to Installing the Coring-Head Cover.

Running the Teach Ground Height Application

-

Rotate the ignition key to the RUN position.

Note: The TRANSPORT mode screen or the AERATE mode screen displays (Figure 65).

-

Move the handlebar so that you can see the outermost tines you positioned in Preparing the Machine.

-

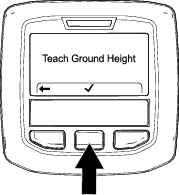

Press the right InfoCenter button until the TEACH GROUND HEIGHT wizard displays.

-

On the Teach Ground Height screen (Figure 66), press the center InfoCenter button.

-

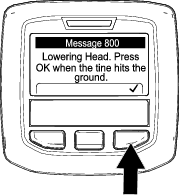

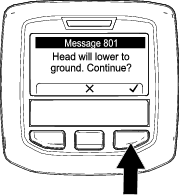

On the Press OK to Start Teach screen (Figure 67), press the right InfoCenter button.

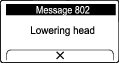

Note: The CALIBRATION ENGAGED message displays (Figure 68), and the coring head slowly lowers.

Important: Keep your hand near the InfoCenter.

Note: The coring head lowers slower if the hydraulic fluid is cold.

-

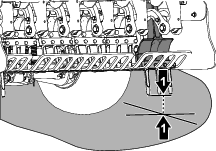

When any tine touches the ground, press the right InfoCenter button on the Lowering Head screen (Figure 69).

Note: Tines should only touch the ground, and not lift or unload the weight from the tires.If the coring head lifts the machine, the machine incorrectly calibrates the ground height, resulting in inaccurate hole depth and entry tufting of the aeration hole.

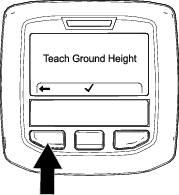

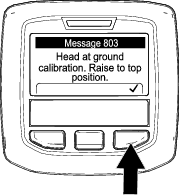

Note: the CALIBRATION COMPLETE message displays (Figure 70), and the head fully raises.

-

Press the left InfoCenter button to exit the Teach Ground Height application (Figure 71).

During Operation

During Operation Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair, secure loose clothing, and do not wear loose jewelry.

-

Do not operate the machine when tired, ill, or under the influence of alcohol or drugs.

-

Keep bystanders, children, and pets out of the operating area. Do not allow children to operate the machine. Allow only people who are responsible, trained, familiar with the instructions, and physically capable to operate the machine.

-

Never carry passengers on the machine.

-

Operate the machine only in good visibility to avoid holes or hidden hazards.

-

Keep your hands and feet away from the tines.

-

Look behind and down before backing up to be sure of a clear path.

-

Stop the machine, shut off the engine, remove the key, wait for all moving parts to stop, and inspect the tines after striking an object or if there is an abnormal vibration in the machine. Make all necessary repairs before resuming operation.

-

Always maintain proper tire pressure.

-

Reduce traction speed on rough roads and surfaces.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution.

-

Evaluate the site conditions to determine if the slope is safe for machine operation, including surveying the site. Always use common sense and good judgment when performing this survey.

-

Review the slope instructions listed below for operating the machine on slopes and review the conditions to determine whether you can operate the machine in the conditions on that day and at that site. Changes in the terrain can result in a change in slope operation for the machine.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction. Make turns slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question.

-

Remove or mark obstructions such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstructions. Uneven terrain could overturn the machine.

-

Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

-

Use extreme caution when operating the machine near drop-offs, ditches, embankments, water hazards, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in. Establish a safety area between the machine and any hazard.

Engaging Parking Brake

-

Fully raise the handlebar to engage the parking brake (Figure 72).

-

Ensure that the handlebar-latch pin extends through the hole in the detent plate (Figure 73).

Warning

If the parking brake does not engage, the machine may move injuring you or bystanders.

Ensure that the handlebar is fully raised and securely latches to the detent plate.

Releasing the Parking Brake

Starting the Engine

-

Fully raise and latch the handlebar engage the parking brake; refer to Engaging Parking Brake.

-

Use the choke (Figure 77) as follows:

-

Before starting a cold engine, move the choke control to the ON position.

-

When starting a warm or hot engine, you may not need to use the choke.

-

-

Move the throttle lever to the FAST position before starting a cold engine.

-

Turn the ignition key to the START position. When the engine starts, release the key.

