Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| After the first 5 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Monthly |

|

| Yearly |

|

| Yearly or before storage |

|

Maintenance Safety

Read the following safety precautions before performing any maintenance on the machine:

-

Shut off the engine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Always wear eye protection while performing an adjustment or repair to protect your eyes from foreign objects that the machine may throw.

-

Check all fasteners at frequent intervals for proper tightness to ensure that the machine is in safe working condition.

-

Do not change the governor settings on the engine.

Purchase only genuine Toro replacement parts and accessories.

Preparing for Maintenance

-

Move the machine to a level surface.

-

Shut off the engine, remove the key, and wait for all moving parts to stop.

-

Disconnect the spark-plug wire. Refer to Replacing the Spark Plug.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

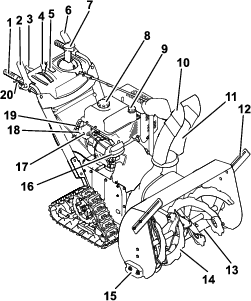

Checking and Adjusting the Auger Skids and Scraper

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

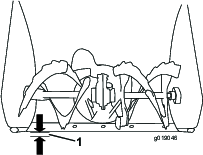

Check the skids and the scraper to ensure that the auger does not contact the paved or gravel surface. Adjust the skids and the scraper as needed to compensate for wear.

-

Loosen the nuts that secure both skids to the auger sides until the skids slide up and down easily.

Important: The auger blades must be supported above the ground by the skids.

-

Ensure that the scraper is 3 mm (1/8 inch) above and parallel to a level surface.

Note: If the pavement is cracked, rough, or uneven, adjust the skids to raise the scraper. For gravel surfaces, adjust the skids further down to prevent the machine from picking up rocks.

-

Move the skids down until they are even with the ground.

-

Firmly tighten the nuts that secure both skids to the auger sides.

Note: To quickly adjust the skids if they loosen, support the scraper 3 mm (1/8 inch) off the pavement, then adjust the skids down to the pavement.

Note: If the skids become excessively worn, you can turn them over and set the unused side toward the pavement.

Inspecting and Tightening the Bogey Wheels

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Refer to Preparing for Maintenance.

-

Inspect the bogey wheels. Tighten the bolts or replace the bogey wheels if necessary.

Checking and Adjusting the Track Tension

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Monthly |

|

-

Refer to Preparing for Maintenance.

-

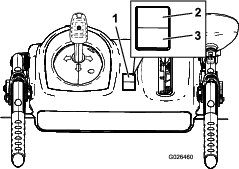

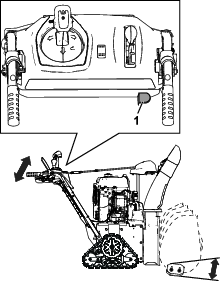

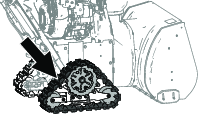

Apply 44 N (10 lbf) between the middle and rear roller (Figure 25).

-

Ensure that the deflection of the track is approximately 9.5 mm (3/8 inch).

-

If the track deflection is not approximately 9.5 mm (3/8) inch or if the tracks are jumping, adjust the track tension as follows:

-

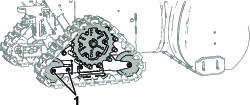

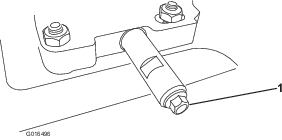

Slightly loosen the nuts on the rear roller yoke (Figure 26).

-

Adjust the hex head bolt as needed (Figure 27).

Note: Turn the bolt clockwise if the track has more than 9.5 mm (3/8 inch) deflection. Turn the bolt counterclockwise if the track has less than 9.5 mm (3/8 inch) deflection.

-

Ensure that the deflection of the track is approximately 9.5 mm (3/8 inch).

-

Tighten the nuts on the rear roller yoke.

-

Repeat for the other track.

-

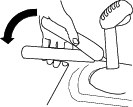

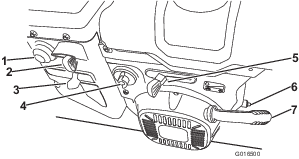

Checking and Adjusting the Traction Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

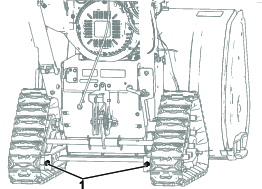

If the machine does not drive in the forward or reverse speeds or it drives when you release the traction lever, adjust the traction cable.

