Maintenance

Maintenance Safety

- If you leave the key in the switch,

someone could accidently start the engine and seriously injure you

or other bystanders. Remove the key from

the switch before you perform any maintenance.

- Before you leave the operator’s position, do the following:

- Park the machine on a level surface.

- Disengage the drives.

- Engage the parking brake.

- Shut off the engine and remove

the key.

- Wait for the machine to cool before

performing maintenance.

- Do not allow untrained personnel

to service the machine.

- Keep your hands and feet away

from moving parts or hot surfaces. If possible, do not make adjustments

with the engine running.

- Keep all guards, shields, switches,

and all safety devices in place and in proper working condition. Frequently

check for worn or deteriorating components

and replace them with genuine Toro parts when necessary.

- Carefully release pressure from

components with stored energy.

|

Warning |

|

Removing or modifying original

equipment, parts, and/or accessories may alter the warranty, controllability,

and safety of the machine. Making unauthorized

modifications to the original equipment or failing to use original Toro parts could lead

to serious injury or death.

- Check the parking brake operation

frequently. Adjust and service it as required.

- Never tamper with safety devices.

Check their proper operation regularly.

- Clean grass, leaves, excessive

grease and oil, and other debris from the cutting unit, muffler, drives,

grass catcher, and engine compartment to

prevent fires.

- Clean up oil or fuel spills and

remove fuel-soaked debris.

- Do not rely solely on mechanical

or hydraulic jacks to support the machine. Use adequate jack stands.

- Keep all parts in good working

condition and all hardware tightened, especially the blade-attachment

hardware.

- To ensure optimum performance,

use only genuine Toro replacement parts and accessories.

Replacement parts and accessories made by other manufacturers could

be dangerous.

Recommended Maintenance Schedule

| After the first 8 hours

|

Change the engine oil.

|

| After the first 50 hours

|

Check the lug-nut torque.

|

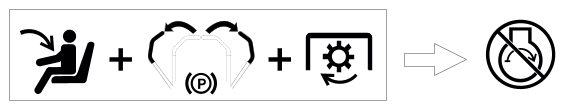

| Before each use or daily |

Check the safety-interlock system.

|

| Check the air cleaner for dirty, loose, or damaged parts. |

| Check the engine-oil level.

|

| Clean the air-intake screen.

|

| Inspect the blades. |

| Inspect the grass deflector for damage.

|

| After each use |

Clean grass and debris from the machine.

|

| Clean the mower-deck housing.

|

| Every 25 hours |

Grease the caster wheel bearings (more often in sandy soil conditions). |

| Check the tire pressure.

|

| Check the belts for wear or cracks.

|

| Every 100 hours |

Change the engine oil (more often in dirty or dusty conditions). |

| Replace or clean and gap the spark plug.

|

| Replace the in-line fuel filter.

|

| Every 100 hours or yearly, whichever

comes first |

Replace the paper air-cleaner element (more often in dirty or dusty

conditions). |

| Every 200 hours

|

Change the engine-oil filter (more often in dirty or dusty conditions). |

| Every 300 hours

|

Check and adjust the valve clearance. Contact an Authorized Service

Dealer. |

| Yearly |

Check the lug-nut torque.

|

| Before storage |

Charge the battery and disconnect the battery cables. |

| Perform all maintenance procedures listed above before storage. |

| Paint any chipped surfaces. |

| |

Refer to your engine owner's manual

for additional maintenance procedures.

Pre-Maintenance Procedures

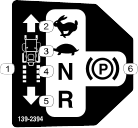

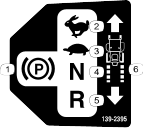

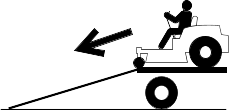

Moving a Non-Functioning Machine

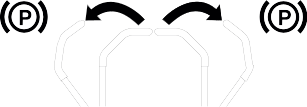

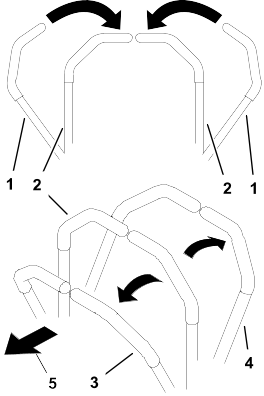

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine and wait for all moving parts to stop before leaving the

operating position.

-

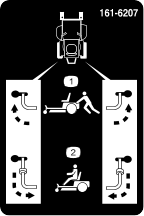

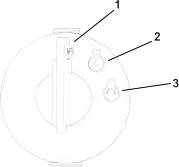

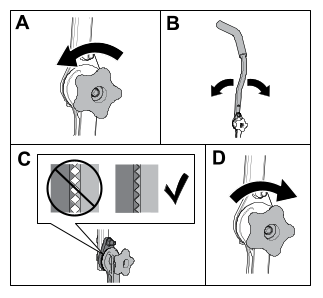

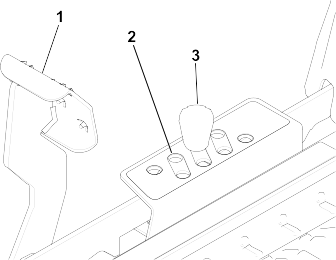

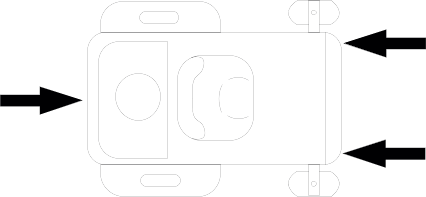

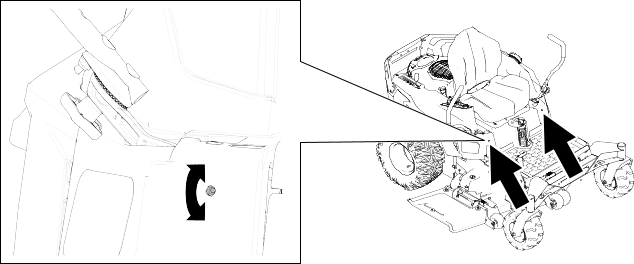

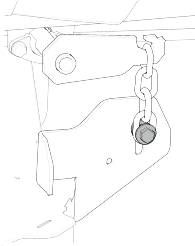

Locate the

bypass levers  on the frame on both sides of

the engine.

on the frame on both sides of

the engine.

-

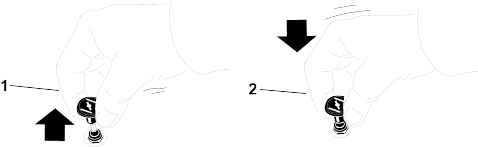

Move both

bypass levers forward through the slotted hole and over to lock them

in place  .

.

|

Warning |

|

Contact

with hot surfaces may cause personal injury.