Important: Do not engage the starter for more than 10 seconds at a time. If the engine fails to start, allow a 30-second cool-down period between attempts. Failure to follow these instructions can burn out the starter motor.

-

After the engine starts, move the choke toward the OFF position. If the engine runs rough or stalls, move the choke back toward the ON position for a few seconds. Then move the throttle lever to desired engine speed.

Note: Repeat this step as required.

Shutting Off the Engine

Caution

Children or bystanders may be injured if they move or attempt to operate the machine while it is unattended.

Always fully raise and latch the handlebar to engage the parking brake, shut off the engine, and remove the key when leaving the machine unattended, even if just for a few minutes.

-

Fully raise and latch the handlebar to engage the parking brake; refer to Engaging Parking Brake.

-

Move the throttle lever (Figure 78) to the SLOW position.

-

Let the engine idle for 60 seconds.

-

Turn the ignition key to the OFF position and remove the key.

-

If you are hauling or storing the machine, close the fuel-shutoff valve (Figure 79).

Important: Close the fuel-shutoff valve before hauling the machine on a trailer or storing the machine. Fully raise and latch the handlebar to engage the parking brake before hauling the machine. Remove the key from the ignition switch to prevent the fuel pump from running and causing the battery to discharge.

Using the Machine

Important: Walk in front of the machine in a forward direction while operating it, do not walk and face rearward when operating the machine.

Speed Lock

Speed Lock in the Transport Mode

Using the Speed Lock allows you to drive the machine without having to hold the traction control.

Note: You cannot use the speed lock feature while driving the machine backward.

Speed Lock in the Aerate Mode

Using the speed lock while aerating allows you to continue driving the machine at the selected hole-spacing speed at the end of an aeration pass, turn the machine around, and begin the next aeration pass without changing the traction control position.

Note: The speed lock feature in the aerate mode is active when the coring head is set for delay-drop mode; the speed lock feature is locked-out in the immediate-drop mode.

Using the Ground-Speed Lock

The ground-speed lock operates like automotive cruise control.

-

Press the transport/aerate switch to the TRANSPORT position (Figure 81).

-

Press the speed-lock switch to the ON position.

-

Drive the machine forward at the desired ground speed.

-

Press the speed-lock switch to the ENGAGE position.

Note: The ground-speed lock maintains the current ground speed at which the machine is driving. You can release the traction control.

-

To disengage the speed lock operation, perform one of the following:

-

Press the speed-lock switch to the OFF position.

-

Rotate the top of the traction control rearward to drive the machine backward.

-

Release the operator presence bail.

-

Press the bump-stop switch.

-

Using the Ground-Speed Lock

Note: The ground-speed lock is not available when aerating in the immediate-drop mode.

-

Press the transport/aerate switch is in the AERATE position (Figure 82).

-

Press the speed-lock switch to the ON position.

-

Drive the machine forward and close the aerate bail.

Note: The ground-speed lock engages, and the coring head lowers.

-

At the end of the aeration pass, release the aerate bail.

Note: The coring head raises, but the machine maintains ground speed at the aeration hole spacing rate.

-

To disengage the speed lock operation, perform one of the following:

-

Press the speed-lock switch to the OFF position.

-

Rotate the top of the traction control rearward to drive the machine backward.

-

Release the operator presence bail.

-

Press the bump-stop switch.

-

Driving the Machine in the Transport Mode

Note: Use the transport mode when you move the machine between job sites.

Note: The machine drives at a reduced variable speed anytime the transport/aeration switch is in the AERATION position.

-

Start the engine, and move the throttle control to the FAST position; refer to Starting the Engine.

-

Lower the handlebar to release the parking brake; refer to Releasing the Parking Brake.

-

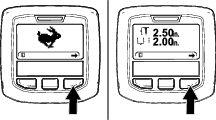

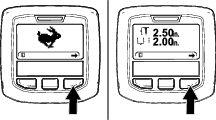

Press the left side of the transport/aeration switch to the TRANSPORT position (Figure 83).

Note: The InfoCenter displays the TRANSPORT icon (Figure 84).

-

Look in the direction of your planned path to ensure that it is clear.

-

Grasp the left or right handlebar and the operator-presence bail (Figure 83), and squeeze the bail to the handle.

-

With you thumb, rotate the left or right traction control to drive the machine as follows:

-

Rotate the top of the traction control forward to drive the machine forward.

