| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This machine is intended to be used by hired, commercial operators for maintaining turf on slopes, tight undulations, areas near water, or bunker lips. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.https://www.toro.com/en-GB for more information, including safety tips, training materials, accessory information, help finding a dealer, or to register your product.

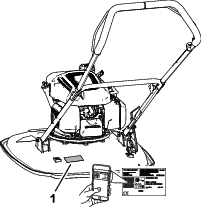

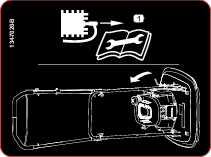

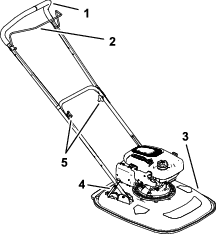

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

Write the product model and serial numbers in the space below:

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives. For details, see the separate product specific Declaration of Conformity (DOC) sheet.

Gross or Net Torque: The gross or net torque of this engine was laboratory rated by the engine manufacturer in accordance with the Society of Automotive Engineers (SAE) J1940 or J2723. As configured to meet safety, emission, and operating requirements, the actual engine torque on this class of mower will be significantly lower. Please refer to the engine manufacturer’s information included with the machine.

Safety

General Safety

Important: Read these instructions carefully before using the machine, and keep them for future reference.

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and functioning properly on the machine.

-

Keep bystanders and children out of the operating area. Do not allow children to operate the machine. Allow only people who are responsible, trained, familiar with the instructions, and physically capable to operate the machine. Local regulations may restrict the age of the operator.

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

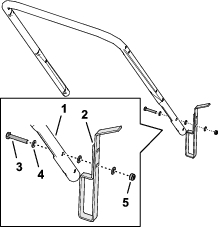

Installing the Handlebar Footstop

Parts needed for this procedure:

| Lower handlebar | 1 |

| Footstop | 1 |

| Bolt (6 x 35 mm) | 1 |

| Washer (6 mm) | 3 |

| Locknut (6 mm) | 1 |

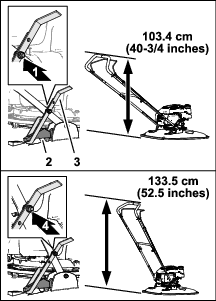

Note: You can only use the footstop to support the handlebar in the vertical position when you assemble the handlebar in the lower position 103.4 cm (40-3/4 inches).

-

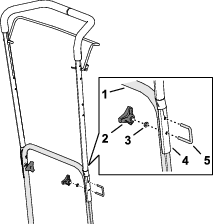

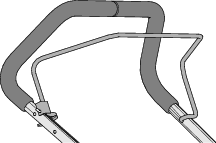

Determine the handlebar height when the footstop is secured to the upstop bracket (Figure 3).

-

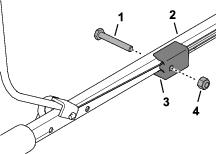

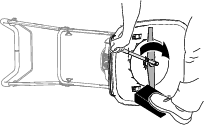

Align the hole in the footstop with the hole in the lower handlebar (Figure 4).

-

Assemble the footstop to the handlebar with a bolt (6 x 35 mm), 3 washers (6 mm), and locknut (6 mm).

-

Tighten the locknut and bolt.

Note: Ensure that you can pivot the footstop.

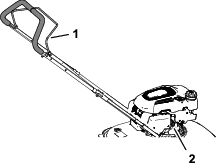

Installing the Handlebar

Parts needed for this procedure:

| T-bushings | 4 |

| Bolt (6 x 55 mm) | 2 |

| Washer (6 mm) | 6 |

| Locknut (6 mm) | 2 |

| Knob | 2 |

| U-bolt | 2 |

| Handlebar fitting | |

| Upper handlebar | 1 |

| Bolt (1/4 x 1-3/4 inches) | 1 |

| Locknut (1/4 inch) | 1 |

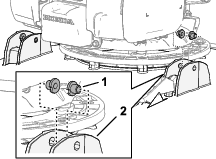

Assembling the Lower Handlebar to the Machine

-

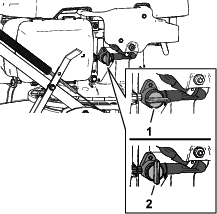

Assemble 2 T-bushings into the handlebar flanges of the mower deck (Figure 5).

