| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

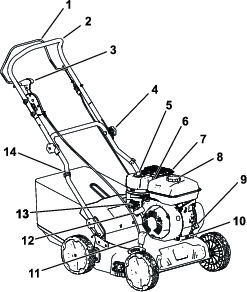

Introduction

This scarifier is intended to be used by residential homeowners. It is designed primarily to loosen the soil and to remove moss and weeds from the soil on well-maintained lawns on residential properties. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for more information, including safety tips, training materials, accessory information, help finding a dealer, or to register your product.

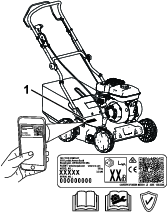

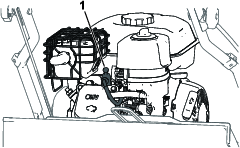

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

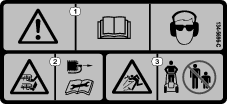

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Do not tamper with or disable safety devices on the machine, and check their proper operation regularly. Do not attempt to adjust or tamper with the engine speed control; doing so may create an unsafe operating condition, resulting in personal injury.

Safety

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury or death.

-

Read, understand, and follow the instructions and warnings in this Operator’s Manual and on the machine and attachments before starting the engine.

-

Do not put your hands or feet near moving parts or under the machine. Keep clear of any discharge opening.

-

Do not operate the machine without all guards and other safety protective devices in place and functioning properly on the machine.

-

Keep bystanders and children out of the operating area. Do not allow children to operate the machine. Allow only people who are responsible, trained, familiar with the instructions, and physically capable to operate the machine.

-

Stop the machine, shut off the engine, remove the ignition key (if equipped), and wait for all moving parts to stop before servicing, fueling, or unclogging the machine.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

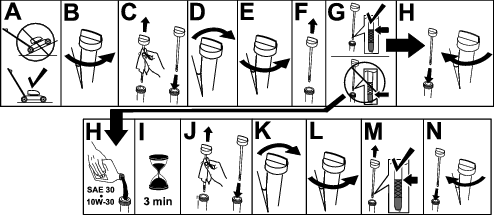

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Important: Remove and discard the protective plastic sheet that covers the engine and any other plastic or wrapping on the machine.

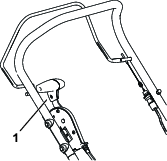

Assembling the Handle

Parts needed for this procedure:

| Carriage bolt | 2 |

| Lock knob | 4 |

| Curved washer | 2 |

| Curved-head bolt | 2 |

Warning

Assembling and unfolding the handle improperly can damage the cables, causing an unsafe operating condition.

-

Do not damage the cables when unfolding the handle.

-

If a cable is damaged, contact an Authorized Service Dealer.

-

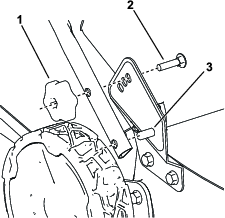

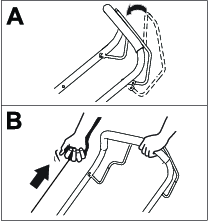

Install the lower handle over the post on the lower handle bracket and position the lower handle for desired handle height (Figure 3).

-

Secure each side of the lower handle to the machine using a carriage bolt and a lock knob. Tighten the lower handlebar knobs.

-

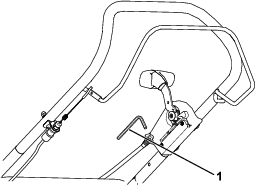

Install each side of the upper handle to the lower handle using a curved washer, curved head bolt, and a lock knob (Figure 4).

-

Secure the cables that extend from the upper handle to the lower handle using the cable clamps.

Adding Oil to the Engine

Important: If the oil level in the engine is too low or too high and you run the engine, you may damage the engine.

Assembling the Grass Bag

Product Overview

| Model | 54610 |

| Weight | 38 kg (77 lb) |

| Length | 122 cm (48 inches) |

| Width | 61 cm (24 inches) |

| Height | 107 cm (42 inches) |

| Width of Cut | 40 cm (16 inches) |

| Depth of Cut (6 positions) | 10 mm above ground to 15 mm below (2/5 inches above ground to 3/5 inches below) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

Always shut off the machine, remove the ignition key (if equipped), wait for all moving parts to stop, and allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Check that all guards and safety devices, such as deflectors and/or grass catcher, are in place and functioning properly.