-

Rotate the top of the traction control rearward to drive the machine backward.

Note: Further rotating the traction control increases the groundspeed of the machine.

-

Stopping the Machine

Important: To immediately stop the machine press the bump-stop switch (Figure 85).

-

If you are aerating, release the aerate bail (Figure 86) to raise the coring head; refer to Raising the Coring Head.

-

Release the traction control, and allow it to move to the NEUTRAL position.

-

Release the operator-presence bail.

-

Fully raise and latch the handlebar to engage the parking brake; refer to Engaging Parking Brake.

Driving the Machine in the Aerating Mode

Note: The machine drives at a reduced variable speed anytime the coring head is raised.

-

Start the engine, and move the throttle control to the FAST position; refer to Starting the Engine.

-

Lower the handlebar to release the parking brake; refer to Releasing the Parking Brake.

-

Press the right side of the transport/aeration switch to the AERATE position (Figure 87).

The InfoCenter displays the current hole depth and hole spacing (Figure 88).

-

Look in the direction of your planned path to ensure that it is clear.

-

Grasp the left or right handlebar and the operator-presence bail (Figure 87), and squeeze the bail to the handle.

-

With you thumb, rotate the top of the left or right traction control to drive the machine forward.

Note: During aeration the machine drives at a speed to meet what you selected for target hole spacing.

-

When using the ground-speed lock, releasing the aerate bail without changing the traction control position causes the machine to maintain ground speed, like cruise control of an automobile.

-

Driving the machine in reverse direction disengages the cruise control effect, and causes the machine to drive at variable-ground speed.

-

When you raise the head to turn the machine around for another pass, you can increase ground speed by moving the traction control farther forward. When you return the traction control to the NEUTRAL position, the machine slows to the required ground speed for aeration hole spacing.

-

Aerating Using the Delay-Drop Mode

Use the front tire to sight the drop point when aerating in delay-drop mode.

-

Press the top of the drop-control switch (Figure 89) to the DROP-DELAY position.

-

Drive the machine in the forward direction; refer to Driving the Machine in the Aerating Mode.

-

As the front tire rolls over the perimeter of aeration area, close either the left or right the aerate bail (Figure 90).

Note: The coring head runs and lowers as the machine moves forward crossing the target aeration area.

Raising the Coring Head

Use the front tire (Figure 91) to sight the raise point when in delay-drop mode.

To raise the core head, perform 1 of the following:

-

As the front tire rolls over the perimeter of aeration area, release the aerate bail (Figure 92).

Note: The machine delays lifting the coring head until the coring head reaches the targeted spot you identified using the front tire and released the aerate bail.

-

Drive the machine in the reverse direction; refer to Driving the Machine in the Reverse Direction.

Aerating Using the Immediate-Drop Mode

-

Press the bottom of the drop-control switch (Figure 93) to the IMMEDIATE-DROP position.

Note: The light in the switch illuminates.

-

Drive the machine in the forward direction; refer to Driving the Machine in the Aerating Mode.

-

Close either the left or right the aerate bail (Figure 94).

Note: The coring head immediately lowers and begins aerating.

Raising the Coring Head

To raise the core head, perform 1 of the following:

-

Release the aerate bail (Figure 95).

Note: The machine lifts the coring head immediately.

-

Drive the machine in the reverse direction; refer to Driving the Machine in the Reverse Direction.

Driving the Machine in the Reverse Direction

Resetting the Bump-Stop Switch

-

Release the traction control and allow it to move to the NEUTRAL position, and release the operator-presence bail (Figure 98).

-

Move away from the bump-stop switch (Figure 99).

Note: A spring in the bump-stop switch resets the switch.

-

Grasp the left or right handlebar and the operator-presence bail (Figure 100), and squeeze the bail to the handle.

-

Drive the machine, refer to Driving the Machine in the Transport Mode or Driving the Machine in the Aerating Mode.

Using the Line Marker

Use the line marker to align aeration rows (Figure 101).

Using Aerator Statistics for Estimating Topdressing

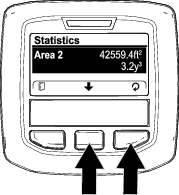

The machine uses 2 counters to log the area aerated and the displaced soil-core volume. Use the information from these counters to estimate the amount of top dressing to apply to the aerated turf area(s).

