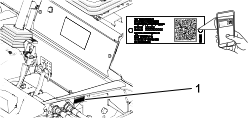

Disclaimers and Regulatory Information

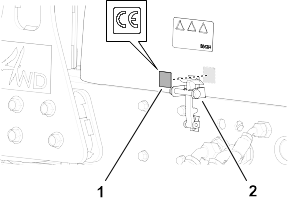

This product complies with

all relevant European directives; for details, please see the separate

product specific Declaration of Conformity (DOC)

sheet.

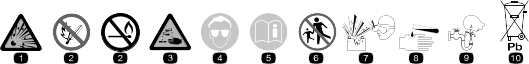

It is a violation of California

Public Resource Code Section 4442 or 4443 to use or operate the engine

on any forest-covered, brush-covered, or grass-covered

land unless the engine is equipped with a spark arrester, as defined

in Section 4442, maintained in effective working

order, or the engine is constructed, equipped, and maintained for

the prevention of fire.

The enclosed engine owner's manual

is supplied for information regarding the US Environmental Protection

Agency (EPA) and the California Emission Control

Regulation of emission systems, maintenance, and warranty. Replacements

may be ordered through the engine manufacturer.

|

| CALIFORNIA |

| Proposition 65 |

| Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. |

| Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. |

| Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. |

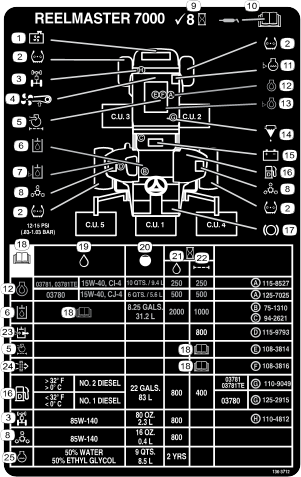

Fuel