-

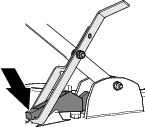

Align the footstop of the handlebar to the up-stop bracket on the deck (Figure 6).

-

Align the hole in the handlebar with the holes in the bushings (Figure 7), and secure handlebar, to the machine with a bolt (6 x 55 mm), 2 washers (6 mm), and a locknut (6 mm).

-

Repeat step 3 at the other side of the machine.

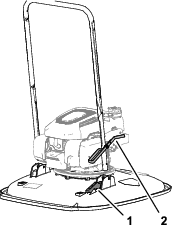

Assembling the Upper and Lower Handlebars

-

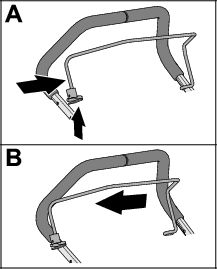

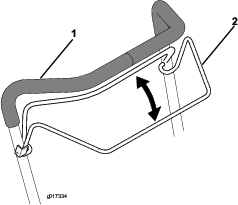

Align the holes on the upper handlebar with the holes in the lower handlebar (Figure 8).

-

Assemble the upper handlebar to the lower handlebar wit the 2 U-bolts, 2 washer (6 mm), and 2 knobs.

Assembling the Cable to the Operator-Presence Bail

-

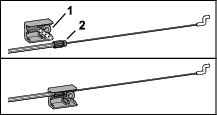

Insert the fitting at the end of the cable sheath into the upper socket of the handlebar fitting (Figure 9).

-

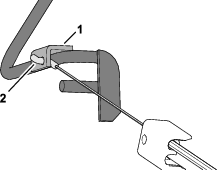

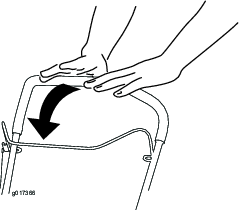

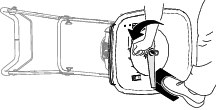

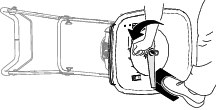

Squeeze the leg of the operator-presence bail until you can remove it from the upper handlebar, and remove the bail from the machine (Figure 10).

-

Insert the cable fitting through the hole in the bracket of the operator-presence bail as shown in Figure 11.

-

Insert the end of the operator-presence bail into the handlebar, squeeze the other leg of bail slightly, and insert the bail into the handlebar (Figure 12).

-

Secure the handlebar fitting to the upper handlebar (Figure 13) with the bolt (1/4 x 1-3/4 inches) and locknut (1/4 inch).

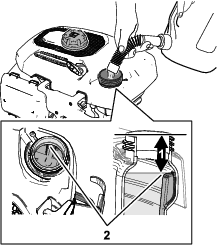

Adding Oil to the Engine

Important: Your machine does not come with oil in the engine. Before starting the engine, add oil to the engine.

API Service Classification: SJ or higher

Oil Viscosity: 10W-30 oil

Oil Capacity: 0.40 L (13.5 oz)

-

Move the machine to a level surface.

-

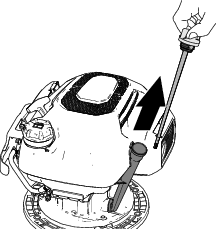

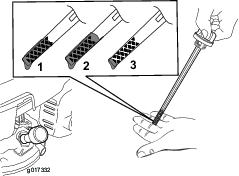

Remove the dipstick from the oil-filler neck and wipe the dipstick with a clean rag (Figure 14).

-

Slowly pour the specified engine oil into the oil-filler neck (Figure 15), and wait 3 minutes.

-

Insert the dipstick into the oil-filler neck, then remove the dipstick.

-

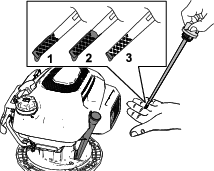

Check the oil level on the dipstick (Figure 16).

Note: If you overfill the engine with oil, drain the excess oil; refer to Draining the Engine Oil.

-

If the oil level is below the upper limit, wipe the dipstick with a clean rag and repeat steps 3 through 5 until the engine-oil level is at the upper limit mark.

-

Insert the dipstick into the oil-filler neck and hand tighten the dipstick securely.