-

The Area 1 counter is not PIN code protected, and is intended to be reset by the machine operator.

Note: If the operator records the Area 1 counter for each aeration site, you can estimate the amount of topsoil and delivery requirements for each site.

-

The Area 2 counter is PIN code protected, and is intended to be reset by the supervisor or their delegate.

-

The area aerated displays in m2 (SI) or ft2 (English) units of measure.

-

The displaced-coring volume displays as m3 (SI) or yd3 (English) units of measure.

-

When viewing the displaced-coring volume counters, the machine calculates the volume using the tine diameter and the tine quantity that you entered in the InfoCenter.

Important: If the tine diameter and/or the tine quantity value(s) are incorrect before aerating the site, the InfoCenter will calculate and display incorrect core volume values for Area 1 and Area 2. If the diameter and/or quantity values are changed after aerating, the InfoCenter will change the displayed volume values.

Accessing the Area and Volume Counters

-

Park the machine on a level surface.

Note: The handlebar remain lowered so that you can view the InfoCenter.

-

Ensure that the engine is running or the ignition key in the RUN position.

-

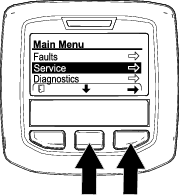

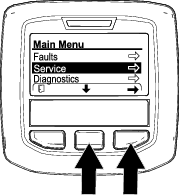

In the InfoCenter, navigate to the MAIN MENU (Figure 103).

-

Press the center InfoCenter button until the SERVICE option is selected, and press the right button.

-

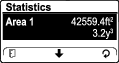

In the SERVICE screen, press the center InfoCenter button until the STATISTICS option is selected, and press the right button (Figure 104).

Note: An AREA counter displays in the STATISTICS screen.

Using the Area 1—Area and Volume Counters

-

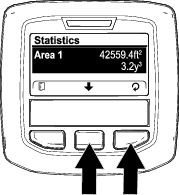

In the STATISTICS screen, press the center InfoCenter button until the AREA 1 option is selected (Figure 106).

-

Record the aeration area and soil-core volume in a worksheet; refer to the example that follows.

Example Aeration Worksheet

Date

Course (if multiple)

Location

Aeration Area

Core Volume

-

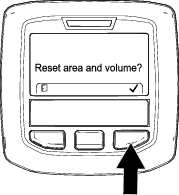

Press the right button to display to the reset area and volume screen.

-

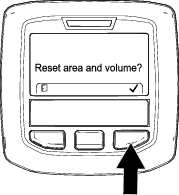

In the RESET AREA AND VOLUME SCREEN, press the right InfoCenter button.

Note: The InfoCenter displays the statistic screen, and the area and volume counters reset to 0.

Note: If you do not reset the Area 1 counter, the area and volume counters continue to accumulate data.

-

Repeat steps 1 through 4 as needed.

-

Press the left InfoCenter button until the RUN screen appears.

Resetting the Area 2—Area and Volume Counters

Note: Resetting the AREA 2 counters does not reset the AREA 1 counters.

-

Enter the PIN code for the PROTECTED MENUS option (Figure 108), refer to Accessing Protected Menus.

-

Enter the PIN to access protected menus; refer to Accessing Protected Menus.

-

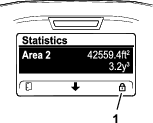

In the STATISTICS screen, press the center InfoCenter button until the AREA 2 option is selected (Figure 109).

-

If needed, record the aeration area and soil-core volume data.

-

Press the right button to display to the reset area and volume screen.

-

In the RESET AREA AND VOLUME SCREEN, press the right InfoCenter button (Figure 110).

Note: The InfoCenter displays the statistic screen, and the area and volume counters reset to 0.

Note: If you do not reset the Area 2 counter, the area and volume counters continue to accumulate data.

-

Press the left InfoCenter button until the RUN screen appears.

Supporting the Coring Head with the Service Latch

Install the service latch before performing coring head maintenance or when storing the machine for more than a couple of days.

Danger

If the coring head is raised and not latched, it can lower unexpectedly and injure you or bystanders.

Any time you service the coring head, including changing of tines or turf guards, use the service latch to secure coring head in the raised position.

-

Raise the coring head.

-

Park the machine on a level surface, fully raise and latch and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Remove the coring head cover; refer to Removing the Coring-Head Cover.

-

Remove the lynch pin securing the service latch to the side plate (Figure 111).

