Maintenance

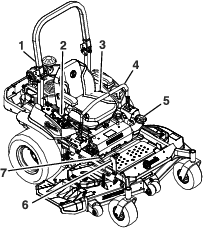

Note: Determine the left and right sides of the machine from the normal operating position.

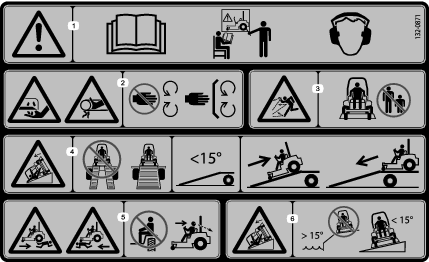

Maintenance Safety

-

Park machine on level ground, disengage drives, set parking brake, stop engine, and remove key. Wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing.

-

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the switch before you perform any maintenance.

-

Never allow untrained personnel to service machine.

-

Disconnect battery or remove spark plug wire before making any repairs. Disconnect the negative terminal first and the positive last. Reconnect positive first and negative last.

-

Keep all guards, shields, switches, and all safety devices in place and in proper working condition. Frequently check for worn or deteriorating components and replace them with genuine Exmark parts when necessary.

Warning

Removal or modification of original equipment, parts and/or accessories may alter the warranty, controllability, and safety of the machine. Unauthorized modifications to the original equipment or failure to use original Exmark parts could lead to serious injury or death. Unauthorized changes to the machine, engine, fuel or venting system, may violate applicable safety standards such as: ANSI, OSHA and NFPA and/or government regulations such as EPA and CARB.

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid accidentally injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

-

If equipped, make sure all hydraulic fluid hoses and lines are in good condition and all hydraulic connections and fittings are tight before applying pressure to hydraulic system.

-

Keep body and hands away from pinhole leaks or nozzles that eject high pressure hydraulic fluid.

-

Use cardboard or paper, not your hands, to find hydraulic leaks.

-

Safely relieve all pressure in the hydraulic system by placing the motion control levers in neutral and shutting off the engine before performing any work on the hydraulic system.

-

-

Use care when checking blades. Wrap the blade(s) or wear gloves, and use caution when servicing them. Only replace damaged blades. Never straighten or weld them.

-

Do not rely solely on mechanical or hydraulic jacks for support. Use adequate jack stands.

-

Carefully release pressure from components with stored energy

-

Keep your hands and feet away from moving parts or hot surfaces. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened, especially the blade-attachment hardware.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| After the first 100 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 250 hours |

|

| Every 400 hours |

|

| Every 500 hours |

|

| Monthly |

|

| Yearly |

|

Periodic Maintenance

Engine Maintenance

Important: Refer to the Engine Owner’s Manual for additional maintenance procedures.

Engine Safety

Warning

The engine can become very hot, especially the muffler and exhaust components. Touching a hot engine can cause severe burns.

Allow the engine to cool completely before service or making repairs around the engine area.

Do Not change the engine governor setting or overspeed the engine.

Check Engine Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine and wait for all moving parts to stop. Make sure unit is on a level surface.

-

Check with engine cold.

-

Clean area around dipstick. Remove dipstick and wipe oil off. Reinsert the dipstick according to the engine manufacturer's recommendations. Remove the dipstick and read the oil level.

-

If the oil level is low, wipe off the area around the oil fill cap, remove cap and fill to the “FULL” mark on the dipstick. Exmark 4-Cycle Premium Engine Oil is recommended; refer to the Engine Owner's manual for an appropriate API rating and viscosity. Do Not overfill.

Important: Do Not operate the engine with the oil level below the “LOW” (or “ADD”) mark on the dipstick, or over the “FULL” mark.

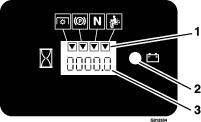

Check Battery Charge

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Monthly |

|

Allowing batteries to stand for an extended period of time without recharging them will result in reduced performance and service life. To preserve optimum battery performance and life, recharge batteries in storage when the open circuit voltage drops to 12.4 volts.

Note: To prevent damage due to freezing, battery should be fully charged before putting away for winter storage.

Charge batteries in an open well ventilated area, away from spark and flames. Unplug charger before connecting or disconnecting from battery. Wear protective clothing and use insulated tools.

Danger

Charging or jump starting the battery may produce explosive gases. Battery gases can explode causing serious injury.

-

Keep sparks, flames, or cigarettes away from battery.

-

Ventilate when charging or using battery in an enclosed space.

-

Make sure venting path of battery is always open once battery is filled with acid.

-

Always shield eyes and face from battery.

Danger

Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. Swallowing electrolyte can be fatal or if it touches skin can cause severe burns.

