Product Overview

Overview of the RTK GPS

- Standard GPS positioning data

retrieved from satellites using GNSS (Global Navigation Satellite

System) is accurate to between 5m and 10m.

This is because the signal received from a satellite is distorted

due to atmospheric and environmental conditions.

Higher precision positioning can be achieved by using an

RTK (Real-Time Kinematic) technique.

- This technique involves the use of an RTK base placed in a fixed

position, which receives GNSS signals from satellites. Since

the base is fixed, the data it receives relates

to its precise location.

- The robots are also fitted with

antennas, which receive GNSS signals from satellites in order to determine

their position. Both the RTK base and the

robots receive the GNSS signals from satellites in different constellations

(GPS, GLONASS, Galileo, BeiDou). Since

the robots are moving however, the evaluation of their position is

less precise that that of the fixed base.

- The RTK base computes correctional data for each of the satellites

and sends these to the robot. The robot is then able to

use these corrections to achieve a positional accuracy

of between 2cm and 3cm. With such accurate positioning, the robot

is able to follow a defined pattern and cover

the field in a series of straight lines.

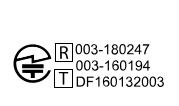

Corrections

can also be made via the cloud using 4G. In this case, obstacles do

not impede the transfer of correctional data

and the base can connect to an unlimited number robots at distances

of up to 15km.

Transfer of corrections using

4G

G520851

One base station can feed corrections

to multiple robots, but each robot must receive corrections from only

1 base station to keep corrections consistent.

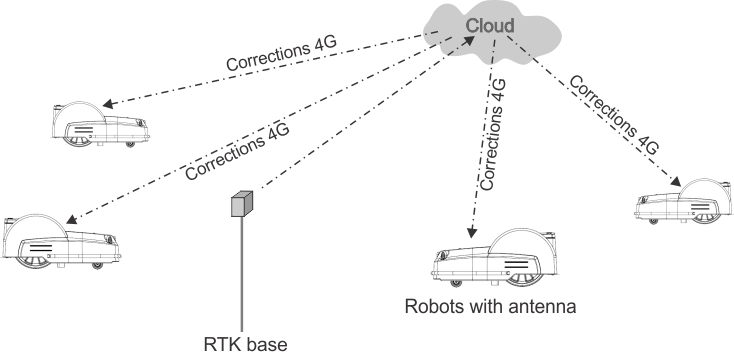

Basic components of the RTK GPS

mowing system

G520852

This topic describes the mechanical

characteristics of the robot.

A user can exercise direct control

over the robot using the User Interface. Once a robot is registered

on the portal running on a web-server:

- The robot can send information

to this server which can be seen by the user.

- The user can issue commands to

the robot, assess its performance and adjust the configuration.