-

Rotate the service latch rearward and align it over the support pin of the coring head.

-

Secure the latch to the support pin with the lynch pin.

-

If needed, install the coring-head cover; refer to Installing the Coring-Head Cover.

Stowing the Service Latch

-

Park the machine on a level surface, fully raise and latch and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

If the coring-head cover is installed, remove it; refer toRemoving the Coring-Head Cover.

-

Remove the lynch pin securing the service latch to the support pin of the coring head (Figure 112).

-

Rotate the service latch down and align it over the support pin of the side plate.

-

Secure the latch to the support pin with the lynch pin.

-

Install the coring-head cover; refer to Installing the Coring-Head Cover.

Replacing a Damaged Tine

Important: Replacing a damaged tine with one that is the same length. Different tine lengths negatively affect hole appearance.

Different tine lengths affect hole appearance.

Refer to Installing Turf Guards, Tine Holders, and Tines for illustrations.

-

Raise the coring head and lock it in position with the service latch.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Loosen the tine holder bolts and remove the old tine(s).

-

Insert the new tine(s) into the tine holder.

-

Torque the tine holder bolts to 40.6 N∙m (30 ft-lb).

-

If needed, repeat this procedure on the remaining arms.

Checking the Tine Ground-Height Calibration

Use the ground height calibration recall application to quickly check the current tine ground height.

Preparing the Machine

-

Ensure that the coring head is raised.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Remove the coring-head cover; refer to Removing the Coring-Head Cover.

-

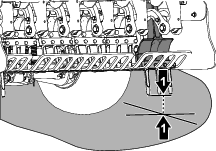

Rotate coring-head pulley (Figure 113) until the outermost tines are aligned closest to the ground.

Important: Keep your fingers away of the area where the belt merges and departs the pulley so that you do not pinch your fingers.

-

Install the coring-head cover; refer to Installing the Coring-Head Cover.

Running the Recall Ground Height Application

-

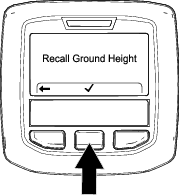

Press the center button on the InfoCenter to navigate to the RECALL GROUND HEIGHT option.

-

Press the right InfoCenter button to select the TEACH GROUND HEIGHT option.

-

On the Recall Ground Height screen (Figure 114), press the center InfoCenter button.

-

On the Head Will Lower screen (Figure 115), press the right InfoCenter button.

Note: The Lowering Head message displays and the coring head lowers.

-

Watch the outermost tines for the following out-of-calibration conditions.

-

The tines begin to penetrate the ground—press the right InfoCenter button (Figure 117) and run the Teach Ground Height application; refer toRunning the Teach Ground Height Application.

-

The tines are above the ground—press the right InfoCenter button and run the Teach Ground Height application; refer to Running the Teach Ground Height Application.

-

-

If the outermost tines lightly touch the ground, press the right InfoCenter button to raise the coring head.

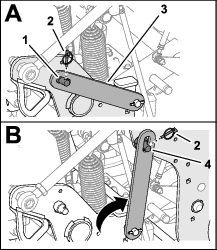

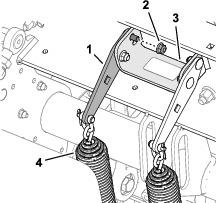

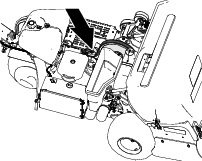

Adjusting the Weight Transfer

The machine transfers weight from the traction unit to the coring head to help maintain hole depth in various soil structures. However, if the soil structure is firm enough to not allow full aeration depth, the coring head may need additional weight transfer. The machine is set for normal weight transfer at the factory. To increase the down pressure of the weight transfer springs, proceed as follows:

Warning

Sudden release of the spring plates could cause injury.

Acquire the help of another person to help adjust the weight transfer spring.

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Loosen the forward flange locknut and carriage bolt that secure the spring-tension plate to the support bracket of the coring head (Figure 118).

Note: Do not remove locknut and carriage bolt.

-

Remove the rear flange locknut that secures the spring brackets to the support bracket.

Note: Do not remove carriage bolt.

-

Insert a 1/2 inch-drive ratchet or breaker bar into the square hole in the spring-tension plate (Figure 119).

-

Rotate the ratchet or breaker bar to relieve the tension on the rear carriage bolt and remove it from the upper hole.

