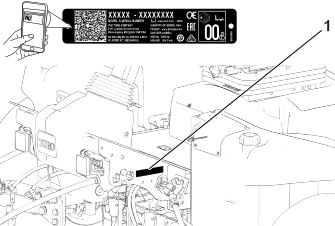

Disclaimers and Regulatory Information

This product complies with all relevant European directives; for details, please see the separate product specific Declaration

of Conformity (DOC) sheet.

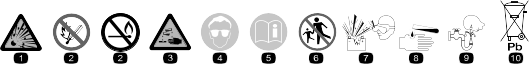

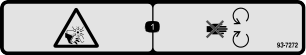

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained

in effective working order, or the engine is constructed, equipped, and maintained for the prevention of fire.

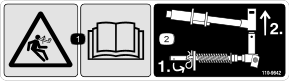

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and

the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through

the engine manufacturer.

|

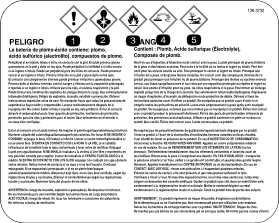

| CALIFORNIA |

| Proposition 65 |

| Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. |

| Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. |

| Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. |

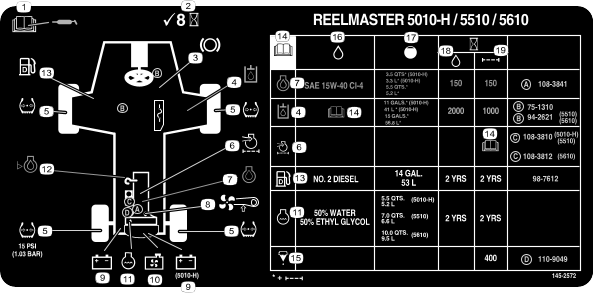

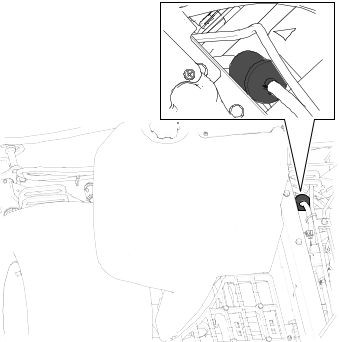

Fuel