-

Wear safety glasses to shield eyes, and rubber gloves to protect skin and clothing when handling electrolyte.

-

Do Not swallow electrolyte.

-

In the event of an accident, flush with water and call a doctor immediately.

Caution

If the ignition is in the “ON” position there is potential for sparks and engagement of components. Sparks could cause an explosion or moving parts could accidentally engage causing personal injury.

Be sure ignition switch is in the “OFF” position before charging the battery.

Check the voltage of the battery with a digital voltmeter. Locate the voltage reading of the battery in the table and charge the battery for the recommended time interval to bring the charge up to a full charge of 12.6 volts or greater.

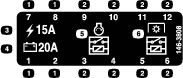

Important: Make sure the negative battery cable is disconnected and the battery charger used for charging the battery has an output of 16 volts and 7 amps or less to avoid damaging the battery (see chart for recommended charger settings).

| Voltage Reading | Percent Charge | Maximum Charger Settings | Charging Interval |

|---|---|---|---|

| 12.6 or greater | 100% | 16 volts/7 amps | No Charging Required |

| 12.4 – 12.6 | 75–100% | 16 volts/7 amps | 30 Minutes |

| 12.2 – 12.4 | 50–75% | 16 volts/7 amps | 1 Hour |

| 12.0–12.2 | 25–50% | 14.4 volts/4 amps | 2 Hours |

| 11.7–12.0 | 0–25% | 14.4 volts/4 amps | 3 Hours |

| 11.7 or less | 0% | 14.4 volts/2 amps | 6 Hours or More |

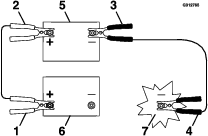

Recommended Jump Starting Procedure

-

Check the weak battery for terminal corrosion (white, green, or blue “snow”), it must be cleaned off prior to jump starting. Clean and tighten connections as necessary.

Caution

Corrosion or loose connections can cause unwanted electrical voltage spikes at anytime during the jump starting procedure.

Do Not attempt to jump start with loose or corroded battery terminals or damage to the engine may occur.

Danger

Jump starting a weak battery that is cracked, frozen, has low electrolyte level, or an open/shorted battery cell, can cause an explosion resulting in serious personal injury.

Do Not jump start a weak battery if these conditions exist.

-

Make sure the booster is a good and fully charged lead acid battery at 12.6 volts or greater. Use properly sized jumper cables (4 to 6 AWG) with short lengths to reduce voltage drop between systems. Make sure the cables are color coded or labeled for the correct polarity.

Caution

Connecting the jumper cables incorrectly (wrong polarity) can immediately damage the electrical system.

Be certain of battery terminal polarity and jumper cable polarity when hooking up batteries.

Note: The following instructions are adapted from the SAE J1494 Rev. Dec. 2001 – Battery Booster Cables – Surface Vehicle Recommended Practice (SAE – Society of Automotive Engineers).

Warning

Batteries contain acid and produce explosive gases.

-

Shield the eyes and face from the batteries at all times.

-

Do Not lean over the batteries.

Note: Be sure the vent caps are tight and level. Place a damp cloth, if available, over any vent caps on both batteries. Be sure the vehicles do not touch and that both electrical systems are off and at the same rated system voltage. These instructions are for negative ground systems only.

-

-

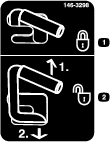

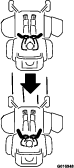

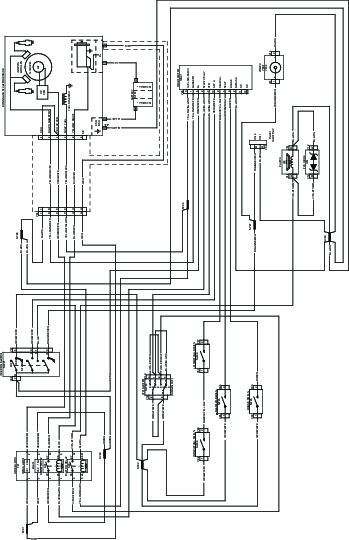

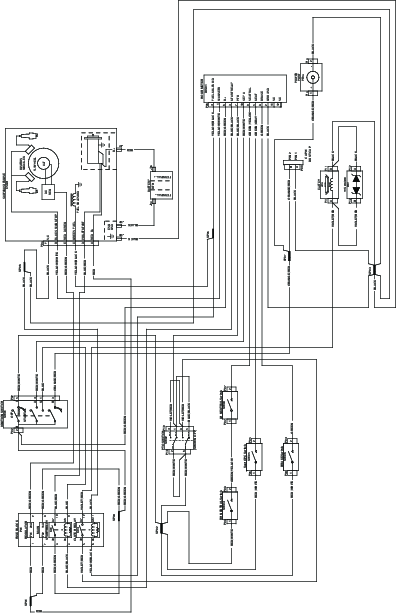

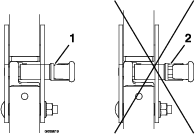

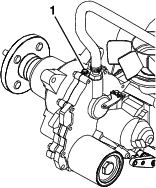

Connect the positive (+) cable to the positive (+) terminal of the discharged battery that is wired to the starter or solenoid as shown in .