Note: The upper hole is the normal weight transfer position.

-

Rotate the spring-tension plate until it aligns with the lower hole in the support bracket, insert the carriage bolt through the holes in the plate and bracket.

Note: The lower hole is the higher weight transfer position. Rotating the spring plates upward increases the weight transfer.

-

Secure the carriage bolt to the support bracket and spring-tension plate with the flange locknut.

-

Torque the locknuts to 37 to 45 N∙m (27 to 33 ft-lb).

Using Manual Ground Following

For optimum hole quality and machine performance, aerate using the automatic ground following system.

Use manual ground following only if the tine-position sensor is damaged.

Adjusting the Depth-Stop Spacers

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Remove the coring-head cover; refer to Removing the Coring-Head Cover.

-

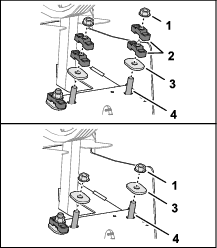

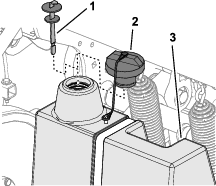

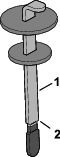

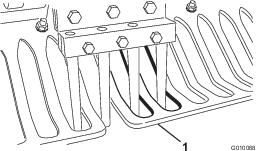

Remove the lynch pin that secures the depth-stop pin and spacers to the stop bracket (Figure 120 and Figure 121).

-

Position the spacers above or below the stop bracket to adjust the coring depth.

-

With all spacers at the top of the stop bracket, the depth setting is 10.7 cm (4-1/4 inches).

-

Thick spacers equate to 19 mm (3/4 inch) increment.

-

Thin spacer equates to 9.5 mm (3/8 inch) depth increment.

Note: You must install all spacers, regardless of their position.

-

-

Assemble the depth-stop pin and the spacers to the stop bracket with the lynch pin.

-

Repeat steps 3 through 5 at the other side of the machine.

Important: Ensure that the spacer location above and below the left and right stop brackets are identical.

-

Install the coring-head cover; refer to Installing the Coring-Head Cover.

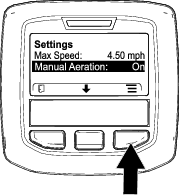

Setting the InfoCenter

Note: If you aerate in manual mode, you must set the InfoCenter for the manual ground following mode each time you start the engine.

-

Turn the ignition key to RUN position.

Note: Do not start the engine.

-

In the InfoCenter, navigate to the MAIN MENU (Figure 122).

-

Press the center InfoCenter button until the SETTING option is selected, and press the right button.

-

Press the center InfoCenter button until the PROTECTED MENUS option is selected (Figure 123), press the right button, and enter your 4-digit pin code (e.g. 1 2 3 4).

-

Press the center InfoCenter button until the MANUAL AERATION option is selected, and press the right button (Figure 124) to set manual aeration to ON.

-

Start the engine.

-

Aerate using Aerating Using the Delay-Drop Mode or the Aerating Using the Immediate-Drop Mode.

Note: When you shut off the engine and start it, the machine defaults to the automatic ground-following mode.

Stowing the Depth-Stop Spacers for Automatic Ground Following

-

Park the machine on a level surface, fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

Remove the coring-head cover; refer to Removing the Coring-Head Cover.

-

Remove the lynch pin that secures the depth-stop pin and spacers to the stop bracket (Figure 125).

-

Position the all the spacers above the stop bracket.

-

Assemble the depth-stop pin and the spacers to the stop bracket with the lynch pin.

Note: You must stow all spacers.

-

Repeat steps 3 through 5 at the other side of the machine.

-

Install the coring-head cover; refer to Installing the Coring-Head Cover.

Adding Additional Weight

With the weight transfer adjusted, it is possible to aerate turf that is hard enough ground cause the machine to lift the rear tires off the ground. This may lead to irregular hole spacing.

If this lifting occurs, you can add optional counterweight plates to the rear frame axle tube. Each counterweight plate adds 28.5 kg (63 lb) to the machine. You can add up to 2 plates. Refer to the Parts Catalog of your machine for the counterweight and hardware part numbers.

Moving the Machine by Hand

Bypassing the Hydraulic Pump and Moving the Machine

Required tools: 15 mm socket and socket wrench

Important: Do not operate the engine with the bypass valve open for more than 10 to 15 seconds.