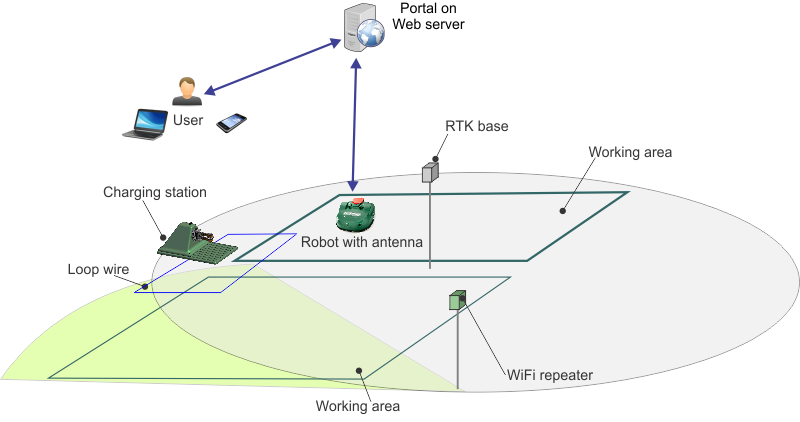

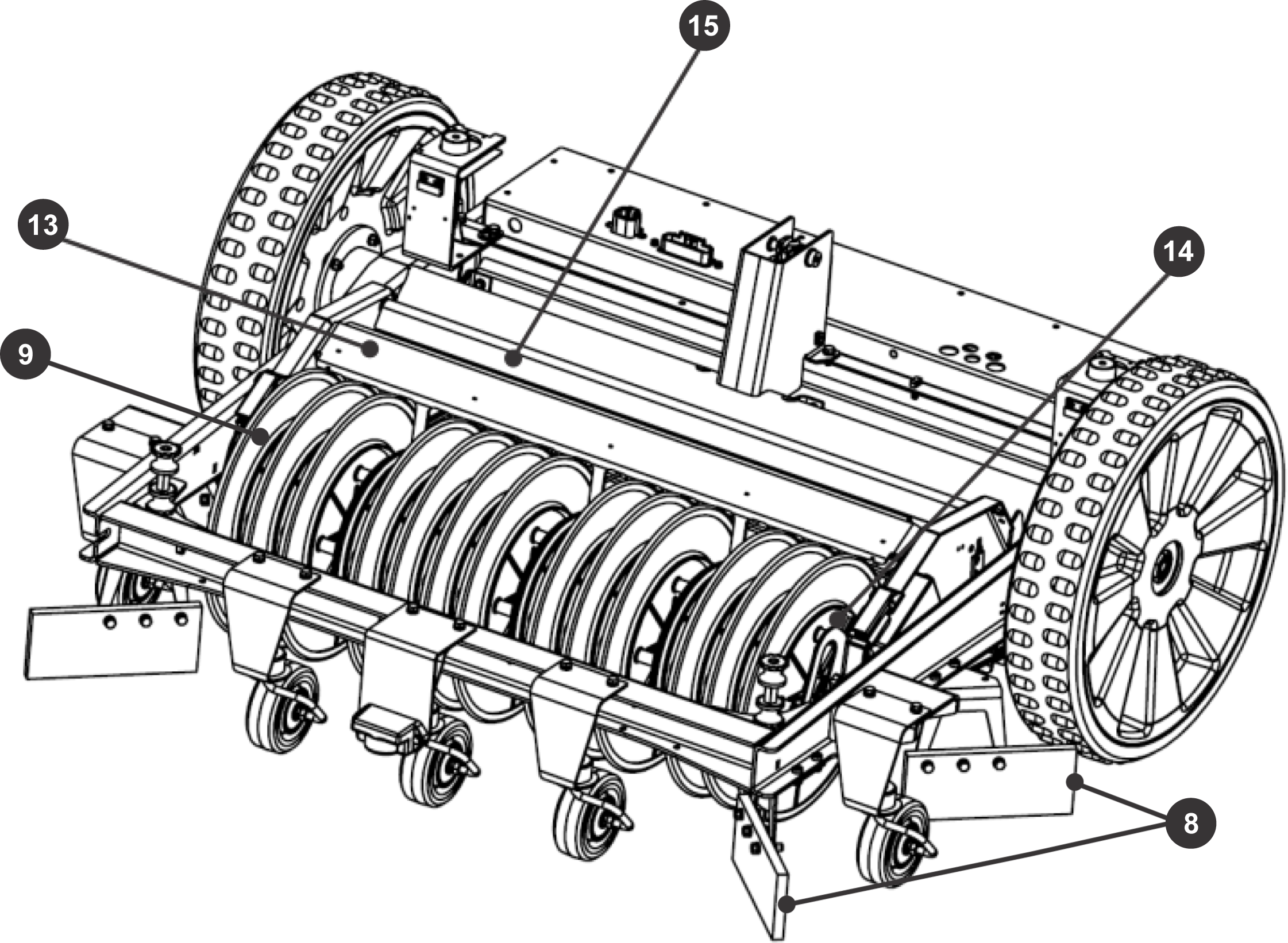

Range Pro 100 Product Overview

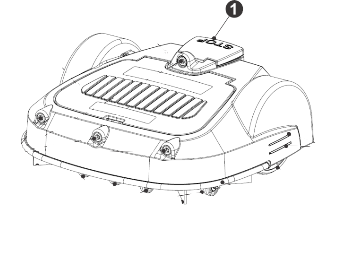

Top view

G537619

G536774

-

Stop button

-

Body

2a: Basket lid

-

Obstacle detection sonars

-

Front wheels

-

Bumper

-

Rear wheels

-

Charge contacts

-

Ball deflectors

-

Collecting roller

-

Collecting basket

-

Power switch

-

Coil

-

Ball counting band

-

Rotational speed detector

-

Full basket detector

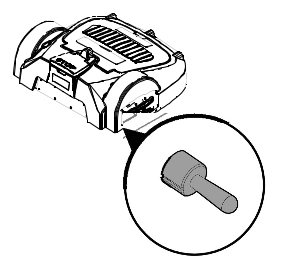

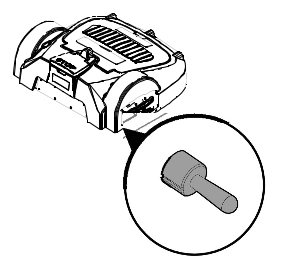

Power switch

|

The power switch is located under

the shell on the right-rear of the robot.

