| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

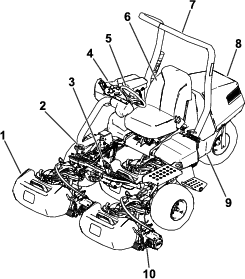

Introduction

This machine is a ride-on, reel-blade greens mower intended to be used by professional, hired operators in commercial applications. It is primarily designed for cutting grass on well-maintained turf. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for more information, including safety tips, training materials, accessory information, help finding a dealer, or to register your product.

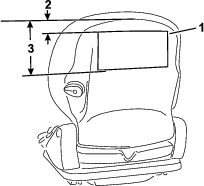

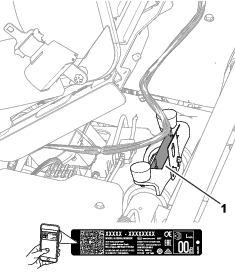

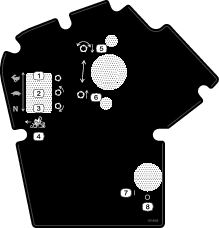

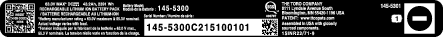

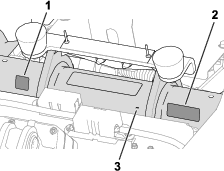

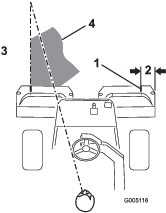

Whenever you need service, genuine Toro parts, or additional information, contact an authorized Toro distributor and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

If this machine is equipped with a telematics device, refer to your authorized Toro distributor for instructions to activate the device.

|

Electromagnetic Compatibility Certification |

|

Domestic: This device complies with FCC Rules Part 15. Operation is subject to the following two conditions: (1) This device may not cause harmful interference and (2) this device must accept any interference that may be received, including interference that may cause undesirable operation. |

|

FCC ID: APV-3640LB IC: 5843C-3640LB |

|

This equipment has been tested and found to comply within the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to connect the interference by one or more of the following measures:

|

|

Argentina |

|

|

Australia |

|

|

Morocco |

|

|---|---|

|

AGREE PAR L’ANRT MAROC |

|

|

Numéro d’agrément: |

MR00004789ANRT20024 |

|

Date d’agrément: |

11/4/2024 |

|

New Zealand |

|

|

|

South Korea |

|

Warning

CALIFORNIA

Proposition 65 Warning

The power cord on this product contains lead, a chemical known to the State of California to cause birth defects or other reproductive harm. Wash hands after handling.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

General Machine Safety Warnings

WARNING—Read all safety warnings, instructions, illustrations

and specifications provided with this machine.

WARNING—Read all safety warnings, instructions, illustrations

and specifications provided with this machine.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

The term “machine” in all of the warnings listed below refers to your mains-operated (corded) machine or battery-operated (cordless) machine.

-

Work area safety

-

Keep work area clean and well lit.Cluttered or dark areas invite accidents.

-

Do not operate the machine in explosive atmospheres, such as in the presence of flammable liquids, gasses, or dust.The machine creates sparks, which may ignite the dust or fumes.

-

Keep children and bystanders away while operating the machine.Distractions can cause you to lose control.

-

-

Electrical safety

-

Machine plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with an earthed (grounded) machine.Unmodified plugs and matching outlets will reduce risk of electric shock.

-

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators.There is an increased risk of electric shock if your body is earthed or grounded.

-

Do not expose the machine to rain or wet conditions.Water entering a machine will increase the risk of electric shock.

-

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord away from heat, oil, sharp edges, or moving parts.Damaged or entangled cords increase the risk of electric shock.

-

When operating the machine outdoors, use an extension cord suitable for outdoor use.Use of a cord suitable for outdoor use reduces the risk of electric shock.

-

If operating the machine in a damp location is unavoidable, use a residual current device (RCD) protected supply.Use of an RCD reduces the risk of electric shock.

-

-

Personal safety

-

Stay alert, watch what you are doing, and use common sense when operating the machine. Do not use the machine while you are tired or under the influence of drugs, alcohol, or medication.A moment of inattention while operating the machine may result in serious personal injury.

-

Use personal protective equipment. Always wear eye protection.Protective equipment such as a dust mask, non-skid safety shoes, or hearing protection used for appropriate conditions will reduce personal injuries.

-

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack.Energising a machine that has the switch on invites accidents.

-

Remove any adjusting key or wrench before turning the machine on.A wrench or a key left attached to a rotating part of the machine may result in personal injury.

-

Do not overreach. Keep proper footing and balance at all times.This enables better control of the machine in unexpected situations.

-

Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts.Loose clothes, jewelry or long hair can be caught in moving parts.

-

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used.Use of dust collection can reduce dust-related hazards.

-

Do not let familiarity gained from frequent use of the machine allow you to become complacent and ignore machine safety principles.A careless action can cause severe injury within a fraction of a second.

-

-

Machine use and care

-

Do not force the machine. Use the correct machine for your application.The correct machine will do the job better and safer at the rate for which it was designed.

-

Do not use the machine if the switch does not turn it on and off.Any machine that cannot be controlled with the switch is dangerous and must be repaired.

-

Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the machine before making any adjustments, changing accessories, or storing the machine.Such preventive safety measures reduce the risk of starting the machine accidentally.

-

Store an idle machine out of the reach of children and do not allow persons unfamiliar with the machine or these instructions to operate the machine.A machine is dangerous in the hands of untrained users.

-

Maintain the machine and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the operation of the machine. If damaged, have the machine repaired before use.Many accidents are caused by a poorly maintained machine.

-

Keep cutting tools sharp and clean.Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

-

Use the machine, accessories, and tool bits etc., in accordance with these instructions, taking into account the working conditions and the work to be performed.Use of the machine for operations different from those intended could result in a hazardous situation.

-

Keep handles and grasping surfaces dry, clean and free from oil and grease.Slippery handles and grasping surfaces do not allow for safe handling and control of the machine in unexpected situations.

-

-

Battery machine use and care

-

Recharge only with the charger specified by a manufacturer.A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

-

Use the machine only with specifically designated batteries.Use of any other batteries may create a risk of injury and fire.

-

When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another.Shorting the battery terminals together may cause burns or a fire.

-

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.Liquid ejected from the battery may cause irritation or burns.

-

Do not use a battery pack or machine that is damaged or modified.Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk or injury.

-

Do not expose a battery pack or machine to fire or excessive temperature.Exposure to fire temperature above 130°C may cause an explosion.

-

Follow all charging instructions and do not charge the battery pack or machine outside the temperature range specified in the instructions.Changing improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

-

-

Service

-

Have your machine serviced by a qualified repair person using only identical replacement parts.This will ensure that the safety of the machine is maintained.

-

Never service damaged battery packs.Service of battery packs should be performed only by the manufacturer or authorized service providers.

-

Lawn Mower Safety Warnings

-

Do not use the lawnmower in bad weather conditions, especially when there is a risk of lightning.This decreases the risk of being struck by lightning.

-

Thoroughly inspect the area for wildlife where the lawnmower is to be used.Wildlife may be injured by the lawnmower during operation.

-

Thoroughly inspect the area where the lawnmower is to be used and remove all stones, sticks, wires, bones, and other foreign objects.Thrown objects can cause personal injury.

-

Before using the lawnmower, always visually inspect to see that the blade and the blade assembly are not worn or damaged.Worn or damaged parts increase the risk of injury.

-

Keep guards in place. Guards must be in working order and be properly mounted.A guard that is loose, damaged, or is not functioning correctly may result in personal injury.

-

Keep all cooling air inlets clear of debris.Blocked air inlets and debris may result in overheating or risk of fire.

-

While operating the lawnmower, always wear non-slip and protective footwear. Do not operate the lawnmower when barefoot or wearing open sandals.This reduces the chance of injury to the feet from contact with the moving blade.

-

While operating the lawnmower, always wear long trousers.Exposed skin increases the likelihood of injury from thrown objects.

-

Do not operate the lawnmower on excessively steep slopes.This reduces the risk of loss of control, slipping and falling which may result in personal injury.

-

When working on slopes, always be sure of your footing, always work across the face of slopes, never up or down and exercise extreme caution when changing direction.This reduces the risk of loss of control, slipping and falling which may result in personal injury.

-

Use extreme caution when reversing or pulling the lawnmower towards you.Always be aware of your surroundings. Always be aware of your surroundings.

-

Do not touch blades and other hazardous moving parts while they are still in motion.This reduces the risk of injury from moving parts.