-

If possible, park the machine on a level surface.

-

Fully raise and latch the handlebar to engage the parking brake, shut off the engine, remove the key, and wait for all moving parts to stop.

-

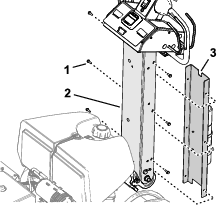

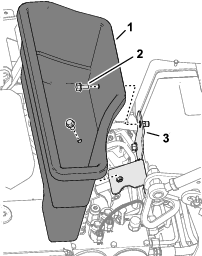

Remove the 2 flange head bolts that secure the storage bin to the bin bracket (Figure 126).

-

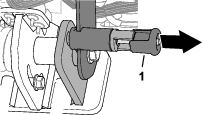

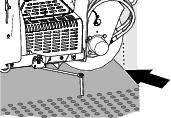

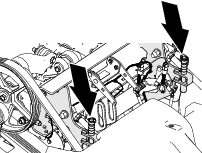

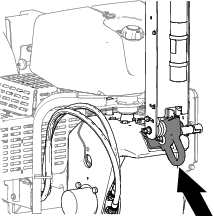

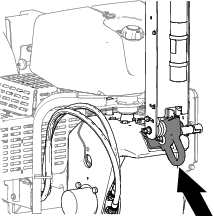

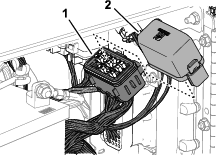

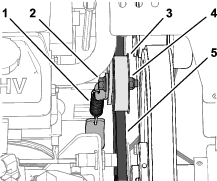

Locate the cover for the bypass-valve screw between the engine and hydraulic pump as shown in Figure 127).

-

Use a 15 mm socket and socket wrench to rotate the bypass valve counterclockwise 1-1/2 turns.

Important: Do not rotate the bypass valve more than 1-1/2 turns.

-

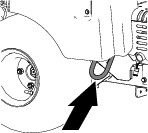

If you tow the machine, pull it using the front tie-down hoop (Figure 128).

Important: Do not push/pull the machine more than 30.5 m (100 ft) or faster than 0.6 km/h (1 mph) because hydraulic component damage may occur.

-

Lower the handlebar to disengage the parking brake before pushing/pulling the machine.

Important: You must lower the handlebar to disengage the parking brake before you move the machine.

Restoring the Hydraulic Pump

Important: You must close the bypass valve to drive the machine. Do not try to operate traction system with the bypass valve open.

-

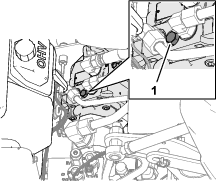

Locate the bypass-valve screw between the engine and hydraulic pump.

Note: The location of the cover for the bypass-valve screw is shown in Figure 129.

-

Use a 15 mm socket and socket wrench to rotate the bypass valve clockwise 1-1/2 turns.

Note: Do not overtighten the bypass screw.

-

Use a 15 mm wrench to install the bypass-screw cover onto the hydraulic pump.

-

Install the storage bin to the bin bracket with the 2 flange-head bolts.

Moving the Machine when the Coring Head is Lowered

If the engine stops running while the coring head lowered and the tines engaged in the soil and you cannot start the engine, perform either Lifting the Coring Head using the Starter or Removing the Tine holders from the Stomper Arms.

Lifting the Coring Head using the Starter

-

Move the key to the RUN position.

-

In the InfoCenter, navigate to the MAIN MENU (Figure 130).

-

Press the center InfoCenter button until the SETTINGS option is selected, and press the right button.

-

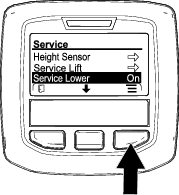

Press the center InfoCenter button until the SERVICE LIFT option is selected (Figure 131), press the right button.

Note: The service lift option changes to YES.

-

Move the key to the START position, and crank the starter for 10 seconds.

Important: Do not engage the starter for more than 10 seconds at a time. If the tines have not cleared the ground, allow a 30-second cool-down period between attempts. Failure to follow these instructions can burn out the starter motor.

Note: The coring head lifts the tines from the ground.

Important: The tines fully clear the ground before moving the machine.

-

Open the bypass valve; refer to Bypassing the Hydraulic Pump and Moving the Machine.

