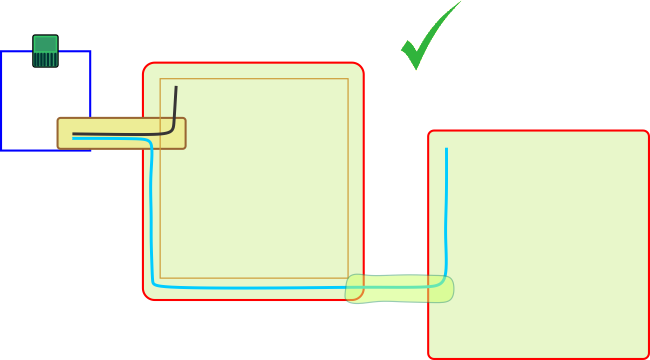

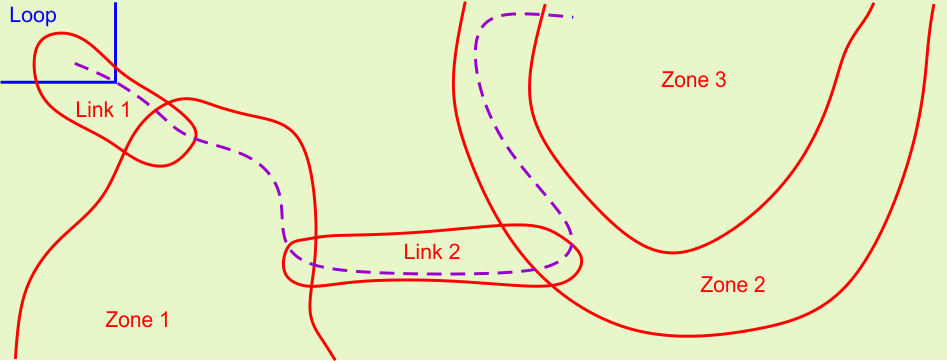

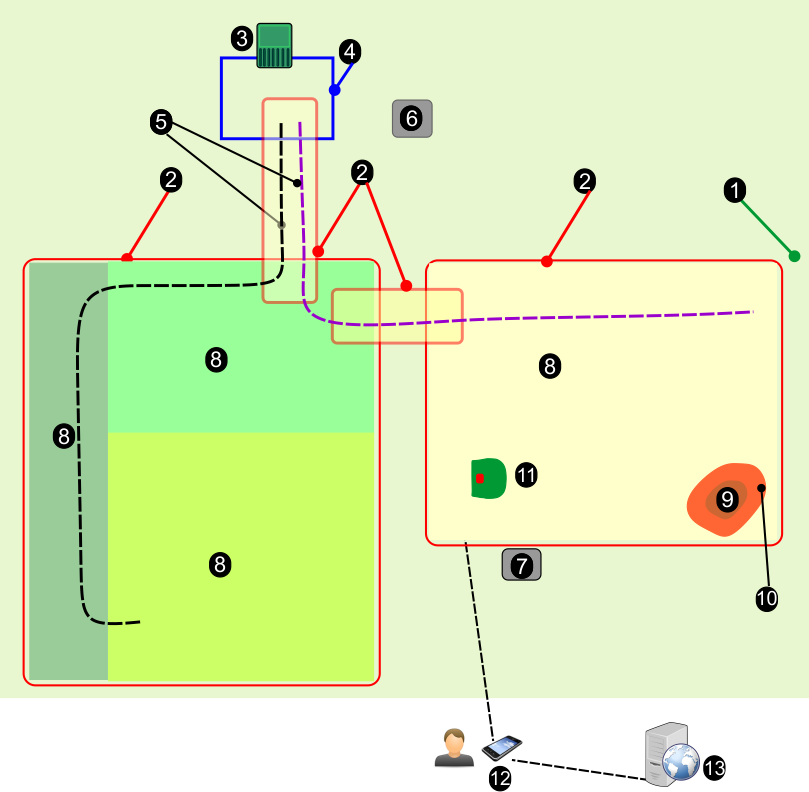

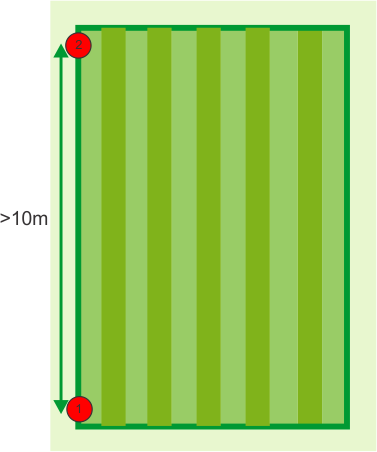

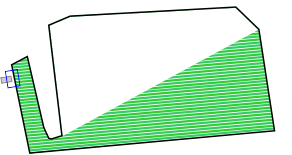

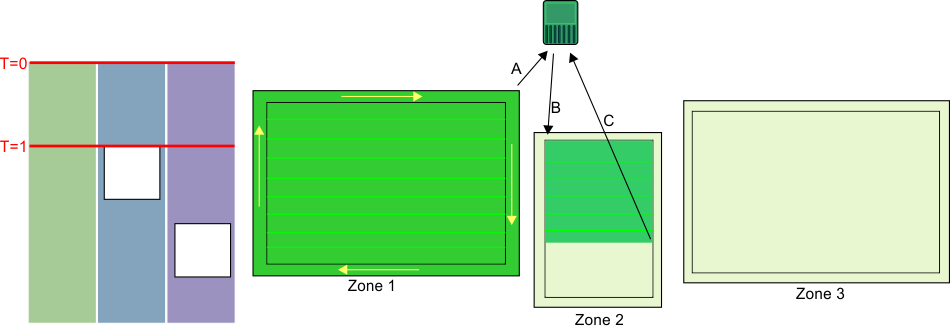

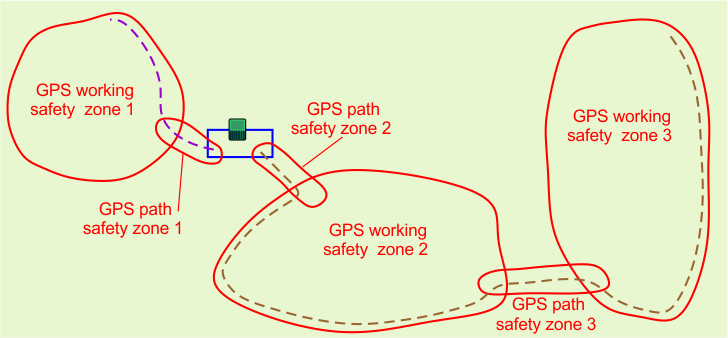

The easiest way in which

to ensure that each zone and its border is mowed regularly is to implement

sequential scheduling. When sequential scheduling

is implemented, the robot will work in each zone in turn and mow the

border when the mowing is complete. The robot

works in conjunction with the defined working schedule.