-

When clearing jammed material or cleaning the lawnmower, make sure all power switches are off and remove (or activate) the disabling device.Unexpected operation of the lawnmower may result in serious personal injury.

Save all warnings and instructions for future reference.

Additional Safety Messages

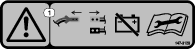

Safety-Alert Symbol

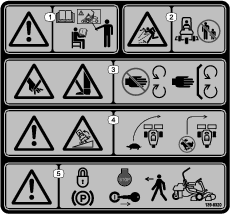

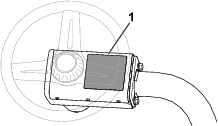

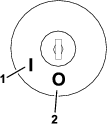

The safety-alert symbol (Figure 2) shown in this manual and on the machine identifies important safety messages that you must follow to prevent accidents.

The safety-alert symbol appears above information that alerts you to unsafe actions or situations and is followed by the word DANGER, WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This manual uses two other words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury or death.

-

Read and understand the contents of this Operator’s Manual before turning on the machine.

-

Allow only responsible and physically capable people to operate the machine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and functioning properly on the machine.

-

Keep bystanders and children out of the operating area.

-

Shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

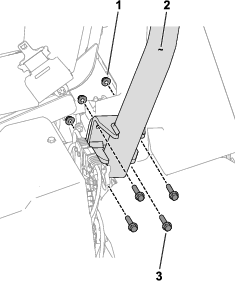

Installing the Roll Bar

Parts needed for this procedure:

| Roll bar assembly | 1 |

| Hex-head bolt (3/8 x 1-1/2 inch) | 8 |

| Nut (3/8 inch) | 8 |

-

Remove the top crate support from the crate.

-

Remove the roll bar from the crate.

-

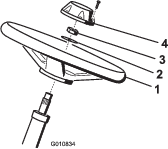

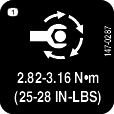

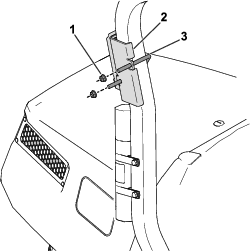

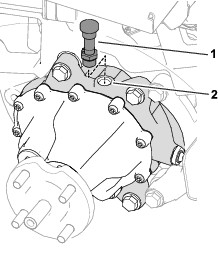

Use 8 hex-head bolts (3/8 x 1-1/2 inch) and 8 nuts (3/8 inch) to secure the roll bar to the roll-bar brackets on each side of the machine (Figure 3).

Note: Have an assistant help you to position and secure the roll bar to the machine.

-

Torque the fasteners to 51 to 65 N∙m (38 to 48 ft-lb).

Installing the Seat

Parts needed for this procedure:

| Seat Kit (order separately; contact your authorized Toro distributor) | 1 |

Acquire the Seat Kit (contact your authorized Toro distributor) and refer to the kit Installation Instructions to install the seat.

Installing the Service Decal

Installing the Steering Wheel

Parts needed for this procedure:

| Steering wheel | 1 |

| Cap | 1 |

| Washer | 1 |

| Locknut | 1 |

Installing the Grass-Basket Hooks

Parts needed for this procedure:

| Grass-basket hook | 6 |

| Flange bolts | 12 |

Use 12 flange bolts to install 6 grass-basket hooks onto the ends of the suspension-arm bars (Figure 7).

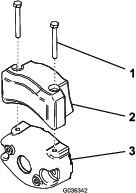

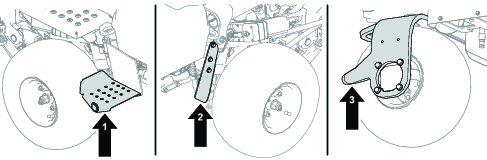

Installing the Cutting Units

Parts needed for this procedure:

| Cutting unit (order separately; contact your authorized Toro distributor) | 3 |

| Grass basket | 3 |

| Electric counterweight | 3 |

| Capscrew | 6 |

| O-ring | 3 |

-

Prepare the cutting units for installation; refer to your cutting unit Operator’s Manual.

-

Apply grease to the inside spline of the drive coupler.

-

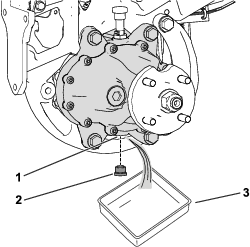

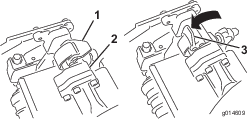

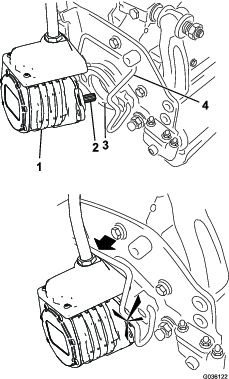

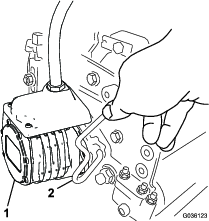

Install an O-ring to each reel motor as shown in Figure 8.

-

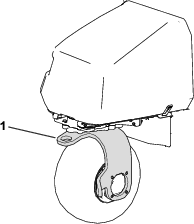

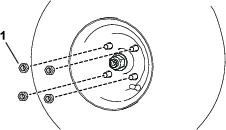

Secure the electrical counterweight to the existing counterweight with 2 capscrews as shown in Figure 9.

-

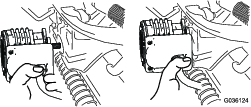

Install the cutting units; refer to Installing the Cutting Units.

-

Install each grass basket onto the grass-basket hooks.

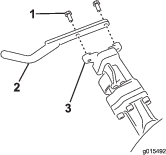

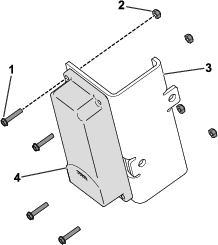

Installing the Telematics Device

Parts needed for this procedure:

| Telematics device | 1 |

| Device bracket | 1 |

| Telematics wire harness | 1 |

| Hex-head bolt (#10 x 1 inch) | 4 |

| Locknut (#10) | 4 |

| U-bolt | 1 |

| Flange nut (3/8 inch) | 2 |

-

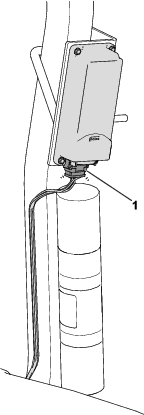

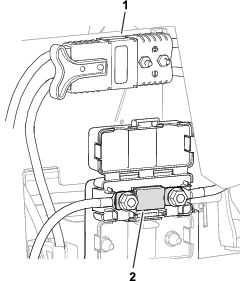

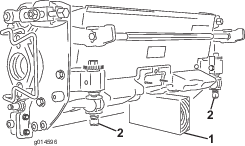

Use 4 hex-head bolts (#10 x 1 inch) and 4 locknuts (#10) to secure the telematics device to the device bracket (Figure 10).

-

Use a U-bolt and 2 flange nuts (3/8 inch) to secure the device bracket to the area above the manual tube on the roll bar (Figure 11).

-

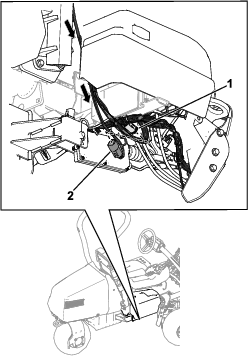

Install the connector labeled P02 on the telematics wire harness to the telematics device (Figure 12).

-

Route the wire harness down the roll bar and connect the wire-harness connector labeled P01 to the connector on the machine wire harness labeled P71 (Figure 13).

Connecting the Main-Power Connectors

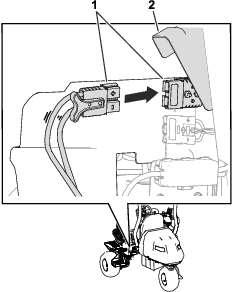

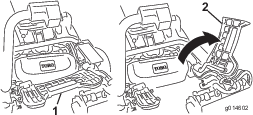

Raise the connector cover and plug in the main-power connectors located near the base of the roll bar on the left side of the machine (Figure 14).

Adjusting the Machine Settings

Use the InfoCenter to adjust the machine settings; refer to Using the InfoCenter to Adjust the Machine Settings.

Adding Rear Weight

Parts needed for this procedure:

| Rear Weight Kit (order separately; contact your authorized Toro distributor) | 1 |

This machine complies with applicable standards with the Rear Weight Kit installed. Refer to your authorized Toro distributor for the Rear Weight Kit.