Move the power

switch toward the front of the machine (to the ON position) to operate the robot. Move the power switch toward the

back of the machine (to the OFF position) for extended idle time

or winter storage. |

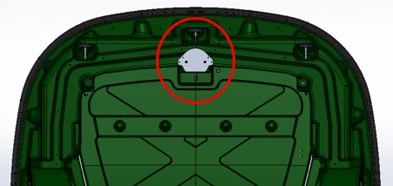

RTK GPS antenna

G536775

This is a specific GNSS antenna

installed at center front of the shell. It is used to receive data

about the robot's global position from satellites.

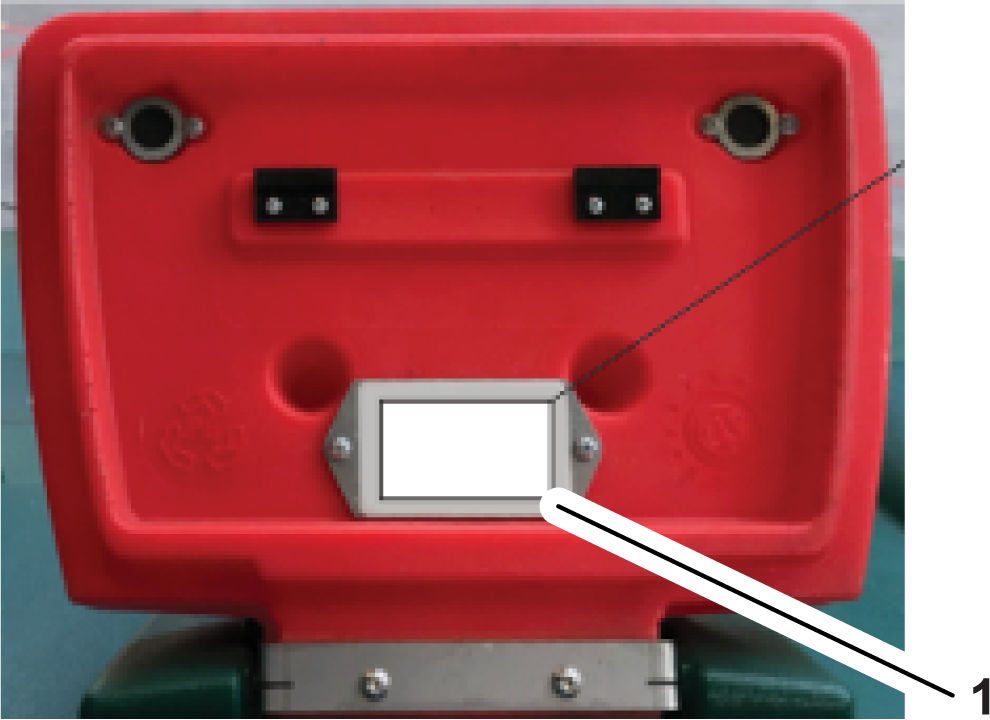

Serial decal

The identification

label can be found on the inside of the Stop button lid as shown below.

G541779

-

Serial decal

Sensor Overview

The machine is equipped with a

comprehensive set of sensors that ensure its safe operation. These

sensors ensure that the robot can detect and

react if an obstacle lies in its path.

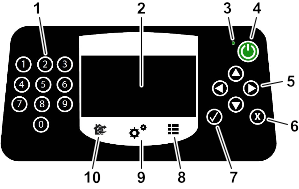

Stop Button

The stop button  is easily visible, situated on

the top of the robot. Pressing this button will cause the robot to

stop moving and cutting. The stop button

also acts as a lid, which when lifted, provides access to the robot's

control user interface. An instruction

must be issued using this control interface in order to restart the

robot.

is easily visible, situated on

the top of the robot. Pressing this button will cause the robot to

stop moving and cutting. The stop button

also acts as a lid, which when lifted, provides access to the robot's

control user interface. An instruction

must be issued using this control interface in order to restart the

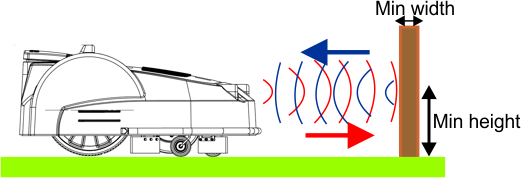

robot. Obstacle Detection Sonars

The robot is equipped with a set

of sonar sensors to detect obstacles. The robot will reduce speed

if the sonar detectors detect an obstacle.