-

Always inspect the machine to ensure that the blades and roller assembly parts are not worn or damaged.

-

Inspect the area where you will use the machine, and remove all objects that could interfere with the operation of the machine or that the machine could throw, including underground objects such as sprinkler heads, irrigation piping, shallow electrical cords, etc.

-

Contact with the moving blades will cause serious injury. Do not put your fingers under the housing.

Fuel Safety

-

Fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

To prevent a static charge from igniting the fuel, place the container and/or machine directly on the ground before filling, not in a vehicle or on an object.

-

Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Do not handle fuel when smoking or around an open flame or sparks.

-

Do not remove the fuel cap or add fuel to the tank while the engine is running or hot.

-

If you spill fuel, do not attempt to start the engine. Avoid creating a source of ignition until the fuel vapors have dissipated.

-

Store fuel in an approved container and keep it out of the reach of children.

-

-

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep your hands and face away from the nozzle and the fuel-tank opening.

-

Keep fuel away from your eyes and skin.

-

Filling the Fuel Tank

| Type | Unleaded gasoline |

| Minimum octane rating | 87 (US) or 91 (research octane; outside the US) |

| Ethanol | No more than 10% by volume |

| Methanol | None |

| MTBE (methyl tertiary butyl ether) | Less than 15% by volume |

| Oil | Do not add to the fuel |

Use only clean, fresh (no more than 30 days old), fuel from a reputable source.

Important: To reduce starting problems, add fuel stabilizer/conditioner to fresh fuel as directed by the fuel-stabilizer/conditioner manufacturer.

-

Clean around the fuel-tank cap and remove the cap from the tank.

Note: Do not fill the fuel tank above the bottom of the fuel-tank neck (Figure 4).

-

Install the fuel-tank cap and tighten it securely by hand.

Checking the Engine-Oil Level

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine.

Adjusting the Handle Height

You may raise or lower the handle to a position comfortable for you.

Remove the lock knobs and carriage bolts from the lower handle, move the handle to 1 of 3 positions, and install the lock knob and carriage bolts in the new position (Figure 3).

Adjusting the Maximum Depth of Cut

Danger

Adjusting the depth-of-cut levers could bring your hands into contact with a moving blade and result in serious injury.

-

Shut off the engine, remove the ignition key (if equipped), and wait for all moving parts to stop before adjusting the depth of cut.

-

Do not put your fingers under the housing when adjusting the depth of cut.

Caution

If the engine has been running, the muffler will be hot and can burn you.

Keep away from the hot muffler.

-

Shut off the machine and wait for all moving parts to stop.

-

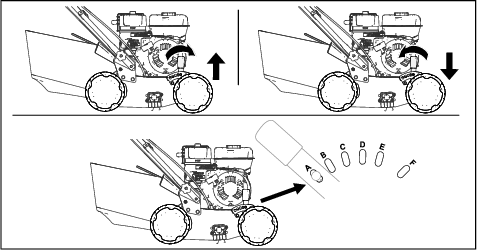

Push downwards on the main handlebars to lift the front wheels off the ground.

-

Move the transport lever all the way back toward you into the transport position (Figure 10).

-

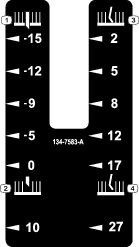

To adjust the max depth of cut, adjust the depth-of-cut lever position by pushing it in toward the machine and moving it to a different slot (Figure 11).

-

To raise the max depth of cut, move the depth-of-cut lever forward

-

To lower the max depth of cut, move the depth-of-cut lever rearward.

-

The depth of cut varies depending on which shaft assembly you have installed; refer to Figure 11 and the following table.