If the machine comes with a 3-Wheel Drive kit, you do not need to install the Rear Weight Kit.

Installing the CE/UKCA Decals

Parts needed for this procedure:

| Production year decal | 1 |

| CE warning decal (Part Number 139-8321) | 1 |

| CE/UKCA decal (Part Number 138-9470) | 1 |

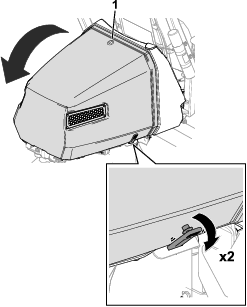

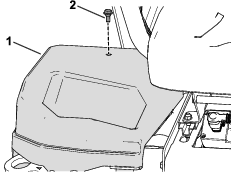

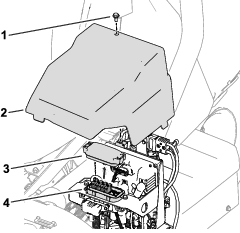

If you use this machine in a country that complies to CE/UKCA standards, install the following decals and hood latch:

-

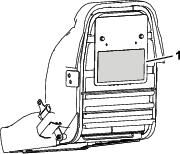

Production year decal and CE/UKCA decal: apply the decals on the frame tube below the seat and serial plate; refer to Figure 15.

-

CE warning decal: Apply the CE warning decal (Part Number 139-8321) over the existing warning decal (Part Number 139-8320) on the steering-wheel cover; refer to Figure 16.

Reducing the Tire Pressure

The tires are overinflated at the factory for shipping purposes. Reduce the pressure to the proper levels before turning on the machine; refer to Checking the Tire Pressure.

Mounting the Battery Charger on a Wall

You can mount the charger on a wall using the wall-mount key holes cut into the back of the unit. Use screws that have a 6 mm (1/4 inch) diameter shaft and a head diameter of 11 mm (0.45 inch).

Important: Survey your work area and determine a location that best meets the criteria for safe and effective operation of the charger.

Charging the Batteries

Charge the batteries; refer to Charging the Lithium-Ion Batteries.

Product Overview

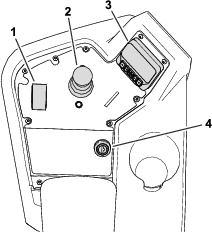

Key Switch

The key switch has 2 positions: ON and OFF (Figure 19).

Use the key switch to turn on or shut off the machine; refer to Turning On the Machine and Shutting Off the Machine.

Function-Control Switch

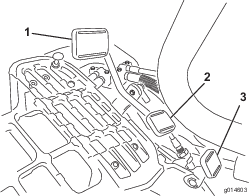

The function-control switch (Figure 18) provides 2 traction selections plus a NEUTRAL position.

-

NEUTRAL position—neutral and backlapping

-

MOW position—used for mowing operation

-

TRANSPORT position—used for transport operation

You can shift from MOW to TRANSPORT or TRANSPORT to MOW (not to NEUTRAL) while the machine is in motion; no damage will result

You can move the switch from TRANSPORT or MOW to NEUTRAL and the machine will come to a stop. If you try to switch from NEUTRAL to MOW or TRANSPORT while the pedal is not in the NEUTRAL position, an advisory occurs.

Lift/Lower Joystick

The lift/lower joystick (Figure 18) raises or lowers the cutting units. The joystick can engage or disengage the cutting-unit reels, depending on the function-control-switch position:

-

Function-control switch in the NEUTRAL position: The cutting units will raise or lower as long as you move the joystick forward or backward, but the reels will not engage unless the machine is in Backlap Mode.

-

Function-control switch in the MOW position: Move the joystick forward during your cutting operation to lower the cutting units and start the reels. Pull back on the joystick to stop the reels and raise the cutting units.

To stop the reels without raising the cutting units, pull back on the joystick momentarily and release it. Moving the joystick forward again will start the reels or pulling back again will lift the cutting units. You must engage this feature in the InfoCenter; refer to Adjusting the Tap-Off Delay.

-

Function-control switch in the TRANSPORT position: The cutting units can be raised, but the reels will not engage. An advisory appears in the InfoCenter if you attempt to lower the cutting units.

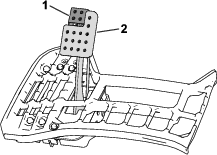

Traction Pedal

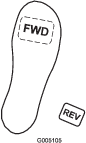

The traction pedal (Figure 20) has 3 functions: to make the machine move forward, to move it backward, and to stop the machine. Press the top of the pedal to move forward; press the bottom to move backward or to assist in stopping when moving forward.

To stop the machine, allow the pedal to move to the NEUTRAL position. Do not rest the heel of your foot on the traction pedal in the REVERSE position while the machine is moving forward (Figure 21).

You can configure the maximum ground speed as follows:

-

3.2 to 8 km/h (3 to 5 mph) forward mowing speed

-

8 to 16 km/h (5 to 10 mph) transport speed

-

3.2 to 4.8 km/h (2 to 3 mph) reverse speed

Steering-Arm-Locking Pedal

Press the pedal (Figure 20) and raise or lower the steering arm for operator comfort, then, release the pedal to lock the arm in place.

Brake Pedal

Press the brake pedal (Figure 22) to stop the machine.

Parking Brake

Use the parking brake (Figure 22) to prevent the machine from moving. To engage the parking brake, push down on the brake pedal and press the top forward to latch. To release the parking brake, press the brake pedal until the parking-brake latch retracts.

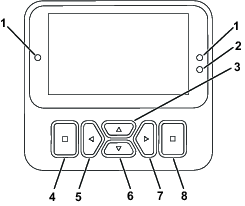

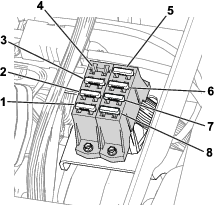

InfoCenter

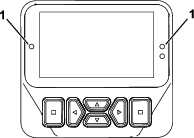

Using the InfoCenter Display

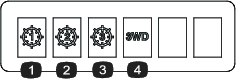

The InfoCenter display (Figure 23) shows information about your machine, such as the operating status, various diagnostics, and other information about the machine.

Note: The purpose of each button may change depending on what is required at the time. Each button is labeled with an icon displaying its current function.

Use the navigational buttons to navigate between several screens and menu items:

-

Splash screen: shows current machine information for a few seconds after you move the key to the ON position.

-

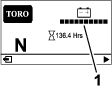

Main information screen (Figure 24): shows current machine information while the key is in the ON position.

-

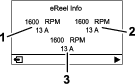

eReel motor screen (Figure 25): shows the speed and current of each cutting-unit motor.

-

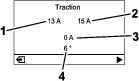

Traction motor screen (Figure 26): shows the current steering angle and the amperage allotted to each traction motor.

-

Main menu: refer to Understanding the InfoCenter Menu Items.

| Hour meter |

| Function-control switch is in the NEUTRAL position. |

| Function-control switch is in the TRANSPORT position. |

| Function-control switch is in the MOW position. |

| The operator must sit in the seat. |

| The parking brake is engaged. |

| The electric parking brake is engaged. |

| The PTO is on. |

| The PTO is disengaged. |

| Battery |

| Indicates when the cutting units are being raised. |

| Indicates when the cutting units are being lowered. |

| Active |

| Inactive |

| Previous |

| Next |

| Increase |

| Decrease |

| Previous screen |

| Next screen |

| Increase value |

| Decrease value |

| Menu |

| Scroll up/down |

| Scroll left/right |

Understanding the InfoCenter Menu Items

To access the main menu, press the back/exit button while at any of the information screens.