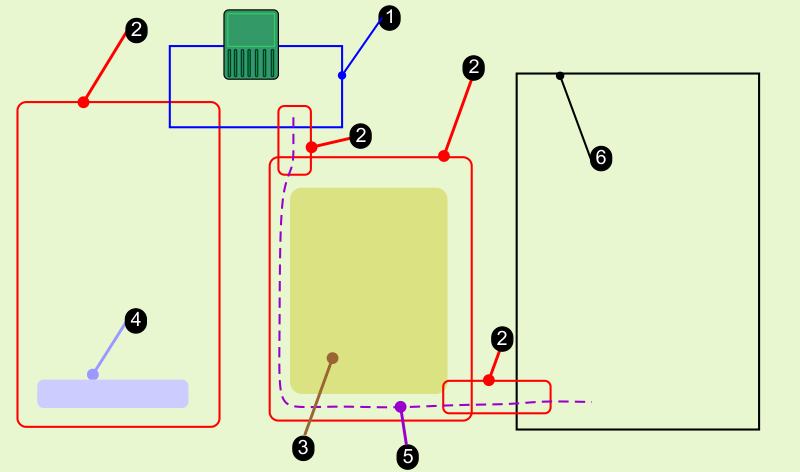

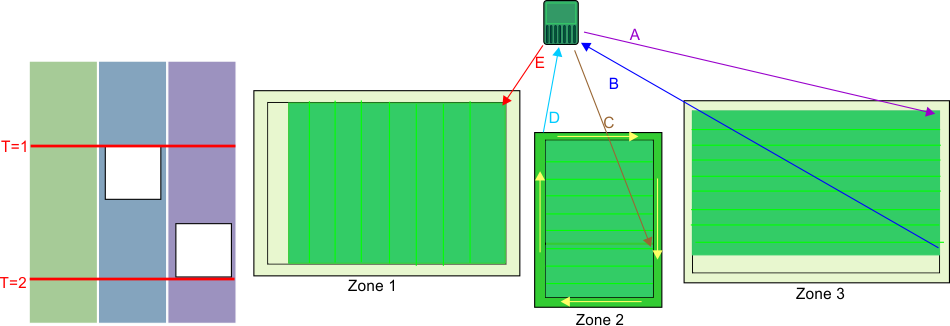

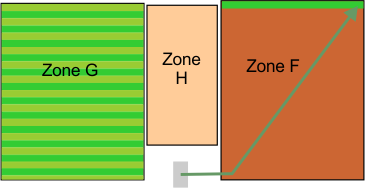

The process

of sequential scheduling is shown in the following figure. Consider

the installation setup with three separate

zones to be mowed. The defined schedule dictates that zones 2 and

3 are unavailable for certain times of the day.

At time T=0, the robot starts

mowing zone 1. When the whole area has been mowed, it mows the border

and then returns to the station (A). It then

moves to zone 2 (B), and mows until time T=1, at which point, the

defined schedule dictates that zone 2 is unavailable.

The robot returns to the station (C).

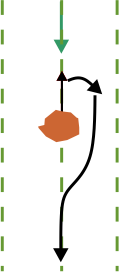

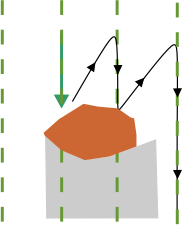

Note: When mowing the border, the robot follows the same direction as was

used when the border was discovered.

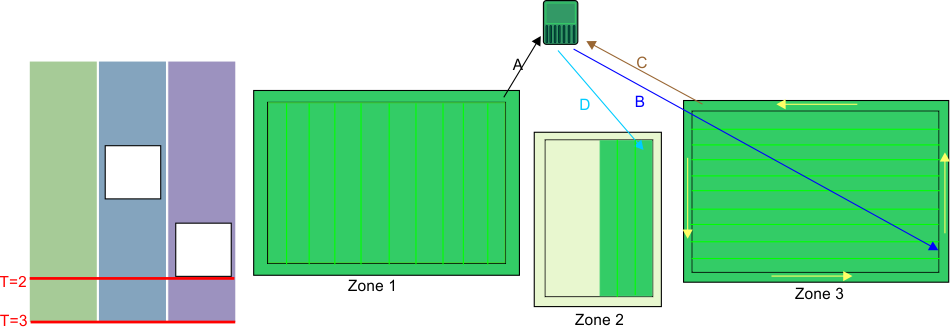

At the time T=1, the robot will

move to zone 3 (A) and mow there until the schedule dictates that

zone 3 is unavailable. The robot will return

to the station (B) and then return to finish mowing zone 2 (C). When

the area has been mowed, it will mow the border

before returning to a station (D). Since zone 3 is still unavailable,

it will move to zone 1 and start mowing in

a new direction (E).

At time T=2, zone 1 is not complete,

when zone 3 becomes available.

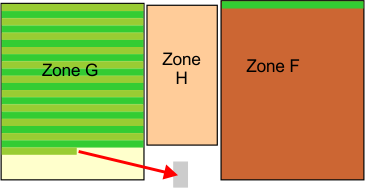

At time T=2, the robot will complete

mowing zone 1 and then mow the border before returning to the station

(A). It will then return to zone 3 (B) and

complete mowing the zone and the border. It will return to the station

(C) and then start mowing zone 2 in a new

direction (D).

Note: It is strongly recommended to use sequential scheduling. If it is

not used, it is necessary to define the percent of time

to be spent working in a particular zone and to specify

explicitly the number of times per week that the border is to be mowed.