Detection of obstacles by sonar

sensors

G536780

The robot gently touches

the obstacle at low-speed. The robot moves backwards and chooses a

random direction between 60° and 120°.

These

sensors can detect objects that are:

- At least 400 mm (15.75 inches)

high

- At least 50 mm (2 inches) wide

(from all angles)

If the robot is always moving

at a slow speed, even if there are no obstacles in view, it indicates

a problem with the sensors. In this case

you should contact the service team for help in analyzing the problem.

There are several potential causes, such

as condensation inside the sonar casing, a cable connector is loose,

or the sonar electronics are damaged. The problem can

be analyzed using Technician's menu

(9) > Service > Sonars and Technician's menu

(9) > Service > Tests > Sonars.

Bumper

The

bumper is a pressure sensor which senses when the robot touches an

obstacle. When the bumper touches the obstacle, the

robot will move backwards and then rotate through an

angle until it can avoid the obstacle.

Coil

The

induction coil detects the intensity of the magnetic field that is

generated within the peripheral wire. The maximum intensity

is located on the wire, which causes the robot

to stop, rotate, and continue mowing in a new direction.

Tilt Sensor

The tilt sensor detects the angle

of the slope on which the robot is working. An alarm is raised and

the robot stops moving if the angle is

exceeded.

Rollover Sensor

The rollover sensor detects whether

the robot has been tipped upside down or whether someone is trying

to start the motor when the robot is upside

down.

Temperature Sensor

The temperature sensor measures

the ambient temperature and will prevent the robot from operating

if this temperature is too low. The minimum

temperature at which the robot can operate is set as an operating

parameter.

Attachments/Accessories

A selection of Toro approved attachments and

accessories is available for use with the machine to enhance and expand

its capabilities. Contact your Authorized Service

Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved

attachments and accessories. To ensure optimum performance

and continued safety certification of the machine, use only genuine Toro replacement parts

and accessories.

Specifications

Note: Specifications and design are subject to change without notice.

Capacity

| Maximum working area |

30,000 m2 (7.4 acres) |

| Recommended working area |

24,000 m2 (5.9 acres) |

| Working speed

|

3.6 km/h (2.2 mph) |

| Standard maximum slope |

30% (17°)

|

| Balls/day

|

Average=15,600. Maximum=19.500. |

| Picking width

|

956 mm (37-5/8 inches) |

| Basket capacity

|

320-350 balls

|

| Maximum noise level |

61 dB(A) at 1 m (39-3/8 inches).

52 dB(A) at 5 m (196-7/8 inches)

|

Battery

| Type

|

LIFePo4

|

| Nominal voltage

|

25.6 V

|

| Nominal capacity

|

19.2 Ah

|

| Energy

|

491.5 Wh

|

| Time to fully charge (minimum) |

80 minutes

|

| Average working time per charge |

240 minutes

|

| Average annual consumption |

620 kWh (based on use during 11

months of the year) |

Weight and Dimensions

| Weight [kg]

|

85 kg (187 lb)

|

| Length [mm]

|

118 cm (46.46 inches) |

| Width [mm]

|

134 cm (52.75 inches) |

| Height [mm]

|

54 cm (21.25 inches) |

Software and Monitoring

| Security PIN code |

Yes

|

| GPS positioning

|

RTK

|

| Robot management via server and

app. |

Standard

|

Intelligence

| Sonar detection of obstacles |

4

|

| Return to station via GPS |

Yes

|

| Multiple starting zone |

Yes

|

| Multi fields

|

Yes, more than 2

|

| Multi robots/station |

Maximum 2 robots using the drop

pit station. |

| Lift sensors

|

No

|

| Reverse sensors

|

Yes. Causes the robot to change

direction. |

| Safety bumper

|

Electronic

|

| Tilt sensors

|

Yes. Causes the robot to stop

when tilted more than 41°.

|

Maintenance

Maintenance Overview

- Maintenance refers to a set of

tasks that should be carried out regularly throughout the mowing season.

- The service interval depends to

some extent on the operational load of your robot, but it is recommended

that it is serviced by an authorized technician

at least once a year.

- Whilst maintaining your robot

for optimum performance, do not attempt to make any changes to your

robot. You risk disturbing its operation,

causing an accident, and damaging parts.

Note: If you notice any unusual behavior or damage, call a technician.