Keep your hands,

feet, face, clothing and other body parts away the engine, muffler

and other hot surfaces.

|

Warning |

|

The

machine could unintentionally move while the bypass levers are locked

forward in the slot and injure you or bystanders.

Lock the bypass

levers rearward after moving the machine.

-

Disengage

the parking brake by moving both motion-control levers down to the

center, unlocked position.

Note: Do not start the machine.

-

Move the

machine as required.

Always

push the machine by hand. Do not tow the machine, because towing may

damage it.

-

Move the

motion-control levers outward to the Park position.

-

Move both

bypass levers rearward and over through the slotted hole to lock them

in place  .

.

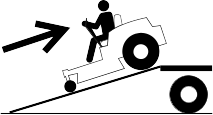

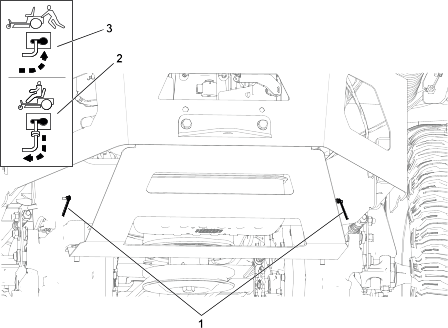

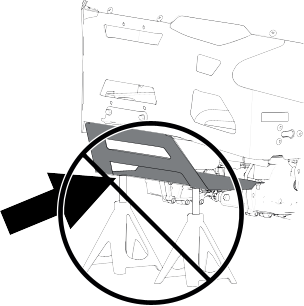

Raising the Machine

-

Use jackstands

to support the machine when you raise it.

|

Warning |

|

Supporting

the machine on the lower muffler shield may damage the shield and

cause the machine to fall, injuring you or bystanders.

Do

not use the lower muffler shield to lift or support the machine.

Lubrication

Greasing the Bearings

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine and wait for all moving parts to stop before leaving the

operating position.

-

Clean the

grease fittings with a rag.

Note: Scrape any paint off the front of the fittings.

-

Connect a

grease gun to each fitting.

-

Pump grease

into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any

excess grease.

Engine Maintenance

Engine Safety

- Keep your hands, feet, face, other

body parts, and clothing away from the muffler and other hot surfaces.

Wait for the engine to cool before performing

maintenance.

- Do not change the engine governor

speed or overspeed the engine.

Air Cleaner Service

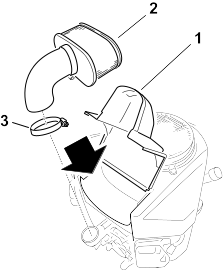

Removing the Air-Cleaner Element

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine and wait for all moving parts to stop before leaving the

operating position.

-

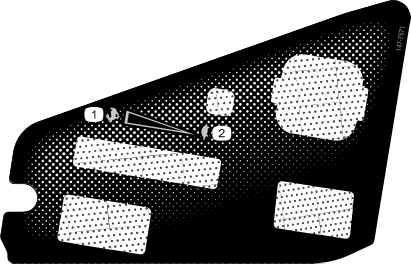

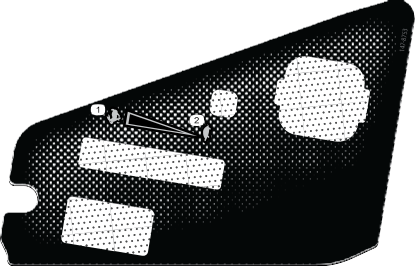

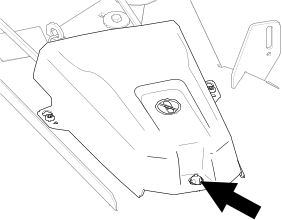

Clean around

the air-cleaner cover  to prevent dirt from getting

into the engine and causing damage.

to prevent dirt from getting

into the engine and causing damage.

-

Loosen the

hose clamp  and remove the paper element

and remove the paper element  .

.

Servicing the Paper Air-Cleaner Element

-

Clean the

paper element by tapping it gently to remove dust.

Note: If it is very dirty, replace the paper element with a new one.

-

Inspect the

element for tears, an oily film, or damage to the rubber seal.

-

Replace the

paper element if it is damaged.

Do

not clean the paper filter.

Engine-Oil Service

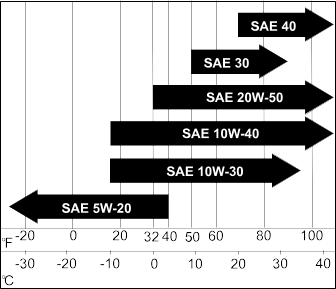

Engine-Oil Specifications

| Oil Type

|

Detergent oil (API service SF,

SG, SH, SJ, or SL) |

| Crankcase Capacity |

1.8 L (61 fl oz);

without filter; 2.1 L (70 fl oz) with filter

|

| Viscosity

|

See the table below |

| |

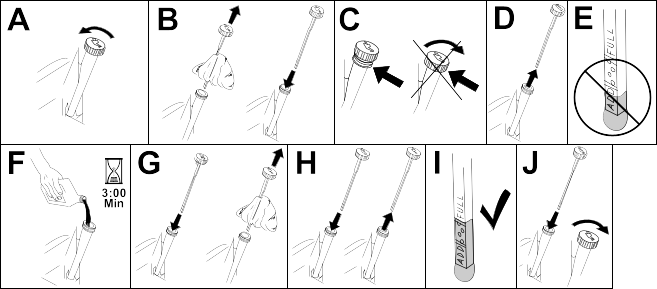

Checking the Engine-Oil Level

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Wait for

the engine to cool so that the oil has had time to drain into the

sump.

-

To keep dirt,

grass clippings, etc., out of the engine, clean the area around the

oil-fill cap and dipstick before removing

it.

-

Check the

engine-oil level as shown.

If

you overfill or underfill the engine crankcase with oil and run the

engine, you may damage the engine.

Changing the Engine Oil

-

Park the

machine so that the drain side is slightly lower than the opposite

side to ensure that the oil drains completely.

-

Disengage

the blade-control switch (PTO) and move the motion-control levers

outward to the Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Drain the

oil from the engine.

-

Slowly pour

approximately 80% of the specified oil into the filler tube and slowly

add the additional oil to bring it to the

Full mark.

-

Dispose of

the used oil per local regulations.

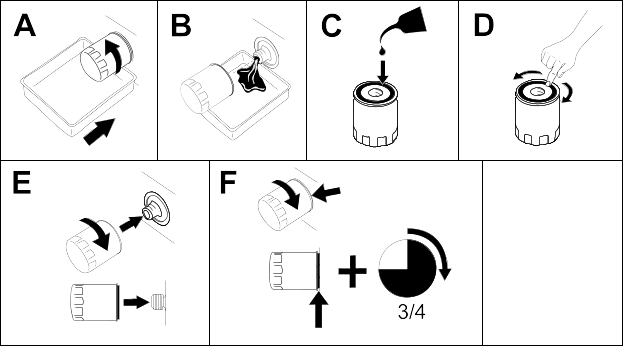

Changing the Engine-Oil Filter

-

Drain the

oil from the engine.