-

Connect the other end of the positive cable to the positive terminal of the booster battery.

-

Connect the black negative (–) cable to the other terminal (negative) of the booster battery.

-

MAKE THE FINAL CONNECTION ON THE ENGINE BLOCK OF THE STALLED VEHICLE (NOT TO THE NEGATIVE POST) AWAY FROM THE BATTERY. STAND BACK.

-

Start the vehicle and remove the cables in the reverse order of connection (the engine block (black) connection is the first to disconnect).

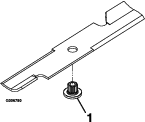

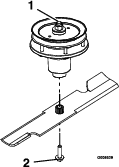

Check Mower Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Lift deck and secure in raised position as stated in the Clean Grass Build-Up Under Deck section.

-

Inspect blades and sharpen or replace as required.

-

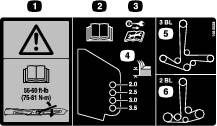

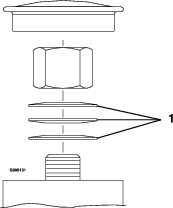

Reinstall the blades (if they were removed) in the following order:

-

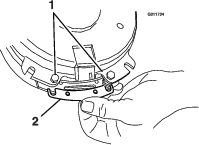

Install bushing through blade with bushing flange on bottom (grass) side of blade.

-

Install bushing/blade assembly into spindle. Make sure the splines on the bushing are engaged in the spindle before tightening the bolt.

-

Apply lubricant to threads of blade bolt to prevent seizing. Copper-based anti-seize preferable. Grease acceptable substitute. Install blade bolt finger tight. Place wrench on the top spindle nut then torque the blade bolts to 50-60 ft-lb (68-81 N-m).

Warning

Incorrect installation of the blade or components used to retain the blade can be dangerous. Failure to use all original components and assembled as shown could allow a blade or blade component to be thrown out from under the deck resulting in serious personal injury or death.

Always install the original Exmark blades, blade bushings, and blade bolts as shown.

-

Check Safety Interlock System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use.

Note: If machine does not pass any of these tests, Do Not operate. Contact an Authorized Service Dealer.

Note: To prevent engine cut-outs on rough terrain, the seat has a 1/2 second time delay before the engine begins to shutdown.

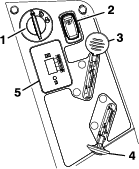

Check the Normal Engine Starting Chart

| System | ||||||

| Parking Brake | PTO | Motion Control Levers | Operator | Outcome | ||

| State of System | Engaged | Disengaged (Blades) | Both levers out (neutral lock) | In seat or out of the seat | Starter should crank | |

|  |  |   |  |

||

Check Engine Starting Circuit Chart

Note: In the Check Engine Starting Circuit Chart, the state of system item that is bold is being checked in each scenario.

| System | |||||

| Parking Brake | PTO (Blades) | Motion Control Levers | Operator | Outcome | |

| State of System | Engaged | Disengaged | Right lever moved in.Left lever moved in. | Operator in seat | Starter must not crank |

|  |   |  |  |

|

| Disengaged | Disengaged | Both levers out (neutral lock) | Operator in seat | Starter must not crank | |

|  |  |  |  |

|

| Engaged | Engaged | Both levers out (neutral lock) | Operator in seat | Starter must not crank | |

|  |  |  |  |

|

Check Shutdown Circuit Chart

Note: The state of system item(s) that is bold is being checked in each scenario.

| System | ||||||

| Engine | Parking Brake | PTO (Blades) | Motion Control Levers | Operator | Outcome | |

| State of System | Running idle (1/3 throttle) | Disengaged | Disengaged | Both levers moved out (neutral lock) | Raise off of seat (but don’t get off) | Engine must begin shutdown within 1 second |

|  |  |  |  |  |

|

| Running idle (1/3 throttle) | Disengaged | Engaged | Both levers moved out (neutral lock) | Raise off of seat (but don’t get off) | Engine must begin shutdown within 1 second | |

|  |  |  |  |  |

|

| Running idle (1/3 throttle) | Engaged | Disengaged | Right lever moved in.Left lever moved in. | Operator in seat | Engine must begin shutdown within 1 second | |

|  |  |   |  |  |

|

| Running idle (1/3 throttle) | Engaged | Engaged | Both levers moved out (neutral lock) | Raise off of seat (but don’t get off) | Engine must begin shutdown within 1 second | |

|  |  |  |  |  |

|

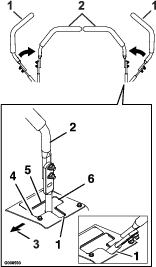

Check Rollover Protections Systems (Roll Bar) Knobs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

