Maintenance

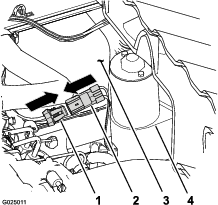

Servicing the Air Cleaner

-

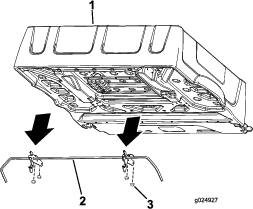

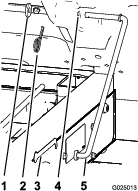

Support the bed with lifting equipment.

-

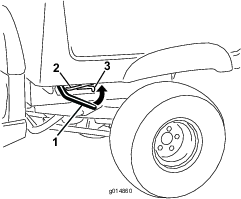

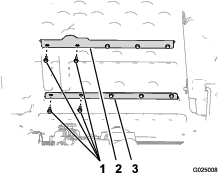

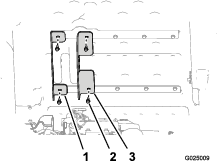

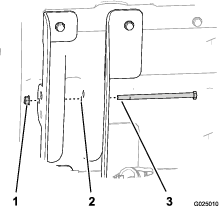

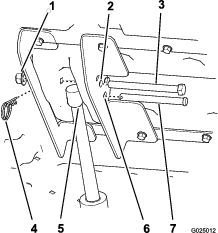

Remove the hairpin cotter and clevis pin securing the actuator rod to the inboard and outboard-lift brackets (Figure 11).

-

Tip the bed all the way up.

-

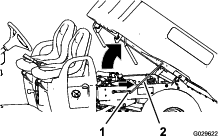

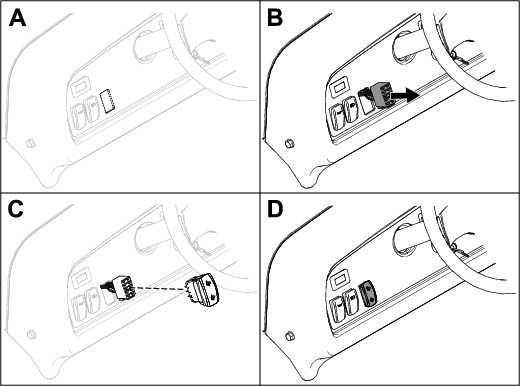

Rotate the actuator forward.

-

Remove the air cleaner and service it as required; refer to the machine Operator’s Manual.

-

Install the air cleaner; refer to the machine Operator’s Manual.

-

Lower the bed and align the lift actuator to the lift brackets (Figure 11).

-

Secure the lift actuator to the lift brackets with the clevis pin and hairpin (Figure 11).