-

Change the

engine-oil filter as shown.

Note: Ensure that the oil-filter gasket touches the engine, and then turn

the oil filter an extra 3/4 turn.

-

Slowly add

the specified oil into the filler tube to bring the oil level to the Full mark.

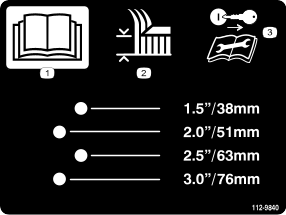

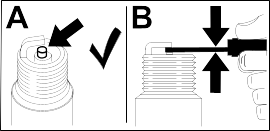

Servicing the Spark Plug

Ensure that

the air gap between the center and side electrodes is correct before

installing the spark plug. Use a spark plug

wrench for removing and installing the spark plug and a gapping

tool or feeler gauge to check and adjust the air gap. Install

a new spark plug if necessary.

Type: NGK® BPR4ES

Air gap: 0.76 mm (0.03 inch)

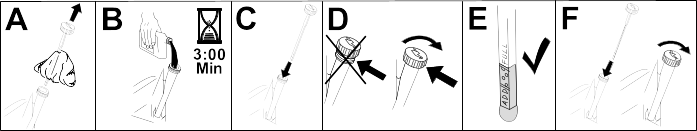

Removing the Spark Plug

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Clean the

area around the base of the plug to keep dirt and debris out of the

engine.

-

Remove the

spark plug.

Checking the Spark Plug

Do not clean the spark plug(s).

Always replace the spark plug(s) when it has a black coating, worn

electrodes, an oily film, or cracks.

If

you see light brown or gray on the insulator, the engine is operating

properly. A black coating on the insulator usually

means the air cleaner is dirty.

-

Set the gap

to 0.75 mm (0.03 inch).

Installing the Spark Plug

Cleaning the Cooling System

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Remove the

air filter from the engine.

-

Remove the

engine shroud.

-

To prevent

debris entering the air intake, install the air filter to the filter

base.

-

Clean debris

and grass from the parts.

-

Remove the

air filter and install the engine shroud.

-

Install the

air filter.

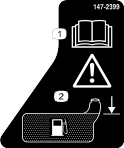

Fuel Maintenance

|

Danger |

|

In certain conditions, fuel is

extremely flammable and highly explosive. A fire or explosion from

fuel can burn you and others and can damage

property.

Refer to Fuel Safety for a complete list of fuel related

precautions.

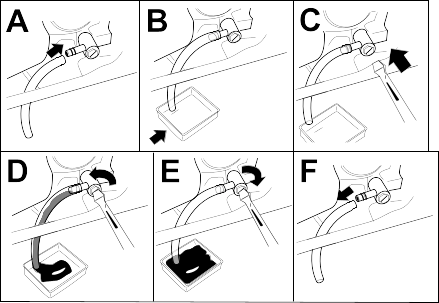

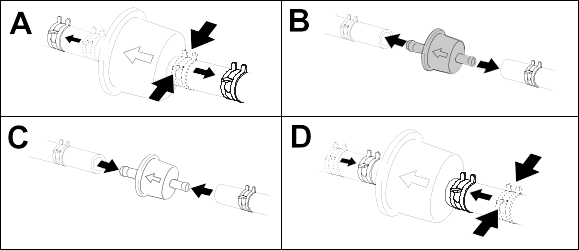

Replacing the Fuel Filter

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Clamp the

fuel lines on both sides of the fuel filter.

-

Replace the

filter.

Note: Ensure that the flow-direction arrow on the replacement filter points

toward the engine.

Never

install a dirty filter after removing it from the fuel line.

-

Remove the

clamps blocking the fuel flow.

Electrical System Maintenance

Electrical System Safety

- Disconnect the cable from the

negative terminal of the battery before repairing the machine.

- Charge the battery in an open,

well-ventilated area, away from sparks and flames. Unplug the charger

before connecting or disconnecting the

battery. Wear protective clothing and use insulated tools.

Battery Service

Removing the Battery

|

Warning |

|

Battery terminals or metal tools

could short against metal machine components, causing sparks. Sparks

can cause the battery gasses to explode,

resulting in personal injury.

- When removing or installing the

battery, do not allow the battery terminals to touch any metal parts

of the machine.

- Do not allow metal tools to short

between the battery terminals and metal parts of the machine.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Disconnect

the negative (black) ground cable from the battery post.

Note: Retain all fasteners.

|

Warning |

|

Incorrectly

removing the cables from battery could damage the machine and cables,

causing sparks. Sparks can cause the battery

gasses to explode, resulting in personal injury.

- Always disconnect the negative

(black) battery cable before disconnecting the positive (red) cable.

- Always connect the positive (red)

battery cable before connecting the negative (black) cable.

-

Slide the

rubber cover off the positive (red) cable.

-

Disconnect

the positive (red) cable from the battery post (+).

Note: Retain all fasteners.

-

Remove the

battery hold-down and lift the battery from the battery tray.

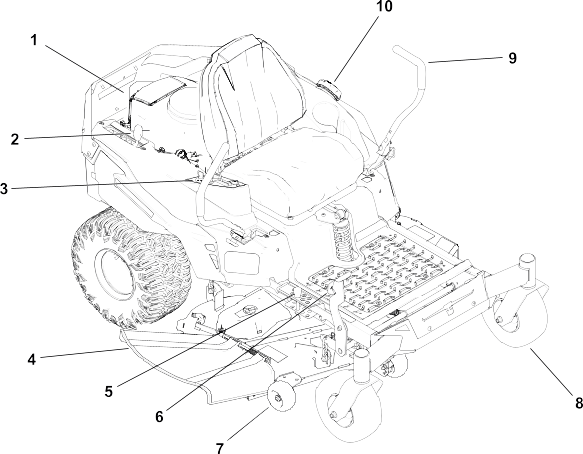

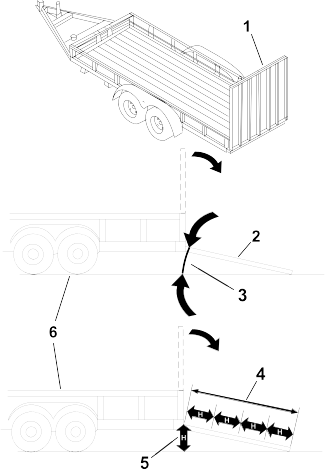

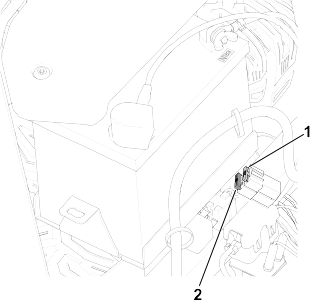

G440221

-

Battery

-

Terminal boot

-

Negative (–) battery post

-

Wing nut, washer, and bolt

-

Battery hold-down

-

Bolt, washer, and nut

-

Positive (+) battery post

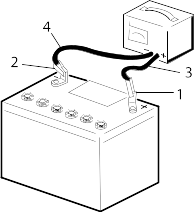

Charging the Battery

|

Warning |

|

Charging the battery produces

gasses that can explode.