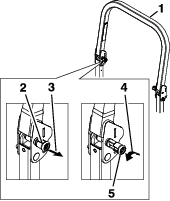

Check that both the mounting hardware and the knobs are in good working condition. Make sure the knobs are fully engaged with the ROPS in the raised position. The upper hoop of the roll bar may need to be pushed forward or pulled rearward to get both knobs fully engaged.

Check Seat Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Visually inspect seat belt for wear, cuts, and proper operation of retractor and buckle. Replace before operating if damaged.

Check for Loose Hardware

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Visually inspect machine for any loose hardware or any other possible problem. Tighten hardware or correct the problem before operating.

Service Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 250 hours |

|

| Every 500 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

See the Engine Owner's Manual for maintenance instructions.

Check Air Filter Assembly (if equipped)

Important: To prevent engine damage, always operate the engine with both air filters and cover installed.

-

When checking or replacing the air filter element, make sure the air filter assembly is installed in the brackets.

-

Position the air cleaner cover so that the breather valve does not interfere with the throttle mechanism.

-

Secure the cover with latches.

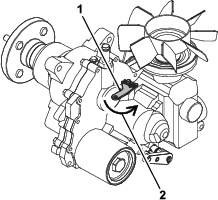

Change Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 100 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Drain oil while engine is warm from operation.

-

Remove dip stick. The oil drain hose is located on right hand side of engine at the rear. Place pan under machine to catch oil. Remove plug from end of drain hose. Allow oil to drain.

-

Replace the oil filter every other oil change. Clean around oil filter and unscrew filter to remove. Before reinstalling new filter, apply a thin coating of Exmark 4–Cycle Premium Engine oil on the surface of the rubber seal. Turn filter clockwise until rubber seal contacts the filter adapter then tighten filter an additional 1/2 to 3/4 turn.

-

Clean around oil fill cover and remove cap. Fill to specified capacity and replace cap.

-

Use oil recommended in the Check Engine Oil Level section. Do Not overfill. Start the engine and check for leaks.

-

Wipe up any spilled oil from engine deck mounting surfaces.

Check Hydraulic Oil and Tank Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine and wait for all moving parts to stop. Engage parking brake.

-

Wait until the machine cools before checking the hydraulic oil.

-

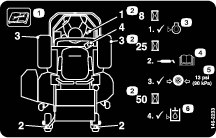

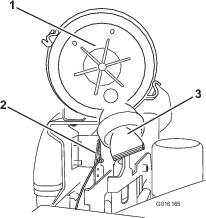

Check expansion tank and if necessary add Exmark Premium Hydro Oil to the FULL COLD line (see Figure 28).

Check Tire Pressures

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Check tire pressure in drive tires and pneumatic casters.

-

Inflate pneumatic casters to 13 psi (90 kPa).

Inflate drive tires to 13 psi (90 kPa).

-

Semi-pneumatic caster tires Do Not need to be inflated.

Note: Do Not add any type of tire liner or foam fill material to the tires. Excessive loads created by foam filled tires may cause failures to the hydro drive system, frame, and other components. Foam filling tires will void the warranty.

Check Condition Of Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

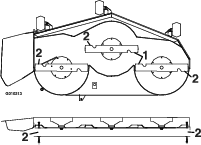

Remove left and right belt shields on deck and lift up floor pan to inspect deck drive belt.

-

Check under machine to inspect the pump drive belt.

Note: No adjustments are required for belt tension.

Lubricate Grease Fittings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Note: See chart for service intervals.

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Lubricate fittings with one to two pumps of NLGI grade #2 multi-purpose gun grease.

Refer to the following chart for fitting locations and lubrication schedule.

Lubrication Chart Fitting Locations Initial Pumps Number of Places Service Interval 1. Front Caster Pivots *0 2 *Yearly

-

Lubricate caster pivots once a year. Remove hex plug and cap. Thread grease zerk in hole and pump with grease until it oozes out around top bearing. Remove grease zerk and thread plug back in. Place cap back on.

Check Spark Plugs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Remove spark plugs, check condition and reset gaps, or replace with new plugs. See Engine Owner's Manual.