-

Pull/push the machine to a nearby location to continue service or load onto a trailer.

Important: Do not pull/push machine for more than 30.5 m (100 ft) and no faster than 1.6 km/h (1 mph), because hydraulic damage may occur.

Removing the Tine holders from the Stomper Arms

-

Remove the tine holders from the stomper arms.

-

Open the bypass valve; refer to Bypassing the Hydraulic Pump and Moving the Machine.

-

Pull/push the machine to a nearby location to continue service or load onto a trailer.

Important: Do not pull/push machine for more than 30.5 m (100 ft) and no faster than 1.6 km/h (1 mph), because hydraulic damage may occur.

Operating Tips

General

Warning

Contacting obstacles with the machine may cause you to lose control of it.

Always be aware of obstacles at the job site. Plan your aeration path to avoid contact with any obstacle by you or the machine.

-

Make very gradual turns when aerating. Never make sharp turns with the coring head engaged. Plan your aeration path before lowering the aerator.

-

Always maintain awareness of what lies ahead in the direction of forward travel. Avoid aeration next to buildings, fences, and other equipment.

-

Look behind frequently to ensure that the machine operates properly, and you maintain alignment with previous pass.

-

Always clear the area of all damaged machine parts, such as broken tines, etc., to prevent their being picked up by mowers or other turf maintenance equipment.

-

Replace broken tines and inspect and correct damage to those still usable. Repair any other machine damage before commencing operation.

-

When aerating with less than the full width of the machine, you may remove tines, but the tine heads should remain installed on the stomper arms to ensure proper balance and operation of the machine.

-

This machine aerates deeper than most greens aerators. On native or modified push-up greens and tees, the deeper depth and longer hollow tines may have difficulty ejecting the complete core. This is due to harder native soil that sticks in the end of the tine. Side-eject greens/tees tines from the manufacturer stay cleaner and reduce the time required to clean the tines out. You will eventually eliminate this condition with continued aeration and top-dressing programs.

Hard Ground

If the ground is too firm to obtain the desired coring depth, the coring head can get into a bouncing rhythm. This is due to the hard pan the tines are attempting to penetrate. Correct this condition by attempting the following:

-

Do not aerate if ground is too hard or dry. You obtain best aeration results after a rain or watering the turf the previous day.

-

Change to a 3-tine head, if attempting to use the 4-tine head or reduce the number of tines per stomper arm. Attempt to maintain a symmetrical tine configuration to evenly load the stomper arms.

-

If ground is hard packed, reduce aerator penetration (depth setting), clean up the cores, water the turf, and re-aerate at a deeper penetration.

Aeration of soil types built on top of hard subsoils (i.e., soil/sand placed over rocky soil) can cause undesired hole quality. This occurs when the aeration depth is greater than the built up soil and the subsoil is too hard to penetrate. When the tines contact this harder subsoil, the aerator may lift and cause the top of the holes to become elongated. Reduce the aerating depth sufficiently to avoid penetration into the hard subsoil.

Entrance Hole Quality

The entrance hole quality is deteriorating when the hole is slotted (pulled forward).

If the hole entrance quality is deteriorating, check the tine ground-height calibration, refer to Checking the Tine Ground-Height Calibration.

Mini Tine (Quad Tine)

Because of the double row design, the mini-tine coring head requires the hole spacing to be set at 6.3 cm (2-1/2 inches). Ground speed is critical to maintain the appearance of 3.2 cm (1-1/4 inches) hole spacing. Refer to Setting the Hole Spacing if your hole spacing requires a small change.

With the mini tine head or larger solid tine use, the turf root structure is important to preventing turf damage due to tearing of the root zone. If the center 2 arms begin to lift the turf or damage to the root zone is excessive, proceed as follows:

-

Increase the hole spacing

-

Decrease tine size

-

Decrease tine depth

-

Remove some of the tines

The lifting action that solid a tine creates when it pulls from the turf may cause turf damage. This lift can tear the root zone if the density of tines or diameter of tines is too high.

Front Hole Dimple or Push During the Aeration Pass (Solid Tines or Softer Soil Conditions)

When aerating with longer solid tines (i.e., 3/8 x 4 inches long) or needle type tines, the front of the holes may become slotted or tufted. To regain excellent hole quality for this configuration, try the following:

-

Calibrate the tine ground height; refer to Calibrating the Tine Ground Height.

-