Never smoke near the battery and

keep sparks and flames away from battery.

Always keep the battery fully

charged. This is especially important to prevent battery damage when

the temperature is below 0°C (32°F).

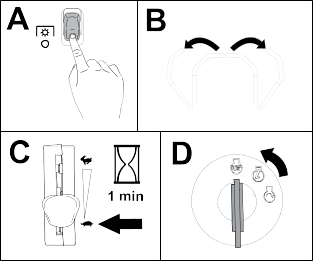

-

Remove the

battery from the machine.

-

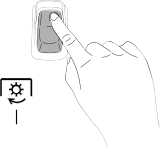

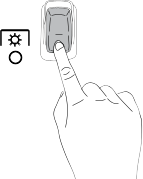

Charge the

battery per the battery charger manufacturer’s instructions.

Do

not overcharge the battery; otherwise, you could damage it.

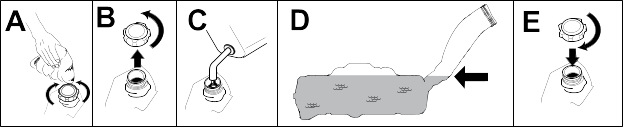

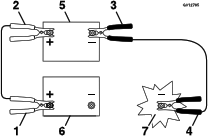

G003792S

- Positive

battery post

- Negative

battery post

- Red (+)

charger lead

- Black

(-) charger lead

-

When the

battery is fully charged, unplug the charger from the electrical outlet

(if applicable), then disconnect the charger

leads from the battery posts.

Cleaning the Battery

Note: Keep the terminals and the entire battery case clean, because a dirty

battery discharges slowly.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine and wait for all moving parts to stop before leaving the

operating position.

-

Remove the

battery from the machine.

-

Wash the

entire case with a solution of baking soda and water.

-

Rinse the

battery with clear water.

-

Coat the

battery posts and cable connectors with Grafo 112X (skin-over) grease

or petroleum jelly to prevent corrosion.

-

Install the

battery.

Installing the Battery

-

Position

the battery in the tray.

-

Using the

fasteners previously removed, install the positive (red) battery cable

to the positive (+) battery terminal.

-

Using the

fasteners previously removed, install the negative battery cable to

the negative (-) battery terminal.

-

Slide the

red terminal boot onto the positive (red) battery post.

-

Secure the

battery with the hold-down.

G440221

-

Battery

-

Terminal boot

-

Negative (–) battery post

-

Wing nut, washer, and bolt

-

Battery hold-down

-

Bolt, washer, and nut

-

Positive (+) battery post

Jump-Starting the Machine

|

Warning |

|

Jump-starting the battery can

produce gasses that can explode.

Do not smoke near the battery,

and keep sparks and flames away from battery.

|

Danger |

|

Jump-starting a weak battery that

is cracked or frozen or has a low electrolyte level or an open/shorted

battery cell can cause an explosion, resulting

in serious personal injury.

Do not jump-start a weak battery

if these conditions exist.

-

Check and

clean corrosion from the battery terminals before jump-starting. Ensure

that the connections are tight.

|

Caution |

|

Corrosion

or loose connections can cause unwanted electrical voltage spikes

at any time during the jump-starting procedure.

Do not attempt

to jump-start the machine with loose or corroded battery terminals,

or damage to the engine may occur.

-

Make sure

that the booster battery is a good and fully charged lead-acid battery

at 12.6 V or greater.

Note: Use properly sized jumper cables with short lengths to reduce voltage

drop between systems. Make sure that the cables are

color coded or labeled for the correct polarity.

|

Warning |

|

Batteries

contain acid and produce explosive gases.

- Shield your eyes and face from

the batteries at all times.

- Do not lean over the batteries.

Note: Ensure that the vent caps are tight and level. Place a damp cloth,

if available, over any vent caps on both batteries. Also

ensure that the machines do not touch and

that both electrical systems are off and at the same rated system

voltage. These instructions are for

negative ground systems only.

-

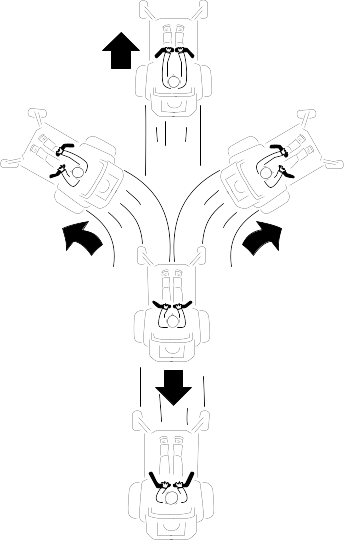

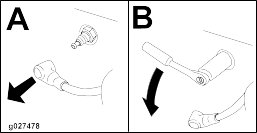

Connect the

positive (+) cable to the positive (+) terminal of the discharged

battery that is wired to the starter or solenoid

as shown:

g012785

- Positive

(+) cable on discharged battery

- Positive

(+) cable on booster battery

- Negative

(–) cable on the booster battery

- Negative

(–) cable on the engine block

- Booster

battery

- Discharged

battery

- Engine

block

-

Connect the

other end of the positive (+) jumper cable to the positive terminal

of the battery in the other machine.

-

Connect an

end of the negative (-) jumper cable to the negative post of the battery

in the other machine.

-

Connect the

other end of the negative (-) jumper cable to a ground point, such

as an unpainted bolt or chassis member.

-

Start the

engine in the other machine. Let it run a few minutes, then start

your engine.

-

Remove the

cables in the reverse order of connection.

-

Install the

cover to the jump post.

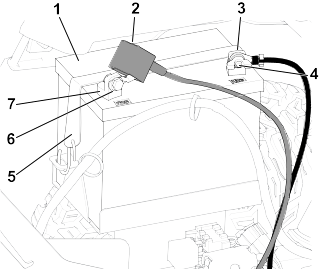

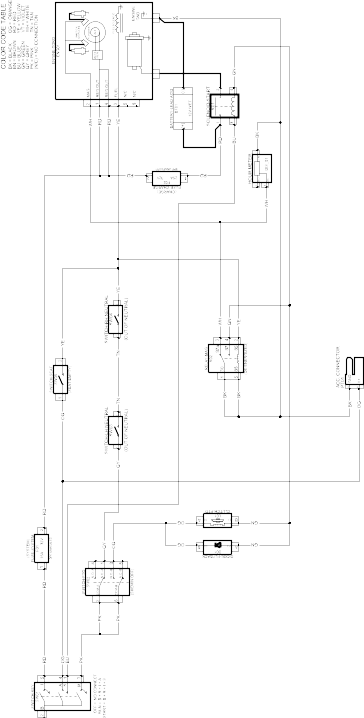

Servicing the Fuses

The electrical

system is protected by fuses. It requires no maintenance; however,

if a fuse blows, check the component/circuit

for a malfunction or short.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Replace the

blown fuse with a new fuse.