Refer to the following tables for a description of the options available from the menus:

| Menu Item | Description |

| FAULTS | The FAULTS menu contains a list of the recent machine faults. Refer to the Service Manual or your authorized Toro distributor for more information on the FAULTS menu. |

| SERVICE | The SERVICE menu contains information on the machine such as hours of use, counts, and calibration. You can also enable the cutting-unit backlap procedure. Refer to the Service table. |

| DIAGNOSTICS | The DIAGNOSTICS menu lists various states and data that the machine currently has. You can use this information to troubleshoot certain issues, as it quickly tells you which machine controls are on/off and lists control levels (e.g., sensor values). |

| SETTINGS | The SETTINGS menu allows you to modify settings for the InfoCenter display. Refer to the Settings table. |

| MACHINE SETTINGS | The MACHINE SETTINGS menu allows you to adjust machine settings, such as reel speed, maximum mowing speed, and maximum transport speed. Refer to the Machine Settings table. |

| ABOUT | The ABOUT menu lists the model number, serial number, and software version of your machine. Refer to the About table. |

| Menu Item | Description |

| HOURS | Lists the total number of hours that the key, engine, reels, and backlap have been on, as well as the next service due. |

| COUNTS | Lists the number of starts, mows, tap-offs, backlaps, and number of times that the engine was cranked longer than 30 seconds. |

| BACKLAP | Engages/disengages the cutting-unit backlap procedure (when you engage this procedure, you can disengage the mode with this setting or by moving the key to the OFF position). |

CALIBRATION  | Allows you to calibrate the steering system, traction system, and lift actuators. Refer to the Service Manual for more information on calibration. |

| Menu Item | Description |

| ENTER PIN | Allows a person (superintendent/mechanic) authorized by your company with the PIN code to access protected menus. |

| BACKLIGHT | Controls the brightness of the LCD display. |

| LANGUAGE | Controls the language used on the InfoCenter. |

| FONT SIZE | Controls the size of the font on the InfoCenter. |

| UNITS | Controls the units used on the InfoCenter. The menu choices are English or metric. |

PROTECT SETTINGS  | Controls the protected menus. |

RESET DEFAULTS | Resets the InfoCenter to default settings. |

| Menu Item | Description |

TAPOFF TIME  | Controls the tap-off delay. |

REEL SPEED  | Controls the blade speed on the cutting units. |

LOWER SPEED | Sets the speed that the cutting units lower to the ground for mowing. |

BACKLAP SPEED  | Controls the backlap speed. |

CLIP CONTROL  | Turns the automatic clip-control feature on or off. |

BLADE COUNT  | Set the number of blades in each reel. This setting is only necessary if CLIP CONTROL is set to ON. |

HEIGHT OF CUT | Sets the desired height of cut. This setting is only necessary if CLIP CONTROL is set to ON. |

MAX MOW  | Sets the maximum machine speed while mowing. |

MAX TRANSPORT  | Sets the maximum machine speed while transporting. |

MAX REVERSE  | Sets the maximum machine speed while moving the machine in reverse. |

SLOW & TURN  | Enables or disables the slow in turn function. |

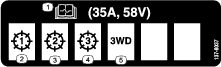

3WD KIT  | Enables or disables the 3-Wheel Drive Kit. |

BATT. RESERVE | Sets the distance that is needed to transport the machine back to the shop when the battery level becomes low. |

| Menu Item | Description |

| MODEL | Lists the model number of the machine. |

| SN | Lists the serial number of the machine. |

| S/W REV | Lists the software revision of the master controller. |

XDM-2700  | Lists the software revision of the InfoCenter. |

CUTTING UNIT 1 | Lists the software revision of the center cutting unit motor. |

CUTTING UNIT 2 | Lists the software revision of the front, left cutting unit motor. |

CUTTING UNIT 3 | List the software revision of the front, right cutting unit motor. |

PRECHARGE | Lists the serial number of the generator. |

LIFT LOWER 1 | Lists the software part number and the revision version for the precharge controller |

LIFT LOWER 2 | Lists the software part number and the revision version for the front left cutting unit. |

LIFT LOWER 3 | Lists the software part number and the revision version for the front right cutting unit. |

TRACTION1 | Lists the software part number and the revision version for the front right traction motor. |

TRACTION2 | Lists the software part number and the revision version for the front left traction motor. |

TRACTION3 | Lists the software part number and the revision version for the 3-Wheel Drive Kit (if equipped). |

STEERING | Lists the software part number and the revision version for the rear steering motor. |

BATTERY TB | Lists the software part number and the revision version for each of the batteries equipped on the machine. |

Note:  Protected

under Protected Menus—accessible only by entering PIN; refer

to Accessing Protected Menus.

Protected

under Protected Menus—accessible only by entering PIN; refer

to Accessing Protected Menus.

Accessing Protected Menus

Note: The factory default PIN code for you machine is either 0000 or 1234.If you changed the PIN code and forgot the code, contact your authorized Toro distributor for assistance.

-

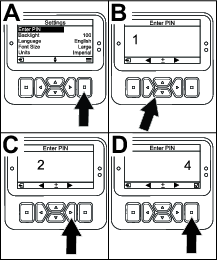

From the MAIN MENU, scroll down to the SETTINGS menu and press the select button (Figure 27).

-

In the SETTINGS menu, scroll to ENTER PIN and press the select button (Figure 28A).

-

To enter the PIN code, press the up/down navigation buttons until the correct first digit appears, then press the right navigation button to move on to the next digit (Figure 28B and Figure 28C). Repeat this step until the last digit is entered.

-

Press the select button (Figure 28D).

Note: If the display accepts the PIN code and the protected menu is unlocked,

displays in the upper right corner of the screen.

displays in the upper right corner of the screen. -

To lock the protected menu, rotate the key switch to the OFF position and then to the ON position.

Viewing and Changing the Protected Menu Settings

-

In SETTINGS, scroll down to PROTECT SETTINGS.

-

To view and change the settings without entering a PIN code, use the select button to change the PROTECT SETTINGS to

(Off).

(Off). -

To view and change the settings with a PIN code, use the select button to change the PROTECT SETTINGS to

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

Understanding the Diagnostic Light

-

Flashing red—active fault

-

Solid red—active advisory

-

Solid blue—calibration/dialog messages

-

Solid green—normal operation

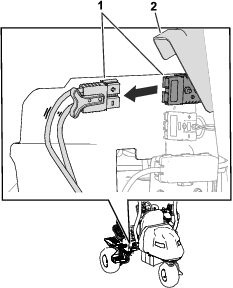

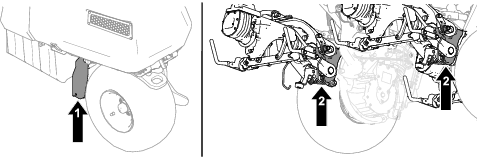

Main-Power Connectors

Before you charge the machine, work on the machine, or install, remove, or work on the cutting units, disconnect the machine from the power supply by raising the connector cover and separating the main-power connectors (Figure 30), located at the base of the roll bar on the left side of the traction unit. Plug the connectors together before operating the machine.

Caution

If you do not disconnect the power to the machine, someone could accidentally turn on the machine, causing serious bodily injury.

Always separate the connectors before working on the machine.

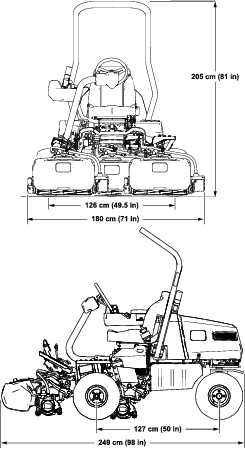

Refer to Figure 31 and the Traction-Unit Specifications Table for traction-unit dimensions and weight.

Note: Specifications and design are subject to change without notice.

| Width of cut | 151 cm (59.5 inches) |

| Wheel track | 126 cm (49.5 inches) |

| Wheel base | 127 cm (50 inches) |

| Overall length (w/baskets) | 249 cm (98 inches) |

| Overall width | 180 cm (71 inches) |

| Overall height | 205 cm (81 inches) |

| Weight* | 705 kg (1,554 lb) |

| *Traction unit equipped with 11-blade cutting units, narrow wiehle rollers, no operator, and the standard seat. | |

| Battery Quantity | 5 |

| Rated Voltage | 60 VDC maximum and 55.2 VDC nominal usage |

| Amp Hours | 199.85 |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com or a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Before Operation

Before Operation Safety

General Safety

-

Never allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Engage the parking brake, shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Know how to stop the machine and shut off the machine quickly.

-

Check that operator-presence controls, safety switches, and safety protective devices are attached and functioning properly. Do not operate the machine unless they are functioning properly.

-

Before mowing, always inspect the machine to ensure that the cutting units are in good working condition.

-

Inspect the area where you will use the machine and remove all objects that the machine could throw.

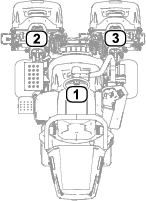

Identifying the Cutting Units

Using the InfoCenter to Adjust the Machine Settings

You can use the InfoCenter to adjust the following machine settings:

-

Tap-off delay; refer to Adjusting the Tap-Off Delay.

-

Reel speed while mowing; refer to Adjusting the Mowing Reel Speed.

-

Cutting-unit lower speed; refer to Setting the Cutting-Unit Lower Speed.

-

Reel speed while backlapping the cutting units; refer to Adjusting the Backlap Reel Speed.

-

Clip control; refer to Setting the Clip-Control Feature.