Product Overview

Operator-Presence Bail

The operator-presence bail (Figure 19) controls the flywheel brake and ignition of the engine.

-

Squeeze the bail to the handlebar to run the engine.

-

Release the bail to the handlebar to shut off the engine.

Fuel-Shutoff Valve

Use the fuel-shutoff valve (Figure 19) to control the flow of fuel to the engine.

-

Close the fuel-shutoff valve when you transport, maintain, or store the machine.

-

Open the fuel-shutoff valve to run the engine.

|

Model |

Cutting width |

Product width |

|---|---|---|

|

02617 |

53 cm (21 inches) |

63.5 cm (25 inches) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.https://www.toro.com/en-GB for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Before Operation

Before Operation Safety

General Safety

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Check that all guards and safety devices are in place and working properly.

-

Always inspect the machine to ensure that the blades, blade bolts, and cutting assembly are not worn or damaged.

-

Inspect the area where you will use the machine and remove all objects that could interfere with the operation of the machine or that the machine could throw.

-

Adjusting the cutting height may bring you into contact with the moving blade, causing serious injury.

-

Replace a faulty muffler.

Fuel Safety

-

Fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

To prevent a static charge from igniting the fuel, place the container and/or machine directly on the ground before filling, not in a vehicle or on an object.

-

Add or drain fuel to the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Do not handle fuel when smoking or around an open flame or sparks.

-

Do not remove the fuel cap or add fuel to the tank while the engine is running or hot.

-

If you spill fuel, do not attempt to start the engine. Avoid creating a source of ignition until the fuel vapors have dissipated.

-

Store fuel in an approved container and keep it out of the reach of children.

-

Replace the cap on the fuel tank and all fuel containers securely.

-

-

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep your hands and face away from the nozzle and the fuel-tank opening.

-

Keep fuel away from your eyes and skin.

-

Fuel Specification

| Type | Unleaded gasoline |

| Minimum octane rating | 87 (US) or 91 (research octane; outside the US) |

| Ethanol | No more than 10% by volume |

| Methanol | None |

| MTBE (methyl tertiary butyl ether) | Less than 15% by volume |

| Oil | Do not add to the fuel |

Use only clean, fresh (no more than 30 days old), fuel from a reputable source.

Important: To reduce starting problems, add fuel stabilizer/conditioner to fresh fuel as directed by the fuel-stabilizer/conditioner manufacturer.

Filling the Fuel Tank

Note: Refer to your engine owner’s manual for additional information.

-

Clean around the fuel-tank cap and remove the cap from the tank.

-

Fill the fuel tank with the specified fuel as shown in Figure 20.

-

Install the cap to the fuel tank.

Checking the Engine Oil Level

Refer to Checking the Engine-Oil Level.

During Operation

During Operation Safety

General Safety

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Disengage the blade and all drive clutches before staring the engine.

-

Start the engine according to the instructions and with your feet well away from the blade.

-

Do not tilt the machine more than necessary to start the engine, and lift only the part that is away from you.

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

When you release the operator-presence control, the engine should shut off and the blade should stop within 3 seconds. If not, stop using your machine immediately and contact an Authorized Service Dealer.

-

Keep bystanders, especially children and pets, out of the operating area. Keep small children out of the operating area and under the watchful care of a responsible adult who is not operating the machine. Stop the machine if anyone enters the area.

-

Operate the machine only in good visibility and appropriate weather conditions. Do not operate the machine when there is the risk of lightning.

-

Wet grass or leaves can cause serious injury if you slip and contact the blade. Avoid mowing in wet conditions if possible.

-

Use extreme care when approaching blind corners, shrubs, trees, or other objects that may block your view.

-

Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven terrain could cause you to lose your balance or footing.

-

If the machine strikes an object or starts to vibrate, immediately shut off the engine, wait for all moving parts to stop, and disconnect the wire from the spark plug before examining the machine for damage. Make all necessary repairs before resuming operation.

-

Never pick up or carry the machine while the engine is running.

-

If the engine has been running, it will be hot and can severely burn you. Keep away from the hot engine.

-

Engine exhaust contains carbon monoxide, which is lethal if inhaled. Do not run the engine indoors or in an enclosed area.

-

Use accessories and attachments approved by Toro only.

