| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This machine dethatches turf. It is intended for small- to medium-sized lawn applications in residential and commercial properties.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product and accessory information, help finding a dealer, or to register your product.

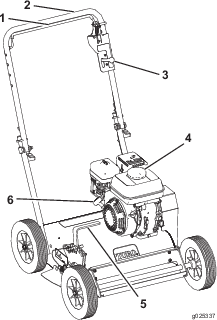

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates the location of the model and serial numbers on the product. Write the numbers in the space provided.

This manual identifies potential hazards and has safety messages identified by the safety alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Important: This engine is not equipped with a spark arrester muffler. It is a violation of California Public Resource Code Section 4442 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land. Other states or federal areas may have similar laws.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety alert symbol, which means Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instruction may result in personal injury or death.

Safe Operating Practices

Training

-

Read the Operator’s Manual and other training material. If the operator(s) or mechanic(s) cannot read English, it is the owner’s responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to himself or herself, other people, or property.

Preparation

-

Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by the manufacturer.

-

Wear appropriate clothing including safety glasses and hearing protection. Long hair, loose clothing, or jewelry may get tangled in moving parts.

-

Inspect the area where the equipment is to be used and remove all objects such as rocks, toys, and wire, which can be contacted by the machine.

-

Use extra care when handling gasoline and other fuels. They are flammable and vapors are explosive.

-

Use only an approved container.

-

Never remove the gas cap or add fuel with the engine running.

-

Allow the engine to cool before refueling.

-

Do not smoke.

-

Never refuel or drain the machine indoors.

-

-

Check that the operator presence controls, safety switches, and shields are attached and functioning properly. Do not operate them unless they are functioning properly.

Operation

-

Never run an engine in an enclosed area.

-

Only operate in good light, keeping away from holes and hidden hazards.

-

Start the engine only from the operator’s position.

-

Never operate without the shields, covers, or other guards securely in place. Be sure all interlocks are functioning properly.

-

Do not change the engine governor setting or overspeed the engine.

-

Raise the flail blades, stop the machine, and shut off the engine before leaving the operator’s position for any reason.

-

Stop the equipment and inspect the flail blades after striking an object or if an abnormal vibration occurs. Make necessary repairs before resuming operation.

-

Keep hands and feet away from the flail blade area.

-

Never carry passengers, and keep pets and bystanders away.

-

Be alert, slow down, and use caution when making turns. Look behind and to the side before changing directions.

-

Do not operate the machine while under the influence of alcohol or drugs.

-

Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate the machine; seek shelter.

-

Use extreme care when loading or unloading the machine into a trailer or truck.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

-

Always be aware of obstacles that may be in the area of operation. Plan your path to avoid contact with any obstacle by you or the machine.

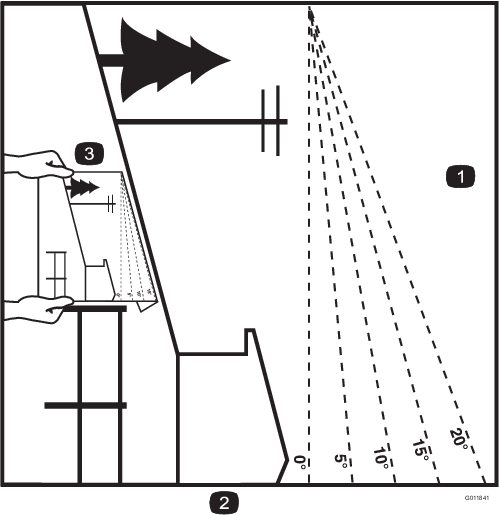

Slope Operation

-

Do not operate near drop-offs, ditches, steep banks, or water. Wheels dropping over edges can cause rollovers, which may result in serious injury or death.

-

Do not operate on slopes when grass is wet. Slippery conditions reduce traction and could cause sliding and loss of control.

-

Do not make sudden turns or rapid speed changes.

-

Reduce speed and use extreme caution on slopes.

-

Do not operate on a slope greater than 20 degrees.

-

Remove or mark obstacles such as rocks, tree limbs, etc. from the operating area.

-

Watch for ditches, holes, rocks, dips, and rises that change the operating angle, as rough terrain could overturn the machine.

-

Always avoid sudden starting or stopping on a slope. If tires lose traction, disengage the flail blades and proceed slowly off the slope.

-

Follow the recommendations for wheel weights or counterweights to improve stability.

Maintenance and Storage

-

Wait for all movement to stop before adjusting, cleaning, or repairing. Raise the flail blades, stop the machine, shut off the engine, and disconnect the spark-plug wire.