-

Height of cut (HOC); refer to Adjusting the Height of Cut (HOC).

-

Number of cutting-unit blades; refer to Adjusting the Number of Cutting-Unit Blades.

-

Maximum mowing speed; refer to Adjusting the Maximum Mowing Speed.

-

Maximum transport speed; refer to Adjusting the Maximum Transport Speed.

-

Maximum reverse speed; refer to Adjusting the Maximum Reverse Speed.

-

Slow and turn; refer to Setting the Slow and Turn Function.

-

Disabling an equipped 3-Wheel-Drive Kit; refer to Disabling an Equipped 3-Wheel-Drive Kit.

-

Battery-reserve capacity; refer to Setting the Battery-Reserve Capacity.

Note: Each setting is passcode-protected. You may need to enter a passcode to edit the settings.

Adjusting the Tap-Off Delay

Navigate to the TAPOFF TIME option to adjust the tap-off delay. The tap-off delay feature allows the cutting units to turn off without raising. The delay setting represents the maximum time for the lift/lower joystick to remain in the rearward position to activate this feature.

Refer to the following table for the delay time options and their corresponding increment numbers:

| Increment Number | Delay Time (Seconds) |

| 1 | Off |

| 2 | 0.050 |

| 3 | 0.100 |

| 4 | 0.150 |

| 5 | 0.200 |

| 6 | 0.250 |

| 7 | 0.300 |

| 8 | 0.350 |

| 9 | 0.400 |

| 10 | 0.450 |

Note: The factory default setting is 1, which disables this feature.

Adjusting the Mowing Reel Speed

Navigate to the REEL SPEED option to adjust the reel speed while mowing. This setting can be adjusted when the clip control setting is OFF; refer to Setting the Clip-Control Feature.

Refer to the following table for the reel speed options and their corresponding increment numbers:

| Increment Number | Reel Speed (RPM) |

| 1 | 800 |

| 2 | 950 |

| 3 | 1100 |

| 4 | 1250 |

| 5 | 1400 |

| 6 | 1550 |

| 7 | 1700 |

| 8 | 1850 |

| 9 | 2000 |

Note: The factory default setting is 2000 rpm (increment number 9).

Setting the Cutting-Unit Lower Speed

Navigate to the LOWER SPEED option to set the speed that the cutting units lower to the ground for mowing. You can toggle between 1 (slowest speed) and 9 (quickest speed).

Test the lower speed before you mow. Adjust the speed as desired.

Note: The factory default setting is 5.

Adjusting the Backlap Reel Speed

Navigate to the BACKLAP RPM option to adjust the reel speed while performing a backlap operation.

Refer to the following table for the reel speed options and their corresponding increment numbers:

| Increment Number | Reel Speed (RPM) |

| 1 | 200 |

| 2 | 240 |

| 3 | 280 |

| 4 | 320 |

| 5 | 360 |

| 6 | 400 |

| 7 | 440 |

| 8 | 480 |

| 9 | 520 |

Note: The factory default setting is 200 rpm (increment number 1).

Adjusting the Clip-Control Feature

Understanding the Radius-Dependent-Speed (RDS) System

To achieve a consistent, high quality-of-cut and a uniform after cut appearance, the machine is equipped with the patent-pending Radius Dependent Speed™ (RDS) system. The RDS system is a clip-control and independent wheel-speed feature that varies the speeds of each reel motor and each traction motor to maintain a constant clip and reduce turf scrubbing in turns while cutting.

When the machine is turning while cutting (e.g., during the clean-up pass), the reel on the inside of the turn will rotate at a slower rpm than the reel on the outside of the turn. The center reel splits the difference of the inside and outside reel speeds so that all three cutting units have the same clip. The sharper the turn, the greater the difference in reel speeds. Additionally, if the machine speed changes while you are cutting, the RDS system adjusts the reel speed to maintain a constant clip. This feature reduces turf thinning on the inside reel (in comparison to other riding greens mowers), which can reduce triplex ring.

The RDS system also adjusts each wheel-motor speed during a turn, similar to the reel-motor speeds changing in a turn. The inside wheel motor will turn at a slower rpm than the outside wheel motor. This minimizes wheel scrubbing in the turn and can reduce triplex ring.

Setting the Clip-Control Feature

Navigate to the CLIP CONTROL option to set the RDS system feature.

-

Clip control set to ON: The machine uses your settings from the HEIGHT OF CUT (HOC) and BLADE COUNT options and the left and right wheel speeds to determine the speed of each reel.

-

Clip control set to OFF: The machine uses your setting from the REEL SPEED option. The reels rotate at a constant rate.

Note: The factory default setting is ON.

Adjusting the Height of Cut (HOC)

Navigate to the HEIGHT OF CUT (HOC) option to adjust the height of cut. The clip control feature must be set to ON to use this feature; refer to Setting the Clip-Control Feature.

Note: The factory default setting is 3.2 mm (0.125 inch).

Adjusting the Number of Cutting-Unit Blades

Navigate to the BLADE COUNT option to adjust the number of cutting-unit blades. Determine the number of blades in your equipped cutting units, and select the appropriate value (5, 8, 11, or 14).

Note: The factory default setting is 11.

Adjusting the Maximum Mowing Speed

Navigate to the MAX MOW option to adjust the maximum mowing speed. You can adjust the speed from 4.8 km/h (3.0 mph) to 8.0 km/h (5.0 mph) in increments of 0.3 km/h (0.2 mph).

Note: The factory default setting is 6.1 km/h (3.8 mph).

Adjusting the Maximum Transport Speed

Navigate to the MAX TRANSPORT option to adjust the maximum transport speed. You can adjust the speed from 8.0 km/h (5.0 mph) to 16.0 km/h (10.0 mph) in increments of 0.8 km/h (0.5 mph).

Note: The factory default setting is 16.0 km/h (10.0 mph).

Adjusting the Maximum Reverse Speed

Navigate to the MAX REVERSE option to adjust the maximum reverse speed. You can adjust the speed from 3.2 km/h (2.0 mph) to 8.0 km/h (5.0 mph) in increments of 0.8 km/h (0.5 mph).

Note: The factory default setting is 4.0 km/h (2.5 mph).

Note: For machine-software versions A through D, the maximum speed is 4.8 km/h (3.0 mph). Update the machine software for the capability to set the maximum speed to 8.0 km/h (5.0 mph).

Setting the Slow and Turn Function

Navigate to the SLOW & TURN option to set the slow and turn function. The slow and turn function slows the machine speed while you turn the machine for another cutting pass on a green.

Note: The factory default setting is OFF.

Disabling an Equipped 3-Wheel-Drive Kit

Navigate to the 3WD KIT option to disable an equipped 3-Wheel-Drive Kit.

If you choose to disable this option, the kit will be enabled again if you cycle the key switch (i.e., turn off, then turn on the machine) with an equipped 3-Wheel-Drive Kit.

Note: When you install the 3-Wheel-Drive Kit, the kit is automatically enabled.

Setting the Battery-Reserve Capacity

Navigate to the BATT. RESERVE option to set the amount of distance needed to transport the machine to the shop. This allows you to have enough battery power (when the battery level becomes too low) to transport the machine to the shop for recharging; refer to Monitoring the Battery-System Charge Level.

Note: You can adjust the distance from 0.8 km (0.5 mi) to 8 km (5 mi) in 0.8 km (0.5 mi) increments.

Understanding the InfoCenter Dialog Messages

When the machine is being calibrated, dialog messages appear in the InfoCenter. These messages are intended to instruct you through the calibration process.