-

Note: Move the depth-of-cut lever all the way forward when transporting the machine.

| Setting | Spring Shaft Assembly | Blade Shaft Assembly |

| A | 2 mm (Ground level) | -15 mm (-3/5 inch) |

| B | 5 mm (1/5 inch) | -12 mm (-1/2 inch) |

| C | 8 mm (5/16 inch) | -9 mm (-3/8 inch) |

| D | 12 mm (17/32 inch) | -5 mm (-3/16 inch) |

| E | 17 mm (11/16 inch) | 0 mm (Ground level) |

| F | 27 mm (1-1/16 inches) | 10 mm (3/8 inch) |

Operating Tips

-

Selecting the correct shaft assembly is necessary to ensure that the blade or tine components do not wear quickly and reduce the component lifetime.

-

The steel blade shaft assembly should be used on lawns with heavy or unmaintained thatch and moss.

-

The spring tine shaft assembly should be used on lawns that are regularly scarified and have a low amount of thatch & moss.

-

-

Begin by cutting the lawn to the lowest height of cut (HOC), to reduce load on the scarifier.

-

Select a HOC on the scarifier that produces an even and consistent amount of material/thatch.

Important: The tine blades should be set so the tips just touch the ground surface. If the blades penetrate the ground excessively the machine will be overloaded, reducing the lifetime.

-

On heavy or unmaintained lawns, begin using the scarifier on a higher HOC to reduce load on the machine and increase the machine’s lifetime.

-

At the end of each run, lift the tines away from the ground to reduce surface wear.

-

A second pass should be made, at a diagonal angle to the first (approximately 30°).

-

Mow to clean up any debris.

During Operation

During Operation Safety

General Safety

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

The blade is sharp; contacting the blade can result in serious personal injury. Shut off the engine, remove the ignition key (if equipped), and wait for all moving parts to stop before leaving the operating position.

-

Keep bystanders out of the operating area. Keep small children out of the operating area and under the watchful care of a responsible adult who is not operating the machine. Stop the machine if anyone enters the area.

-

Always look down and behind you before moving the machine in reverse.

-

Operate the machine only in good visibility and appropriate weather conditions. Do not operate the machine when there is the risk of lightning.

-

Wet grass or leaves can cause serious injury if you slip and contact the blades. Avoid operating the machine in wet conditions.

-

Use extreme care when approaching blind corners, shrubs, trees, or other objects that may block your view.

-

Do not operate the machine without the rear deflector lowered or the grass bag installed. Stop the blade(s) when crossing gravel surfaces.

-

Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven terrain could cause you to lose your balance or footing.

-

If the machine strikes an object or starts to vibrate, immediately shut off the engine, remove the ignition key (if equipped), wait for all moving parts to stop, and disconnect the wire from the spark plug before examining the machine for damage. Make all necessary repairs before resuming operation.

-

Before leaving the operating position, shut off the engine, remove the ignition key (if equipped), and wait for all moving parts to stop.

-

If the engine has been running, it will be hot and can severely burn you. Keep away from the hot engine.

-

Operate the engine only in well-ventilated areas. Exhaust gases contain carbon monoxide, which is an odorless, deadly poison.

-

Check the grass catcher components and the discharge chute frequently for any wear or deterioration and replace them with genuine Toro parts when necessary.

Slope Safety

-

Operate the machine across the face of slopes; never up and down. Use extreme caution when changing direction on slopes.

-

Do not operate the machine on excessively steep slopes. Poor footing could cause a slip-and-fall accident.

-

Operate the machine with caution near drop-offs, ditches, or embankments.

Starting the Engine

-

Push up on the engine On/Off switch so it is in the ON position.

-

Move the fuel-valve lever to the OPEN position.

-

Move the choke lever to the ON position.

Note: A warm or hot engine may not require choking.

-

Move the throttle lever to the FAST position.

-

Move the transport lever all the way back toward you into the transport position (Figure 10).

-

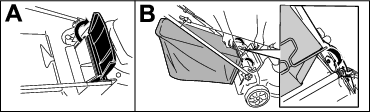

Hold the blade-control bar against the handle (A of Figure 13).

-

From the engine, pull the recoil-start handle (B of Figure 13).

Note: When you pull the recoil-start handle, pull it lightly until you feel resistance, then pull it sharply. Allow the rope to return to the handle slowly.

Note: If the machine does not start after several attempts, contact an Authorized Service Dealer.