- When carrying out these maintenance

procedures the following safety regulations should be observed:

- Stop the machine: Always switch

off the power and wait for the all moving parts to stop before handling

the machine.

- Operate the disabling device before

the following:

- Before working on or lifting the

machine.

- Before clearing a blockage.

- Before checking, cleaning or working

on the machine.

- After striking a foreign object

to inspect the machine for damage.

- If the machine starts to vibrate

abnormally.

- Keep all nuts, bolts, and screws

tight to be sure the machine is in safe working condition.

- Use gloves: Protective gloves

must be worn whenever handling the machine.

- Always use OEM (Original Equipment

Manufacturer) parts. In addition to the risk of accidents, the use

of any non-OEM parts will result

in the annulment of the guarantee for any resulting damage.

Recommended Maintenance Schedule

Note: These procedures should be carried out at the recommended frequency

by the regular user of the robot.

Note: Throughout the mowing season, you should regularly check that all

screws, nuts, and bolts are properly tightened. Tighten

any that are loose, and if there is damage or evidence

of a problem, contact an authorized Toro distributor.

| Before each use or daily |

|

| Every 40 hours |

|

| |

|

|

|

|

|

|

|

|

| Every 6 months

|

|

| Yearly or before storage |

|

| |

Cleaning

Cleaning the Machine

During periods

of wet weather it is necessary to ensure that mud and grass do not

accumulate on the moving parts, which are

the wheels and the cutting heads. These should be inspected and cleaned

daily.

-

Press the

red button to stop the robot.

-

Turn the

machine onto its rear side.

-

Turn the

machine off.

-

Remove any

accumulations of grass and dirt using a blower, compressed air, and/or

a wire brush.

-

Rub the body

with a soft, damp cloth or sponge.

-

If the body

is very dirty, use a soapy solution.

Cleaning the Charge Contacts

-

Rub the charge

contact surfaces with sandpaper (280 grade) until they appear clean.

Cleaning the Bumper

-

Check that

the bumper material is intact. If there are cuts or tears, contact

an authorized Toro distributor.

-

Clean the

bumper with a damp cloth.

Cleaning the Sonar Sensors

The sonar sensors need to be kept

clean if they are to operate properly. All sensors need to work properly.

If any of the sensors are not operating properly,

an alarm is issued.

-

Remove any

mud, grass, or dirt and wipe with a damp cloth.

Cleaning the Front Wheels

-

Remove any

mud and grass with a wire brush or a cloth.

-

Check that

the wheels rotate easily and that there is not too much play. If there

is too much play, replace the wheels.

Cleaning the Front Wheel Axle

-

Clean the

front wheel axle with a brush and/or a cloth.

-

Visually

inspect the axle. If there is a problem, replace the axle.

Cleaning the Rear Wheels

-

Remove any

mud and grass using a wire brush.

Electrical System Maintenance

Checking the Wiring

-

Visually

inspect the wiring under the robot. If any problems are detected,

contact an authorized Toro distributor.

Battery Service

The automatic (programmed) operation

of the robot optimizes battery life. It is advisable to allow the

robot to manage its working cycles. If these

work cycles seem unusually short, contact an authorized Toro distributor

to check the condition of the battery.

Note: It is possible to monitor these cycles using the portal.

Glossary

Border mode

When the robot cuts the

grass at the very edge of the field. This is done a number of times

per week.

Cycle

A cycle is a working session

of the robot. It starts when the robot leaves the station and ends

when it returns to the station or there is an problem

that halts the working cycle.

Entity

A collection of robots

and users that operate within a site. Information about the robots

in an entity can be viewed on the web portal.

GPS navigation zone

This is an

RTK GPS zone that is defined by the border discovery process. it encompasses

the entire working area. Sub-zones can then be created

by copying and editing this zone to optimise the efficiency of the

robot.

GPS point

A specific point within

a parcel that the robot uses to return to or leave a station. The

point is defined by its latitude and longitude.

The robot takes a direct route to this point then follows the trackborder

and the loop wire to return to the station.

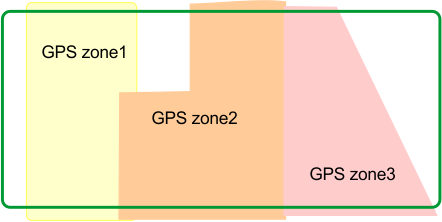

GPS zone

A GPS zone is defined by

set of GPS coordinates. It allows a wired parcel to be subdivided

without having to use additional wires and channels.