Change Fuel Filter

A fuel filter is installed between the fuel tank and the engine. Replace when necessary.

Note: It is important to reinstall the fuel line hoses and secure with plastic ties the same as they were originally installed at the factory to keep the fuel line away from components that could cause fuel line damage.

Change Hydraulic System Filter and Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 400 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Raise the rear of machine up and support with jack stands (or equivalent support) just high enough to allow drive wheels to turn freely.

-

Carefully clean area around the filters. It is important that no dirt or contamination enter the hydraulic system.

-

Place a catch pan under the hydro.

-

Remove and retain the oil filter covers on each of the transaxles. Remove and discard the o-ring from the covers.

-

Allow the oil to drain. Remove and discard the filters from the transaxle housings.

Install a new o-ring onto the filter cover and reinstall the cover. Torque to 200-300 in-lb (23-34 N-m).

-

Remove the top oil fill vent port plug and fill until it reaches the oil fill vent port. Reinstall the vent port plug and continue to fill as stated in Check Hydraulic Oil and Tank Level.

Hydro Oil Service Interval Exmark Premium Hydro Oil (Preferred) After first 100 hours*Every 400 hours thereafter Mobil 1 15W50 After first 100 hours *Every 250 hours thereafter *May need more often under severe conditions.

-

Remove the catch pan and properly dispose of hydro oil and filter according to local codes.

Note: Do Not change the hydraulic system oil (except for what can be drained when changing filter), unless it is felt the oil has been contaminated or been extremely hot.Changing oil unnecessarily could damage hydraulic system by introducing contaminants into the system.

Hydraulic System Air Purge

Air must be purged from the hydraulic system when any hydraulic components, including oil filter are removed.

-

Stop engine and wait for all moving parts to stop. Raise the rear of the machine up onto jack stands high enough to raise the drive wheels off the ground.

-

Check oil level as stated in Check Hydraulic Oil and Tank Level section.

-

Start engine and move throttle control ahead to full throttle position. Move the speed control lever to the middle speed position and place the drive levers in the “drive” position.

-

Open the drive wheel release on each pump.

-

With the machine running, slowly stroke the drive levers from forward to reverse several times. Then, retighten the drive wheel release valves. Slowly stroke the drive levers from forward to reverse several times.

-

If either drive wheel still does not rotate, stop and repeat steps 4 and 5 above for the respective pump. If wheels rotate slowly, the system may prime after additional running. Check oil level as stated in Check Hydraulic Oil and Tank Level section.

-

Allow the machine to run several minutes after the charge pumps are “primed” with drive system in the full speed position. Check oil level as stated in Check Hydraulic Oil and Tank Level section.

-

Check hydro drive linkage adjustment as stated in Hydro Drive Linkage Adjustment section in Adjustments.

Check Spark Arrester

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Warning

Hot exhaust system components may ignite gasoline vapors even after the engine is stopped. Hot particles exhausted during engine operation may ignite flammable materials. Fire may result in personal injury or property damage.

Do Not refuel or run engine unless spark arrester is installed.

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Wait for muffler to cool.

-

If any breaks in the screen or welds are observed, replace arrester.

-

If plugging of the screen is observed, remove arrester and shake loose particles out of the arrester and clean screen with a wire brush (soak in solvent if necessary). Reinstall arrester on exhaust outlet.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut Type” are used on the following fasteners:

-

ROPS spring pin housing.

-

Hydro park brake anchor mounting bolt

-

Deck lift link mounting bolt.

Thread locking adhesives are required for some hardware on engines — see the Engine manual.

Copper-Based Anti-seize

Copper-based anti-seize is used in the following location:

On threads of Blade Bolts. See Check Mower Blades section.

Dielectric Grease

Dielectric grease is used on all blade type electrical connections to prevent corrosion and loss of contact. Dielectric grease should not be applied to sealed connectors.

Adjustments

Note: Disengage PTO, shut off engine, wait for all moving parts to stop, engage parking brake, and remove key before servicing, cleaning, or making any adjustments to the machine.

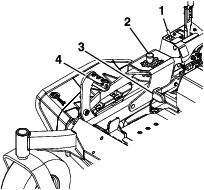

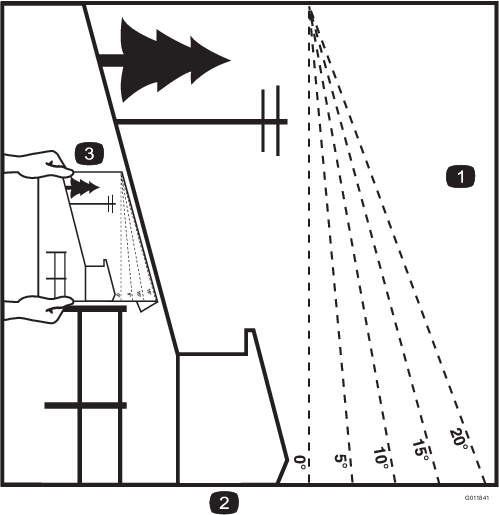

Deck Leveling

-

Position the mower on a flat surface.