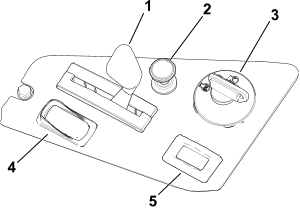

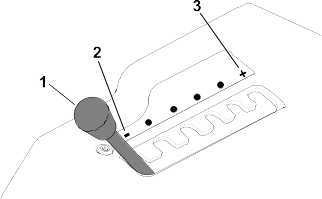

G440132

- Charge

circuit (15 A)

- Main

(25 A)

Drive System Maintenance

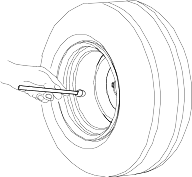

Checking the Tire Pressure

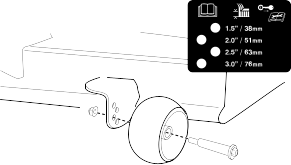

Maintain the air pressure in the

front and rear tires as specified. Uneven tire pressure can cause

an uneven cut. Check the pressure at the valve

stem when the tires are cold to get the most accurate pressure reading.

-

Inflate the

front caster wheel tires to 206 kPa (30 psi) or the pressure indicated

on the sidewall, whichever is lower.

-

Inflate the

rear drive-wheel tires to 90 kPa (13 psi).

Checking the Wheel Lug Nuts

-

Check and

torque the wheel lug nuts to 108

N∙m (80 ft-lb).

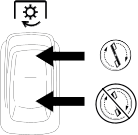

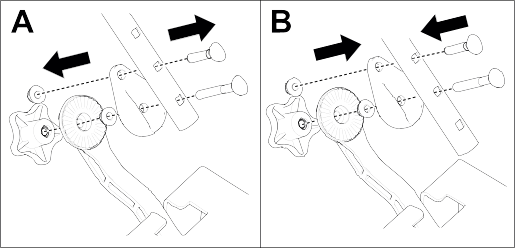

Adjusting the Tracking

When driving

the machine forward full speed across a flat, level surface, if the

machine pulls to 1 side, adjust the tracking.

If the machine

pulls to the left, adjust the right motion-control lever; if the machine

pulls to the right, adjust the left motion-control

lever.

Note: You can adjust the tracking only for driving forward.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Locate the

tracking-adjustment bolt near the motion-control lever on the particular

side that needs adjusting.

-

Rotate the

bolt to decrease the speed for that particular wheel.

Note: Rotate the bolt a small amount to make minor adjustments.

-

Start the

machine and drive forward across a flat, level surface with the motion-control

levers fully forward to check if the machine

tracks straight. Repeat the procedure as needed.

Belt Maintenance

Inspecting the Belts

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine and wait for all moving parts to stop before leaving the

operating position.

-

Set the height

of cut at the lowest cutting position.

-

Inspect the

belt for wear. Replace the belt if it is worn.

The signs of

a worn belt include squealing while the belt is rotating; the blades

slipping while cutting grass; and frayed

edges, burn marks, and cracks on the belt.

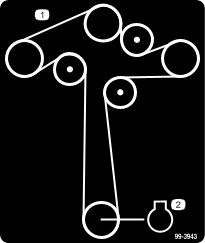

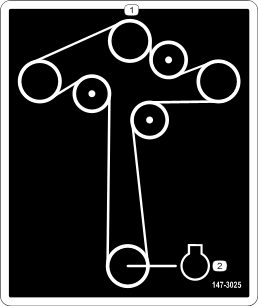

Replacing the Mower Belt

The signs of a worn belt include

squealing while the belt is rotating, blades slipping while cutting

grass, and frayed edges, burn marks, and cracks

on the belt. Replace the mower belt if any of these conditions are

evident.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Set the height

of cut at the lowest cutting position.

-

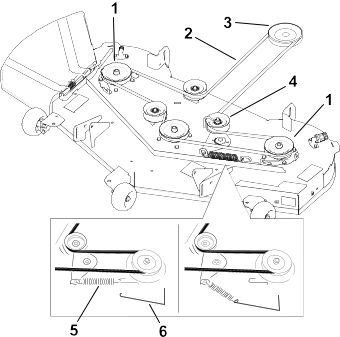

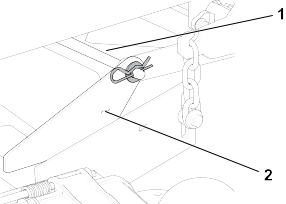

Remove the

pulley covers as follows:

- For 50-inch or 54-inch decks,

remove the hairpin cotter

and push in the tab on

the cover.

and push in the tab on

the cover.

- For 60-inch decks, pull up the

side of the cover with the grommet and slide the cover off.

-

For 50-inch

or 54-inch decks, loosen the nut securing the wire form to the idler

pulley.

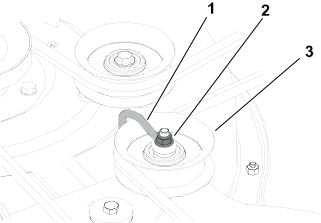

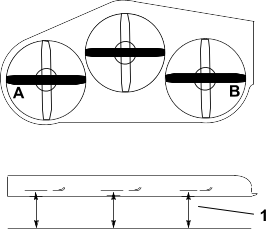

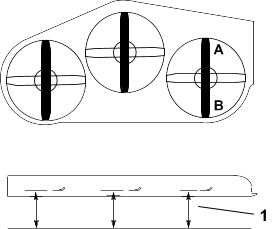

G336421s

- Wire

form

- Nut

- Idler

pulley

-

Using a spring-removal

too (Toro Part No. 92-5771), remove the idler spring from the deck

hook to remove tension on the idler pulley.

|

Warning |

|

The

spring is under tension when installed and can cause personal injury.

Be careful when removing the belt.

G454314

- Deck

pulley

- Mower

belt

- Engine

pulley

- Idler

pulley

- Spring

- Spring-removal

tool

-

Roll the

belt off the pulleys.

-

Route the

new belt around the engine pulley and mower pulleys.

-

Use the spring-removal

tool to install the idler spring over the deck hook and place tension

on the idler pulley and the mower belt.

-

Tighten the

nut securing the wire form to the idler pulley.

Note: Position the wire form against the idler arm.