-

Clean grass and debris from the blades, drives, mufflers, and engine to help prevent fires. Clean up oil or fuel spills.

-

Let the engine cool before storing, and do not store the machine near a flame.

-

Shut off the fuel while storing or transporting the machine on trailers. Do not store fuel near flames or drain indoors.

-

Park the machine on level, hard ground. Never allow untrained personnel to service it.

-

Use jack stands or safety latches to support components when required.

-

Carefully release pressure from components with stored energy.

-

Remove the spark-plug wire before making any repairs.

-

Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

Use only Toro-approved attachments. The warranty may be voided if the machine is used with unapproved attachments.

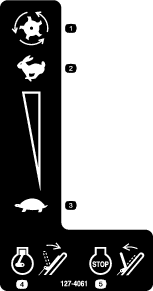

Slope Indicator

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

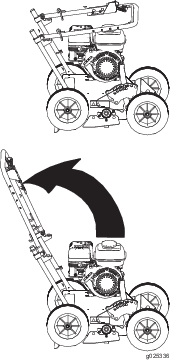

Unfolding the Handle

Checking the Engine-Oil Level

The machine comes from the factory with oil in the engine crankcase, however, it may be necessary to add oil; refer to Servicing the Engine Oil.

Product Overview

Recoil Starter

Pull the recoil-starter handle to start the engine (Figure 6).

Fuel Shutoff Valve

Close the fuel-shutoff valve when transporting or storing the machine (Figure 6).

Choke Lever

Before starting a cold engine, move the choke lever forward. After the engine starts, regulate the choke to keep the engine running smoothly. As soon as possible, move the choke lever all the way rearward.

Note: A warm engine requires little or no choking.

Operator-Presence Bail

The operator-presence bail allows the machine to start/run.

To start the machine, hold down the operator presence bail (Figure 7). Continue to hold down the operator presence bail to allow the machine to run.

Throttle Lever

Move the control forward to increase the engine speed, and rearward to decrease speed (Figure 8).

Depth-Control Lever

The depth-control lever allows you to set the depth of the flail blades in 10 different cutting positions along with 1 position for transportation.

To adjust the depth, remove the hairpin cotter, pull the locking pin out, and move the lever forward or rearward to the desired depth setting (Figure 9).

Important: Do not pull the lever side-to-side, as this bends the lever.

Note: Specifications and design are subject to change without notice.

| Width | 69.9 cm (27.5 inches) |

| Length (operating) | 111.8 cm (44 inches) |

| Length (with handle stored) | 86.4 cm (34 inches) |

| Height (operating) | 94 cm (37 inches) |

| Height (with handle stored) | 63.5 cm (25 inches) |

| Weight | 61.2 kg (135 lbs) |

Attachments/Accessories

Approved attachments and accessories are available for use with the machine to enhance and expand its capabilities. Contact an Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

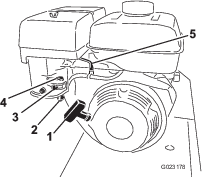

Checking the Engine-Oil Level

-

Shut off the engine, disengage the flail blades, and wait for all moving parts to stop.

-

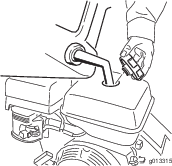

Clean around the dipstick to prevent dirt from falling into the filler hole, which causes damage to the engine (Figure 10).

Note: Ensure that the engine is level.

-

Unscrew the dipstick and wipe the end clean (Figure 10).

-

Insert the dipstick fully onto the filler tube (Figure 10).

Important: Do not screw it in.

-

Remove the dipstick again and look at the end (Figure 11).

Note: If the engine-oil level is low, slowly pour only enough oil into the filler tube to raise the level to the middle of the dipstick

Important: Do not overfill the crankcase with engine oil and run the engine; engine damage may result.

Cleaning Debris from the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Disengage the flail blades, shut off the engine, and wait for all moving parts to stop.

-

Brush dirt and debris away from the air cleaner and engine openings.

Adding Fuel

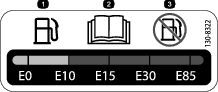

Recommended Fuel:

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

Ethanol: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Gasoline with 15% ethanol (E15) by volume is not approved for use. Never use gasoline that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved gasoline may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless a fuel stabilizer is used.

-

Do not add oil to gasoline.

Important: To reduce starting problems, add fuel stabilizer to the fuel all season, mixing it with gasoline less than 30 days old; run the machine dry before storing it for more than 30 days.Do not use fuel additives other than a fuel stabilizer/conditioner. Do not use fuel stabilizers with an alcohol base such as ethanol, methanol, or isopropanol.