Slope Safety

-

Slopes are a major factor related to loss of control accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution. Before using the machine on a slope, do the following:

-

Review and understand the slope instructions in the manual.

-

Evaluate the site conditions of the day to determine if the slope is safe for machine operation. Use common sense and good judgment when performing this evaluation. Changes in the terrain, such as moisture, can quickly affect the operation of the machine on a slope.

-

-

Always be sure of your footing, and keep a firm hold on the handles. Walk; never run.

-

Trim across the face of slopes, never up and down.

-

Exercise extreme caution when changing direction on slopes.

-

Do not trim on steep slopes.

-

Use extreme caution when reversing or pulling the machine toward you.

-

Avoid mowing on wet grass. Poor footing could cause a slip-and-fall accident.

-

Remove or mark obstacles such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstacles.

-

Mow with caution near drop-offs, ditches, or embankments.

-

When using the machine, always keep both hands on the handle.

-

When cutting from the top of a slope and you need a longer reach, use an approved extended handle.

Fuel Shutoff Valve

-

Rotate the handle of the fuel shutoff valve horizontal to open the valve.

-

Rotate the handle of the fuel shutoff valve vertical to close the valve.

Starting the Engine

-

Open the fuel-shutoff valve; refer to Fuel Shutoff Valve.

-

Close the operator-presence bail against the handlebar.

-

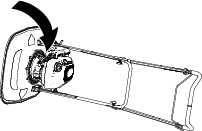

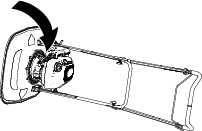

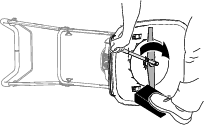

Place your foot on the deck and tilt the machine toward you (Figure 23).

-

While holding the operator-presence bail, pull the recoil-starter grip.

Note: If the machine does not start after several attempts, contact an Authorized Service Dealer or authorized Toro distributor.

Shutting Off the Engine

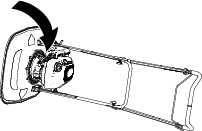

To shut off the engine, release the operator-presence bail (Figure 24).

Important: When you release the operator-presence bail, both the engine and cutting disc should stop within 3 seconds. If they do not stop properly, stop using your machine immediately and contact an Authorized Service Dealer or authorized Toro distributor.

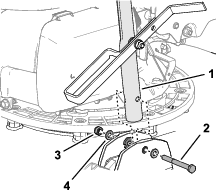

Supporting the Handlebar with the Footstop

Note: If you assembled to the low-handlebar position 103.4 cm (40-3/4 inches), use the footstop to support the handlebar in the vertical position

-

To release the handlebar, lift the handlebar and rotate the footstop forward (Figure 25).

-

To support the handlebar, position the handlebar and rotate the footstop rearward.

Adjusting the Cutting Height

Warning

Adjusting the cutting height may bring you into contact with the moving blade, causing serious injury.

-

Shut off the engine and wait for all moving parts to stop.

-

Wear cut-resistant gloves while handling the blade.

Caution

If the engine has been running, the muffler will be hot and can severely burn you.

Keep away from the hot muffler.

Removing the Blade

-

Close the fuel-shutoff valve; refer to Fuel-Shutoff Valve.

-

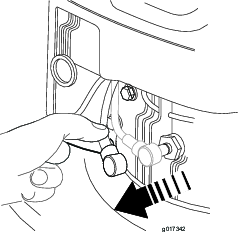

Disconnect the wire from the spark plug.

-

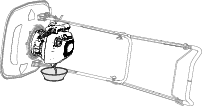

Tip the machine on its side, with the dipstick down.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped in another direction, oil may fill the valve train—requiring at least 30 minutes to drain.

-

Use a block of wood to hold the blade steady (Figure 27).

-

Use the wrench provided with the machine to remove the blade by rotating the bolt counterclockwise (Figure 27).

Important: Wear safety glasses and cut-resistant gloves when removing the blade.

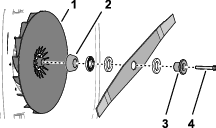

Positioning the Blade Spacers

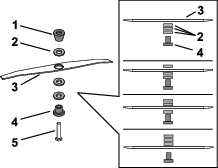

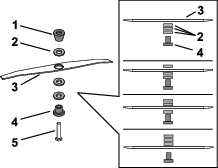

Change the position of the spacers to adjust the cutting height as shown in Figure 28.