-

Install the

pulley covers.

Mower-Deck Maintenance

Blade Safety

- Inspect the blades periodically

for wear or damage.

- Use care when checking the blades.

Wrap the blade(s) or wear gloves and use caution when servicing them.

Only replace damaged blades; never straighten

or weld them.

- On multi-bladed machines, take

care as rotating one blade can cause other blades to rotate.

- Replace worn or damaged blades

and bolts in sets to preserve balance.

Blade Service

To ensure a superior quality of

cut, keep the blades sharp. For convenient sharpening and replacement,

keep extra blades on hand.

Replace the

blades if they hit a solid object, or if the blade is out of balance

or bent.

Before Inspecting or Servicing the Blades

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Disconnect

the spark-plug wires from the spark plugs.

Checking for Bent Blades

The machine must be on a level

surface for this procedure.

-

Raise the

mower deck to the highest height-of-cut position.

-

While wearing

thickly padded gloves, or other adequate hand protection, slowly rotate

the blade into a position that allows

you to measure the distance between the cutting edge and the level

surface.

-

Measure from

the tip of the blade to the level surface.

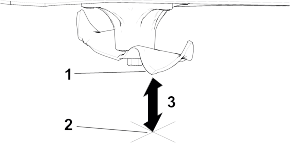

G451422

- Blade

(in position for measuring)

- Level

surface

- Measured

distance between blade and the surface (A)

-

Rotate the

same blade 180 degrees so that the opposite blade edge is now in the

same position.

G451423

- Blade

edge previous measured

- Opposite

blade edge

-

Measure from

the tip of the blade to the level surface.

G451422

- Blade

(in position for measuring)

- Level

surface

- Measured

distance between blade and the surface (B)

-

If the difference

between A and B is greater than 3 mm (1/8 inch), replace the blade.

Note: If you replace the blade and the difference continues to exceed 3

mm (1/8 inch), the blade spindle could be bent. Contact

an Authorized Service Dealer for service.

-

Repeat this

procedure each blade.

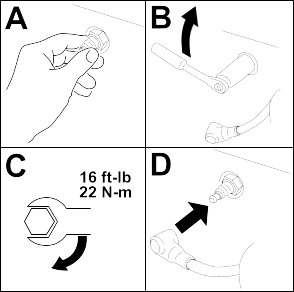

Removing the Blades

-

Hold the

blade end using a rag or thickly padded glove.

-

Remove the

blade as shown.

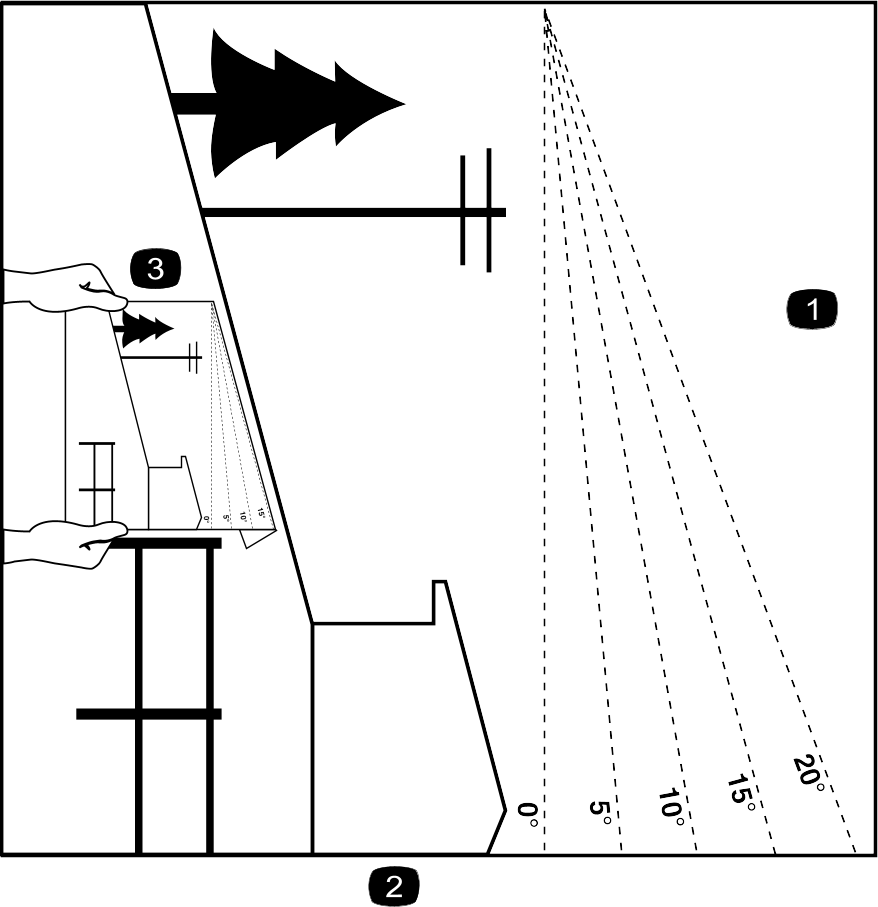

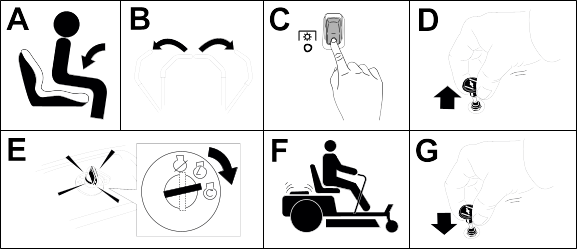

Sharpening the Blades

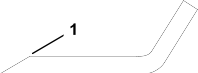

-

Use a file

to sharpen the cutting edge at both ends of the blade. Ensure to maintain

the original angle  .

.

Note: Remove the same amount of material from both cutting edges so that

the blade retains its balance.

-

Check the

balance of the blade  by putting it on a blade

balancer

by putting it on a blade

balancer  .

.

Note: If the blade stays in a horizontal position, the blade is balanced

and can be used.

If the blade

is not balanced, file some metal off the end of the sail area only.

-

Repeat this

procedure until the blade is balanced.

Installing the Blades

|

Warning |

|

Operating a machine after incorrectly

installing the blade assembly and/or not using genuine Toro blade and blade hardware

could allow a blade or blade component to be thrown out from under

the deck, resulting in serious injury

or death.

Always install genuine Toro blades and blade

hardware according to the instructions.

-

Install the

blade as shown.

Note: The curved part of the blade must be pointing upward toward the inside

of the mower to ensure proper cutting.

-

Torque the

blade bolt to 81

to 108 N·m (60 to 80 ft-lb).

Leveling the Mower Deck

Ensure that

the mower deck is level any time you install the mower deck or when

you see an uneven cut on your lawn.

Preparing to Level the Mower Deck

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Ensure that

the tires are inflated to the correct specifications and the caster

wheels are facing straight forward.