-

After the engine starts, gradually move the choke lever back to the OFF position. If the engine stalls or hesitates, move the choke back to the ON position again until the engine warms up, then move it to the OFF position.

Shutting Off the Engine

To shut off the engine, release the blade-control bar and move the transport lever all the way back toward you into the transport position (Figure 10).

Engaging the Scarifier

When the scarifier engine is turned on, the roller begins to rotate.

Slowly move the transport lever all the way forward to lower the roller into the ground (Figure 14).

Note: If you have the blade reel shaft installed and the scarifier does not penetrate the ground at the desired depth, adjust the max depth of cut; refer to Adjusting the Maximum Depth of Cut.

When you are finished scarifying, push downwards on the handlebars to lift the frond wheels off the ground, then move the transport lever all the way back toward you into the transport position and release the blade-control bar to shut off the machine.

Bagging the Clippings

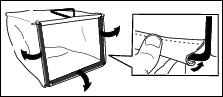

Note: Install and remove the grass bag from the right side of the machine.

Installing the Grass Bag

Removing the Grass Bag

To remove the bag, reverse the steps in Installing the Grass Bag.

After Operation

After Operation Safety

General Safety

-

Always shut off the machine, wait for all moving parts to stop, allow the machine to cool, and disconnect the spark plug wire from the spark plug before adjusting, servicing, cleaning, or storing it.

-

Clean grass and debris from the machine to help prevent fires. Clean up oil or fuel spills.

-

Never store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

Hauling Safety

-

Prior to hauling, move the transport lever into the transport position.

-

Use care when loading or unloading the machine.

-

Secure the machine from rolling.

Cleaning under the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

For best results, clean under the machine soon after you have completed operating the machine.

-

Shut off the engine, wait for all moving parts to stop, and allow the machine to cool.

-

Disconnect the spark-plug wire from the spark plug; refer to Preparing for Maintenance.

-

Raise the machine to its highest depth-of-cut setting.

-

Move the machine onto a paved level surface.

-

Holding the handle, tilt the machine up so the bottom of the deck is accessible (Figure 16).

-

Spray a stream of water under the deck (Figure 16).

Important: Do not spray the engine with water; water can damage the engine or contaminate the fuel system.

-

When no more debris come out, lower the machine, stop the water, and move the machine to a dry area.

-

Connect the spark plug wire and run the engine for a few minutes to dry the underside of the machine.

Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| After each use |

|

| Every 50 hours |

|

| Every 200 hours |

|

| Yearly |

|

| Yearly or before storage |

|

Important: Refer to your engine owner’s manual for additional maintenance procedures.

Maintenance Safety

-

Always shut off the machine, wait for all moving parts to stop, allow the machine to cool, and disconnect the spark-plug wire from the spark plug before adjusting, servicing, cleaning, or storing it.

-

Wear gloves and eye protection when servicing the machine.

-

The blades are sharp; contacting the blade can result in serious personal injury. Wear gloves when servicing the blades. Do not repair or alter the blades.

-

Never tamper with safety devices. Check their proper operation regularly.

-

Tipping the machine may cause the fuel to leak. Fuel is flammable and explosive, and can cause personal injury. Run the engine dry or remove the fuel with a hand pump; never siphon the fuel.

-

To ensure optimum performance of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Preparing for Maintenance

-

Shut off the engine, wait for all moving parts to stop, and allow the machine to cool.

-

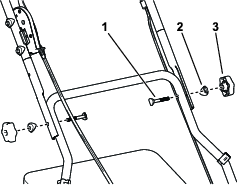

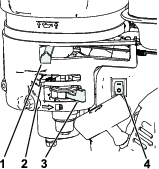

Disconnect the spark-plug wire from the spark plug (Figure 17).

-

After performing the maintenance procedure(s), connect the spark-plug wire to the spark plug.

Replacing the Shaft Assembly

The scarifier includes a blade shaft assembly for scarifying and a separate tine shaft assembly for aeration.

-

Prepare the machine for maintenance; refer to Preparing for Maintenance.

-

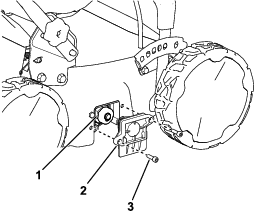

Remove the hex wrench from the transport lever assembly (Figure 18).

