|

60-XXX-66

|

There is a PMU precharge failure.

|

Restart the machine; if issues persist, contact an Authorized Service Dealer.

|

|

60-XXX-69

|

There is a PMU failure.

|

Restart the machine; if issues persist, contact an Authorized Service Dealer.

|

|

60-XXX-71

|

Battery 1 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-72

|

Battery 2 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-73

|

Battery 3 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-74

|

Battery 4 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-75

|

Battery 5 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-76

|

Battery 6 has indicated a relay failure.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-77

|

There is a positive metal-oxide-semiconductor (MOS) failure in the PMU.

|

Contact an Authorized Service Dealer.

|

|

60-XXX-79

|

A motor braking component is too hot

|

-

Shut off the machine and allow it to cool before starting it again.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-80

|

Battery 1 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-81

|

Battery 2 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-82

|

Battery 3 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-83

|

Battery 4 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-84

|

Battery 5 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-85

|

Battery 6 is too hot.

|

-

Shut off the machine, remove the battery, and wait for the battery to cool.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-86

|

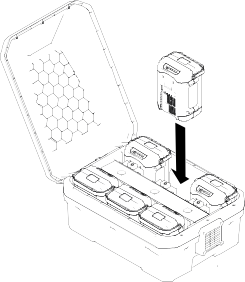

There is a failure with battery 1 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-87

|

There is a failure with battery 2 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-88

|

There is a failure with battery 3 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-89

|

There is a failure with battery 4 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-90

|

There is a failure with battery 5 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-91

|

There is a failure with battery 6 or the battery-charge level is too low.

|

-

Ensure that the battery is installed properly.

-

Remove and charge the battery. Install the battery.

-

If issues persist, replace the battery or contact an Authorized Service Dealer.

|

|

60-XXX-92

|

There is a PMU failure.

|

Ensure that the battery is fully seated in the slot; if issues persist, contact an Authorized Service Dealer.

|

|

60-XXX-93

|

There is a PMU failure.

|

Ensure that the battery is fully seated in the slot; if issues persist, contact an Authorized Service Dealer.

|

|

60-XXX-94

|

The PMU system is too hot.

|

-

Shut off the machine and allow it to cool before starting it again.

-

Operate the machine in the appropriate temperature range.

|

|

60-XXX-95

|

The PMU communication timed out.

|

Ensure that the battery is fully seated in the slot; if issues persist, contact an Authorized Service Dealer.

|