-

Check the

mower deck for bent blades; remove and replace any bent blades.

-

Raise the

mower deck to the 76 mm (3 inch) height-of-cut setting.

Checking the Mower-Deck Level

-

Position

the blades side-to-side.

-

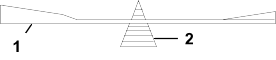

Measure at

locations  and

and  from a level surface to the cutting

edge of the blade tips

from a level surface to the cutting

edge of the blade tips  .

.

The difference between the measurements

should be no more than 5 mm (3/16 inch). If the measurement is larger,

adjust the side-to-side level.

-

Position

1 blade front-to-rear.

-

Measure at

locations  and

and  from a level surface to the cutting

edge of the blade tips

from a level surface to the cutting

edge of the blade tips  .

.

The front blade tip should be

1.6 to 7.9 mm (1/16 to 5/16 inch) lower than the rear blade tip. If

the measurement is not correct, adjust

the front-to-rear level.

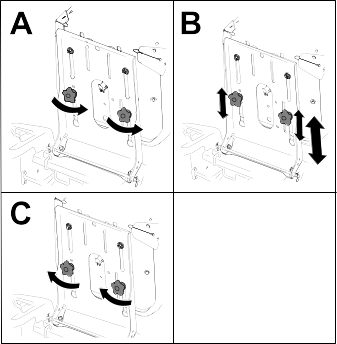

Leveling the Mower Deck

-

Set the anti-scalp

rollers to the top holes or remove them completely for this procedure.

-

Set the height-of-cut

lever to the 76 mm (3 inch) position.

-

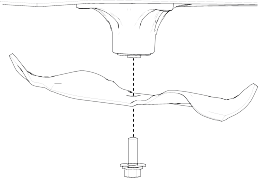

Place 2 blocks  , each having a thickness of 6.6

cm (2-5/8 inches), under each side of the front edge of the deck.

, each having a thickness of 6.6

cm (2-5/8 inches), under each side of the front edge of the deck.

Do

not place the blocks under the anti-scalp roller brackets.

-

Place 2 blocks  , each having a thickness of 7.3

cm (2-7/8 inches), under each side of the rear edge of the deck.

, each having a thickness of 7.3

cm (2-7/8 inches), under each side of the rear edge of the deck.

-

Loosen the

fasteners connecting the chains on all 4 corners of the deck and ensure

that the mower deck sits securely on all

4 blocks.

-

Remove any

slack from the deck chains and ensure that the deck-lift foot lever

is pushed back against the stop.

-

Tighten the

fasteners.

-

Ensure that

the blocks fit snugly under the deck edge and that all attachment

bolts are tight.

-

Check the

side-to-side level and front-to-rear level; repeat the procedure until

the measurements are correct.

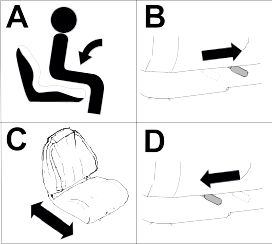

Removing the Mower Deck

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

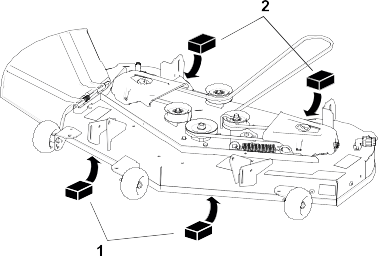

Lower the

height-of-cut lever to the lowest position.

-

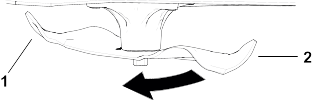

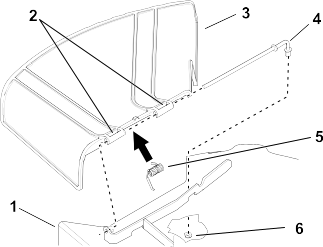

Remove the

hairpin cotter and washer from the front support rod  , and remove the rod from the

deck bracket

, and remove the rod from the

deck bracket  .

.

Note: Retain all parts for future installation.

-

Lift the

deck and chains off the brackets at all 4 corners of the deck.

-

Slide the

mower deck rearward to remove the mower belt from the engine pulley.

-

Slide the

mower deck out from underneath the machine.

Installing the Mower Deck

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Slide the

mower deck under the machine.

-

Lower the

height-of-cut lever to the lowest position.

-

Lift the

mower deck chains onto the deck-lift brackets.

-

Attach the

front support rod  to the deck bracket

to the deck bracket  with the hairpin cotter and washer.

with the hairpin cotter and washer.

-

Install the

mower belt onto the engine pulley.

Replacing the Grass Deflector

|

Danger |

|

An uncovered discharge opening

allows objects to be thrown toward you or bystanders. Also, contact

with the blade could occur. Thrown objects

or blade contact will cause serious injury or death.

Do not operate

the mower with the discharge deflector raised, removed, or altered

unless a grass collection system or mulch

kit is in place and working properly.

-

Park the

machine on a level surface, disengage the blade-control switch, and

move the motion-control levers outward to the

Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

Remove the

nut from the rod under the mower deck.

G451625

- Mower

deck

- Grass-deflector

pivot

- Grass

deflector

- Rod

- Spring

- Nut

-

Slide the

rod out.

-

Remove the

damaged or worn grass deflector.

-

Install the

new grass deflector.

-

Slide the

straight end of the rod through the rear grass deflector pivot.

-

Place the

spring on the rod, with end wires down, and between the grass deflector

brackets.

-

Slide the

rod through the second grass-deflector pivot.

-

Insert the

rod at the front of the grass deflector into the bracket on the deck.

-

Secure the

rear end of the rod into the mower with the nut.

The

grass deflector must be spring-loaded in the down position. Lift the

deflector up to test that it snaps into the full-down

position.

Cleaning

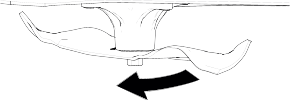

Washing the Underside of the Mower

Deck

You can wash the machine with

a mild detergent and water. Do not pressure wash the machine. Avoid

excessive use of water, especially near

the control panel, under the seat, around the engine, hydraulic pumps,

and motors.

Wash the underside of the mower

deck after each use to prevent grass buildup for improved mulch action

and clipping dispersal.

-

Park the

machine on a level surface, disengage the blade-control switch (PTO),

and move the motion-control levers outward

to the Park position.

-

Shut off

the engine, remove the key, and wait for all moving parts to stop

before leaving the operating position.

-

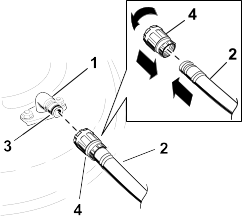

Attach a

hose  to the hose coupling

to the hose coupling  , then attach the hose coupling

to the end of the mower washout fitting

, then attach the hose coupling

to the end of the mower washout fitting  and turn the water on high.

and turn the water on high.

