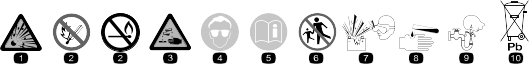

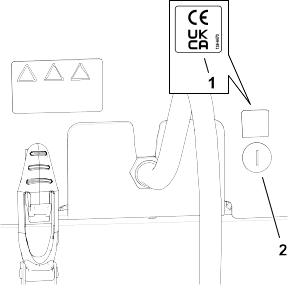

Disclaimers and Regulatory Information

This product complies with

all relevant European directives; for details, please see the separate

product specific Declaration of Conformity (DOC)

sheet.

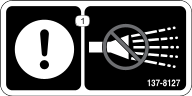

It is a violation of California

Public Resource Code Section 4442 or 4443 to use or operate the engine

on any forest-covered, brush-covered, or grass-covered

land unless the engine is equipped with a spark arrester, as defined

in Section 4442, maintained in effective working

order, or the engine is constructed, equipped, and maintained for

the prevention of fire.

The enclosed engine owner's manual

is supplied for information regarding the US Environmental Protection

Agency (EPA) and the California Emission Control

Regulation of emission systems, maintenance, and warranty. Replacements

may be ordered through the engine manufacturer.

|

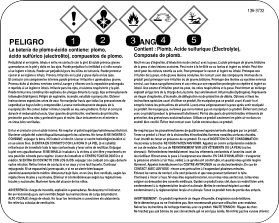

| CALIFORNIA |

| Proposition 65 |

| Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. |

| Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. |

| Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. |

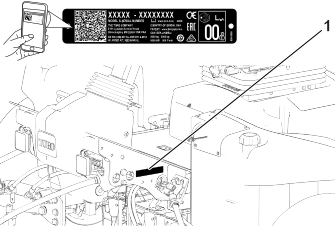

Electromagnetic Compatibility Certification

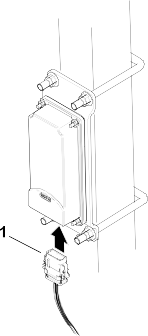

If this machine is equipped with

a telematics device, refer to your authorized Toro distributor for

instructions to activate the device.

| Domestic: This device complies with FCC

Rules Part 15. Operation is subject to the following two conditions:

(1) This device may not cause

harmful interference and (2) this device must accept any interference

that may be received, including interference that

may cause undesirable operation. |

| FCC ID: APV-3640LB IC: 5843C-3640LB |

| This equipment has been tested

and found to comply within the limits for a Class B digital device,

pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation.

This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instructions,

may cause harmful interference to radio communications. However, there

is no guarantee that interference will

not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception,

which can be determined by

turning the equipment off and on, the user is encouraged to try to

connect the interference by

one or more of the following measures:

|

| Argentina

|

New Zealand |

|

|

| Australia

|

South Korea |

|

|

| Morocco

|

| AGREE PAR L’ANRT MAROC

Numéro

d’agrément: MR00004789ANRT20024 Date d’agrément: 11/4/2024 |

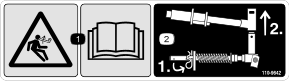

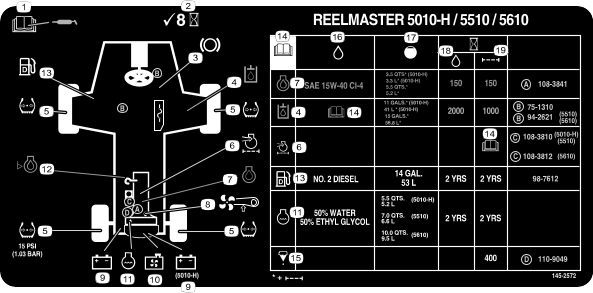

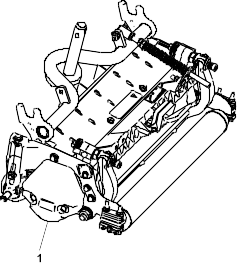

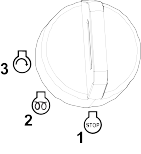

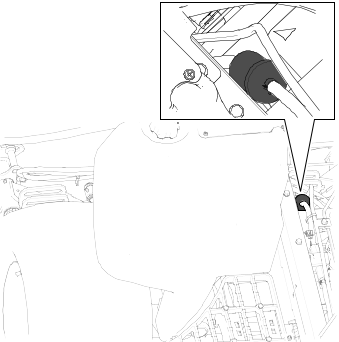

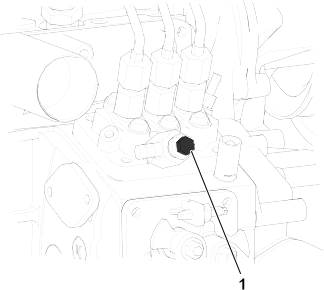

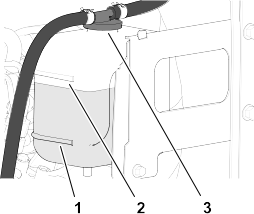

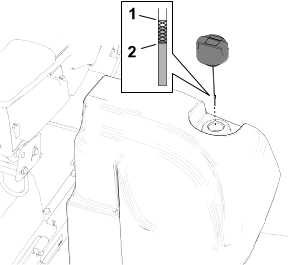

Fuel