-

Using the hex wrench, remove the 2 screws securing the bearing housing and the reel shaft from the right side of the machine (Figure 19).

Note: Retain all removed parts for later installation.

-

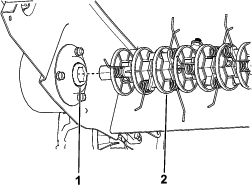

Slide the other end of the shaft assembly out of the drive and replace with the desired shaft assembly (Figure 20).

-

Install the bearing housing so that it secures the newly installed shaft assembly using the 2 hex-head screws removed in step 3 and store the hex wrench in the transport lever assembly (Figure 19).

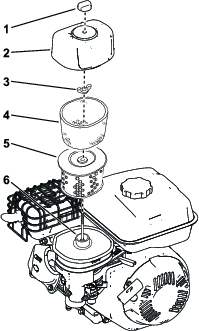

Servicing the Air Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 200 hours |

|

| Yearly |

|

Important: Do not operate the engine without the air-filter assembly; extreme engine damage will occur.

-

Refer to Preparing for Maintenance.

-

Remove the nut that secures the cover (Figure 21).

-

Remove the air-filter cover (Figure 21).

Important: Ensure that no dirt or debris fall into the base.

-

Remove the foam and paper elements from the base.

-

Remove the foam element from the paper element

-

Inspect the foam and paper elements and replace them if they are damaged or excessively dirty.

-

If the filter is damaged or is wet with oil or fuel, replace it.

-

If the filter is dirty, tap it on a hard surface several times or blow the debris outward from the interior of the filter using compressed air at less than 207 kPa (30 psi).

Note: Do not brush or blow dirt from the outside of the filter; either forces dirt into the fibers.

-

-

Clean the air-filter body and cover using a damp rag. Keep dirt away from the air opening.

-

Clean the foam element in warm, soapy water or in a nonflammable solvent.

Note: Do not use fuel to clean the foam element because it could create a risk of fire or explosion.

-

Rinse and dry the foam element thoroughly.

-

Dip the foam element in clean engine oil, then squeeze out the excess oil.

Note: Excess oil in the foam element restricts the air flow through the element and may reach the paper filter and clog it.

-

Wipe dirt from the base and the cover with a moist rag.

Important: Ensure that no dirt or debris fall into the base.

-

Install the air-cleaner elements and ensure that they are properly positioned.

-

Install the cover and screw the fastener down securely.

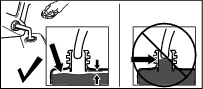

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 50 hours |

|

| Yearly |

|

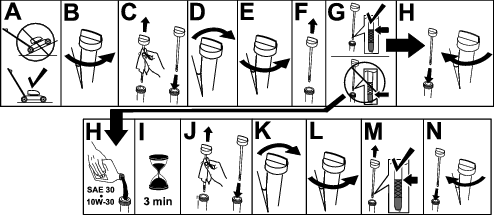

Note: Run the engine a few minutes before changing the oil to warm it. Warm oil flows better and carries more contaminants.

| Engine oil capacity | 0.53 L (18 fl oz)* |

| Oil viscosity | SAE 30 or SAE 10W-30 detergent oil |

| API service classification | SJ or higher |

*There is residual oil in the crankcase after you drain the oil. Do not pour the entire capacity of oil into the crankcase. Fill the crankcase with oil as directed in the following steps.

-

Move the machine to a level surface.

-

Refer to Preparing for Maintenance.

-

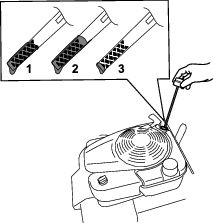

Remove the dipstick by rotating the cap counterclockwise and pulling it out (Figure 22).

-

Tip the machine forward, remove the oil-drain plug, and drain the used oil from the oil-drain plug hole (Figure 7).

Important: Before tipping the machine to change the oil, allow the fuel tank to run dry through normal use. If you must tip the machine prior to running out of fuel, use a hand fuel pump to remove the fuel.

Warning

Tipping the machine may cause the fuel to leak. Fuel is flammable, explosive, and can cause personal injury.