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Check the tire pressure in the drive tires. Proper inflation pressure for tires is 13 psi (90 kPa). Adjust if necessary.

-

Position the transport lock in the latching position.

-

Carefully rotate the blades from side to side.

-

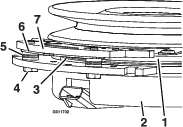

Measure between the outside cutting edges and the flat surface (Figure 30). If both measurements are not within 3/16 inch (5 mm), an adjustment is required; continue with this procedure.

-

Set anti-scalp rollers to top holes or remove completely for this adjustment.

-

Raise the deck to the transport (5 1/2 inch (14 cm) cutting height) position.

-

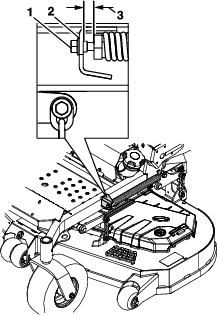

Slowly loosen the adjusting screw on the lift assist spring until the screw can be removed (see Figure 31). Save the screw for reinstallation.

-

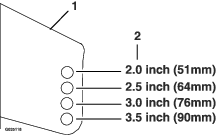

Set the height-of-cut lever to the 3 inch (76 mm) position. Place two “B” thick blocks (see Block Height and Rake Table) under the rear edge of the cutting deck skirt; one on each side of the cutting deck. Place two “A” thick blocks under each side of the front edge of the deck, but not under the anti-scalp roller brackets.

Deck Size Front Block Height “A” Rear Block Height “B” Rake “R” 48, 52, & 60 2.63 inches (6.7 cm) 2.88 inches (7.3 cm) 1/16–5/16 inch (1.6–7.9 mm) -

Carefully rotate the blades side to side (Figure 30).

-

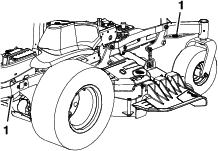

Loosen the leveling adjust locking nuts (item 1 Figure 32) on all four corners so that the deck is sitting securely on all four blocks. Make sure that the slack is removed from the deck hangers and the deck lift foot lever is pushed back against the stop, then tighten the four leveling adjust locking nuts.

-

Recheck that blocks fit just snugly under the deck skirt. Make sure all attachment bolts are tight

-

Continue leveling the deck by checking the front-to-rear blade slope; refer to Adjusting the Blade Slope.

-

Recheck blades for levelness and repeat deck leveling procedure if necessary.

-

Raise the deck to the transport (5 1/2 inch (14 cm) cutting height) position.

-

Reinstall the lift assist spring adjusting screw that was removed in Step 9.

-

Set the gap between the spring and bracket to 3/8–5/8 inch (9–16 mm).

Pump Drive Belt Tension

Self-tensioning - No adjustment necessary.

Deck Belt Tension

Self-tensioning - No adjustment necessary.

Adjusting the Parking Brake

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Check to make sure brake is adjusted properly. This procedure must be followed after the first 100 hours or when a brake component has been removed or replaced.

-

Drive the machine onto a level surface.

-

Disengage the blade control switch (PTO), move the motion control levers to the neutral locked position and set the parking brake.

-

Stop the engine, wait for all moving parts to stop, and remove the key.

-

Setup the machine to be pushed by hand (see Drive Wheel Release Valves in the Operation section).

-

Raise the back of the machine up and support the machine with jack stands.

-

Engage/disengage the brake and check each drive tire to make sure each brake engages/disengages.

-

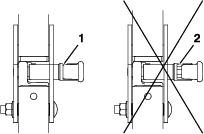

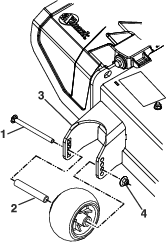

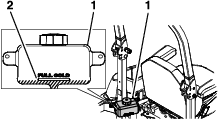

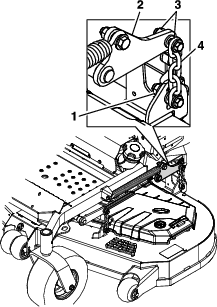

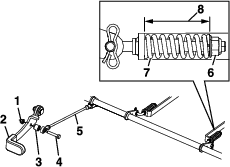

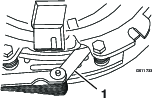

If adjustment is necessary, disengage the park brake. Remove and retain the nut, spacer, and screw from the brake linkage shaft (see Figure 33).