Note: Spread petroleum jelly on the washout fitting O-ring  to make the coupling slide on

easier and protect the O-ring.

to make the coupling slide on

easier and protect the O-ring.

-

Sit on the

seat, lower the mower to the lowest height-of-cut, and start the engine.

-

Engage the

blade-control switch and let the mower run for 1 to 3 minutes.

-

Disengage

the blade-control switch, shut off the engine, remove the key, and

wait for all moving parts to stop.

-

Turn the

water off and remove the coupling from the washout fitting.

Note: If the mower is not clean after 1 washing, soak it and let it stand

for 30 minutes. Then repeat the process.

-

Run the mower

again for 1 to 3 minutes to remove excess water.

|

Warning |

|

A

broken or missing washout fitting could expose you and others to thrown

objects or blade contact. Contact with a blade or

thrown debris can cause injury or death.

- Replace broken or missing washout

fitting immediately, before using machine again.

- Never put your hands or feet under

the mower or through openings in the machine.

Disposing of Waste

Engine oil, batteries,

hydraulic fluid, and engine coolant are pollutants to the environment.

Dispose of these according to your state and

local regulations.

Troubleshooting

The fuel tank is showing signs

of collapsing or the machine is frequently showing signs of running

out of fuel.

| Possible Cause |

Corrective Action |

| The air-cleaner paper element

clogged. |

-

Clean the

paper element.

|

The engine overheats.

| Possible Cause |

Corrective Action |

| The engine load is excessive. |

-

Reduce the

ground speed.

|

| The oil level in the crankcase

is low. |

-

Add oil to

the crankcase.

|

| The cooling fins and air

passages under the engine-blower housing are plugged. |

-

Remove the

obstruction from the cooling fins and air passages.

|

| The air cleaner is dirty. |

-

Clean or

replace the air-cleaner element.

|

| Dirt, water, or stale fuel

is in the fuel system. |

-

Contact an

Authorized Service Dealer.

|

The starter does not crank.

| Possible Cause |

Corrective Action |

| The blade-control switch

is engaged. |

-

Disengage

the blade-control switch.

|

| The motion-control levers

are not in the park position. |

-

Move the

motion-control levers outward to the park position.

|

| The battery is dead. |

-

Charge the

battery.

|

| The electrical connections

are corroded or loose. |

-

Check the

electrical connections for good contact.

|

| A fuse is blown. |

-

Replace the

fuse.

|

| A relay or switch is damaged. |

-

Contact an

Authorized Service Dealer.

|

The engine does not start, starts

hard, or fails to keep running.

| Possible Cause |

Corrective Action |

| The fuel tank is empty. |

-

Fill the

fuel tank.

|

| The choke (if applicable)

is not on. |

-

Move the

choke lever to the on position.

|

| The air cleaner is dirty. |

-

Clean or

replace the air-cleaner element.

|

| The spark-plug wire(s)

is loose or disconnected. |

-

Install the

wire(s) on the spark plug.

|

| The spark plug(s) is pitted,

fouled, or the gap is incorrect.

|

-

Install a

new, correctly gapped spark plug(s).

|

| There is dirt in fuel filter. |

-

Replace the

fuel filter.

|

| Dirt, water, or stale fuel

is in fuel system. |

-

Contact an

Authorized Service Dealer.

|

| There is incorrect fuel

in the fuel tank. |

-

Drain the

tank and replace the fuel with the proper type.

|

| The oil level in the crankcase

is low. |

-

Add oil to

the crankcase.

|

The engine loses power.

| Possible Cause |

Corrective Action |

| The engine load is excessive. |

-

Reduce the

ground speed.

|

| The air cleaner is dirty. |

-

Clean the

air-cleaner element.

|

| The oil level in the crankcase

is low. |

-

Add oil to

the crankcase.

|

| The cooling fins and air

passages under the engine blower housing are plugged. |

-

Remove the

obstruction from the cooling fins and air passages.

|

| The spark plug(s) is pitted,

fouled, or the gap is incorrect.

|

-

Install a

new, correctly gapped spark plug(s).

|

| The fuel-tank vent is blocked. |

-

Contact an

Authorized Service Dealer.

|

| There is dirt in the fuel

filter. |

-

Replace the

fuel filter.

|

| Dirt, water, or stale fuel

is in the fuel system. |

-

Contact an

Authorized Service Dealer.

|

| There is incorrect fuel

in the fuel tank. |

-

Contact an

Authorized Service Dealer.

|

The machine does not drive.

| Possible Cause |

Corrective Action |

| The bypass valves are open. |

-

Close the

tow valves.

|

| The traction belts are

worn, loose, or broken. |

-

Contact an

Authorized Service Dealer.

|

| The traction belts are

off the pulleys. |

-

Contact an

Authorized Service Dealer.

|

| The transmission has failed. |

-

Contact an

Authorized Service Dealer.

|

The machine vibrates abnormally.

| Possible Cause |

Corrective Action |

| The cutting blade(s) is/are

bent or unbalanced. |

-

Install new

cutting blade(s).

|

| The blade mounting bolt

is loose. |

-

Tighten the

blade mounting bolt.

|

| The engine mounting bolts

are loose. |

-

Tighten the

engine mounting bolts.

|

| The engine pulley, idler

pulley, or blade pulley is loose.

|

-

Tighten the

appropriate pulley.

|

| The engine pulley is damaged. |

-

Contact an

Authorized Service Dealer.

|

| The blade spindle is bent. |

-

Contact an

Authorized Service Dealer.

|

| The motor mount is loose

or worn. |

-

Contact an

Authorized Service Dealer.

|

The cutting height is uneven.

| Possible Cause |

Corrective Action |

| The blade(s) is not sharp. |

-

Sharpen the

blade(s).

|

| A cutting blade(s) is/are

bent. |

-

Install a

new cutting blade(s).

|

| The mower is not level. |

-

Level the

mower from side-to-side and front-to-rear.

|

| An anti-scalp roller (if

applicable) is not set correctly.

|

-

Adjust the

anti-scalp wheel height.

|

| The underside of the mower

deck is dirty. |

-

Clean the

underside of the mower deck.

|

| The tire pressure is incorrect. |

-

Adjust the

tire pressure.

|

| A blade spindle is bent. |

-

Contact an

Authorized Service Dealer.

|

The blades do not rotate.

| Possible Cause |

Corrective Action |

| The drive belt is worn,

loose or broken. |

-

Install a

new drive belt.

|

| The drive belt is off of

the pulley. |

-

Install the

drive belt and check the adjusting shafts and belt guides for the

correct position.

|

| The power-takeoff (PTO)

switch or PTO clutch is faulty.

|

-

Contact an

Authorized Service Dealer.

|

| The mower belt is worn,

loose, or broken. |

-

Install a

new mower belt.

|