GPS zones in a wired parcel

G520046

This provides greater flexibility

in defining working areas since the robot can be scheduled to work

with optimum efficiency over the zones.

Idle

A robot will enter idle mode,

if the current mission has been ended using the Stop button. By default

the robot will enter the sleep mode after 15 minutes.

Island

A loop in the peripheral

wire specially installed to prevent the robot working inside it. The

peripheral wire is taken around the obstacle and

the approach and return wires laid next to each other.

Map

Map of the robots routes on the

portal.

Mapping

The information built up

by the robot using GPS data.

NoGo zone

GPS-defined No-Go zones

are regions on the field defined by GPS coordinates where the robot

can never enter during any of its autonomous operating

states. GPS-defined No-Go zones are used to exclude zones from the

working area of the robot that cannot be detected

during border discovery. Use of GPS-defined No-Go zones allows the

robot to calculate the most efficient mowing pattern

in advance. GPS-defined No-Go zones are used to exclude obstacles,

typically done by islands and pseudo islands.

Obstacle

An object in the field

that the robot must avoid. Obstacles can be permanent (e.g., trees,

furniture) or transitory, (e.g., animals). Obstacles

are detected by sensors. Permanent obstacles can be avoided by making

loops in the peripheral wire to form "islands" or

"pseudo-islands".

Parcel

An area to be mowed within

a peripheral wire. At least one parcel is associated with one wire.

Several parcels can be defined.

Percentage

This represents the proportion

of time that the robot will spend working a particular parcel. If

there is only one parcel, the robot will spend 100%

of its time there.

Peripheral wire

A wire laid

below the surface of the field which defines the area in which the

robot works. The area defined by the peripheral

wire is termed a "parcel".

Pseudo-island

The peripheral

wire is taken around the obstacle, maintaining a specific distance

between the approach and the return wires.

Robot status values

- Off

Robot has been switched off.

- Off after alarm

Robot has switched itself off

after an alarm.

- Alarm

Robot is in a state of alarm.

- Staying

Robot is waiting at a charge station.

- Charge

Robot is charging the battery.

- Heading for unload station

Robot is going to the drop pit

station to unload balls. This status starts when a robot decides to

return to the station.

- Heading for charge station

Robot is going to the charging

station. This status starts when the robot decides to return to the

station.

- Leaving station

Robot is leaving the station and

starting to work.

RTK GPS zone

The working area for a

robot performing pattern mowing. The RTK GPS zone is defined by the

robot making a tour of the peripheral wire.

Site

The entire area which includes

the area in which the robot works.

Sleep

A robot will enter sleep

mode 15 minutes after an alarm has occurred which has not been cleared.

After 2 days in sleep mode, the robot will enter

the OFF mode. This will also occur if the battery charge level reaches

a low level. When in sleep mode the robot uses minimal

power to reduce the risk of the battery.

The robot can be brought out of

sleep mode by:

- clearing the alarm and switching

the robot on, using the button on the LED screen

- pushing the robot to the charging

station, if the battery is flat

- sending a remote wakeup command

via the web portal

Start zone

A defined position within

a parcel which determines where the robot will start working.

Station loop

A station loop is a short

wire around a charging station which is used to guide the robot into

the station. When the robot detects that it is in

the station loop, it follows the wire until it arrives in the station.

Terrain

An area of grass surrounding

the field that is not to be mowed.

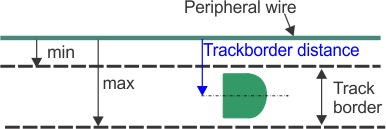

Track border

A width of grass around

the edge of the parcel in which the robot works. The robot follows

the track border when leaving or returning to a

station unless it is using GPS. There is no track border specified

for a wire that acts as a "return to station loop".

The track border lies next to

the peripheral wire, and is defined by minimum and maximum dimensions

set as installation parameters. It is wider than

the robot. The path taken by the robot within the track border is

selected in a random manner. This ensures that the

robot does not repeatedly move along the same path and so create ruts

in the field. If the robot encounters an obstacle

whilst in the track border, the sensors will cause it to reverse

and then rotate through a random angle in order to proceed.

This may be repeated a number of times if necessary.

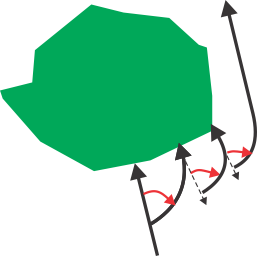

Maneuvers to avoid an obstacle

within the track border

G520315