Danger

In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can damage property.

-

Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any gasoline that spills.

-

Never fill the fuel tank inside an enclosed trailer.

-

Do not fill the fuel tank completely full. Add gasoline to the fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck. This empty space in the tank allows gasoline to expand.

-

Never smoke when handling gasoline, and stay away from an open flame or where gasoline fumes may be ignited by a spark.

-

Store gasoline in an approved container and keep it out of the reach of children. Never buy more than a 30-day supply of gasoline.

-

Do not operate without the entire exhaust system in place and in proper working condition.

Danger

In certain conditions during fueling, static electricity can be released, causing a spark which can ignite the gasoline vapors. A fire or explosion from gasoline can burn you and others and can damage property.

-

Always place gasoline containers on the ground away from your vehicle before filling.

-

Do not fill gasoline containers inside a vehicle or on a truck or trailer bed, because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove gas-powered equipment from the truck or trailer, and refuel the equipment with its wheels on the ground.

-

If this is not possible, then refuel such equipment on a truck or trailer from a portable container rather than from a gasoline dispenser nozzle.

-

If a gasoline dispenser nozzle must be used, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

Filling the Fuel Tank

-

Disengage the flail blades, shut off the engine, and wait for all moving parts to stop.

-

Allow the engine to cool.

-

Clean around the fuel-tank cap and remove it (Figure 12).

Note: The cap is tethered to the fuel tank.

-

Add unleaded gasoline to the fuel tank until the level is just inside the mesh filter basket.

Important: This space in the tank allows gasoline to expand. Do not fill the fuel tank completely full.

-

Install the fuel-tank cap securely.

-

Wipe up any spilled gasoline.

Starting and Stopping the Engine

Starting the Engine

-

Turn on the fuel valve.

-

Move the choke lever to the left if you are starting a cold engine.

-

Move the throttle lever midway between the SLOW (turtle) and FAST (rabbit) positions.

Note: A warm or hot engine may not require choking.

-

With one hand, hold down the operator-presence bail.

-

Pull the recoil handle sharply to start the engine.

-

After the engine starts, gradually move the choke to the right.

Note: If the engine stalls or hesitates, move the choke left again until the engine warms up.

-

Move the throttle lever to desired setting.

Stopping the Engine

-

Release the operator-presence bail.

-

Turn the fuel valve off.

-

Wait for all moving parts to stop.

Operating the Machine

-

Move the depth-control lever to the desired setting.

-

Start the engine.

-

Push down on the handle to raise the front wheels off the ground.

-

Slowly lower the front wheels to the ground, allowing the blades to gradually work into the grass and soil.

-

When finished, release the operator presence bail, shut off the engine, and raise the cutting blades to the transport setting.

Operating Tips

Dethatching

-

Set the flail blades 3 to 6 mm (1/8 to 1/4 inch) into the earth (below the zero position).

-

Mow yard shorter than normal mowing length before dethatching.

-

Dethatch a lawn before the prime growing season.

-

After dethatching, remove thatch and debris from lawn with rake.

-

Use time of soil exposure to fertilize and seed lawn.

-

Give lawn extra watering after dethatching.

Power Raking/Renovation

To break new ground or till an existing lawn, set the flail blades 6 to 12 mm (1/4 to 1/2 inch) into the earth (below the zero position). Allow the machine to move at its own pace through the soil, going forward and backward over the area to be leveled, or making multiple passes from different directions.

Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 25 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 300 hours |

|

| Yearly or before storage |

|

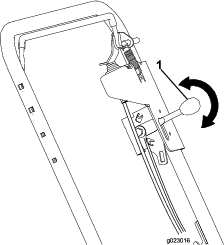

Pre-Maintenance Procedures

Disconnecting the Spark-Plug Wire

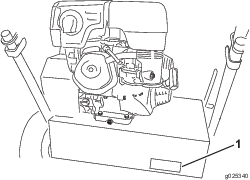

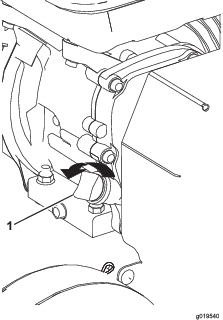

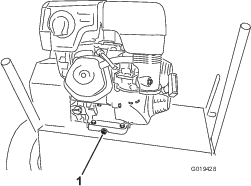

Before performing any maintenance on the engine, belts, or cutting blades, disconnect the spark-plug wire from the spark plug (Figure 13).

Lubrication

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

Grease Specification: NGLI grade No. 2 multi-purpose.