Note: Each spacer changes the cutting height of the blade 6.3 mm (1/4 inch).

Installing the Blade

-

Align the curved ends of the blade toward mower deck, and assemble the retainer, blade, spacers, and conical spacer to the impeller with the bolt.

Important: Always assemble the conical spacer directly below the impeller and the retainer under the head of the bolt.

-

Torque the blade bolt to 25 N∙m (18 ft-lb).

Note: A bolt torqued to 25 N∙m (18 ft-lb) is very tight. While holding the cutting blade with block of wood, put your weight behind the torque wrench, and tighten the bolt.

-

Tip the machine up, connect the spark-plug wire to the spark plug, and open the fuel-shutoff valve.

Operating Tips

General Mowing Tips

-

Place the hoop of the footstop under the upstop to increase handling of the machine.

-

Inspect the area where you will use the machine and remove all objects that the machine could throw.

-

Avoid striking solid objects with the blade. Never deliberately mow over any object.

-

If the machine strikes an object or starts to vibrate, immediately shut off the engine, disconnect the wire from the spark plug, and examine the machine for damage.

-

For best performance, ensure that the blade is sharp before the cutting season begins.

-

Replace a damaged blade with a new Toro replacement blade.

-

Ensure that a sharpened blade is the same length as the intact cutting line.

Cutting Grass

-

Cut only about a third of the grass blade at a time. Do not cut below the highest setting (30 mm or 1-1/4 inches) unless the grass is sparse, or it is late fall when grass growth begins to slow down; refer to Adjusting the Cutting Height.

-

Do not mow grass over 15 cm (6 inches) long because the machine may plug or the engine may stall.

-

Wet grass and leaves tend to clump on the yard and can cause the machine to plug or the engine to stall. Mow only in dry conditions if possible.

Warning

Wet grass or leaves can cause serious injury if you slip and contact the blade.

Mow only in dry conditions if possible.

-

Be aware of a potential fire hazard in very dry conditions, follow all local fire warnings, and keep the machine free of dry grass and leaf debris.

-

If the finished lawn appearance is unsatisfactory, try 1 or more of the following:

-

Inspect the cutting unit and/or replace the blade.

-

Walk at a slower pace while mowing.

-

Raise the cutting height on your machine.

-

Cut the grass more frequently.

-

Overlap cutting swaths instead of cutting a full swath with each pass.

-

Cutting Leaves

-

After cutting the lawn, ensure that half of the lawn shows through the cut leaf cover. You may need to make more than a single pass over the leaves.

-

Mowing grass over 15 cm (6 inches) in length is not recommended. If the leaf cover is too thick, the machine may plug and cause the engine to stall.

-

Slow down your mowing speed if the machine does not cut the leaves finely enough.

After Operation

After Operation Safety

General Safety

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Clean grass and debris from the machine to help prevent fires. Clean up oil or fuel spills.

-

Never store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

Hauling Safety

-

Secure the machine.

-

Use care when loading and unloading the machine.

Cleaning the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

Warning

The machine may dislodge material from under the machine housing.

-

Wear eye protection.

-

Stay in the operating position (behind the handle).

-

Do not allow bystanders in the area.

-

Tip the machine on its side, with the dipstick down.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped in another direction, oil may fill the valve train—requiring at least 30 minutes to drain.

-

Use a brush or compressed air to remove grass and debris from the exhaust guard, the top cowl, and the surrounding deck areas.

-

Clean the cooling system; remove grass clippings, debris, or dirt from the engine air cooling fins and starter.

Note: Clean the cooling system more frequently in dirty or high-chaff conditions.

Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| After each use |

|

| Every 25 hours |

|

| Every 100 hours |

|

| Yearly |

|

Maintenance Safety

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Disconnect the spark-plug wire from the spark plug before performing any maintenance procedure.

-

Wear gloves and eye protection when servicing the machine.

-

Examine the machine regularly and replace any worn or damaged parts. Do not replace the cutting means with metal parts; use only the cutting elements that are suitable for use at the operating speed of the machine.

-

Never tamper with safety devices. Check their proper operation regularly.