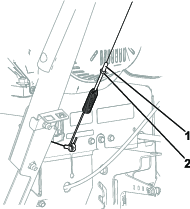

With the traction level disengaged, ensure that the there is no slack in the traction cable (Figure 28).

If there is slack in the traction cable, the left (traction) cable is not properly adjusted.

To adjust the traction cable, do the following:

-

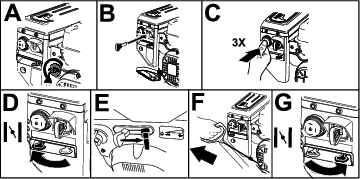

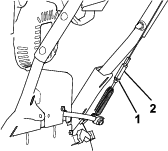

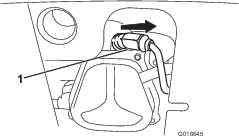

Loosen the jam nut (Figure 29).

-

Loosen or tighten the turnbuckle until the cable is taught.

-

Tighten the jam nut.

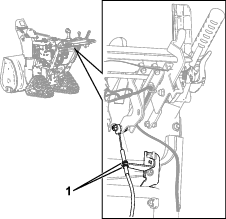

Checking and Adjusting the Auger/Impeller Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

-

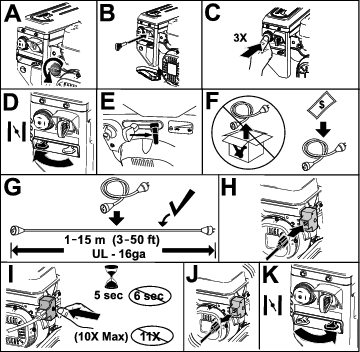

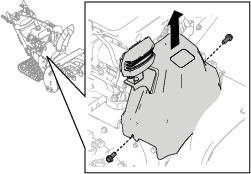

Remove the 2 screws that are holding the belt cover in place (Figure 30).

-

Remove the belt cover (Figure 30).

-

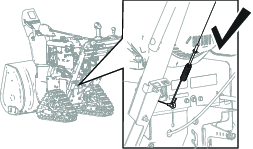

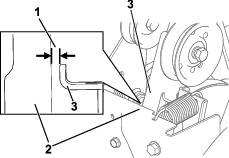

With the auger/impeller lever disengaged, ensure that the gap between the auger clutch arm and the frame of the machine is 1.5 mm (1/16 inch) as shown in Figure 31.

-

If the auger/impeller cable is not properly adjusted, do the following steps:

-

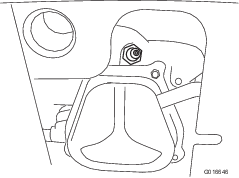

Loosen the jam nut (Figure 32).

-

Loosen or tighten the turnbuckle that adjusts the tension on the cable (Figure 32).

-

Adjust the turnbuckle until you obtain the proper gap.

-

Tighten the jam nut.

-

Insert the 2 screws that you previously removed on the belt cover.

-

If the auger/impeller cable is properly adjusted but a problem remains, contact an Authorized Service Dealer.

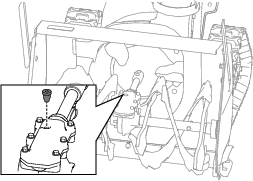

Checking the Auger-Gearbox-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Move the machine to a level surface.

-

Clean the area around the pipe plug and remove the pipe plug from the gearbox (Figure 33).

Note: If needed, use pliers to assist in removing the pipe plug.

-

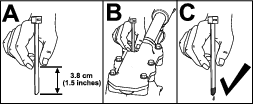

Check the oil level using a suitable measuring device, such as a clean cable tie. The oil should be approximately 3.8 cm (1.5 inches) below the filler opening (Figure 34).

-

If the oil level is low, add GL-5 or GL-6, SAE 85-95 EP gear oil lubricant to the gearbox, then check the oil level again.

Note: Do not use synthetic oil.