-

Check both spring lengths as shown in Figure 33. If adjustment is necessary, turn the spring retention nut clockwise to shorten and counterclockwise to lengthen.

-

Push the parking brake lever all the way forward and down. Rotate the brake linkage shaft until the end aligns with hole in lever.

-

Shorten the linkage by turning it clockwise.

-

Lengthen the linkage by turning it counterclockwise.

Insert the brake linkage shaft into parking brake hole and secure with the screw, spacer, and nut as shown in Figure 33. Repeat step 6 and readjust if necessary.

-

-

When adjustment is complete, remove the jack stands or equivalent support and lower the machine.

-

Place the machine into the “operating” position. Refer to the Drive Wheel Release Valves section in Operation.

Motion Control Handle Adjustment

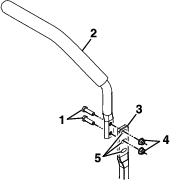

Adjusting the height:

The motion control levers can be adjusted higher or lower for maximum operator comfort.

-

Remove the hardware holding the control lever to the control arm shaft.

-

Move the control lever to the next set of holes. Secure the lever with the hardware.

-

Repeat the adjustment for the opposite control lever.

Adjusting the Tilt

The motion control levers can be tilted fore or aft for maximum operator comfort.

-

Loosen the upper bolt holding the control lever to the control arm shaft.

-

Loosen the lower bolt just enough to pivot the control lever fore or aft. Tighten both bolts to secure the control in the new position.

-

Repeat the adjustment for the opposite control lever.

Full Forward Tracking Adjustment

If the machine travels or pulls to one side, when the motion control levers are in the full forward position, adjust the tracking screw.

-

Insert a 3/16 inch hex wrench through the access hole on the front cover panel, rotate the tracking screw clockwise or counterclockwise to adjust the travel of the lever.

-

Drive the machine and check the full forward tracking.

-

Repeat steps 1 and 2 until desired tracking is obtained.

Motion Control Linkage Adjustment

Located on either side of the machine, below the seat are the pump control linkages. Rotating the end nut with a 1/2 inch deep socket wrench allows fine tuning adjustments so that the machine does not move in neutral. Any adjustments should be made for neutral positioning only.

-

Prior to starting the engine, push the deck lift pedal and remove the height of cut pin. Lower deck to the ground.

-

Raise the rear of machine up and support with jack stands (or equivalent support) just high enough to allow drive wheels to turn freely.

-

Remove the electrical connection from the seat safety switch, located under the bottom cushion of the seat. The switch is a part of the seat assembly.

-

Temporarily install a jumper wire across the terminals in the connector of the main wiring harness.

-

Start engine. Brake must be engaged and motion control levers out to start engine. Operator does not have to be in the seat. Run engine at full throttle and release brake.

-

Run the machine at least 5 minutes with the drive levers at full forward speed to bring hydraulic oil up to operating temperature.

Note: The motion control lever needs to be in neutral while making any necessary adjustments.

-

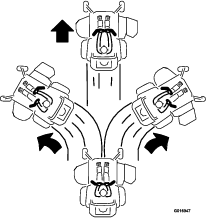

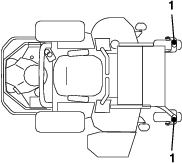

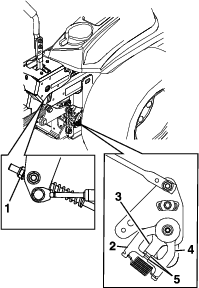

Bring the motion control levers into the neutral position. The control plate tabs should touch the return to neutral plates on the hydros. Adjust pump control rod lengths by turning the nut in the appropriate direction until the wheels slightly creep in reverse (see Figure 36). Move the motion control levers to the reverse position and while applying slight pressure to the lever allow the reverse indicator springs to bring the levers back to neutral. The wheels must stop turning or slightly creep in reverse.

The motion control cover may need to be removed to gain access.

-

Shut off the machine. Remove jumper wire from wire harness and plug connector into seat switch.

-

Remove the jack stands.

-

Raise the deck and reinstall the height of cut pin.

-

Check that the machine does not creep in neutral with the park brake disengaged.

Electric Clutch Adjustment

No adjustment necessary. However, when the clutch brake has worn to the point where the clutch no longer engages consistently, the shim can be removed to extend the clutch life (not applicable for Lazer Z E-Series with 48 inch decks).

Removing the Shim:

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Allow the machine to cool completely before starting these instructions.

-

Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers.

-

Check the condition of the wire harness leads, connectors, and terminals. Clean or repair as necessary.

-

Verify that 12V is present at the clutch connector when the PTO switch is engaged.