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

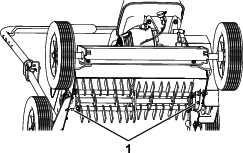

Lubricate the grease fittings under the deck with a grease gun and the specified grease (Figure 14).

Engine Maintenance

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 300 hours |

|

Important: Do not operate the engine without the air-filter assembly; extreme engine damage will occur.

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

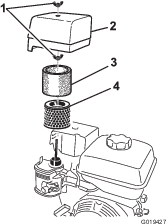

Remove the nut that secures the cover ().

-

Remove the cover.

Note: Be careful to prevent dirt and debris from falling into the base.

-

Remove the nut-restraining air-filter assembly.

-

Remove the foam and paper elements from the base ().

-

Remove the foam element from the paper element ().

-

Inspect the foam and paper elements, and replace them if they are damaged or excessively dirty.

-

If the paper element is excessively dirty, replace it.

Note: Never try to brush dirt off the paper element; brushing forces the dirt into the fibers.

-

Clean the foam element in warm, soapy water or in a nonflammable solvent.

-

Rinse and dry the foam element thoroughly.

-

Dip the foam element in clean engine oil, then squeeze out the excess oil.

Note: Excess oil in the foam element restricts the air flow through the element and may reach the paper filter and clog it.

-

Wipe dirt from the base and the cover with a moist rag.

Note: Be careful to prevent dirt and debris from entering the air duct leading to the carburetor.

-

Install the air-cleaner elements and ensure that they are properly positioned.

-

Securely install the cover with the nut.

Servicing the Engine Oil

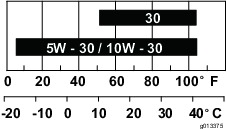

Oil Type: Detergent oil (API service SJ or higher)

Crankcase Capacity: 1.1 L (37 oz)

Viscosity: See the table below (Figure 16).

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 25 hours |

|

| Every 100 hours |

|

Warning

Oil may be hot after the engine has been run, and contact with hot oil can cause severe personal injury.

Avoid contacting the hot engine oil when you drain it.

-

Shut off the engine by releasing the operator-presence bail, disengage the flail blades, and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Raise the front wheels a few inches off the ground and place a pan under the drain plug to catch the oil.

-

Remove the drain plug (Figure 17).

-

When the oil has drained completely, lower the front wheels to the ground, replace the drain plug, and torque to 18 N-m (13 ft-lb).

Note: Dispose of the used oil at a certified recycling center.

-

Remove the dipstick and slowly pour oil into the filler hole until the oil level reaches the middle of the dipstick (Figure 11).

-

Replace and secure the dipstick.

-

Wipe up any spilled oil.

-

Connect the wire to the spark plug.

Cleaning the Sediment Cup

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Danger

In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can damage property.

-

Shut off the engine and keep heat, sparks, and flame away.

-

Handle fuel only outdoors.

-

Wipe up spills immediately.

-

Do not smoke while handling fuel.

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

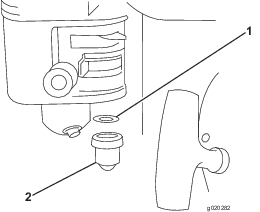

Move the fuel-shutoff valve to the OFF position.

-

Remove the sediment cup and O-ring (Figure 18).

-

Wash the sediment cup in a non-flammable solvent and dry it thoroughly.

-

Place the O-ring in the fuel valve and install the sediment cup, tightening it securely.

-

Move the fuel-shutoff lever to the ON position.

Note: If any fuel leaks, repeat this procedure and replace the O-ring.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 200 hours |

|

Use an NGK BPR6ES spark plug or equivalent.

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes because grit entering the cylinder can damage the engine.

-

Set the gap on the plug to 0.76 mm (0.03 inch) ().

-

Carefully install the spark plug by hand (to avoid cross threading) until it is hand tight.

-

Tighten the spark plug an additional 1/2 turn if it is new; otherwise, tighten it an additional 1/8 to 1/4 turn.

Important: A loose spark plug can become very hot and can damage the engine; overtightening a spark plug may damage the threads in the cylinder head.

-

Connect the wire to the spark plug.

Belt Maintenance

Checking the Belt Tension

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Park the machine on a level surface, shut off the engine, disconnect the spark-plug wire, and raise the flail blades to the highest position.

-

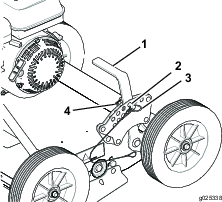

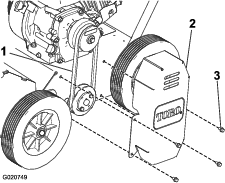

Remove the 4 bolts securing the belt cover to the left side of the machine and remove the cover (Figure 20).