Refer to the following table for a list of each dialog message:

| Message Number | InfoCenter Message Text |

| 1 | Return pedal to neutral |

| 4 | Move pedal to max forward and hold |

| 5 | Max forward calibration passed |

| 9 | Max forward calibration failed. Voltage out of spec |

| 13 | Move pedal to max reverse and hold |

| 14 | Max reverse calibration passed |

| 16 | Max reverse calibration failed. Voltage out of spec |

| 17 | Calibration failed. Pedal position unknown |

| 18 | Return pedal to neutral. Continue? |

| 100 | Calibration is engaged |

| 101 | Calibration is complete |

| 102 | Cycle the key switch |

| 110 | Inhibit calibration. Component not responding |

| 111 | Inhibit calibration. Component not ready |

| 112 | Inhibit calibration. Fault active |

| 113 | Inhibit calibration. Not in seat |

| 114 | Inhibit calibration. Not in neutral |

| 115 | Inhibit calibration. In neutral |

| 116 | Inhibit calibration. Parking brake is engaged |

| 300 | Return pedal to neutral |

| 301 | Center steering wheel. Continue? |

| 302 | Manually center rear wheel. Continue? |

| 303 | Steer rear wheel max left. Continue? |

| 304 | Steer rear wheel max right. Continue? |

| 305 | Rear wheel center out of range |

| 306 | Rear wheel angle out of range |

| 400 | Caution: Machine must be on jack stands. Continue? |

| 401 | Inhibit calibration. Contactor open |

| 402 | Inhibit calibration. Pedal in Neutral |

| 403 | Return pedal to neutral |

| 404 | Wait for wheels to stop |

| 405 | Move pedal to max forward and hold |

| 406 | Calibration active. Hold pedal |

| 500 | Lift/Lower extend active |

| 501 | Lift/Lower retract active |

| 502 | Move joystick to lower position |

| 503 | Move joystick to raise position |

| 504 | Is the cutting unit installed? Continue? |

| 1100 | Traction diagnostic messages enabled |

| 1101 | Steering diagnostic messages enabled |

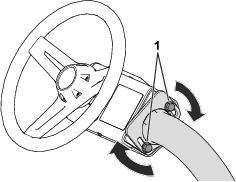

Tilting the Steering Wheel

You can tilt the steering wheel to a comfortable operating position.

Performing Daily Maintenance

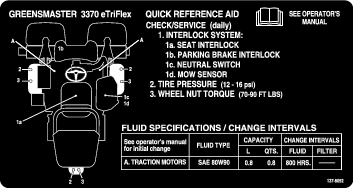

Before turning on the machine each day, perform the following procedures:

-

Check the reel-to-bedknife contact; refer to Checking the Reel-to-Bedknife Contact.

-

Check the tire pressure; refer to Checking the Tire Pressure.

-

Check the safety-interlock system; refer to Checking the Safety-Interlock System.

-

Check the parking brake function by actuating the parking brake and ensuring that it engages; refer to Parking Brake.

During Operation

During Operation Safety

General Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Before you turn on the machine, ensure that all drives are in neutral, the parking brake is engaged, and you are in the operating position.

-

Do not carry passengers on the machine.

-

Keep bystanders and children out of the operating area. If co-workers must be present, use caution and ensure that the grass baskets are installed on the machine.

-

Operate the machine only in good visibility to avoid holes or hidden hazards.

-

Avoid mowing on wet grass. Reduced traction could cause the machine to slide.

-

Keep your hands and feet away from the cutting units.

-

Look behind and down before backing up to be sure of a clear path.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision.

-

Stop the cutting units whenever you are not mowing.

-

Slow down and use caution when making turns and crossing roads and sidewalks with the machine. Always yield the right-of-way.

-

Do not leave an activated machine unattended.

-

Before you leave the operating position, do the following:

-

Park the machine on a level surface.

-

Lower the cutting units to the ground and ensure that they are disengaged.

-

Engage the parking brake.

-

Shut off the machine and remove the key.

-

Wait for all movement to stop.

-

-

Operate the machine only in good visibility and appropriate weather conditions. Do not operate the machine when there is the risk of lightning.

Rollover Protection System (ROPS) Safety

-

Do not remove any of the ROPS components from the machine.

-

Ensure that the seat belt is attached and that you can release it quickly in an emergency.

-

Always wear your seat belt.

-

Check carefully for overhead obstructions and do not contact them.

-

Keep the ROPS in safe operating condition by thoroughly inspecting it periodically for damage and keeping all the mounting fasteners tight.

-

Replace all damaged ROPS components. Do not repair or alter them.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution.

-

Evaluate the site conditions to determine if the slope is safe for machine operation, including surveying the site. Always use common sense and good judgment when performing this survey.

-

Review the slope instructions, listed below, for operating the machine on slopes. Before you operate the machine, review the site conditions to determine whether you can operate the machine in the conditions on that day and at that site. Changes in the terrain can result in a change in slope operation for the machine.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction. Make turns slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question.

-

Remove or mark obstructions such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstructions. Uneven terrain could overturn the machine.

-

Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

-

Use extreme caution when operating the machine near drop-offs, ditches, embankments, water hazards, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in. Establish a safety area between the machine and any hazard.

-

Identify hazards at the base of the slope. If there are hazards, mow the slope with a pedestrian-controlled machine.

-

If possible, keep the cutting units lowered to the ground while operating on slopes. Raising the cutting units while operating on slopes can cause the machine to become unstable.

-

Use extreme caution with grass-collection systems or other attachments. These can change the stability of the machine and cause a loss of control.

Breaking in the Machine

8 hours of operation is required for the break-in period.

Since the first hours of operation are critical to future dependability of the machine, monitor its functions and performance closely so that minor difficulties, which could lead to major problems, are noted and can be corrected. Inspect the machine frequently during break-in for signs of loose fasteners or any other malfunction.

Turning On the Machine

Note: Inspect the areas beneath the cutting units to ensure that they are clear of debris.

-

Sit in the operator’s seat and fasten the seatbelt.

-

Insert the key into the switch and move it to the ON position.

Checking the Machine after Turning On the Machine

-

Move the function-control switch to the MOW position.

-

Disengage the parking brake.

-

Move the lift/lower joystick forward momentarily.

The cutting units should lower and all the reels should rotate.

-

Move the lift/lower joystick rearward.

The cutting reels should stop rotating and the cutting units should raise to the full transport position.

Understanding the Safety-Interlock System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Danger

If safety-interlock switches are disconnected or damaged, the machine could operate unexpectedly, which will result in serious injury or death.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock switches daily, and replace any damaged switches before operating the machine.

The purpose of the safety-interlock system is to prevent operation of the machine where there is possible injury to you or damage to the machine.

The safety-interlock system prevents the machine from moving unless:

-

The parking brake is disengaged.

-

You are seated in the operator's seat.

-

The function-control switch is in the MOW position or the TRANSPORT position.

Additionally, the safety-interlock system prevents the reels from operating unless the function-control switch is in the MOW position (except when the machine is in Backlap Mode).

Checking the Safety-Interlock System

Perform the following steps to check the interlock system:

-

Rise from the seat, turn on the machine, disengage the parking brake, move the function-control switch to the MOW or TRANSPORT position, and engage the traction pedal.

The machine should not move, as you are not in the seat. This indicates that the interlock system is operating correctly. Correct the problem if it is not operating properly.

-

Sit in the seat, turn on the machine, engage the parking brake, move the function-control switch to the MOW or TRANSPORT position, and engage the traction pedal.

The machine should not move, as the parking brake is engaged. This indicates that the interlock system is operating correctly. Correct the problem if it is not operating properly.

-

Sit in the seat, turn on the machine, disengage the parking brake, move the function-control switch to the NEUTRAL position, and engage the traction pedal.

The machine should not move, as the function-control switch is in the NEUTRAL position. This indicates that the interlock system is operating correctly. Correct the problem if it is not operating properly.

-

Sit on the seat, move the traction pedal to the NEUTRAL position, move the function-control switch to the NEUTRAL position, engage the parking brake, turn on the machine, and move the lift/lower joystick forward to lower the cutting units.

The cutting units should lower but not start rotating. If they start rotating, the interlock system is not operating correctly; correct the problem before operating the machine.

Driving the Machine without Mowing

-

Ensure that the cutting units are fully raised.

-

Sit in the seat, fasten the seat belt, disengage the parking brake, and move the function-control switch to the TRANSPORT position to drive the machine without mowing.

-

Always approach irregular areas at a reduced speed and cross severe undulations carefully.

-

Familiarize yourself with the width of the machine. Do not attempt to pass between objects that are close together to prevent costly damage and downtime.

Mowing the Green

Before mowing greens, find a clear area and practice performing basic machine functions (e.g., turning on and stopping the machine, raising and lowering the cutting units, and turning).

Inspect the green for debris, remove anything that may damage the cutting units while mowing, remove the flag from the cup, and determine the best direction to mow. Base the direction to mow on the previous mowing direction. Always mow in an alternate pattern from the previous mowing so that the grass blades are less apt to lay down and will have a greater chance of being cut.

Cutting the Green

-

Start on 1 edge of the green so that you can use the ribbon procedure of cutting.

Note: This holds compaction to a minimum and leaves a neat, attractive pattern on the greens.

-

Move the function-control switch to the MOW position.

-

Push forward the lift/lower mow lever as the front edges of the grass baskets cross the outer edge of the green.

Note: This procedure drops the cutting units to the turf and starts the reels.