-

Tipping the machine may cause the fuel to leak. Fuel is flammable and explosive, and can cause personal injury. Run the engine dry or remove the fuel with a hand pump; never siphon the fuel.

-

Keep all fasteners tight to ensure that the machine is in safe working condition.

-

Do not change the engine governor setting or overspeed the engine.

-

To ensure optimum performance of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Preparing for Maintenance

Warning

Tipping the machine may cause the fuel to leak. Fuel is flammable, explosive and can cause personal injury.

Run the engine dry or remove the fuel with a hand pump; never siphon.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped with the dipstick aligned up, oil may fill the valve train—requiring at least 30 minutes to drain.

-

Shut off the engine and wait for all moving parts to stop.

-

Move the machine to a level surface.

-

Disconnect the spark-plug wire from the spark plug (Figure 32).

-

Close the fuel-shutoff valve; refer to Fuel Shutoff Valve.

Important: If you are repairing the machine, empty the fuel tank.

-

After performing the maintenance procedure(s), open the fuel valve and connect the spark-plug wire to the spark plug.

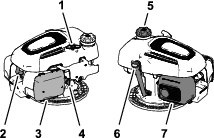

Replacing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

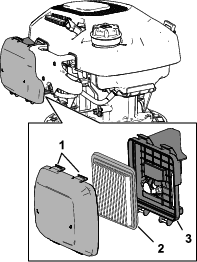

Press down on the latch tabs at top of the air-filter cover (Figure 33).

-

Remove the cover.

-

Remove the filter element (Figure 33).

-

Inspect the paper air filter.

-

If the filter damaged, wet with oil or fuel, and excessively dirty, replace it.

-

If the filter is dirty, tap it on a hard surface several times or blow compressed air less than 207 kPa (30 psi) through the side of the filter that faces the engine.

Note: Do not brush the dirt off the filter; brushing forces dirt into the fibers.

-

-

Clean the air-filter base and cover using a moist rag. Do not wipe dirt into the air duct.

-

Insert the filter into the filter base.

-

Install the cover.

Engine Oil Specification

API Service Classification: SJ or higher

Oil Viscosity: 10W-30 oil

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

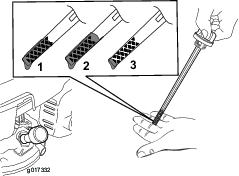

Remove the dipstick from the oil-filler neck and wipe the dipstick with a clean rag.

-

Insert the dipstick into the oil-filler neck, then remove the dipstick.

Important: Do not thread the dipstick into the filler neck.

-

Check the oil level on the dipstick.

-

If the oil level is near or below the lower limit mark on the dipstick (Figure 34), slowly pour the specified engine oil into the oil-filler neck (Figure 35) and wait 3 minutes.

-

Wipe the dipstick with a clean rag and repeat steps 3 through 5 until the engine-oil level is at the upper limit mark.

-

Insert the dipstick into the oil-filler neck and hand tighten the dipstick securely.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 25 hours |

|

Draining the Engine Oil

-

If the engine is cold, run it 1 to 2 minutes to warm the oil.

-

Ensure that the fuel tank contains little or no fuel so that the fuel does not leak when you tip the machine onto its side.

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

Remove the dipstick from the oil-filler neck and wipe the dipstick with a clean rag.

-

Align a drain pan next to the deck at the oil-filler neck side of the machine and on the ground (Figure 35).

-

Tip the machine onto its side with the oil-filler neck down to drain the oil out the filler neck.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped in another direction, oil may fill the valve train—requiring at least 30 minutes to drain.

-

Return the machine to the operating position.

-

Clean spilled oil from the machine.

Note: Dispose of the used oil properly at a local recycling center.

Adding Oil to the Engine

Oil Capacity: 0.40 L (13.5 oz)

-

Slowly pour the specified engine oil into the oil-filler neck (Figure 35) and wait 3 minutes.

-

Insert the dipstick into the oil-filler neck, then remove the dipstick.

Important: Do not thread the dipstick into the filler neck.

-

Check the oil level on the dipstick (Figure 38).

Note: If you overfill the engine with oil, drain the excess oil; refer to Draining the Engine Oil.

-

If the oil level is below the upper limit, wipe the dipstick with a clean rag and repeat steps 1 through 3 until the engine-oil level is at the upper limit mark.