-

Install the pipe plug in the gearbox.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 50 hours |

|

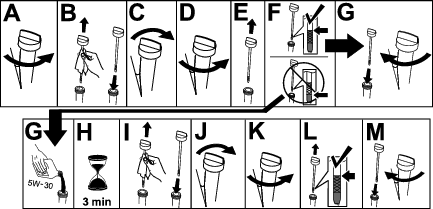

If possible, run the engine for a few minutes before changing the oil because warm oil flows better and carries more contaminants.

| Engine oil capacity | 0.95 L (32 fl oz)* |

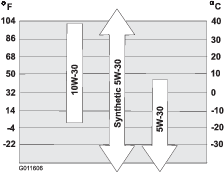

| Oil viscosity | Refer to Figure 36. |

| API service classification | SJ or higher |

*There is residual oil in the crankcase after you drain the oil. Do not pour the entire capacity of oil into the crankcase. Fill the crankcase with oil as directed in the following steps.

-

Move the machine to a level surface.

-

Clean the area around the oil-drain nut (Figure 35).

-

Slide an oil-drain pan under the drain extension and remove the oil-drain nut.

-

Drain the oil.

Note: Dispose of the used oil properly at a local recycling center.

-

Install the oil-drain nut and tighten it securely.

-

Clean around the oil fill/dipstick.

-

Unscrew the dipstick and remove it.

-

Carefully pour about 3/4 of the engine capacity of oil into the oil-fill tube.

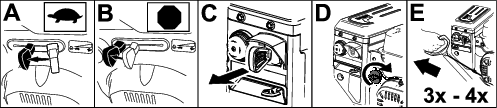

Use Figure 36 to select the best oil viscosity for the outdoor temperature range expected:

-

Wait 3 minutes for the oil to settle in the engine.

-

Wipe the dipstick clean with a clean cloth.

-

Insert the dipstick into the oil-fill tube and screw it in, then remove the dipstick.

-

Read the oil level on the dipstick.

-

If the oil level on the dipstick is too low, carefully pour a small amount of oil into the oil-fill tube, wait 3 minutes, and repeat steps 10 through 12 until the oil level on the dipstick is correct.

-

If the oil level on the dipstick is too high, drain the excess oil until the oil level on the dipstick is correct.

Important: If the oil level in the engine is too low or too high and you run the engine, you may damage the engine.

-

-

Install the dipstick into the oil-fill tube securely.

Replacing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Warning

Replacing the spark plug while the engine is hot can result in burns.

Wait until the engine is cool to replace the spark plug.

Use a Toro spark plug or equivalent (Champion® RN9YC or NGK BPR6ES).

-

Remove the boot (Figure 37).

-

Clean around the base of the spark plug.

-

Remove and discard the old spark plug.

Note: You will need a ratchet wrench extension to remove the spark plug.

-

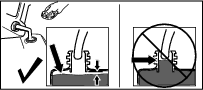

Set the gap between the electrodes on a new spark plug at 0.76 mm (0.030 inch) as shown in Figure 39.

-

Install the new spark plug, tighten it firmly, and attach the ignition wire to the spark plug.

Note: Ensure that the ignition wire snaps completely into place on the spark plug.

Replacing the Drive Belts

If the auger/impeller drive belt or the traction-drive belt becomes worn, oil-soaked, or otherwise damaged, have an Authorized Service Dealer replace the belt.

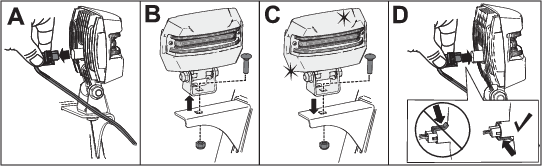

Replacing the Headlight

Replace the headlight assembly (Toro part number 138-0670) when needed.

-

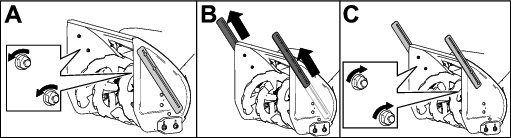

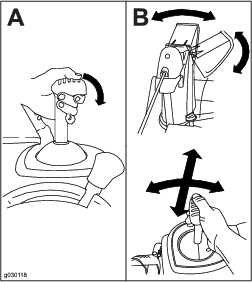

Remove the headlight wire from the back of the headlight (A of Figure 40).

-

Remove the bolt and nut holding the headlight assembly onto the headlight bracket and then remove the old headlight assembly (B of Figure 40).

-

Secure the new headlight assembly onto the headlight bracket with the previously removed nut and bolt (C of Figure 40).

-

Insert the headlight wire straight into the back of the headlight until it is securely in place (D of Figure 40).