-

Check the tension of the belt (Figure 20).

Note: The belt should not flex more than a 12 mm (1/2 inch) with moderate finger pressure applied to the span just above the machine frame.

-

If the belt tension is loose, refer to Adjusting the Belt Tension.

-

Install the belt cover before operating the machine.

Adjusting the Belt Tension

-

Stop the machine on a level surface and shut off the engine by releasing the operator-presence bail.

-

To tighten the belt, loosen the 4 mounting nuts securing the engine to the frame.

-

Move the engine to tighten the belt to the proper tension.

-

Secure the 4 mounting nuts and bolts.

Note: Torque the bolts that secure the engine to the frame to 271 N-m (200 in-lb).

Maintaining the Flail Blades

Inspecting the Flail Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

When the flail blades are worn down and are no longer functioning properly, refer to Replacing the Flail Blades.

Important: Perform this procedure when the fuel tank is empty or nearly empty. Tip the machine forward to keep air filter up.

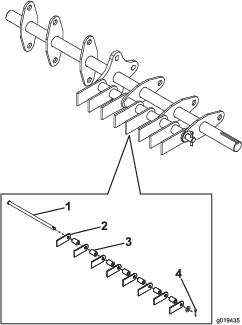

Replacing the Flail Blades

When the flail blades are worn down and no longer functioning properly, replace them as follows:

Important: Preform this procedure when the fuel tank is empty or nearly empty.

-

Stop the machine on a level surface and shut off the engine by releasing the operator-presence bail.

-

Lower the flail blades to the lowest position.

-

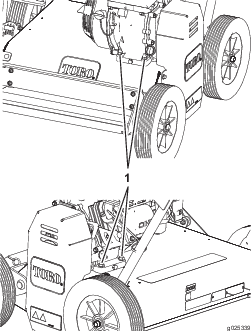

Tilt the machine forward onto its nose, and rest it on a block of wood.

Note: It will take 2 people to tip the machine forward safely.

-

Spin the flail-blade assembly.

Note: It should spin freely. If it makes a grinding noise and is halting, the bearings are worn; replace them when you replace the blades.

-

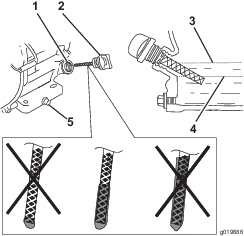

Remove the cotter pin from the rod with the worn down flail (Figure 22).

-

Carefully pull out the rod to release the flails and spacers (Figure 22).

-

Replace worn down flails with new ones and discard the old flails.

-

Carefully add flails and spacers to rod in the same order as they were removed.

Important: Align the rod with the formed head toward the center of the machine.

-

Add the cotter pin to lock the rod, flails, and spacers into place.

Storage

-

Raise the flail blades, stop the machine, shut off the engine, and disconnect the spark-plug wire.

-

Remove dirt and grime from the entire machine.

Important: You can wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water, especially near the engine.

-

Service the air cleaner; refer to Servicing the Air Cleaner.

-

Change the engine oil; refer to Changing the Engine Oil.

-

For storage over 30 days, prepare the traction unit as follows:

-

Add a petroleum-based stabilizer/conditioner to the fuel in the tank. Follow the mixing instructions from the stabilizer manufacturer. Do not use an alcohol-based stabilizer (ethanol or methanol).

Note: A fuel stabilizer/conditioner is most effective when mixed with fresh gasoline and used at all times.

-

Run the engine until it stops from running out of fuel.

-

Choke the engine.

-

Start and run the engine until it will not start again.

-

Dispose of fuel properly. Recycle the fuel according to local codes.

Important: Do not store stabilizer/conditioned gasoline over 90 days.

-

-

Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

-

Paint all scratched or bare metal surfaces with paint from an Authorized Service Dealer.

-

Store the machine in a clean, dry garage or storage area.

-

Cover the machine to protect it and keep it clean.

Removing the Machine from Storage

-

Check and tighten all fasteners.

-

Inspect the spark plug and replace it if it is dirty, worn, or cracked; refer to the engine Owner’s Manual.

-

Install the spark plug until it is hand-tight, then an additional 1/2 turn if it is new, otherwise, tighten it an additional 1/8 to 1/4 turn.

-

Perform any needed maintenance procedures; refer to .

-

Check the engine-oil level; refer to Checking the Engine-Oil Level.

-

Fill the fuel tank with fresh gasoline; refer to Filling the Fuel Tank.

-

Connect the wire to the spark plug.