Important: The center cutting unit lifts or lowers slightly after the front cutting units do; therefore, you should practice gaining the required timing necessary to minimize the cleanup mowing operation and prevent scalping of the fringe.The center cutting unit lift and lower is based on ground speed. A slower ground speed increases the lift or lower delay; a faster speed decreases the lift or lower delay. The machine monitors the ground speed and updates this delay so that all three cutting units drop in a line.

-

Overlap a minimal amount with the previous cut on return passes.

Note: To assist in maintaining a straight line across the green and keeping the machine an equal distance from the edge of the previous cut, imagine a sight line approximately 1.8 to 3 m (6 to 10 ft) ahead of the machine to the edge of the uncut portion of the green (Figure 35). Include the outer edge of the steering wheel as part of the sight line; i.e., keep the steering wheel edge aligned with a point that is always kept the same distance away from the front of the machine.

-

As the front edges of the baskets cross the edge of the green, pull back the lift/lower joystick rearward and hold it until all the cutting units have risen. This stops the reels and lifts the cutting units.

Important: Time this step correctly so that you do not cut into the fringe area, yet cut as much of the green as possible to minimize the amount of grass left to mow around the outer periphery.

-

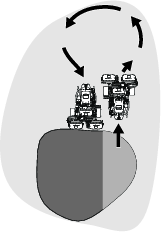

To cut down on operating time and to ease the lineup for the next pass, momentarily turn the machine in the opposite direction, then turn it in the direction of the uncut portion. This movement is a tear-shaped turn (Figure 34), which quickly lines the machine up for your next pass.

Note: If the Slow and Turn function is engaged, the machine slows down during the turn without requiring you to release pressure on the traction pedal.

Note: Try to make as short of a turn as possible, except during warmer weather—a wider arc minimizes the turf bruising.

Important: Never stop the machine on a green, especially while the cutting units are engaged; damage to the turf may result. Stopping the machine on a green may leave marks or indentations from the wheels.

Cutting the Periphery and Finishing the Job

-

Finish cutting the green by mowing the outer periphery. Change the direction of cutting from the previous mowing.

Refer to Understanding the Radius-Dependent-Speed (RDS) System to improve the after-cut appearance and reduce triplex ring.

Note: Always keep weather and turf conditions in mind and be sure to change the direction of mowing from the previous cutting.

-

When you finish mowing the outer periphery, tap the lift/lower joystick rearward to stop the reels (if the tap-off delay feature is engaged), then drive off the green. When all the cutting units are off the green, move the lift/lower joystick rearward to raise the cutting units.

Note: This step minimizes grass clumps left on the green.

-

Replace the flag.

-

Empty the grass baskets of all clippings before you transport the machine to the next green.

Note: Heavy wet clippings cause strain on the baskets, suspensions, and actuators. This adds unnecessary weight to the machine, which decreases energy efficiency.

Monitoring the Battery-System Charge Level

Refer to the main information screen in the InfoCenter to determine the battery-system charge level; refer to Using the InfoCenter Display.

Understanding the Low Battery-Level Advisories

-

When the battery level reaches a low percentage, an low-battery advisory appears on the InfoCenter. When you are operating at this battery percentage, finish cutting the current green, then transport the machine to a designated battery-charging area and charge the batteries; refer to Charging the Lithium-Ion Batteries.

-

If the battery level becomes too low (i.e., below 10%) while you are operating the machine, an advisory appears on the InfoCenter. While you are operating at this battery percentage, you can only transport the machine at a slower speed; the cutting units cannot be engaged. Transport your machine to a designated battery-charging area and charge the batteries; refer to Charging the Lithium-Ion Batteries.

Shutting Off the Machine

-

Transport the machine to a level surface.

-

Move the function-control switch to the NEUTRAL position.

-

Engage the parking brake.

-

Rotate the key to the OFF position to shut off the machine.

-

Remove the key.

After Operation

After Operation Safety

General Safety

-

Engage the parking brake, shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Clean grass and debris from the machine, especially the cutting units and drives, to help prevent fires.

-

Disconnect the main-power connectors while storing or hauling the machine.

-

Disengage the drive to the attachment whenever you are hauling or not using the machine.

-

Allow the machine to cool before storing the machine in any enclosure.

-

Maintain and clean the seat belt(s) as necessary.

-

Do not store the machine where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

Battery and Charger Safety

General

WARNING: Risk of fire and electric shock—The batteries have no user-serviceable parts.

-

Confirm the voltage that is available in your country before using the charger.

-

Do not charge the machine in a wet environment; keep it protected from rain and snow.

-

A risk of fire, electric shock, or injury may result from using an accessory not recommended or sold by Toro.

-

To reduce risk of a battery explosion, follow these instructions and the instructions for any equipment that you intend to use near the charger. To reduce risk of a battery explosion, follow these instructions and the instructions for any equipment that you intend to use near the charger.

-

Batteries could emit explosive gasses if they are significantly overcharged.

-

Refer to an authorized Toro distributor to service or replace a battery.

Training

-

Never allow children or untrained people to operate or service the charger. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Read, understand, and follow all instructions on the charger and in the manual before operating the charger. Be familiar with the proper use of the charger.

Preparation

-

Keep bystanders and children away while charging.

-

Shut off the machine and wait until the machine has completely powered down before charging. Failure to do this may cause arcing.

-

Ensure that the area is well ventilated while charging.

-

Use the charger only within the voltage range specified in this Operator's Manual, and use only a power cord approved by Toro.

-

Contact your authorized Toro distributor for the proper charger and power cord.

Operation

-

Do not charge a frozen battery.

-

Do not abuse the cord. Do not carry the charger by the cord or pull on the power supply cord to disconnect the charger from the receptacle. Store the cord away from heat, oil, and sharp edges.

-

Connect the charger directly to a grounding receptacle. Do not use the charger on an ungrounded outlet, even with a grounding adapter.

-

Do not alter the provided power cord or plug.

-

Remove metal items such as rings, bracelets, necklaces, and watches when working with a lithium-ion battery. A lithium-ion battery can produce enough current to cause a severe burn.

-

Use an extension cord that can handle the charging amperage specified in this Operator's Manual. If you are charging outdoors, use an extension cord rated for outdoor use.

-

If the power supply cord is damaged while it is plugged in, disconnect the cord from the wall receptacle and contact an authorized Toro distributor for a replacement.

-

Unplug the charger from the electrical outlet when not in use, before moving it to another location, or prior to servicing it.

Maintenance and Storage

-

Store the charger indoors in a dry, secure place that is out of the reach of unauthorized users.

-

Do not disassemble the charger.

-

Take the charger to an authorized Toro distributor when service or repair is required.

-

Unplug the power cord from the outlet before starting any maintenance or cleaning to reduce risk of electric shock.

-

Maintain or replace safety and instruction labels as needed.

-

Do not operate the charger with a damaged cord or plug. Contact an authorized Toro distributor to obtain a replacement cord.

-

If the charger is damaged, do not use it; take it to an authorized Toro distributor.

Towing Safety

-

Tow only with a machine that has a hitch designed for towing. Do not attach towed equipment except at the hitch point.

-

Follow the manufacturer’s recommendation for weight limits for towed equipment and towing on slopes. On slopes, the weight of the towed equipment may cause loss of traction and loss of control.

-

Never allow children or others in or on towed equipment.

-

Travel slowly and allow extra distance to stop when towing.

Inspecting and Cleaning after Mowing

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

After mowing, thoroughly wash the machine with a garden hose without a nozzle so that excessive water pressure does not contaminate and damage the seals, bearings, and electronics. Do not wash the electrical connections with water.

Important: Do not use brackish or reclaimed water to clean the machine.

Important: Do not use power-washing equipment to wash the machine. Power-washing equipment may damage the electrical system, loosen important decals, or wash away necessary grease at friction points. It may force water under seals, contaminating oil or grease contained housings. Avoid excessive use of water near the control panel and batteries.

Inspect the cutting units for sharpness after you clean the machine.

Hauling the Machine

-

Use care when loading or unloading the machine into a trailer or a truck.

-

Use a full-width ramp for loading the machine into a trailer or a truck.

-

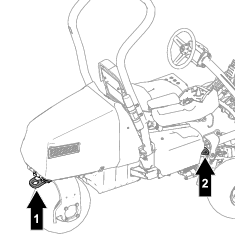

Tie the machine down securely using straps, chains, cable, or ropes. Both front and rear straps should be directed down and outward from the machine (Figure 36).