-

Insert the dipstick into the oil-filler neck and hand tighten the dipstick securely.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

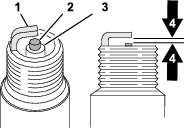

Spark Plug Specification: Champion RN9YC or equivalent.

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a worn, damaged, or dirty spark plug. Do not clean the electrodes because grit entering the cylinder can damage the engine.

-

Adjust the air gap (Figure 39) between the center electrode and side electrode to 0.76 mm (0.030 inch).

-

Install the spark plug and gasket.

-

Torque the plug to 20 N∙m (15 ft-lb).

-

Connect the wire to the spark plug.

Blade Maintenance

Warning

The blade is sharp; contacting the blade can result in serious personal injury.

-

Disconnect the wire from the spark plug.

-

Wear cut-resistant gloves when servicing the blade.

Checking the Blade

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

Tip the machine onto its side with the oil-filler neck down.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped in another direction, oil may fill the valve train—requiring at least 30 minutes to drain.

-

Check the blade for wear or damage.

-

If the blade is damaged or cracked, remove and replace it immediately.

-

If the blade edge is dull or nicked, remove it, have it sharpened or replaced, and install the blade.

-

-

Tip the machine upright.

Replacing the Blade

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Important: You need a torque wrench to install the blade. If you do not have a torque wrench or are uncomfortable performing this procedure, contact an authorized Toro distributor or Authorized Service Dealer.

Removing the Blade

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

Tip the machine onto its side with the oil-filler neck down.

Important: Always tip the machine onto its side with the dipstick aligned down. If the machine is tipped in another direction, oil may fill the valve train—requiring at least 30 minutes to drain.

-

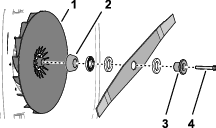

Record the position of the spacers.

-

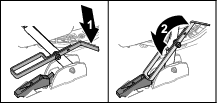

Use a block of wood to hold the blade steady (Figure 43).

-

Use the wrench provided with the machine to remove the blade by rotating the blade bolt counterclockwise (Figure 42).

Important: Wear safety glasses and cut resistant gloves when removing the blade.

Installing the Blade

-

Align the curved ends of the blade toward mower deck, and assemble the retainer, blade, spacers, and conical spacer to the impeller with the bolt.

Important: You must always assemble the conical spacer directly below the impeller and the retainer under the head of the bolt.

-

Torque the blade bolt to 25 N∙m (18 ft-lb).

Note: A bolt torqued to 25 N∙m (18 ft-lb) is very tight. While holding the cutting blade with block of wood, put your weight behind the torque wrench, and tighten the bolt.

-

Tip the machine upright.

Storage

Storage Safety

-

Shut off the engine, remove the key (if equipped), and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Allow the engine to cool before storing the machine in any enclosure.

-

Allow the engine to cool before storing the machine in any enclosure.

-

Never store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

-

Remove grass, leaves, and debris from the muffler and engine compartment to help prevent fires.

Preparing the Machine for Storage

Warning

Fuel vapors can explode.

-

Do not store fuel more than 30 days.

-

Do not store the machine in an enclosure near an open flame.

-

Allow the engine to cool before storing it.

-

On the last refueling of the year, add fuel stabilizer to the fuel as directed by the engine manufacturer.

-

Run the machine until the engine shuts off from running out of fuel.

-

Start the engine again and allow it to run until it shuts off. When you can no longer start the engine, the fuel system is empty.

-

Disconnect the wire from the spark plug.

-

Remove the spark plug, add 30 ml (1 fl oz) of oil through the spark-plug hole, and pull the recoil-starter grip slowly several times to distribute oil throughout the cylinder.

-

Install the spark plug and torque it to 20 N∙m (15 ft-lb).

-

Check the blade for wear or damage. If the blade is dull, have it sharpened; if the blade is damaged, replace it.

-

Tighten all nuts, bolts, and screws.

-

Store the machine in a cool, clean, dry place.

Troubleshooting

| Problem | Possible Cause | Corrective Action |

|---|---|---|

| The engine does not start. |

|

|

| The engine starts hard or loses power. |

|

|

| The engine runs rough. |

|

|

| The machine or engine vibrates excessively. |

|

|

| There is an uneven cutting pattern. |

|

|