Run the engine dry or remove the fuel with a hand pump; never siphon.

-

After draining the used oil, return the machine to the operating position and install the oil-drain plug.

-

Carefully pour about 3/4 of the engine capacity of oil into the oil-fill tube.

-

Wait 3 minutes for the oil to settle in the engine.

-

Wipe the dipstick clean with a clean cloth.

-

Insert the dipstick into the oil-fill tube, then remove the dipstick.

-

Read the oil level on the dipstick (Figure 22).

-

If the oil level on the dipstick is too low, carefully pour a small amount of oil into the oil-fill tube, wait 3 minutes, and repeat steps 8 through 10 until the oil level on the dipstick is correct.

-

If the oil level on the dipstick is too high, drain the excess oil until the oil level on the dipstick is correct.

-

-

Install the dipstick into the oil-fill tube securely.

-

Recycle the used oil properly.

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Yearly |

|

Replace the blades when the machine hits a solid object or if the blades are damaged or bent. Use only genuine Toro replacement blades.

Warning

The blades and tines are sharp; contacting a blade or tine can result in serious personal injury.

Wear padded gloves when working with the shaft assembly.

Warning

A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, resulting in serious personal injury.

-

Inspect the blades periodically for wear or damage.

-

Replace a worn or damaged blade.

Note: Maintain sharp blades; sharp blades help the machine run smoothly and cut cleanly without excessively tearing or shredding the turf.

-

Refer to Preparing for Maintenance.

-

Tip the machine onto its left side until the upper handle rests on the ground.

Important: Before tipping the machine to inspect or replace the blades, allow the fuel tank to run dry through normal use. If you must tip the machine prior to running out of fuel, use a hand fuel pump to remove the fuel. Tip the machine onto its left side (exhaust guard down, oil filter up) so that oil does not leak into the air filter.

-

Inspect the scarifier roller shaft for bent or damaged blades in need of replacement, if any need to be replaced contact your Authorized Service Dealer.

-

Remove any grass or debris that may be wrapped around the ends of the shaft assembly.

Storage

Store the machine in a cool, clean, dry place.

Storage Safety

Always shut off the machine, wait for all moving parts to stop, allow the machine to cool, and disconnect the spark plug wire from the spark plug before adjusting, servicing, cleaning, or storing it.

Preparing the Machine for Storage

-

On the last refueling of the year, add fuel stabilizer to the fuel as directed by the engine manufacturer.

Important: Old fuel in the fuel tank is the leading cause of hard starting. Do not store the fuel without fuel stabilizer more than 30 days, and do not store stabilized fuel beyond the duration recommended by the fuel-stabilizer manufacturer.

-

Dispose of any unused fuel properly. Recycle it according to local codes or use it in your automobile.

-

Run the machine until the engine shuts off from running out of fuel.

-

Start the engine again and allow it to run until it shuts off. When you can no longer start the engine, it is sufficiently dry.

-

Disconnect the wire from the spark plug and connect the wire to the retaining post (if equipped).

-

Remove the spark plug, add 30 ml (1 fl oz) of engine oil through the spark-plug hole, and pull the starter rope slowly several times to distribute oil throughout the cylinder to prevent cylinder corrosion during the off-season.

-

Loosely install the spark plug.

-

Tighten all nuts, bolts, and screws.

Remove the Machine from Storage

-

Check and tighten all fasteners.

-

Remove the spark plug and spin the engine rapidly by pulling the recoil-start handle to blow the excess oil from the cylinder.

-

Install the spark plug and tighten it with a torque wrench to 20 N∙m (15 ft-lb).

-

Perform any maintenance procedures; refer to .

-

Check the engine-oil level; refer to Checking the Engine-Oil Level.

-

Fill the fuel tank with fresh fuel; refer to Filling the Fuel Tank.

-

Connect the wire to the spark plug.

Troubleshooting

| Problem | Possible Cause | Corrective Action |

|---|---|---|

| The engine does not start. |

|

|

| The engine runs rough. |

|

|

| The scarifier is hard to push. |

|

|

| The discharge chute becomes blocked. |

|

|

| The machine vibrates or makes unusual noises. |

|

|

| Unsatisfactory scarifying results. |

|

|