Towing the Machine

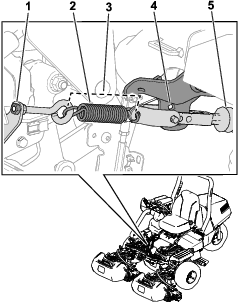

Note: Refer to Figure 37 for this procedure.

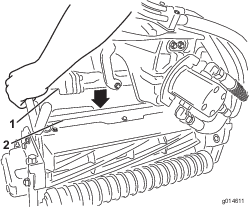

To tow the machine, you must perform the following procedure to release the brake actuator:

-

Engage the parking brake.

-

Remove the key and disconnect the main-power connectors.

Important: If the main-power connectors are connected while towing, electrical damage may result.

-

If the 3-Wheel Drive Kit is installed, disconnect the kit-wire-harness connectors from the main wire harness.

Important: If the kit and machine wire harnesses are connected while towing, electrical damage may result.

-

Chock both sides of the front tires.

-

Release tension on the spring by loosening the nut that secures the eyebolt to the spring bracket (Figure 37).

-

Remove the spring.

-

Insert a ratchet (3/8 inch) through the hole of the arm bracket and push in the actuator shaft.

Danger

When the actuator is released from the brake, the machine is able to free wheel. A free-wheeling machine can cause serious injury to bystanders.

If the machine is not being towed, engage the parking brake.

-

Have an assistant sit in the seat, fasten the seatbelt, and use the brake while you tow the machine.

Note: This ensures that the machine is under control when you tow the machine.

-

Remove the chocks from the tires.

-

When the machine is ready to be towed, disengage the parking brake.

-

Use the rear castor fork to tow the machine (Figure 38).

Important: Do not exceed 5 km/h (3 mph) while towing the machine. Damage to the electrical components may result.

After you have towed the machine to your intended destination, perform the following steps:

Maintaining the Lithium-Ion Batteries

Warning

The batteries contain high voltage, which could burn or shock you.

-

Do not attempt to open the batteries.

-

Use extreme care when handling a battery with a cracked case.

-

Use only the charger designed for the batteries.

The lithium-ion batteries hold a sufficient charge to perform intended work during its life span. During the first 4 years of operation, the total area that you can cut per a single full charge is 13,006 m2 (140,000 ft2). This performance is based on the following conditions:

-

Your reel blades and bedknives are sharp.

-

The bedknife and reel contact is adjusted per the Operator's Manual.

-

The groomer is set at half of the height of cut or higher.

-

The rear roller brushes are set to the lightest contact.

-

8 miles of transport distance is needed.

-

The golf course that you perform work on is lightly undulated.

As time goes by, the total amount of work that the batteries are able to complete on a single charge gradually diminishes.

Note: Your results may vary depending on the distance that you need to transport the machine, the undulations that you travel across, the contact setting and sharpness of the bedknife and reel, and other factors as discussed in this section.

To achieve maximum life and use from your batteries, follow these guidelines:

-

Do not open the battery.

-

Store/park the machine in a clean, dry garage or storage area, away from direct sunlight, heat sources, rain, and wet conditions. Refer to Battery Storage Requirements for temperature requirements.

-

If you are mowing in hot conditions or in sunlight, the battery may overheat. If this happens, a high-temperature alert will appear on the InfoCenter. In this condition, the cutting units are disengaged and the machine slows down.

Immediately drive the machine to a cool location out of the sun, turn off the machine, and allow the batteries to cool fully before resuming operation.

-

Adjust the reel-to-bedknife contact to be as light as possible. This reduces the power that is needed to run the cutting units, and increases the amount of work the machine performs on each charge. Refer to Checking the Reel-to-Bedknife Contact.

-

Ensure that the sharpness of the bedknives and reels are maintained. A dull blade increases power consumption and reduces the amount of work that the machine performs on each charge.

-

If you are using groomers, the groomer height should not exceed more than half of the height of cut. If the height of cut is over 1/2 inch, the groomer height should not exceed 1/4 inch.

-

Adjust the rear-roller-brush contact to be as light as possible. This reduces the power that is needed to run the cutting units, and increases the amount of work the machine performs on each charge.

-

Use lights (if your machine is equipped with the Light Kit) only when it is necessary.

Transporting the Lithium-Ion Batteries

The US Department of Transportation and international transportation authorities require that lithium-ion batteries be transported using special packaging and only be transported by carriers certified to haul them. In the US, you are allowed to transport a battery when it is installed on the machine as battery powered equipment, with some regulatory requirements. Contact the US Department of Transportation or the appropriate government body in your country for detailed regulations on transportation of your batteries or the machine with the batteries equipped.

For detailed information on shipping a battery, contact your authorized Toro distributor.

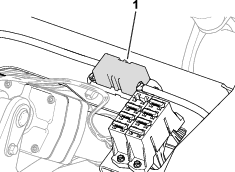

Understanding the Lithium-Ion Battery Charger

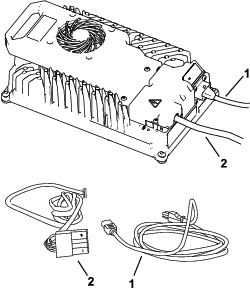

Refer to Figure 39 for an overview of the battery-charger displays and cords.

Connecting to a Power Source

To reduce the risk of electric shock, this charger has a 3-prong grounded plug (type B). If the plug does not fit into the wall receptacle, other grounded plug types are available; contact an authorized Toro distributor.

Do not change the charger or the power-supply-cord plug in any way.

Danger

Contact with water while charging the machine could cause electric shock, causing injury or death.

-

Do not handle the plug or the charger with wet hands or while standing in water.

-

Do not charge the batteries in the rain or in wet conditions.

Important: Check the power supply cord periodically for holes or cracks in the insulation. Do not use a damaged cord. Do not run the cord through standing water or wet grass.

-

Insert the charger plug on the power-supply cord into the matching input power socket on the charger.

Warning

A damaged charger cord can cause an electrical shock or a fire.

Thoroughly inspect the power supply cord before using the charger. If the cord is damaged, do not operate the charger until you obtain a replacement.

-

Insert the wall plug end of the power supply cord into a grounded electrical outlet.

Charging the Lithium-Ion Batteries

Caution

Attempting to charge the batteries with a charger not provided by Toro can result in excessive heat and other related product malfunctions, which can lead to property damage and/or injury.

Use the Toro-provided charger to charge the batteries.

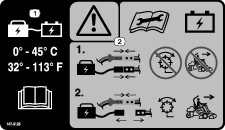

Recommended temperature range for charging: 0° to 45°C (32° to 113°F)

Important: Charge the batteries only in temperatures that are within the recommended range.

Note: The charger will not function in temperatures exceeding the minimum or maximum temperatures.

-

Park the machine in the designated location for charging.

-

Engage the parking brake and move the function-control switch to the NEUTRAL position.

-

Ensure that the cutting units are disengaged and lower them to the ground.

-

Shut off the machine and remove the key.

-

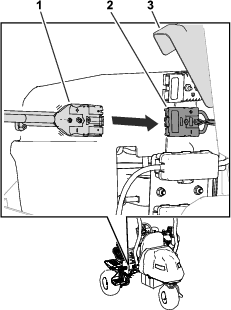

Disconnect the power from the machine by separating the main-power connectors; refer to Main-Power Connectors.

-

Ensure that the connectors are free of dust and debris.

-

Raise the connector cover and slide the charger-output connector into the charger connector on the machine (Figure 40).

Note: The machine connector is located below the main-power connector that is secured to the machine.

-

Connect the charger power cord to a power source; refer to Connecting to a Power Source.

-

Observe the charger to ensure that the batteries are charging.

Note: You can connect the main-power connectors to see the current battery-charge percentage and amperage in the InfoCenter; refer to Monitoring the Charging Process and Troubleshooting.The charger will also illuminate with a green light while the machine is charging.

-

Disconnect the charger when the machine reaches a sufficient level; refer to Completing the Charging Process.

Monitoring the Charging Process and Troubleshooting

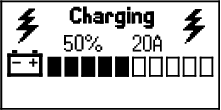

-

The InfoCenter shows the battery charge percentage and amperage.

Batteries with a lower voltage charge first; once they reach the voltage of the other batteries, all batteries charge simultaneously.

When charging is complete, the machine InfoCenter displays 10 solid bars.

-

If there is a fault, an error message will appear in the InfoCenter.

To correct an error, refer to the machine Service Manual. If none of these solutions correct the issue, contact an authorized Toro distributor.

Completing the Charging Process

When charging is complete, the battery-charging indicator light shows solid green and the charging-output indicator light disappears.

-

Disconnect the charger connector from the machine connector.

-