-

Measure the gap between the rotor and armature. If the gap is greater than .04 inch (1 mm), proceed with the following steps:

-

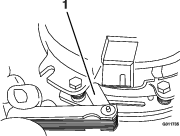

Loosen both brake mounting bolts one-half to one full turn (see Figure 38).

Note: Do Not remove the brake pole from the field shell/armature. The brake pole has worn to match the armature and needs to continue to match after the shim is removed to ensure proper brake torque.

-

Using needle nose pliers, or by hand, take hold of the tab and remove the shim (Do Not discard the shim until proper clutch function has been confirmed).

-

Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers.

-

Re-torque each bolt (M6 x 1) to 10 ft-lb (13 N-m) +/-0.5 ft-lb (0.7 N-m).

-

Using a 0.010 inch thick feeler gauge, verify that a gap is present between the rotor and armature face on both sides of the brake pole as shown. (Due to the way the rotor and armature faces wear (peaks and valleys) it is sometimes difficult to measure the true gap.)

-

If the gap is less than 0.010 inch, then reinstall the shim and reference the Troubleshooting section.

-

If the gap is sufficient, proceed to the safety check in step 6.

-

-

Perform the following safety check:

-

Sit on the seat and start the engine.

-

Make sure the blades Do Not engage with the PTO switch “off” and the clutch disengaged.

If the clutch does not disengage, reinstall the shim and reference the Troubleshooting section.

-

Engage and disengage the PTO switch ten consecutive times to ensure the clutch is functioning properly. If the clutch does not engage properly, reference the Troubleshooting section.

-

-

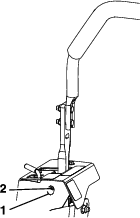

Caster Pivot and Gauge Wheel Pivot Bearings Pre-Load Adjustment

Remove dust cap from caster and tighten nyloc nut until washers are flat and back off 1/4 of a turn to properly set the pre-load on the bearings. If disassembled, make sure the spring disc washers are reinstalled as shown in Figure 41.

Cleaning

Cleaning and Storing Safety

-

Park machine on level ground, disengage drives, set parking brake, stop engine, and remove key. Wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing.

-

Clean grass and debris from the cutting unit, muffler, drives, grass catcher, and engine compartment to prevent fires.

-

Allow the machine to cool before storing the machine in any enclosure. Do Not store the machine or fuel container, or refuel, where there is an open flame, spark, or pilot light such as on a water heater or other appliance.

Clean Debris From Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Clean off any oil, debris, or grass build-up on the machine and cutting deck, especially under deck belt shields, around the fuel tank, around engine and exhaust area.

Important: You can wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water, especially near the control panel, under the seat, around the engine, hydraulic pumps, and motors.

Clean Engine and Exhaust System Area

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Caution

Excessive debris around engine cooling air intake and exhaust system area can cause engine, exhaust area, and hydraulic system to overheat which can create a fire hazard.

Clean all debris from engine and exhaust system area.

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Clean all debris from rotating engine air intake screen, around engine shrouding, and exhaust system area.

-

Wipe up any excessive grease or oil around the engine and exhaust system area.

Remove Engine Shrouds and Clean Cooling Fins

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Remove cooling shrouds from engine and clean cooling fins. Also clean dust, dirt and oil from external surfaces of engine which can cause inadequate cooling.

-

Make sure cooling shrouds are reinstalled. Operating the engine without cooling shrouds will cause engine damage due to overheating.

Clean Grass Build-Up Under Deck

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

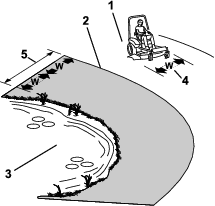

Raise deck to the transport (5 1/2 inch (14 cm) cutting height) position. Lift the front of unit and support unit using jack stands or equivalent support.

-

Clean out any grass build-up from underside of deck and in discharge deflector.

Waste Disposal

Motor Oil Disposal

Engine oil and hydraulic oil are both pollutants to the environment. Dispose of used oil at a certified recycling center or according to your state and local regulations.

Battery Disposal

Danger

Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. Swallowing electrolyte can be fatal or if it touches skin can cause severe burns.

-

Wear safety glasses to shield eyes, and rubber gloves to protect skin and clothing when handling electrolyte.

-

Do Not swallow electrolyte.

-

In the event of an accident, flush with water and call a doctor immediately.

Federal law states that batteries should not be placed in the garbage. Management and disposal practices must be within relevant federal, state, or local laws.

If a battery is being replaced or if the unit containing the battery is no longer operating and is being scrapped, take the battery to a local certified recycling center. If no local recycling is available return the battery to any certified battery reseller.